F-shaped steel mill roll double-hole type and rolling method

A pass and section steel technology, applied in rolls, metal rolling, metal rolling, etc., can solve the problems of low output, low yield, poor rolling stability, etc., to reduce production costs, increase yield, and reduce rolling. Stability-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

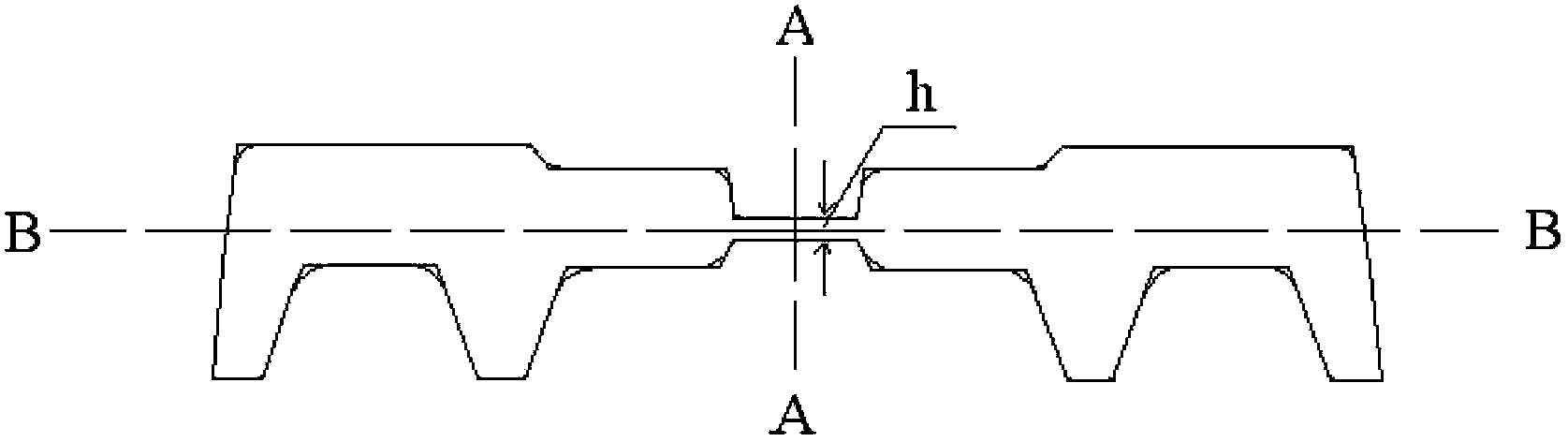

[0027] The upper and lower rolls of the universal rough rolling mill and the universal finishing mill all have the symmetrical pass of the present invention;

[0028] In order to make the reversible billeting machine adapt to the universal rolling mill with the above-mentioned symmetrical pass, the roll pass on the reversible billeting machine is also symmetrical.

[0029] The rolling method is as follows:

[0030] Step 1, using a two-roll reversible billet breaker (BD) to roll the billet, so as to roll out the rolled piece required to enter the universal rolling mill.

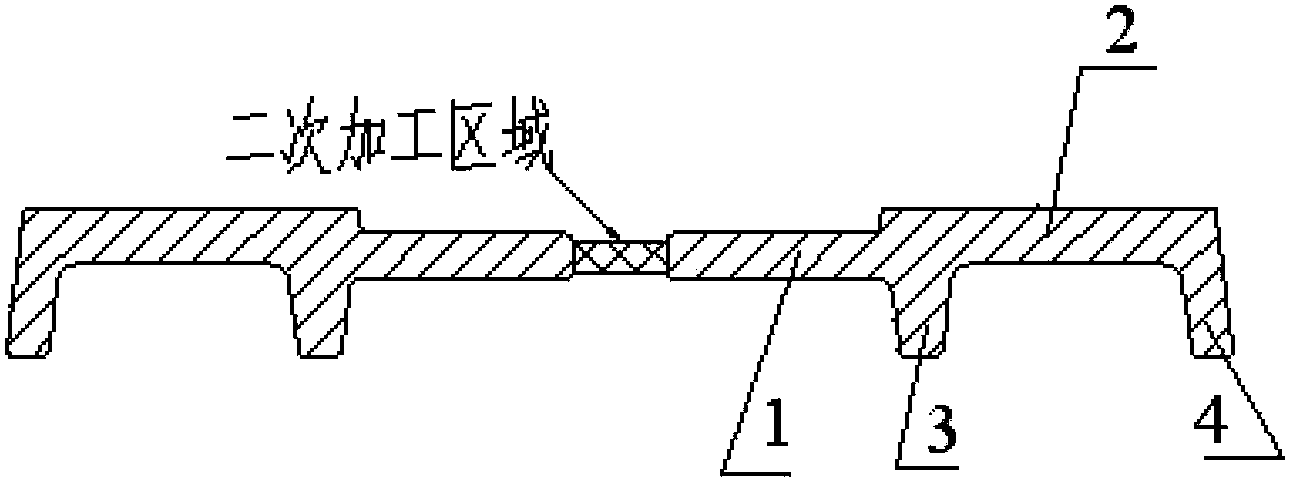

[0031] Step 2, using UR / E / UF rolling mills to roll the rolled pieces in turn to obtain a pair of F-shaped steels connected as a whole (ie rolled products with symmetrical passes), see figure 1 , which includes a pair of symmetrical F-shaped steels and a secondary processing area connecting the pair of F-shaped steels.

[0032] Step 3: Carry out sawing, planing and turning on the middle connection area of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com