Patents

Literature

48results about How to "Realize automatic oiling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

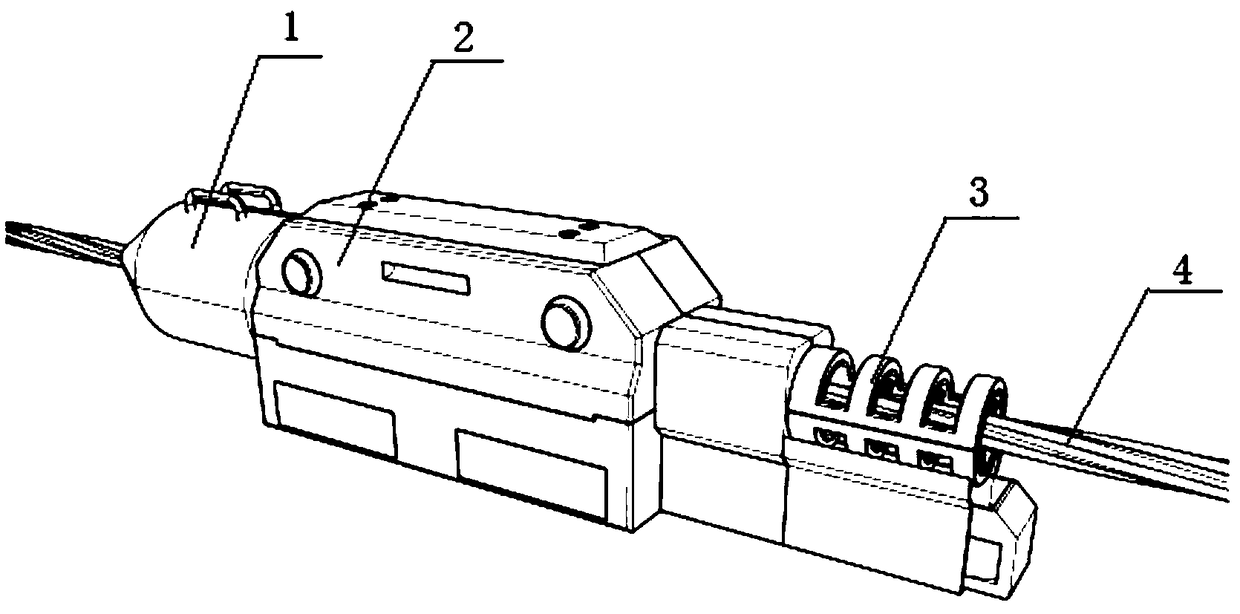

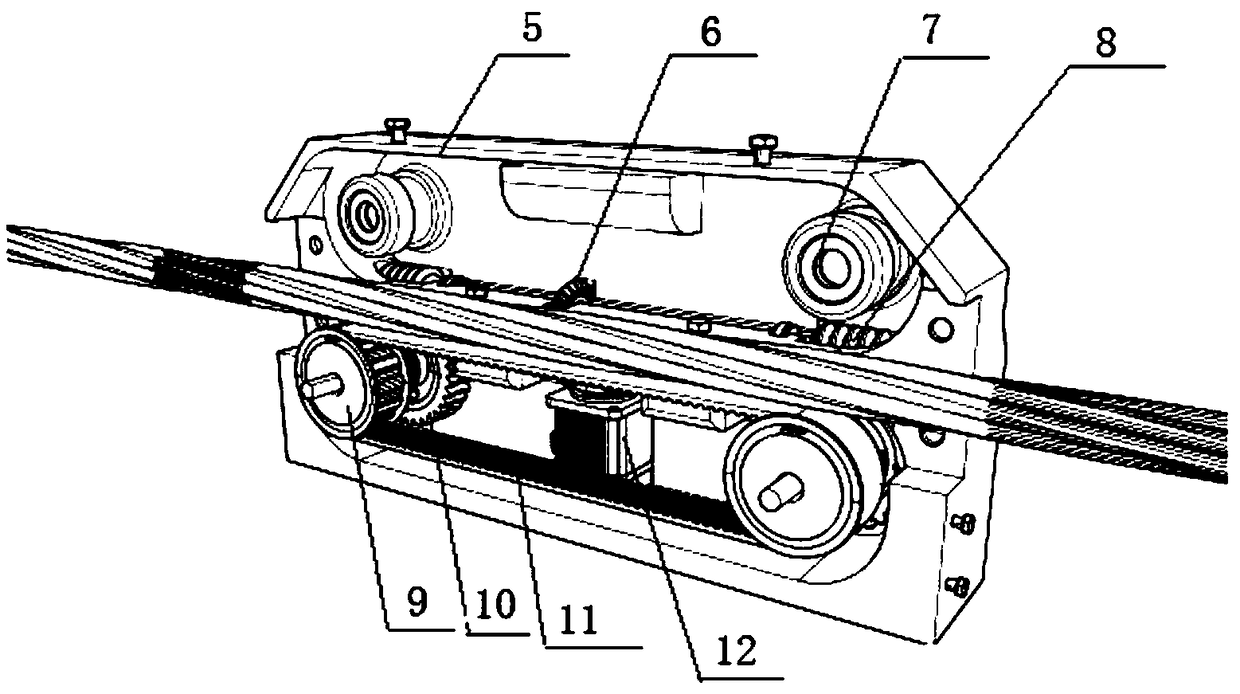

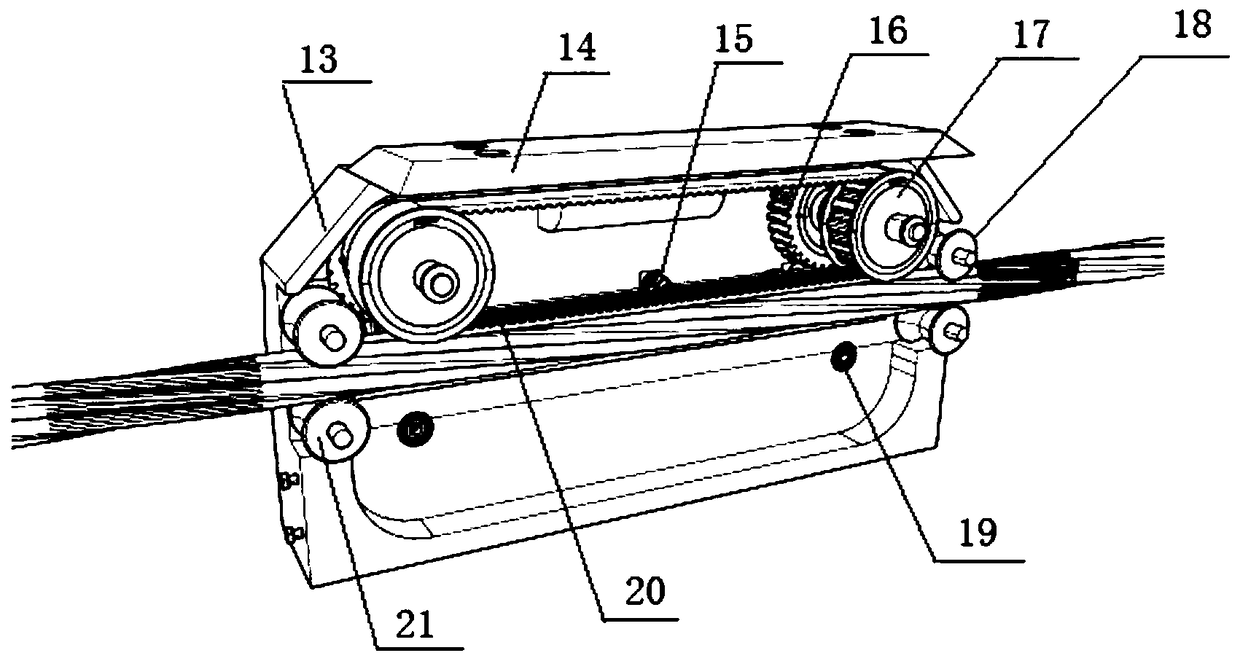

Integral aerial steel wire rope oil removing and lubricating device

ActiveCN108622803ASolve the problem of inconvenient oil removal and lubricationRealize automatic degreasingCleaning using toolsLoad-engaging elementsOperation modeLubrication

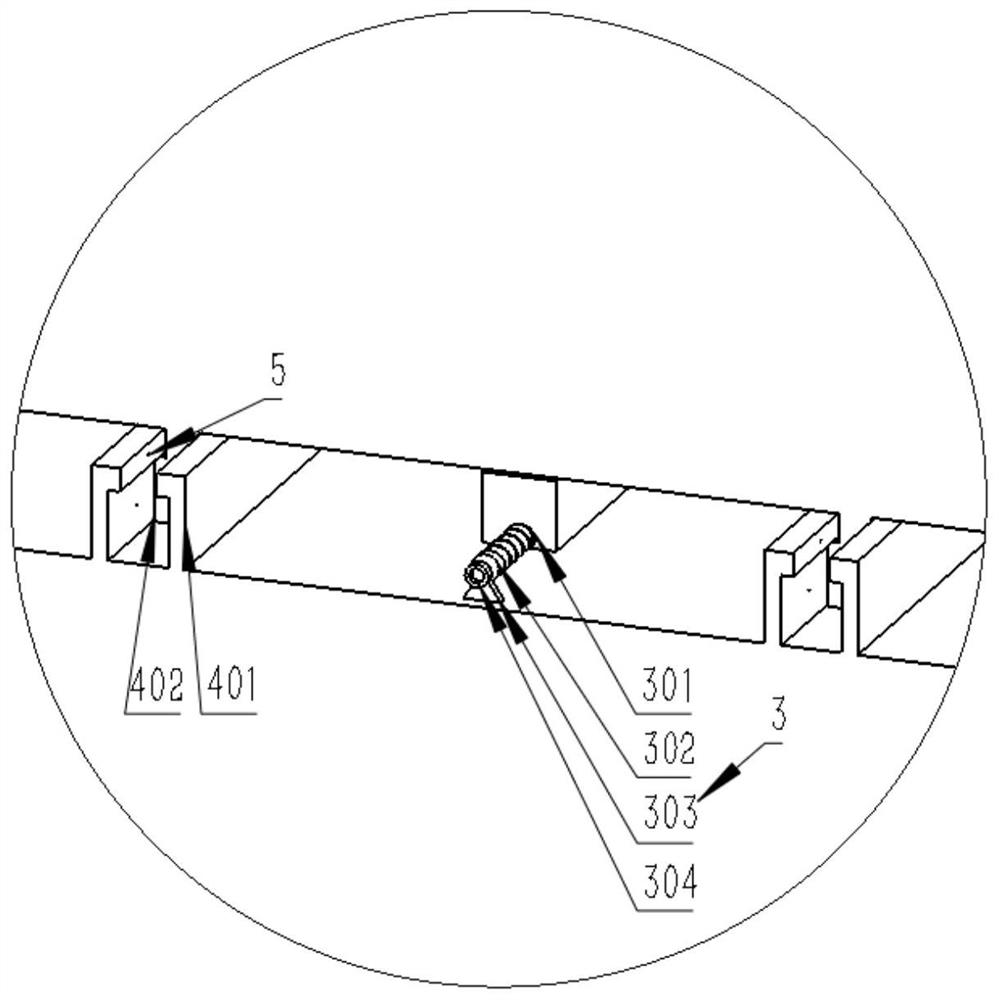

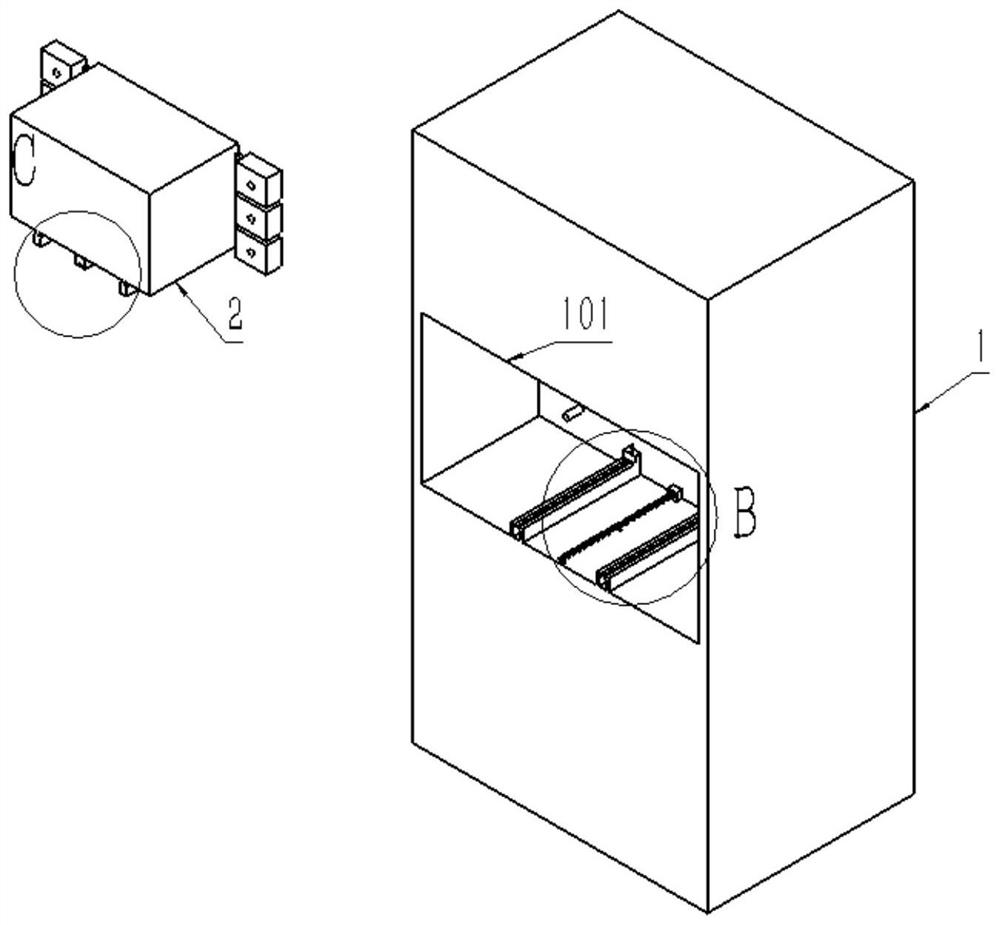

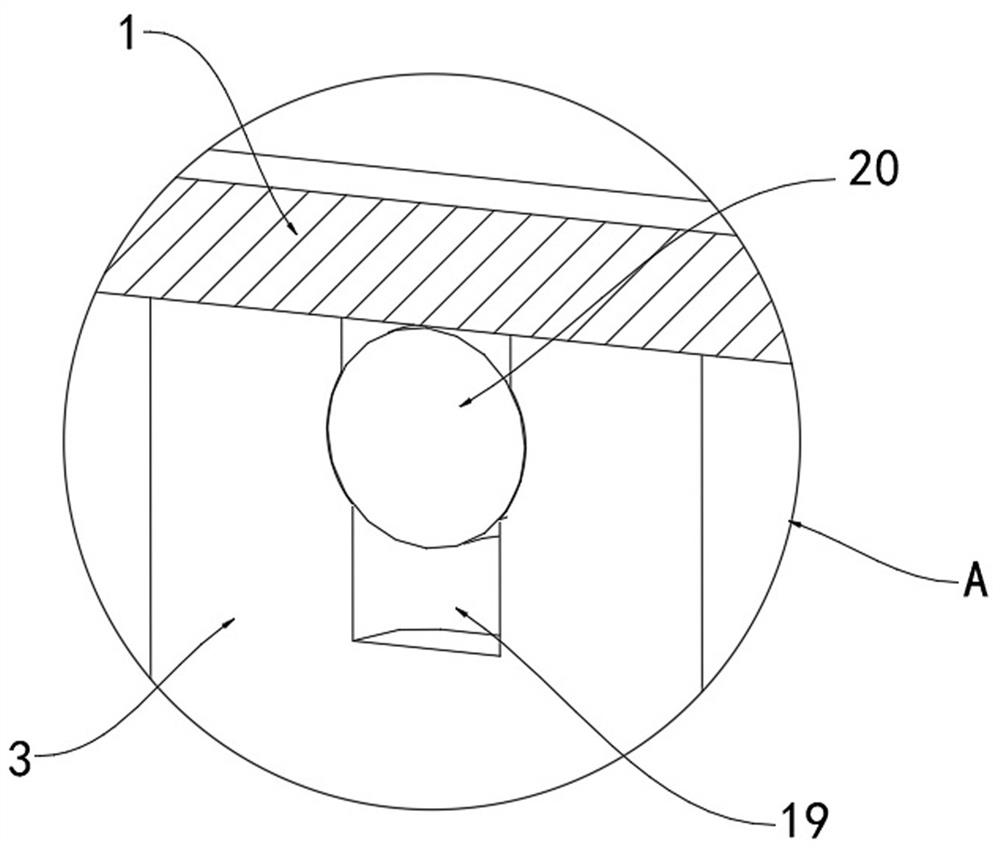

The invention relates to an integral aerial steel wire rope oil removing and lubricating device. The device comprises an oil removing mechanism, a cable walking mechanism and an oil coating mechanism;the oil removing mechanism and the oil coating mechanism are positioned on two sides of the cable walking mechanism; the oil removing mechanism comprises a brush, a brush base and an oil collecting tank; the brush and the brush base are of symmetric buckling structures; the oil collecting tank is positioned at the lower part of the brush; the cable waslking mechanism comprises a shell, a first walking wheel mechanism and a second walking wheel mechanism; the shell comprises a first shell and a second shell symmetrically mounted; the first walking wheel mechanism is mounted in the first shell;the second walking wheel mechanism is mounted in the second shell; the first walking wheel mechanism and the second walking wheel mechanism tightly hold a steel wire rope, and drive the oil removingmechanism and the oil coating mechanism to walk; and the oil coating mechanism is an oil cylinder mounted in an opposite buckling manner. The device is compact in structure and less in occupied space,can realize efficient and convenient lubrication of the crane steel wire rope, and changes a traditional operation mode with low manual coating efficiency and high safety risk.

Owner:TIANJIN UNIV OF SCI & TECH

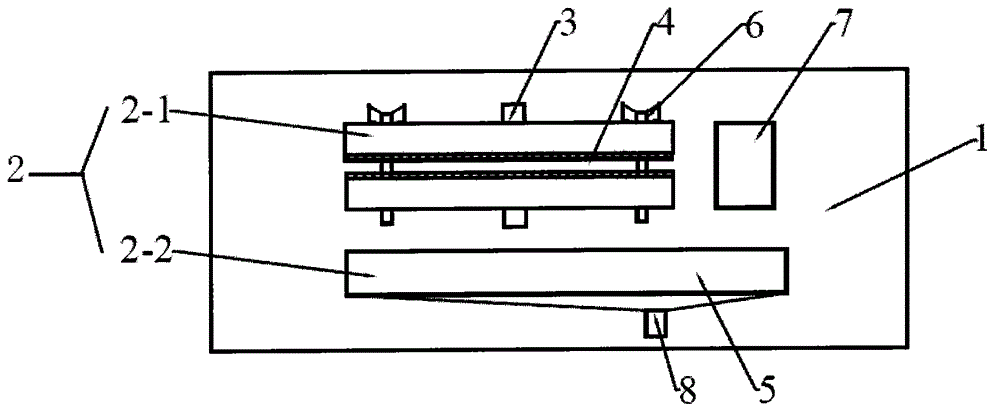

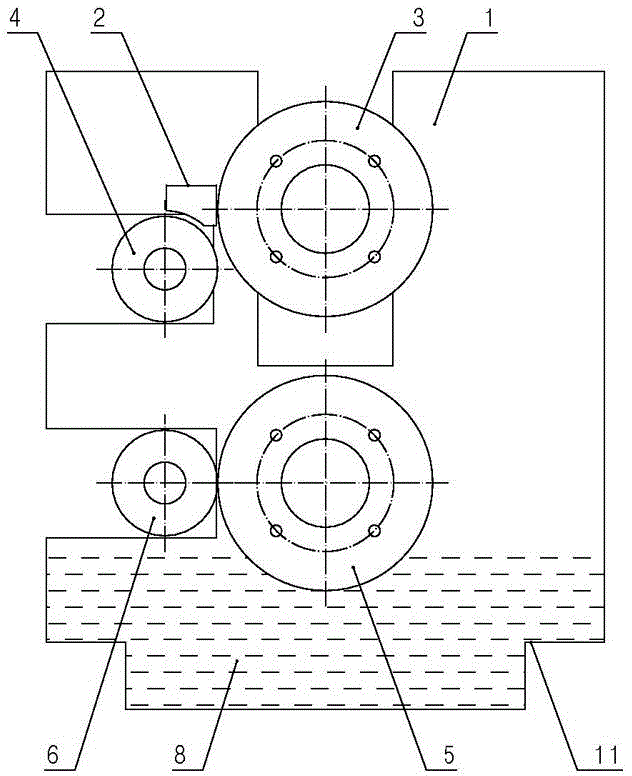

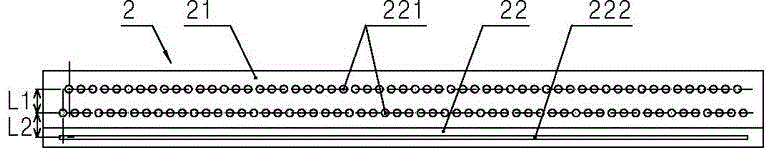

Plate oiling device

InactiveCN106694303AReasonable structureSufficient oilLiquid surface applicatorsCoatingsLiquid level sensorOil storage

The invention relates to an oiling device, and especially a plate oiling device. The plate oiling device comprises a plate, an upper oiling roller and a lower oiling roller, an upper oil storage tank is arranged at the upper side of the upper oiling roller, a part of the upper oiling roller stretches into the upper oil storage tank, a lower oil storage tank is arranged at one side of the lower oiling roller, a part of the lower oiling roller deeps into the lower oil storage tank, the upper oil storage tank and the lower oil storage tank are respectively provided with oil inlet tubes connected with an oil barrel, every oil inlet tube is provided with a solenoid valve, every solenoid valve is connected with a controller, the upper oil storage tank and the lower oil storage tank are respectively provided with liquid level sensors, and the liquid level sensors are connected with the controller. The plate oiling device has the advantages of reasonable structure, good functionality, high automation degree, facilitation of the working intensity of workers, and improvement of the product quality.

Owner:李磊

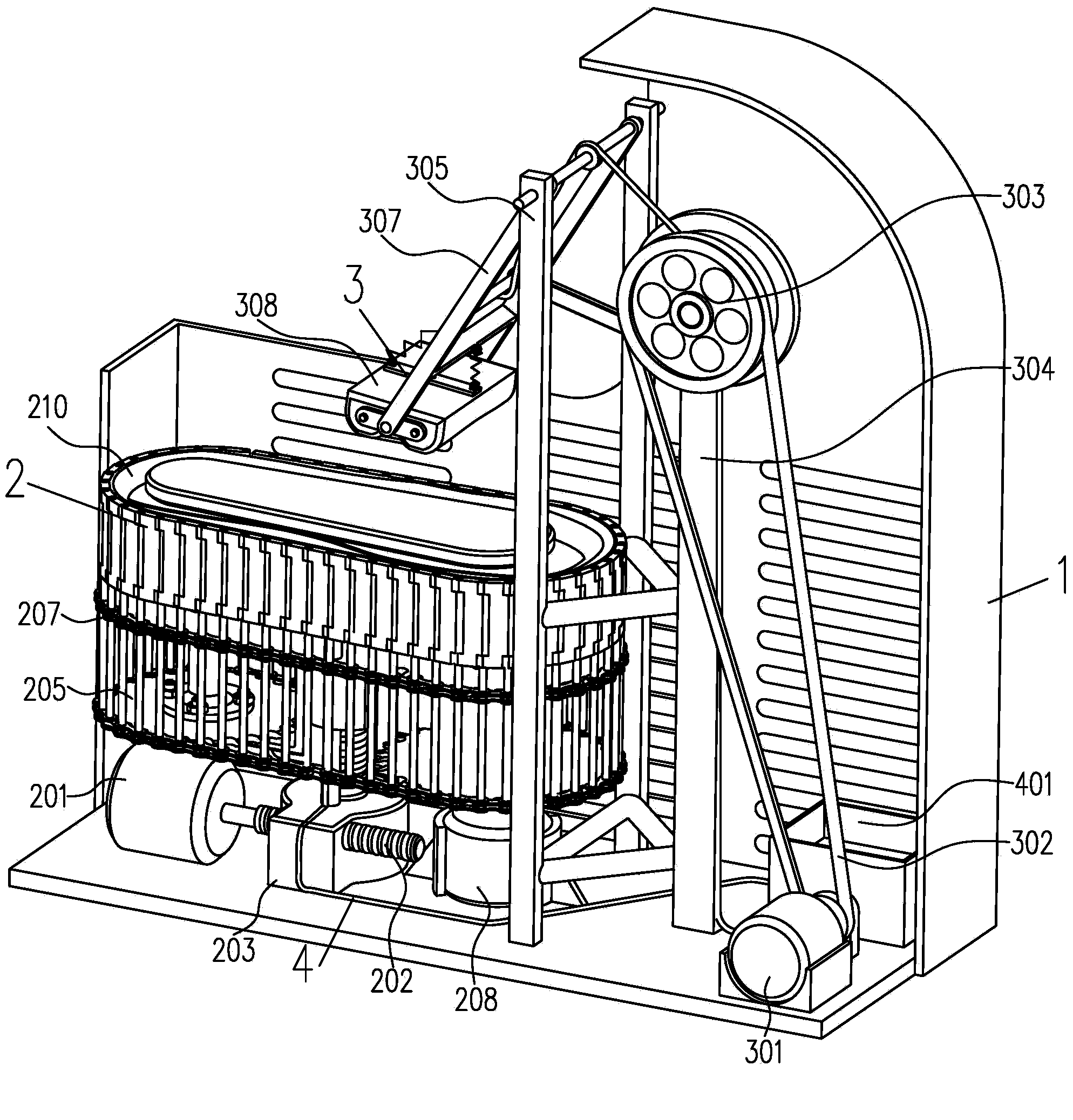

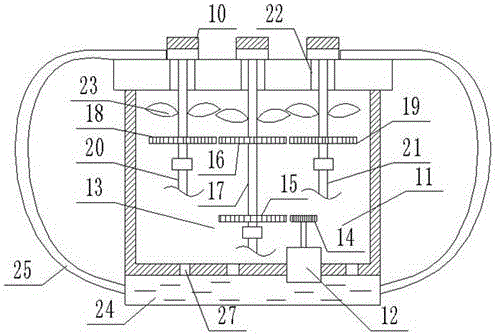

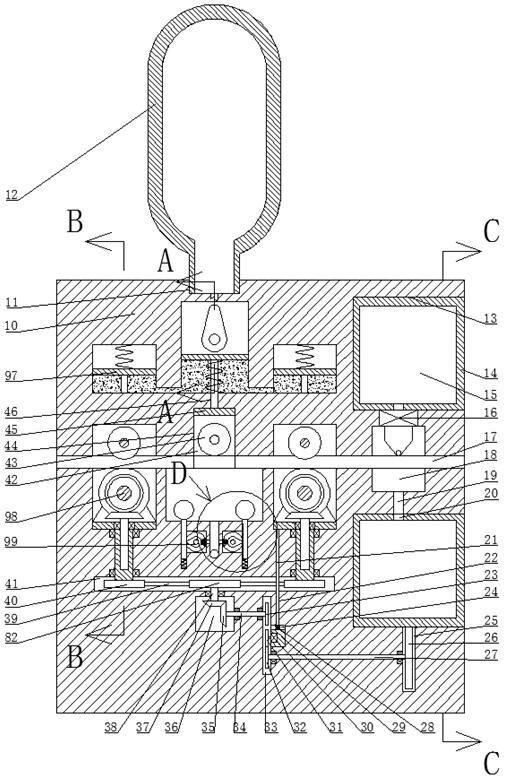

Full-automatic shoe-cleaning machine

The invention discloses a full-automatic shoe-cleaning machine, which consists of a machine shell, an upper cleaning device, a vamp cleaning device and an oiling system, wherein the upper cleaning device comprises a motor A, a worm I, a worm gear case, a worm II, a chain wheel, a chain wheel frame, a chain transmission device, a motor B, a foot support and an annular gasbag hairbrush; the vamp cleaning device comprises a motor C, a belt, a big belt pulley, a support I, a support II, a connecting rod, a rocker, a gasbag hairbrush and a spring; the oiling system comprises an oil storage box, an oil transmission pipe, a piston, an oil ejection hole, an oil ejection nozzle and a one-way valve; the chain transmission device is fixedly provided with the annular gasbag hairbrush; the oil ejection hole is formed in the gasbag hairbrush; the big belt pulley, the connecting rod and the rocker form a crank and rocker mechanism; the oil ejection hole and the oil ejection nozzle are used for ejecting oil. The automatic oiling and the omnibearing cleaning are realized for leather shoes, the degree of automation is high, and the cleaning effect is good.

Owner:ANHUI UNIV OF SCI & TECH

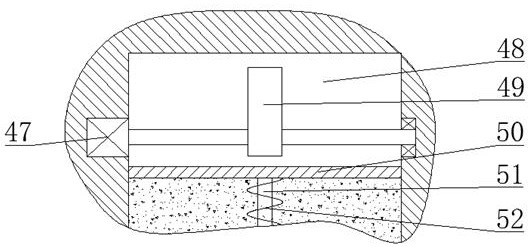

Wafer lapping equipment with dust collection function

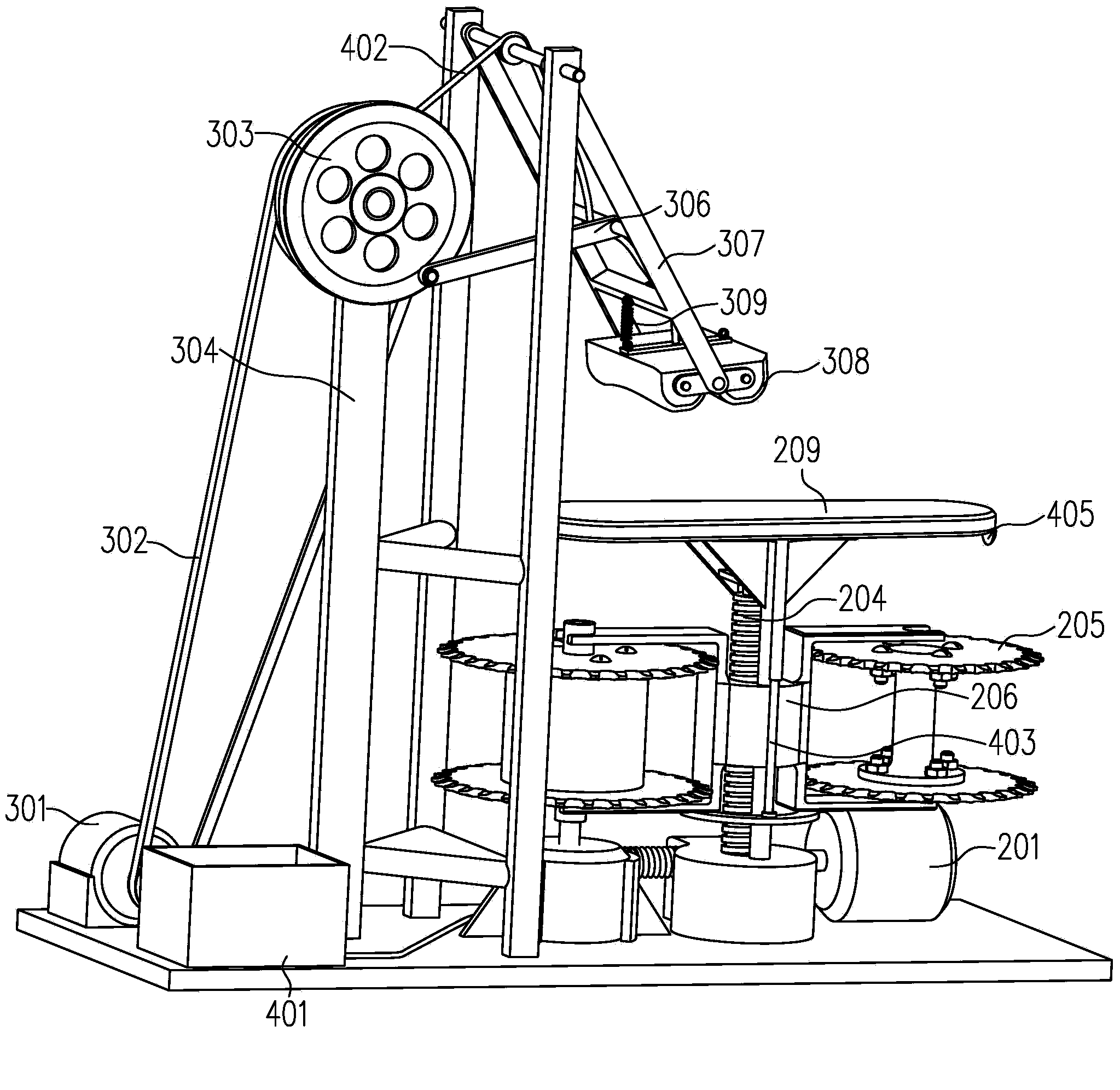

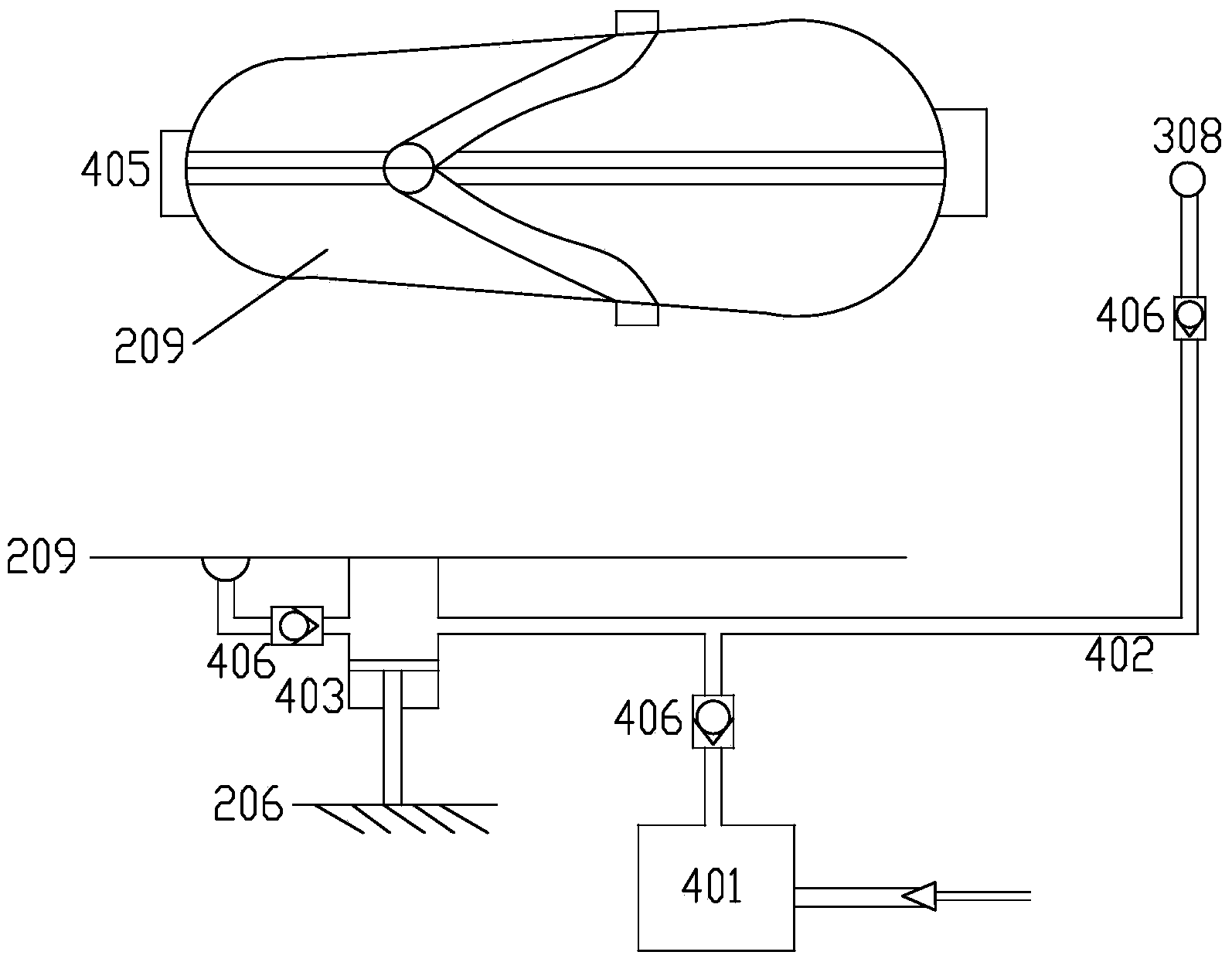

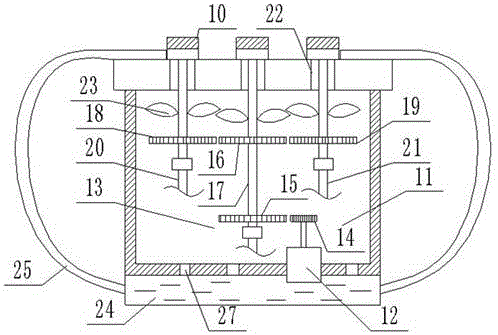

ActiveCN106826537ARealize automatic recyclingRealize automatic oilingLapping machinesWork carriersFuel tankEngineering

The invention relates to the technical field of photoelectronic information, and discloses wafer lapping equipment with a dust collection function. The wafer lapping equipment comprises a base platform, wafer carrying bosses, a working table, a lapping mechanism and a pressurizing mechanism, wherein a first driving mechanism is arranged in the working table; the first driving mechanism comprises a motor and a transmission structure; first through holes communicating with the inside of the working table are formed in the surface of the working table; rotating shafts of the transmission mechanism penetrate through the through holes and are used for supporting the wafer carrying bosses; fan blades are arranged on the rotating shafts between the wafer carrying bosses and a driven gear; an oil tank is connected below the working table; second through holes communicating with the oil tank are formed in the bottom of the working table; the oil tank is connected with oil conveying pipes; and oil outlets of the oil conveying pipes are located at two of the first through holes. The invention aims to provide the wafer lapping equipment with the dust collection function; in a process of lapping wafers, dust generated by lapping can be collected, and heat dissipation and lubrication effects can be achieved on the equipment.

Owner:重庆晶宇光电科技有限公司

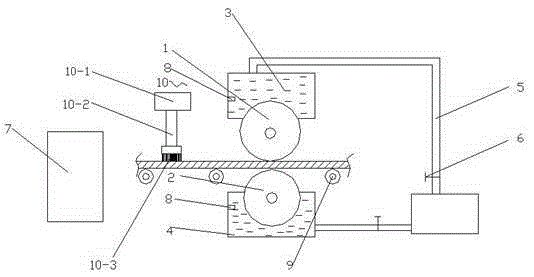

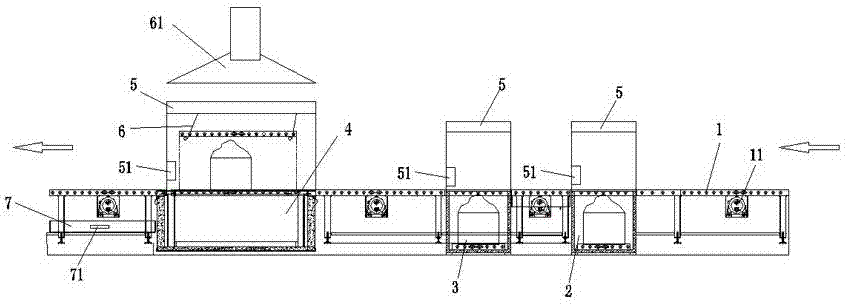

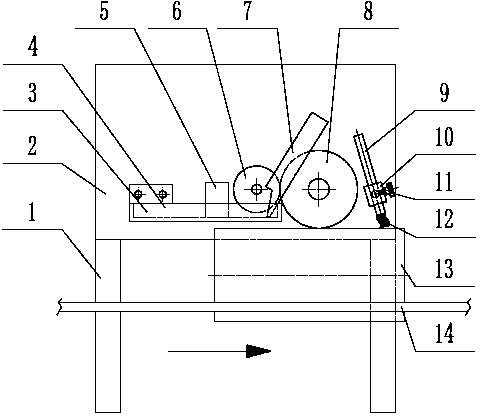

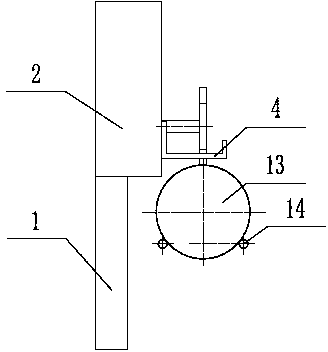

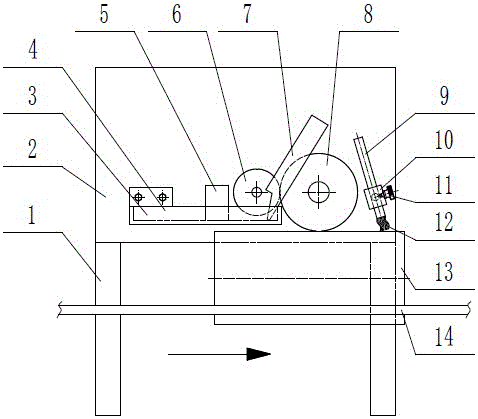

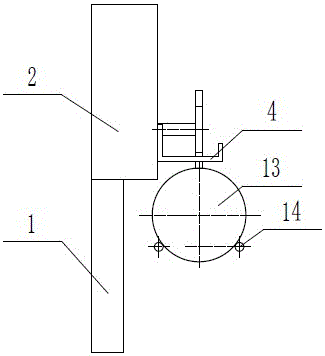

Chain oiling system

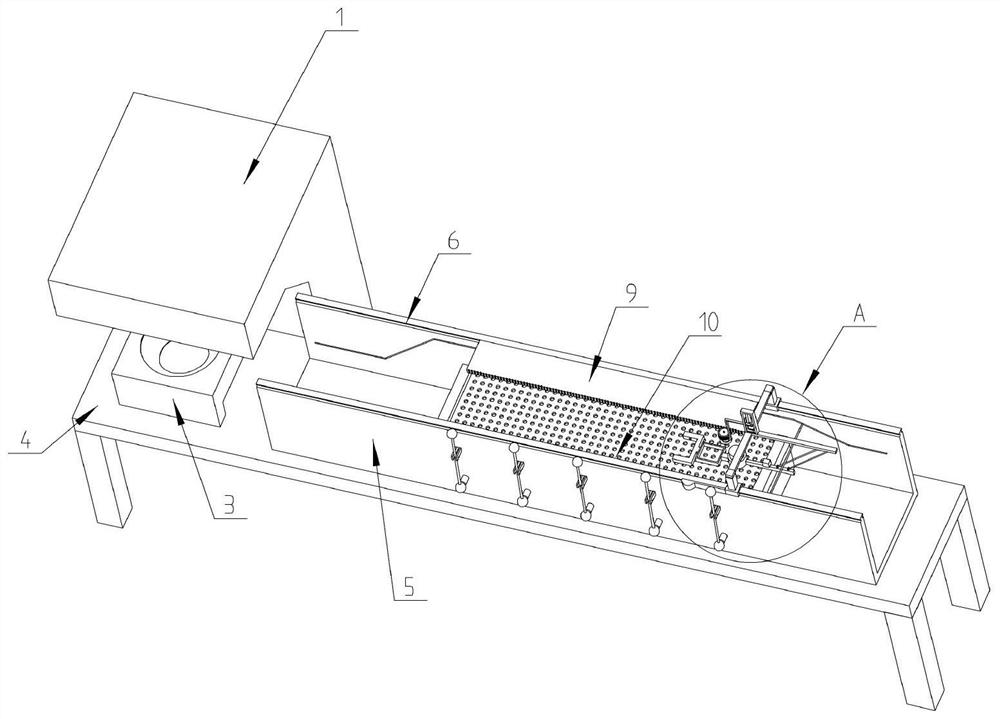

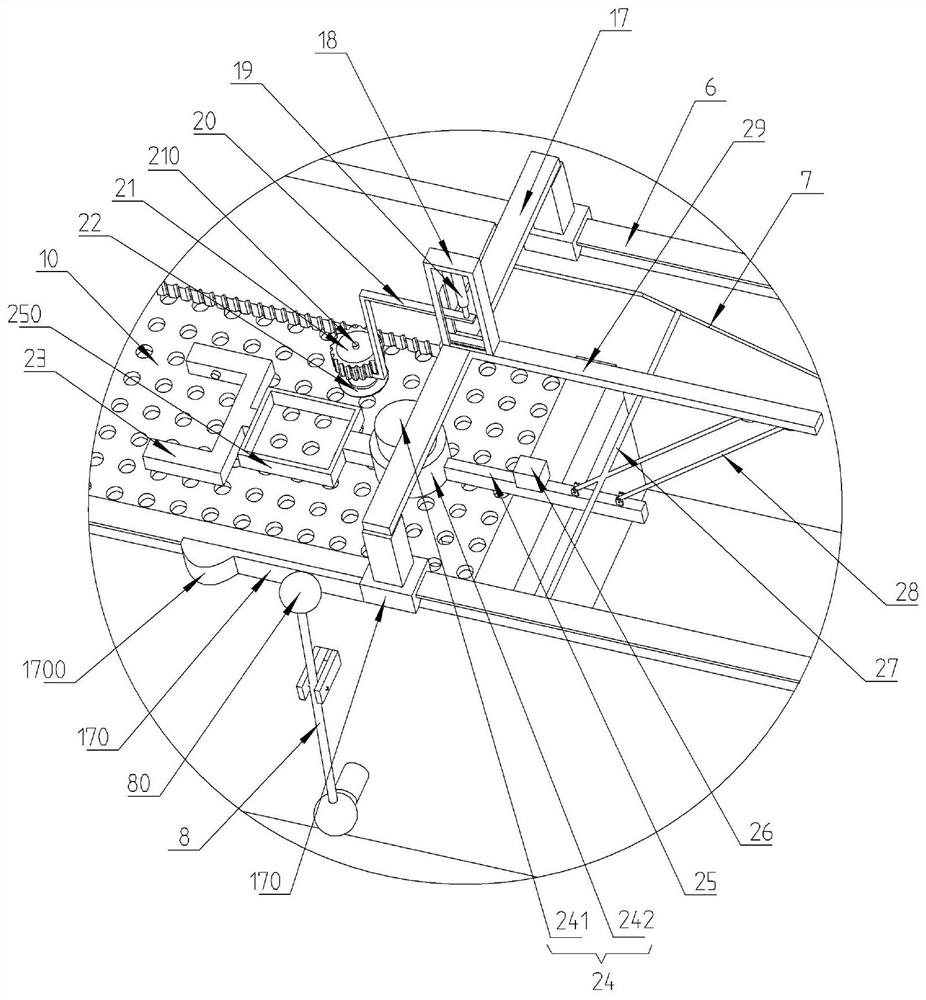

ActiveCN103752761ARealize automatic oilingPrecise time controlMetal chainsControl engineeringElectric machinery

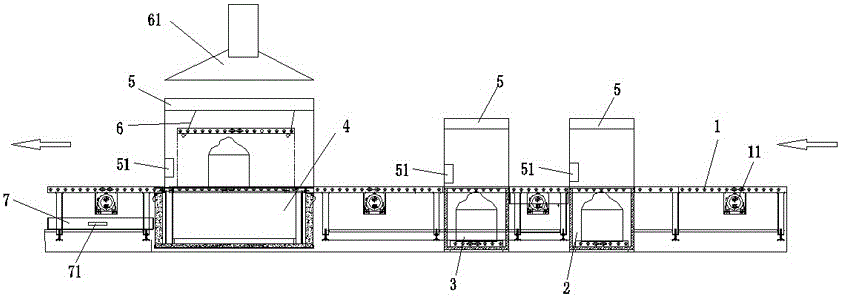

The invention discloses a chain oiling system, comprising a conveying platform, a power device, an oiling slot, a subpart conveying platform and a lifting device arranged on the oiling slot, and a controller, wherein the lifting device comprises a longitudinal motor and a transverse motor, so that the subpart conveying platform can move up and down and left and right. The system achieves the automatic oiling of a chain through the automatic lifting device and the controller. A worker only needs to put the chain on the conveying platform, and subsequent machining processes can be automatically completes, so that the labor is greatly saved, the work efficiency is improved, and the oiling time and pressure of the chain can be accurately controlled, and the oiling quality is improved.( / b).

Owner:浙江西塘实业有限公司

Candy forming machine

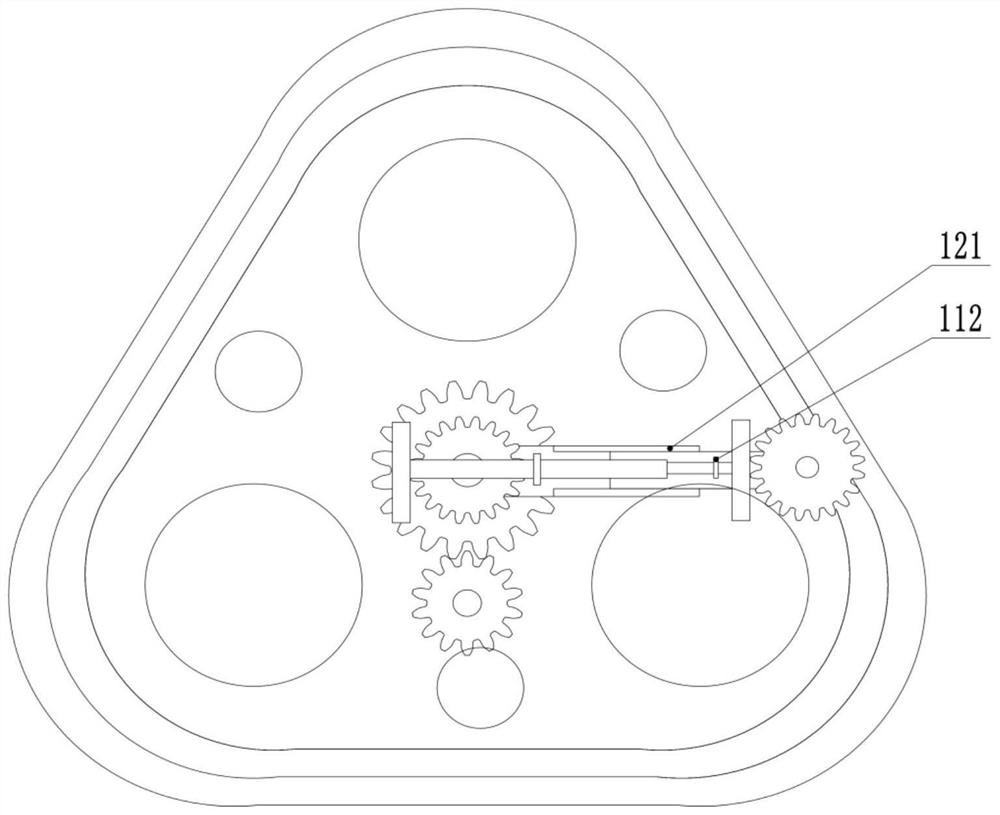

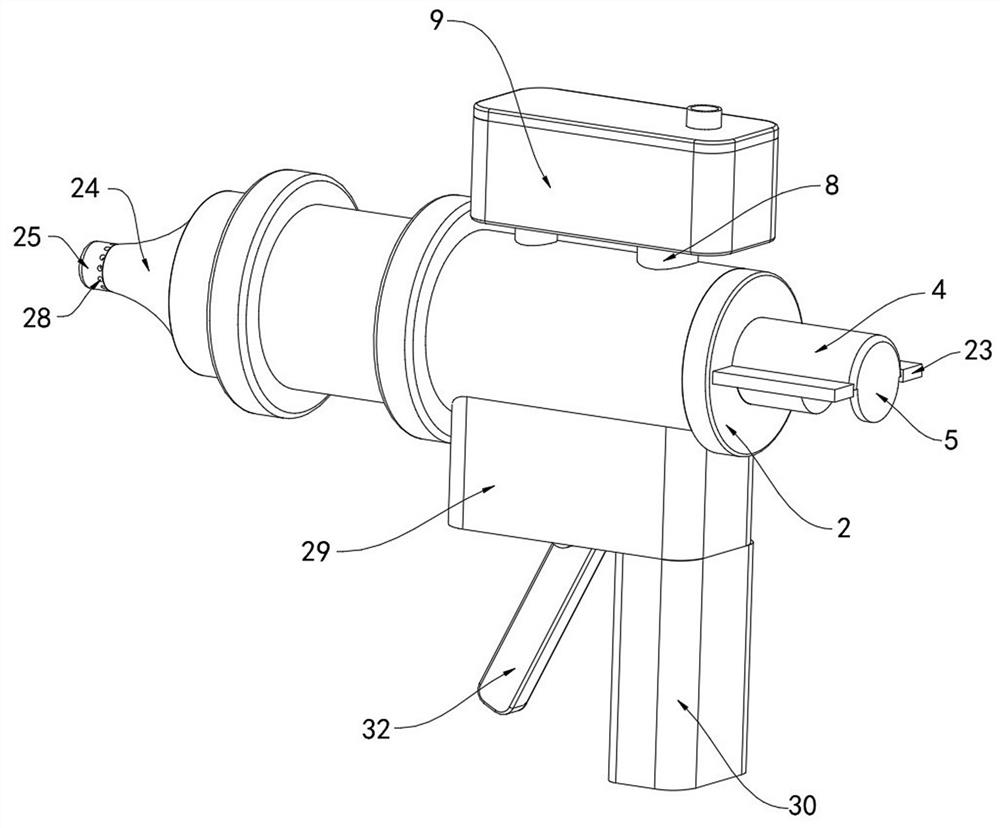

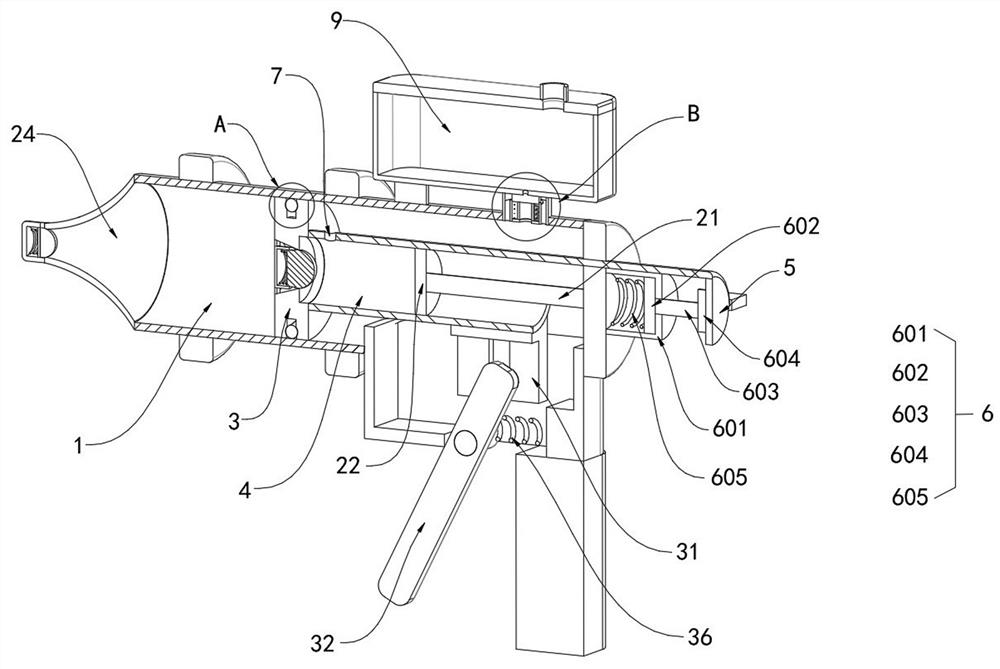

PendingCN105533086ACompact structureRealize automatic oilingConfectionerySweetmeatsMolding machineEngineering

The invention discloses a candy forming machine, comprising a compression roller mechanism, a shaping mechanism and a forming pressing wheel mechanism which are arranged sequentially from an input end of a conveying table to an output end of the conveying table, wherein the compression roller mechanism comprises an upper compression roller and a lower compression roller of which the axial directions are both vertical to the conveying direction of the conveying table; a feeding end of the upper compression roller and a feeding end of the lower compression roller are respectively provided with a feeding mechanism; and the side of the upper compression roller and the side of the lower compression roller are respectively provided with an oiling mechanism. According to the candy forming machine, the oiling mechanisms are arranged at the sides of the upper compression roller and the lower compression roller, so that a uniform and thin oil layer is coated on each of the upper compression roller and the lower compression roller, so as to realize automatic oiling on the surface of massecuite; after the oiled massecuite is processed by the shaping mechanism, the required thickness of the massecuite can be realized; and then the massecuite is formed once through the forming pressing wheel mechanism, so that the massecuite is made to be small candies. The candy forming machine has high rolling speed and high rolling efficiency.

Owner:金冠(中国)食品有限公司

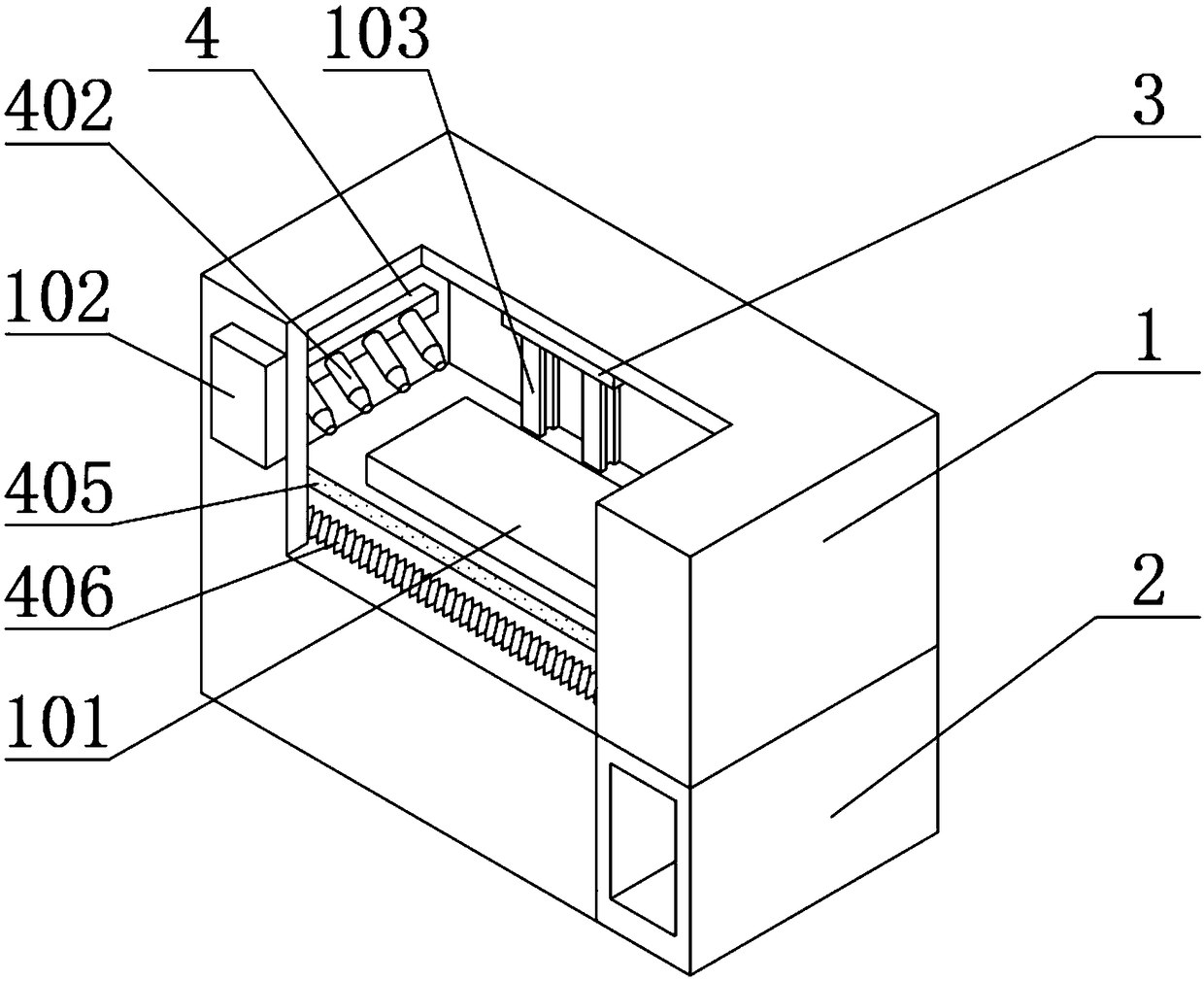

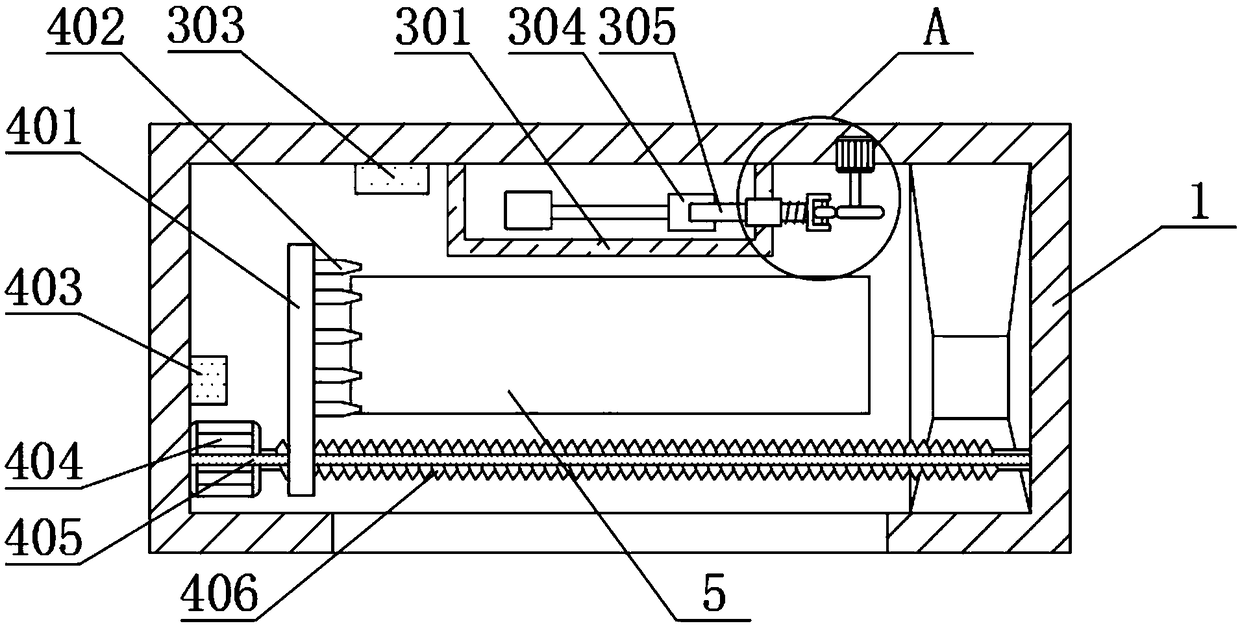

Intelligent machining control system for numerically-controlled machine tool

ActiveCN109333142AImprove space utilizationReduce replacement frequencyMaintainance and safety accessoriesCamFuel tank

The invention relates to the technical field of numerically-controlled machine tools, in particular to an intelligent machining control system for a numerically-controlled machine tool. The intelligent machining control system for the numerically-controlled machine tool comprises a main body device, a collecting device, an oil filling device and a chip removing device; the collecting device is fixedly connected to the lower side of the right end of the main body device; the chip removing device is fixedly connected to the inner side of the left end of the main body device; the oil filling device is fixedly connected to the back end of the inner side of the main body device; and the main body device comprises a carrying plate, a control panel, slide rails and a main shell, and the carryingplate which is horizontally arranged is fixedly connected to the inner side of the main shell. According to the intelligent machining control system for the numerically-controlled machine tool, an oiltank, a plugging block, a rolling wheel, a cam, a supporting rod and an oil outlet are arranged, the plugging block can be indirectly driven to move through the effect of the cam, and then automaticoil feeding of the slide rails is achieved; and a fixing frame, air blowing cylinders, a sliding rod and a screw are arranged, the fixing frame can drive the air blowing cylinders to do reciprocatingmotion, and then gathering and removing of chips on the surface of the carrying plate are achieved.

Owner:福建唐煌数控雕刻机械设备有限公司

Tinplate oiling device

InactiveCN103962272ARealize automatic oilingSimple structureLiquid surface applicatorsWelding/cutting auxillary devicesTinShape object

The invention provides a tinplate oiling device, and belongs to the technical field of metal tin making. The tinplate oiling device comprises an oiling mechanism and an oil brushing mechanism; the oiling mechanism and the oil brushing mechanism are arranged just above tinplate and are both fixed on a rack; the oil brushing mechanism is arranged on the front end of the oiling mechanism, and the oiling mechanism comprises an oil storage groove, a rear baffle, a front baffle, a driving wheel and an oiling wheel; the driving wheel is rotatably arranged in the oil storage groove; the oiling wheel is rotatably arranged on the rack and is tangential with the driving wheel; the lower end of the oiling wheel is tangential with the upper end of a tinplate; the oil brushing mechanism comprises a support, a fastening screw and an oil brushing pen; the support is fixed on the rack and is internally provided with a pen passing hole; the oil brushing pen is inserted into a pen passing hole in the support and is fixed by the fastening screw; the front end of the oil brushing pen is provided with a hair-shaped object which is in contact with the tinplate. The tinplate oiling device provided by the invention is simple in structure, can oil the tinplate automatically, and improves the production efficiency.

Owner:TONGXIANG XILIANG TIN CANS

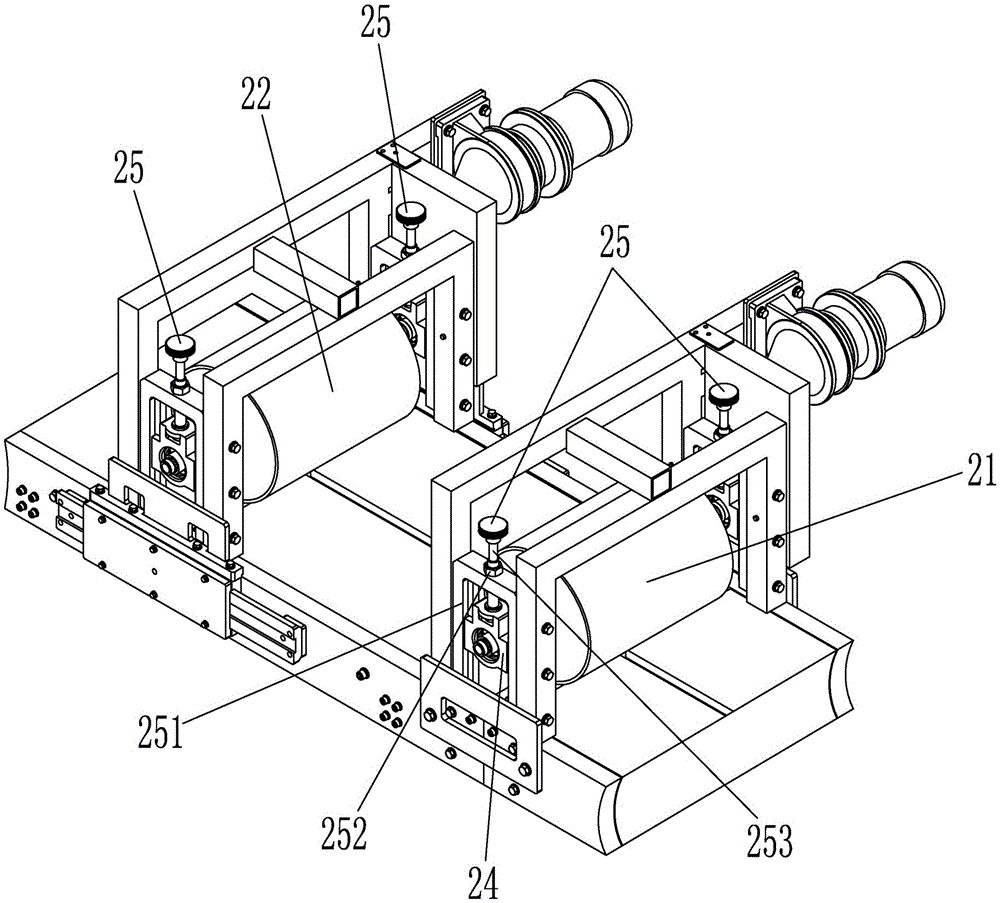

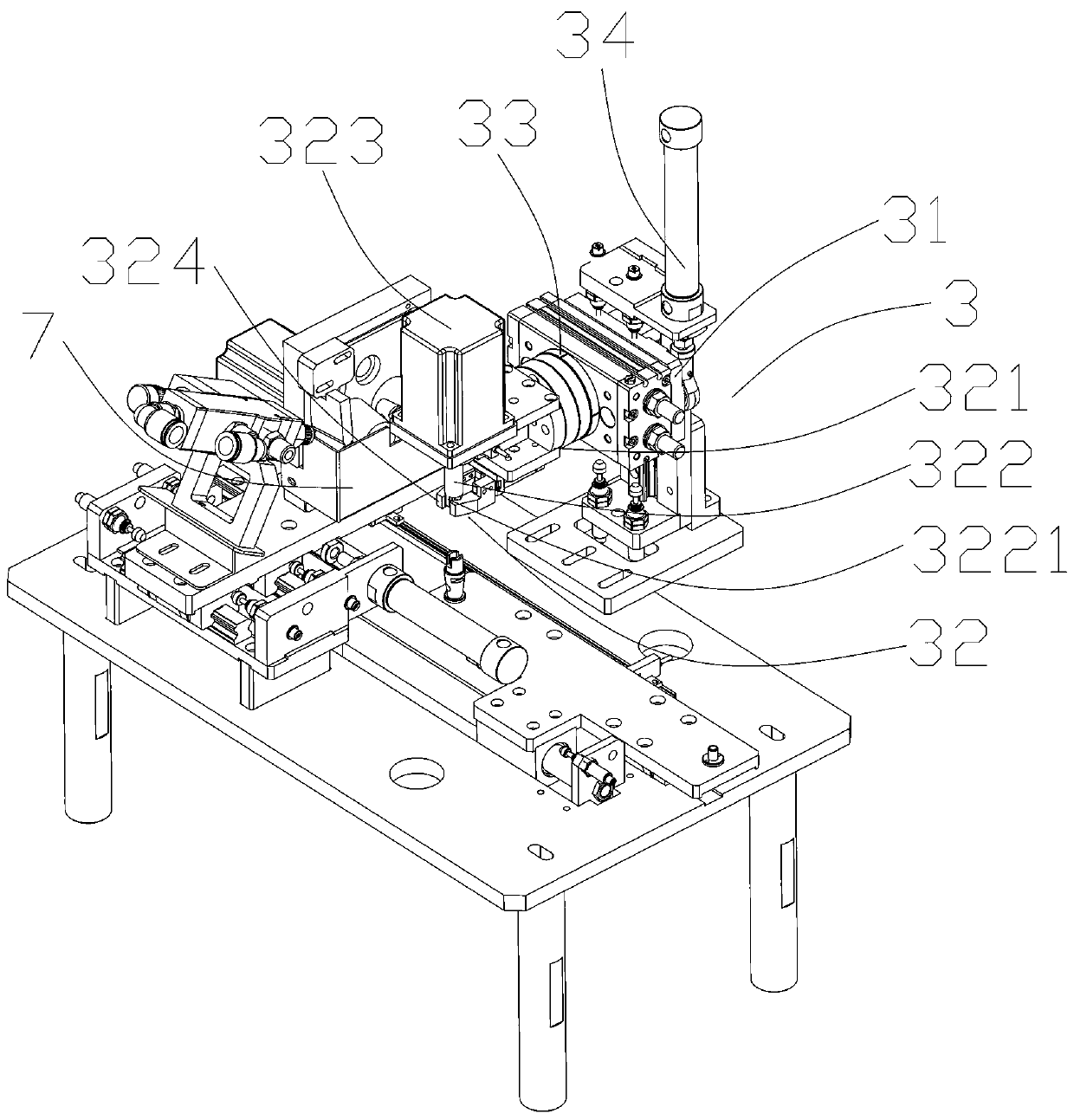

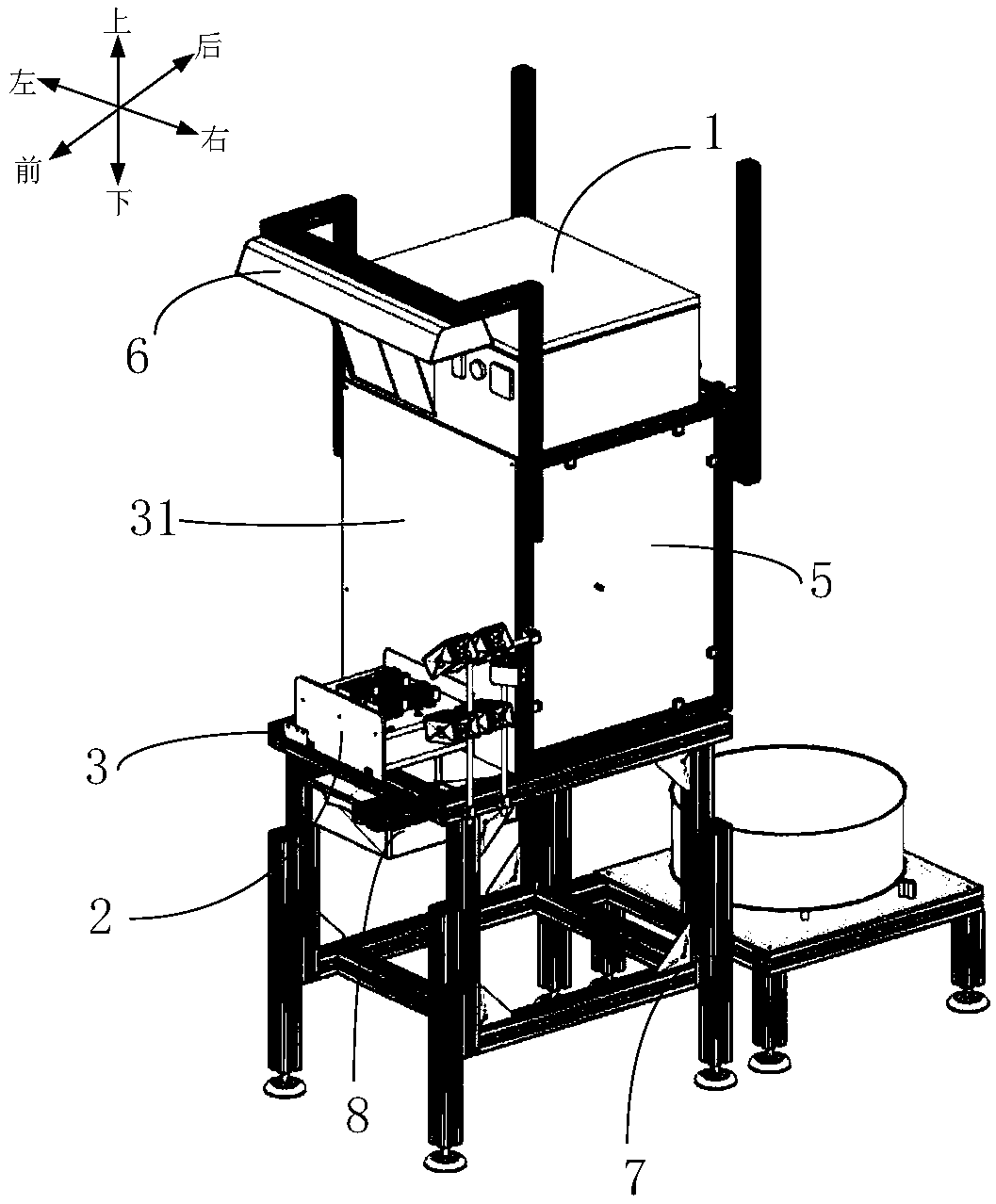

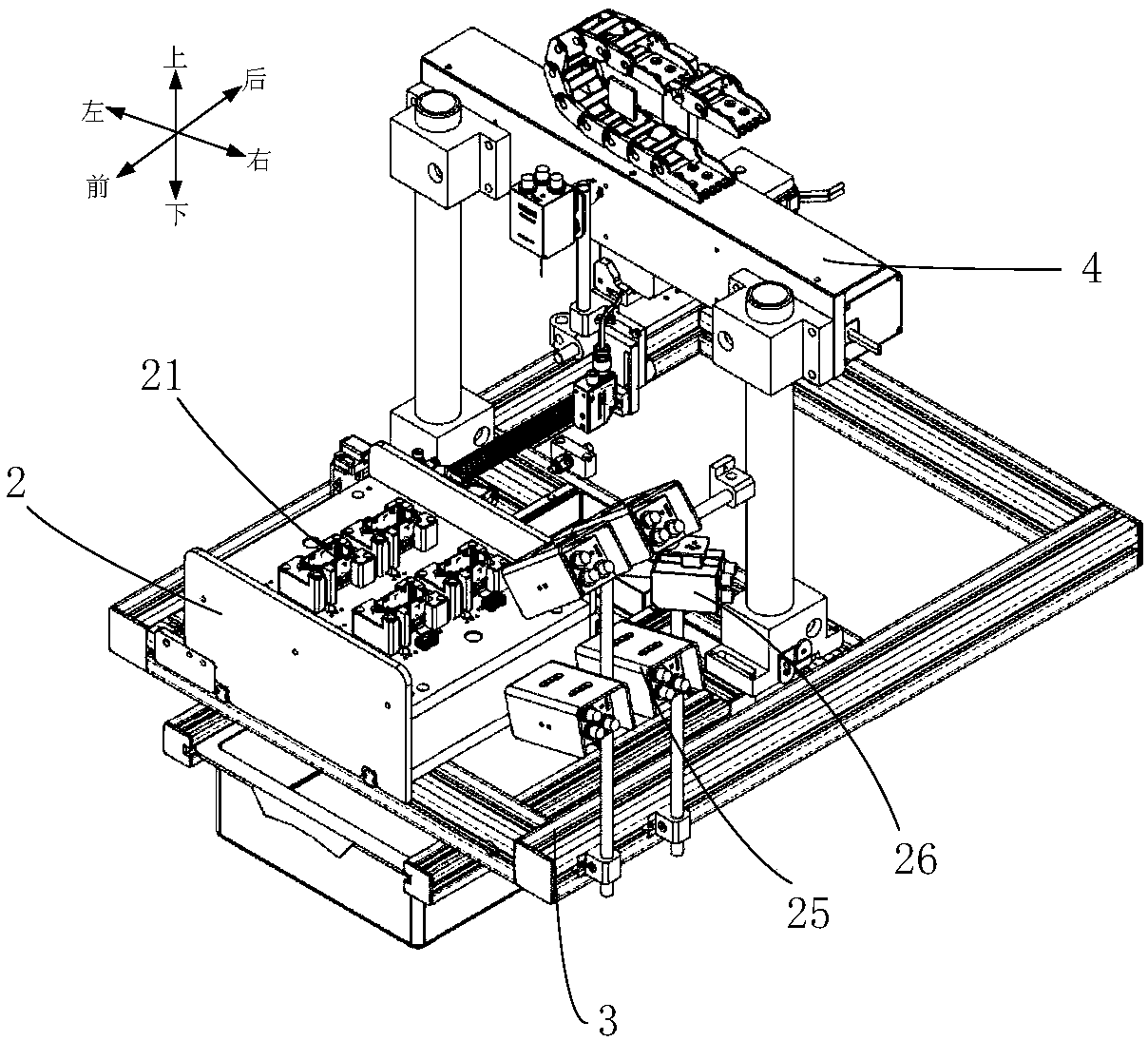

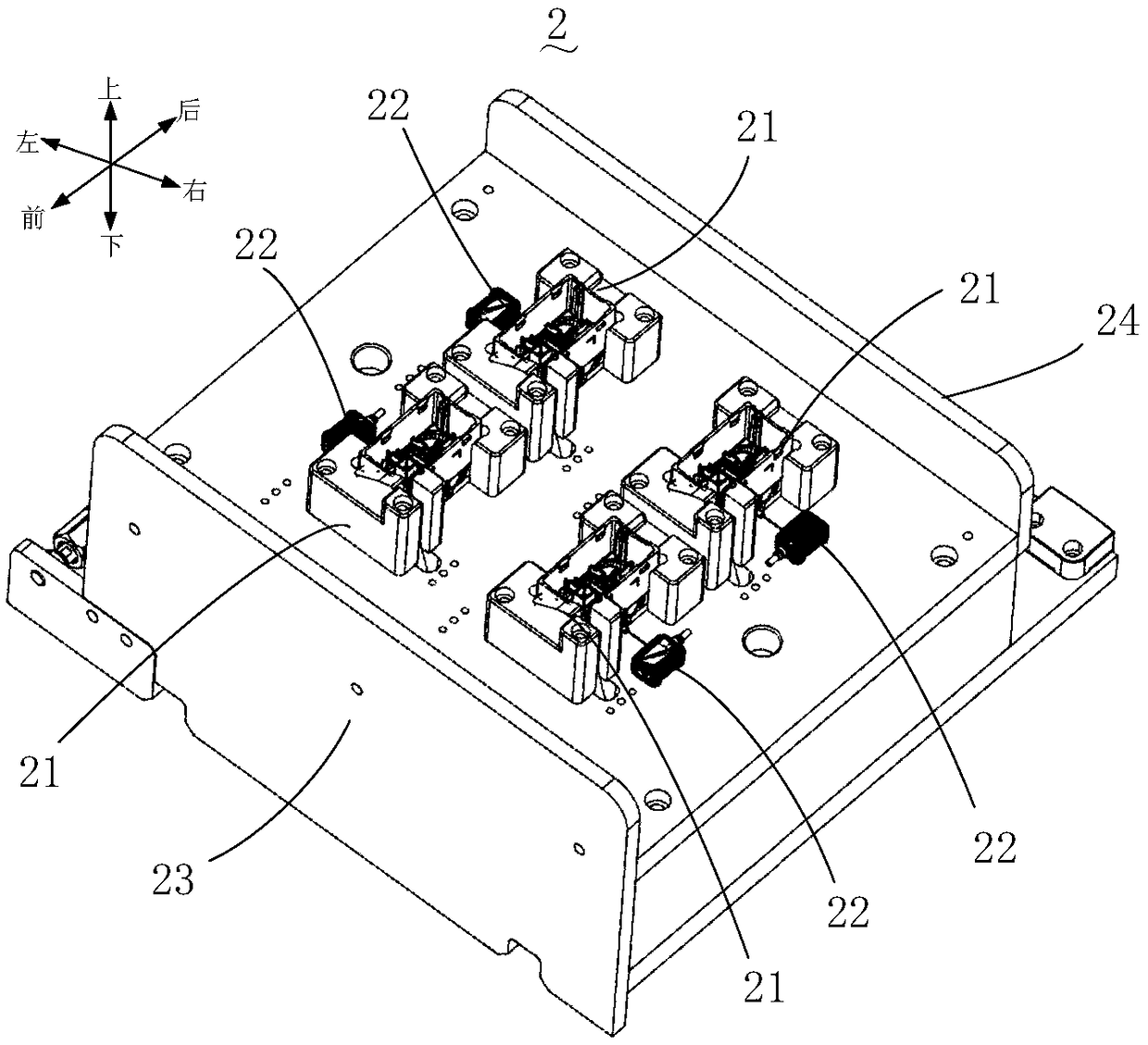

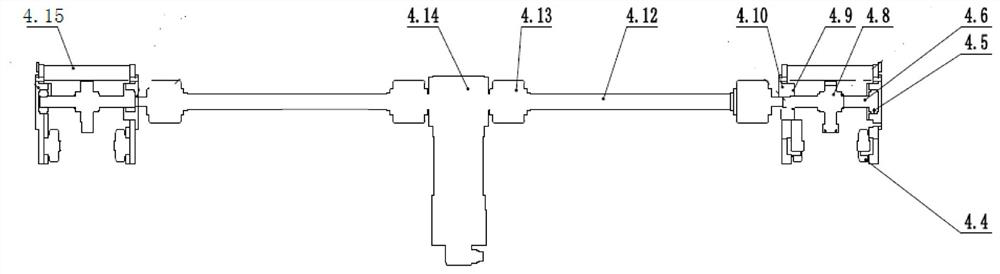

Oil applying device for HVAC part of automobile air conditioner

ActiveCN108043663ARealize automatic oilingOil evenlyLiquid surface applicatorsCoatingsLow noiseFeed drive

The invention provides an oil applying device for an HVAC part of an automobile air conditioner. The oil applying device for the HVAC part of the automobile air conditioner comprises a support and anelectronic control box installed on the support. The support is provided with an oil applying device, an oil feeding device and a feeding drive device. The oil applying clamp is installed above the oil feeding device. The feeding drive device is installed right in front of the oil feeding device. The oil applying clamp comprises an installation plate, an air cylinder support, an oil feeding air cylinder, an oil feeding nozzle, an upper noise reduction block and a moving plate. The oil feeding device comprises an oil nozzle support, an oil inlet pipe and a lower oil nozzle. The feeding drive device comprises a tray, a workpiece clamp groove, a sliding block, a reset spring, a sliding groove, a sliding rail, a tray drive air cylinder and a lower noise reduction block. The oil applying devicefor the HVAC part of the automobile air conditioner achieves automatic oil application of the HVAC part, the oil application position on the surface of the HVAC part is more accurate, oil applicationis more uniform, the positions of the upper oil nozzle and the lower oil nozzle are adjustable, so that the specific oil application position can be adjusted according to different HAVC parts, and the adaptability of the oil applying device is improved.

Owner:广州品晟汽车空调设备股份有限公司

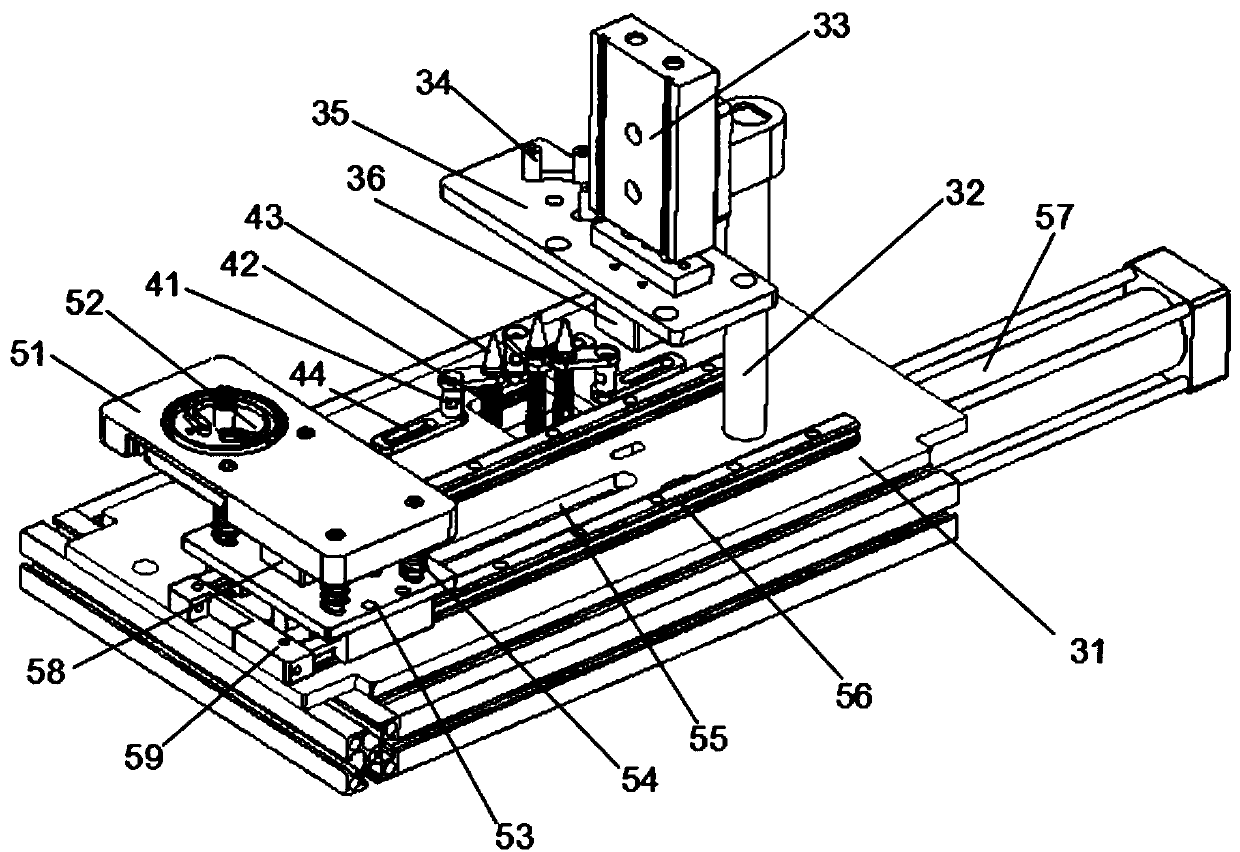

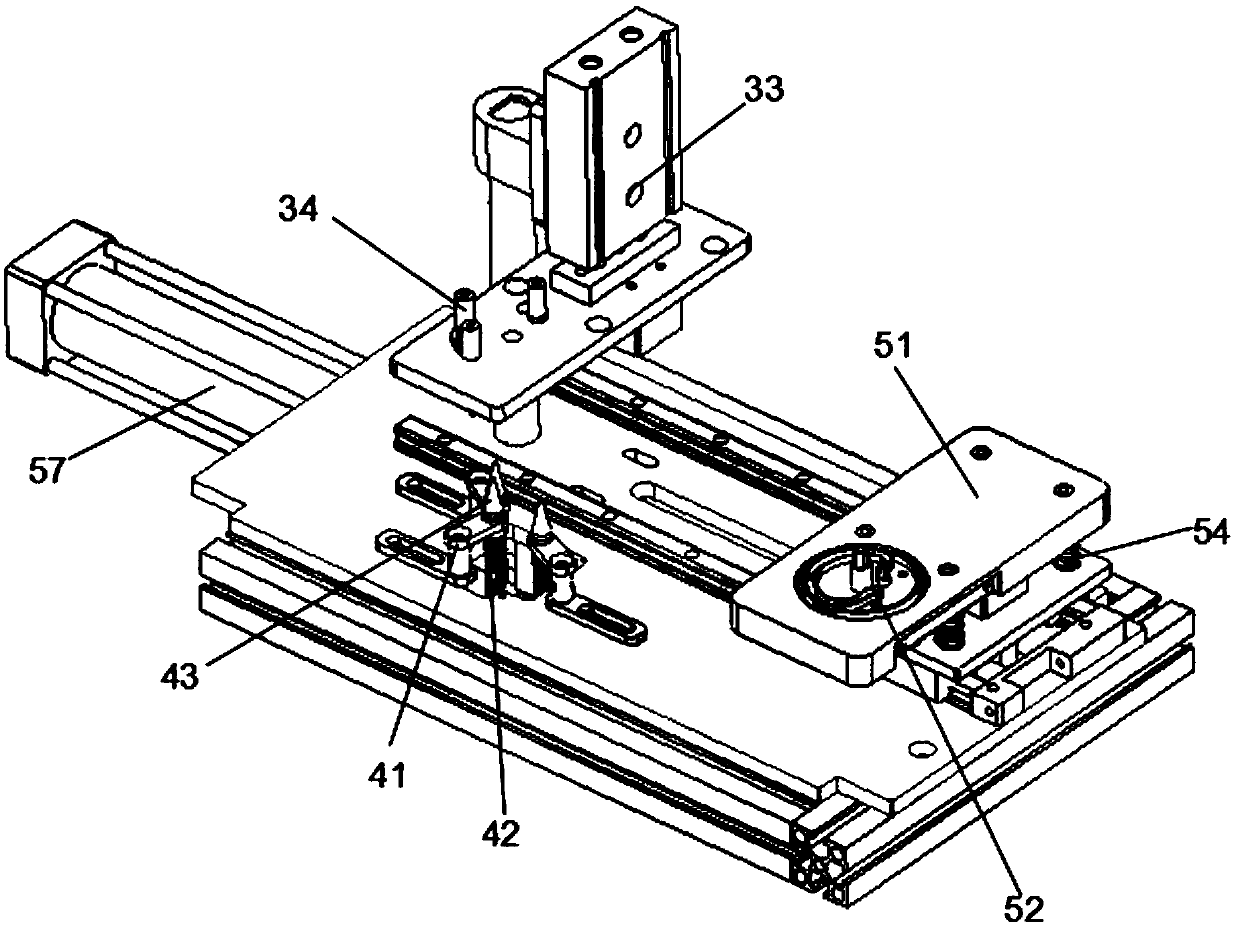

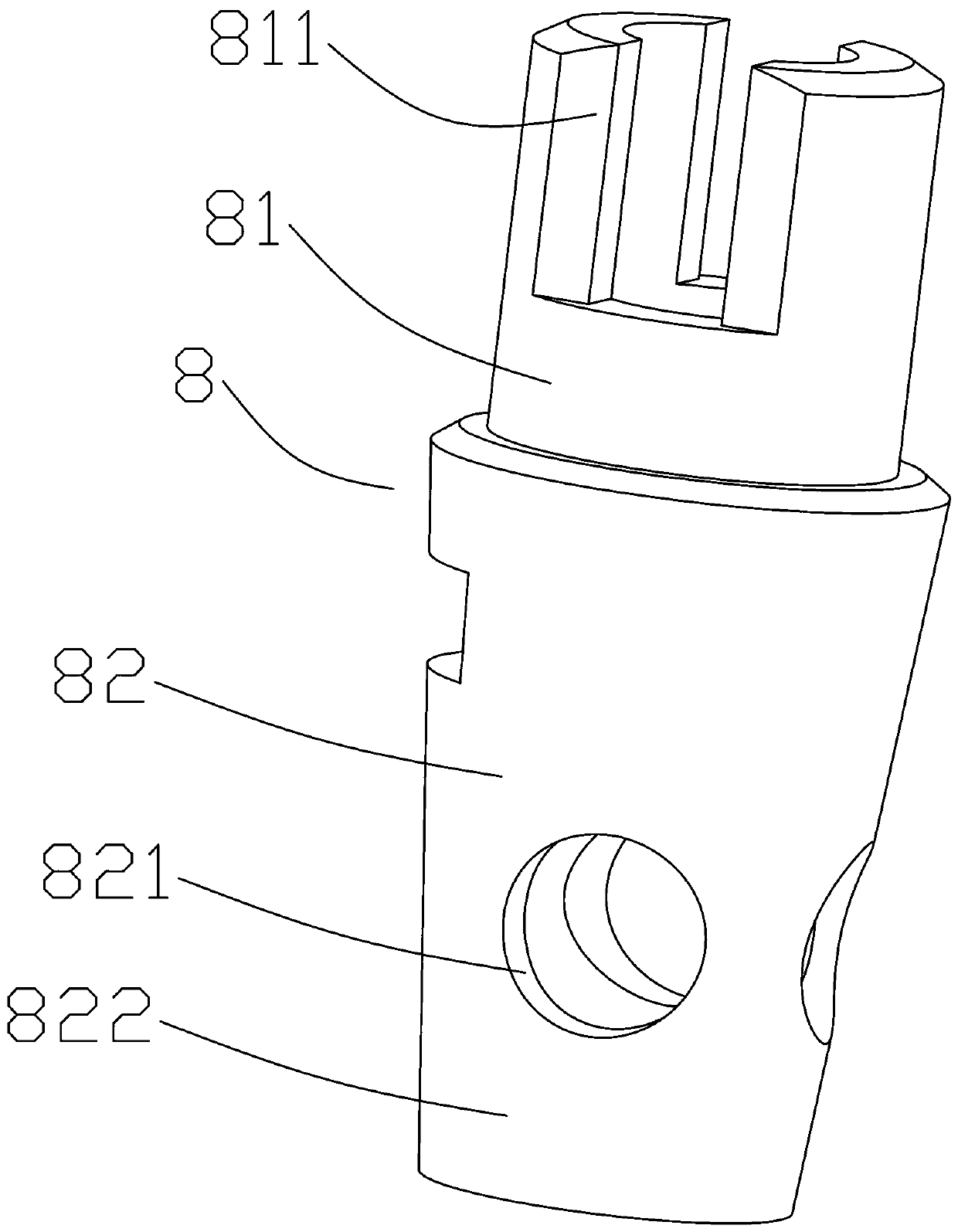

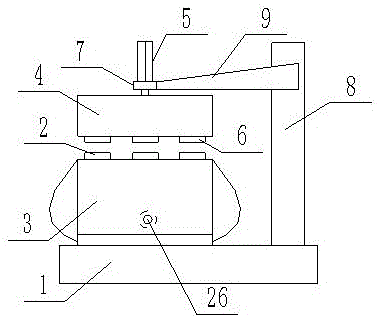

Valve core oil coating device

PendingCN110404724ARealize automatic oilingImprove oiling efficiencyLiquid surface applicatorsCoatingsMechanical engineeringCoating

The invention relates to a valve core oil coating device. The device solves the problem that an existing valve core is low in manual oil coating efficiency. The device comprises an machine frame, a valve core oil coating mechanism, a valve core feeding mechanism, a valve core supplying mechanism, wherein the valve core oil coating mechanism is arranged on the machine frame and is used for coatingoil on a valve core, and the valve core feeding mechanism is used for feeding for the valve core oil coating mechanism; the valve core feeding mechanism comprises a feeding supporting plate, a valve core feeding clamping mechanism and a first rotating air cylinder, wherein the feeding supporting plate is arranged on the machine frame, the first rotating air cylinder are used for driving the valvecore feeding clamping mechanism to rotate and feed; and the valve core oil coating mechanism comprises an oil coating wheel mechanism which is used for coating oil to the valve core through rotation,an oil suction wheel which is opposite to the oil coating mechanism and is used for coating oil to the oil coating wheel mechanism, a point oil mechanism used for spraying oil to the oil suction wheel, and a scraping plate used for scraping and coating the oil on the oil suction wheel. According to the device, the valve core feeding mechanism is used for feeding and transferring the valve core, the valve core feeding mechanism is used for automatic feeding of the valve core, the valve core oil coating mechanism is used for automatically coating the valve core, so that automatic oil coating ofthe valve core is realized, the oil coating efficiency is high, and the labor cost is saved.

Owner:深圳市佳宇精密机电科技有限公司

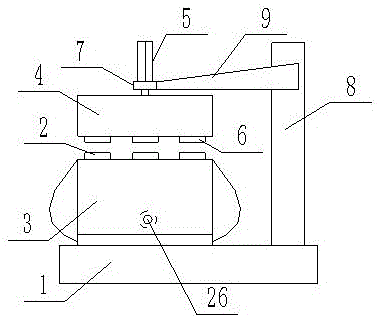

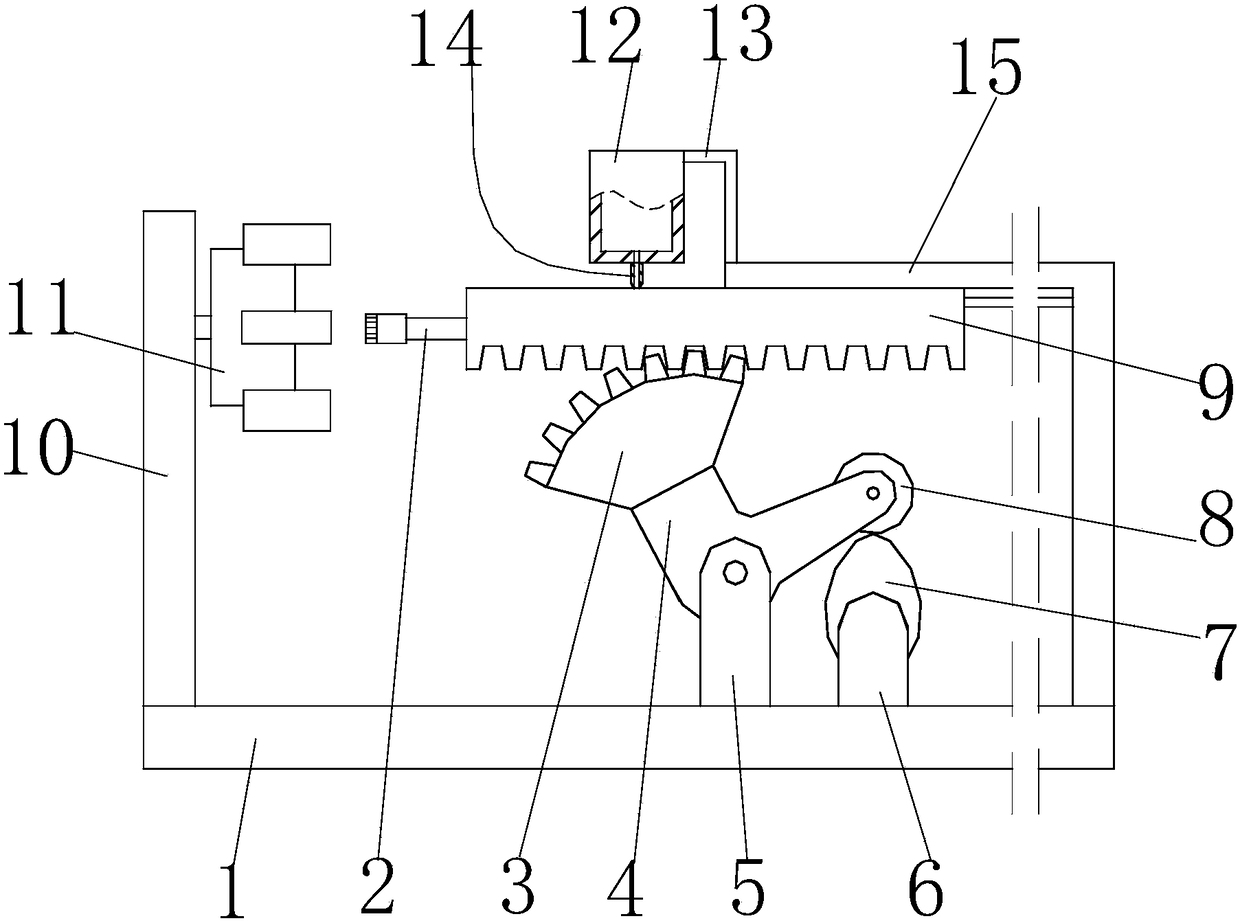

Processing oil coating device

InactiveCN108212650AHigh degree of automationEasy to useLiquid surface applicatorsCoatingsAgricultural engineeringCam

The invention relates to a processing oil coating device, which comprises a bottom plate, wherein a three-claw chuck is arranged at the left side of the bottom plate; a hair brush is arranged at the right side of the three-claw chuck; the hair brush is welded with a right rack; the right rack is engaged with a fan-shaped gear; the fan-shaped gear is connected with a V-shaped swinging frame; the middle part of the swinging frame is hinged to a hinging seat; a counterweight wheel is arranged at the right side of the swinging frame; the lower end of the counterweight wheel is abutted with a cam;the cam is connected with a motor. A hanging frame used for horizontally sliding and installing the right rack is fixedly arranged at the right side on the bottom plate; a hanging rod is arranged at the left side on the hanging frame; an oil barrel is fixedly arranged on the hanging frame; an oil dripping pipe is arranged at the lower end of the oil barrel. On the premise of supplying oil throughthe oil dripping pipe, the reciprocating left and right sliding of the hair brush is controlled through the swinging of the swinging frame; the hair brush oil staining and the coating are controlled to be alternately performed; the goal of realizing the automatic oil coating on the end surface of the steel rod in the processing gap can be realized; the effects of convenient use and labor saving can be achieved.

Owner:WUHU HENGHAO MACHINERY MFG

Steel wire rope protective greasing device

The invention discloses a steel wire rope protective greasing device which comprises an operating platform. A grease supply sleeve is arranged on the operating platform; a grease inlet connected with a grease tank is arranged on the grease supply sleeve; a plurality of grease outlet holes are formed in the inner surface of the grease supply sleeve; the inner surface of the grease supply sleeve is lined with a flexible grease coating; and a grease collecting container is arranged below the grease supply sleeve. The steel wire rope protective greasing device is simple in structure and has the advantages that grease is supplied to the grease supply sleeve through the grease tank; the flexible grease coating is uniformly coated with the grease; when a steel wire rope moves and passes through the grease supply sleeve, automatic greasing can be achieved, so that the phenomenon of non-uniform greasing caused by manual operation can be avoided; and meanwhile, the greasing mount can be controlled by controlling the movement speed of the steel wire rope and the grease supply amount.

Owner:徐金楼

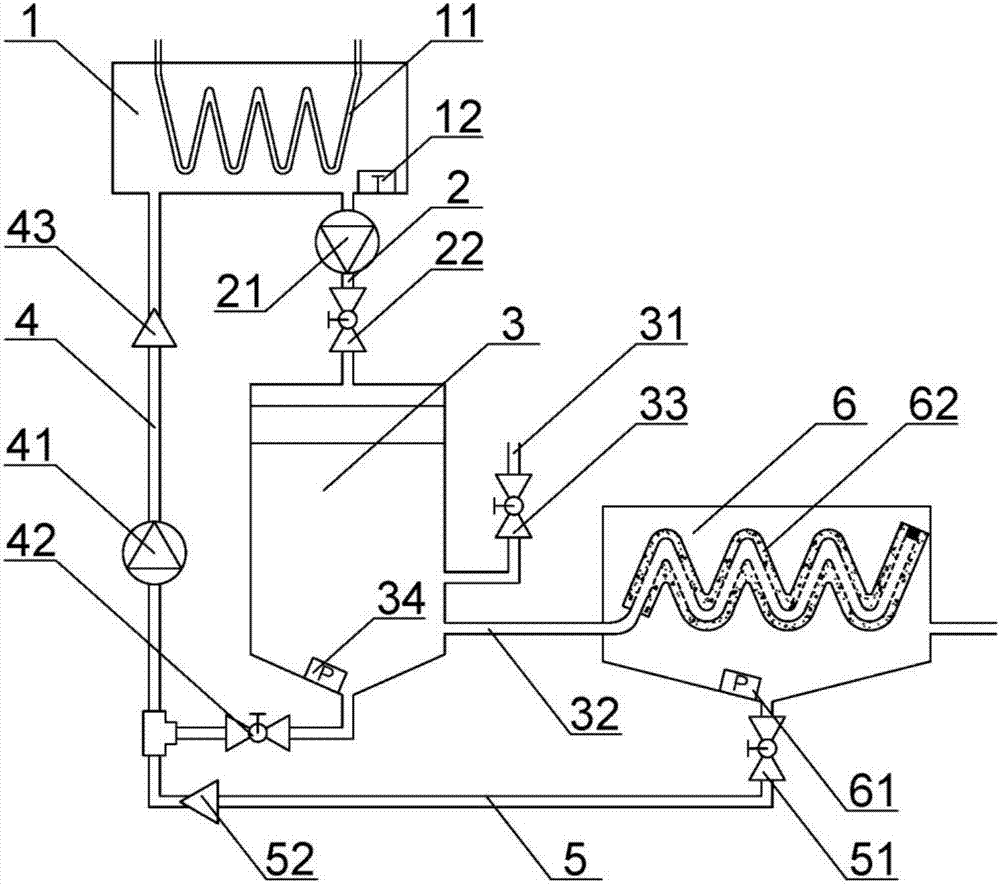

Lubrication compensation compressor

ActiveCN107989776AHigh purityGuaranteed to workPositive displacement pump componentsPositive-displacement liquid enginesFuel tankLubrication

The invention discloses a lubrication compensation compressor. A first oil pump on an oil inlet pipe drives conveying of lubricating oil from an oil storage tank to a compression cylinder; a second oil pump on a first oil return pipe drives conveying of the lubricating oil from the compression cylinder to the oil storage tank; a first oil pressure sensor is arranged in the compression cylinder; acontrol module controls an oil pump and a valve to work according to pressure values acquired by the first oil pressure sensor; when the lubricating oil in the compression cylinder reaches a certain quantity, the control module controls each valve to act to return the lubricating oil in the compression cylinder to the oil storage tank through the first oil return pipe to achieve the purpose of circular lubrication; a cooling device is arranged in the oil storage tank; when the temperature of the lubricating oil in the oil storage tank reaches a certain value, the control module controls the cooling device to cool the lubricating oil; lubricating oil components in compressed gas are filtered through an oil filter cylinder to improve the purity of the compressed gas; and the lubrication compensation compressor realizes the functions of automatic detection and automatic oiling, and guarantees long-time normal work of the compressor.

Owner:安徽寅时压缩机制造有限公司

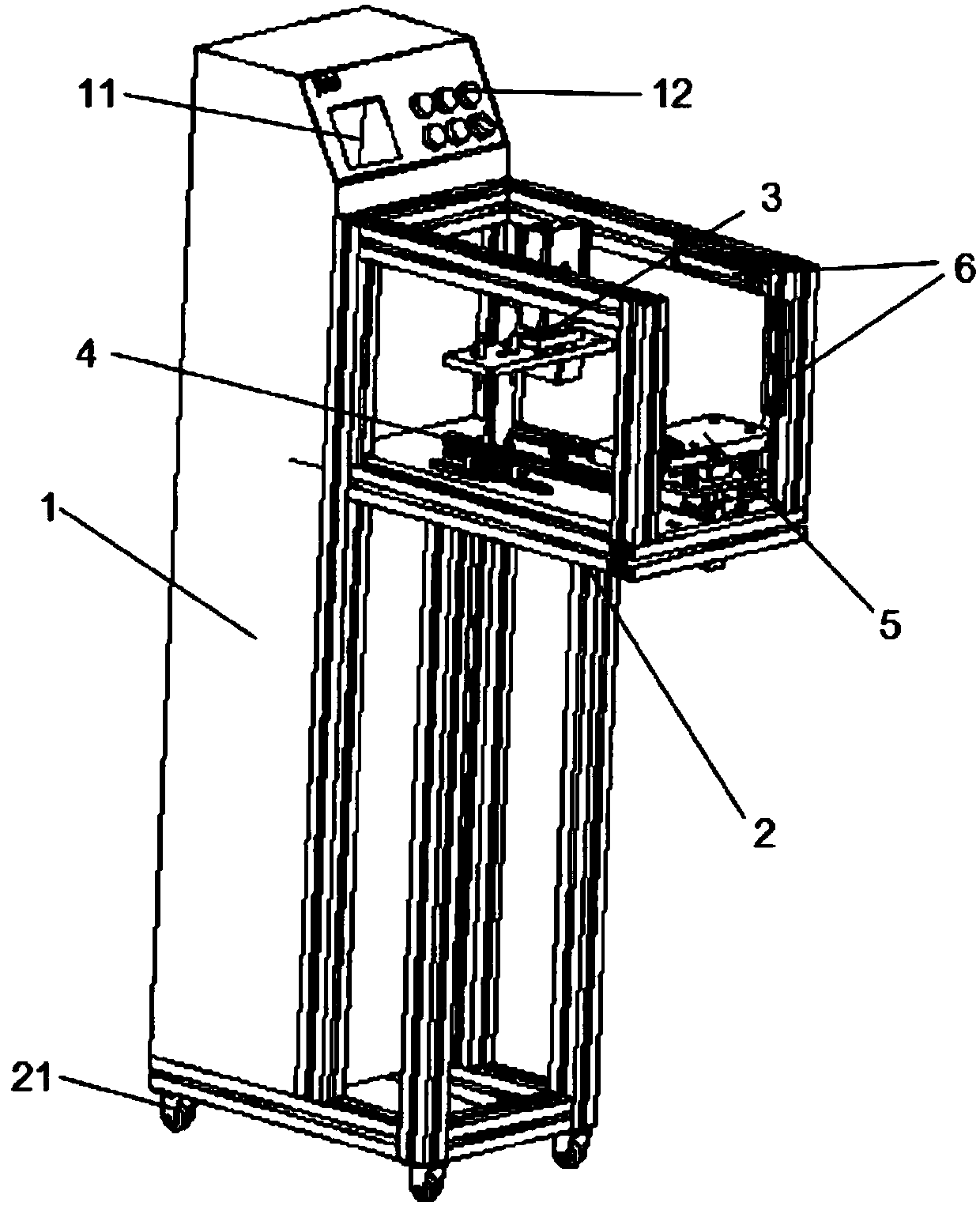

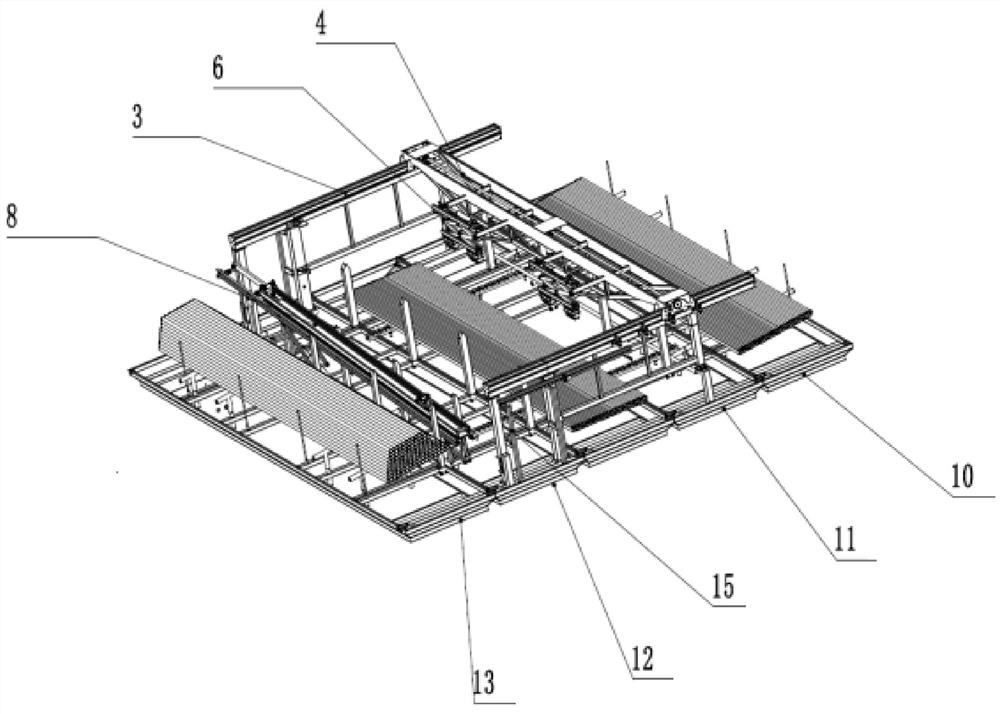

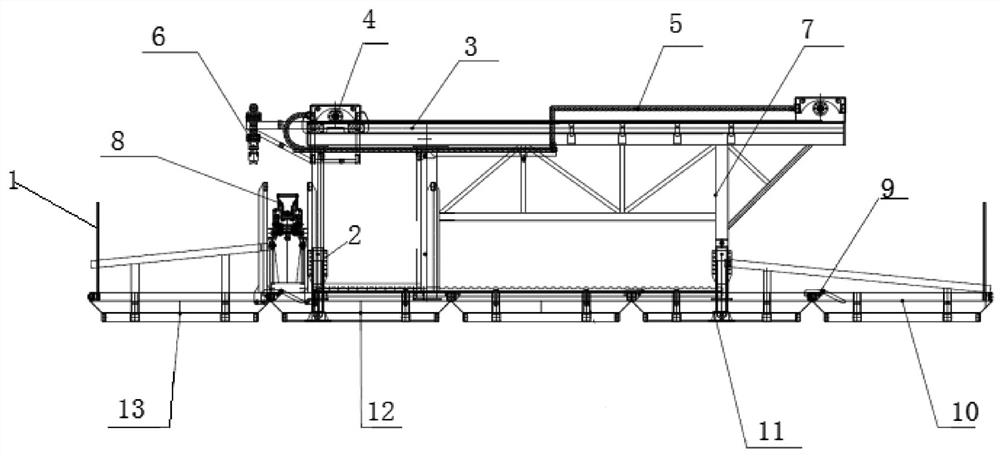

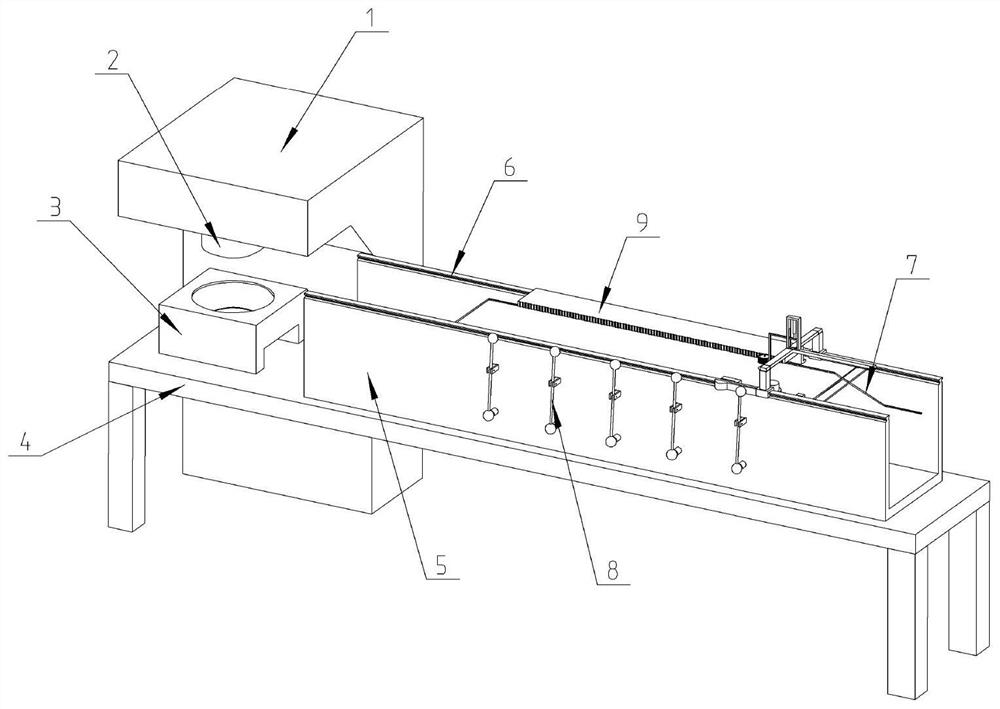

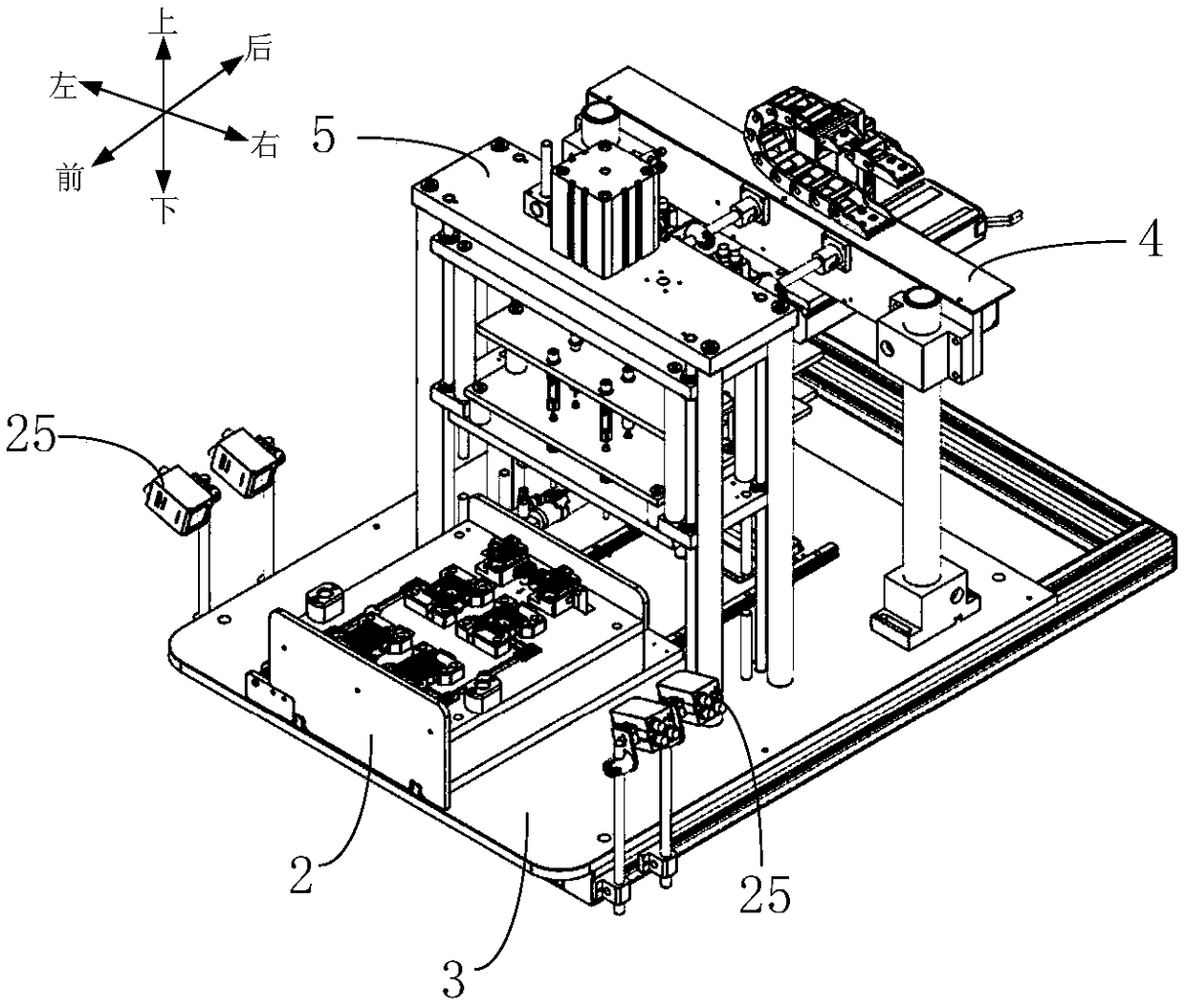

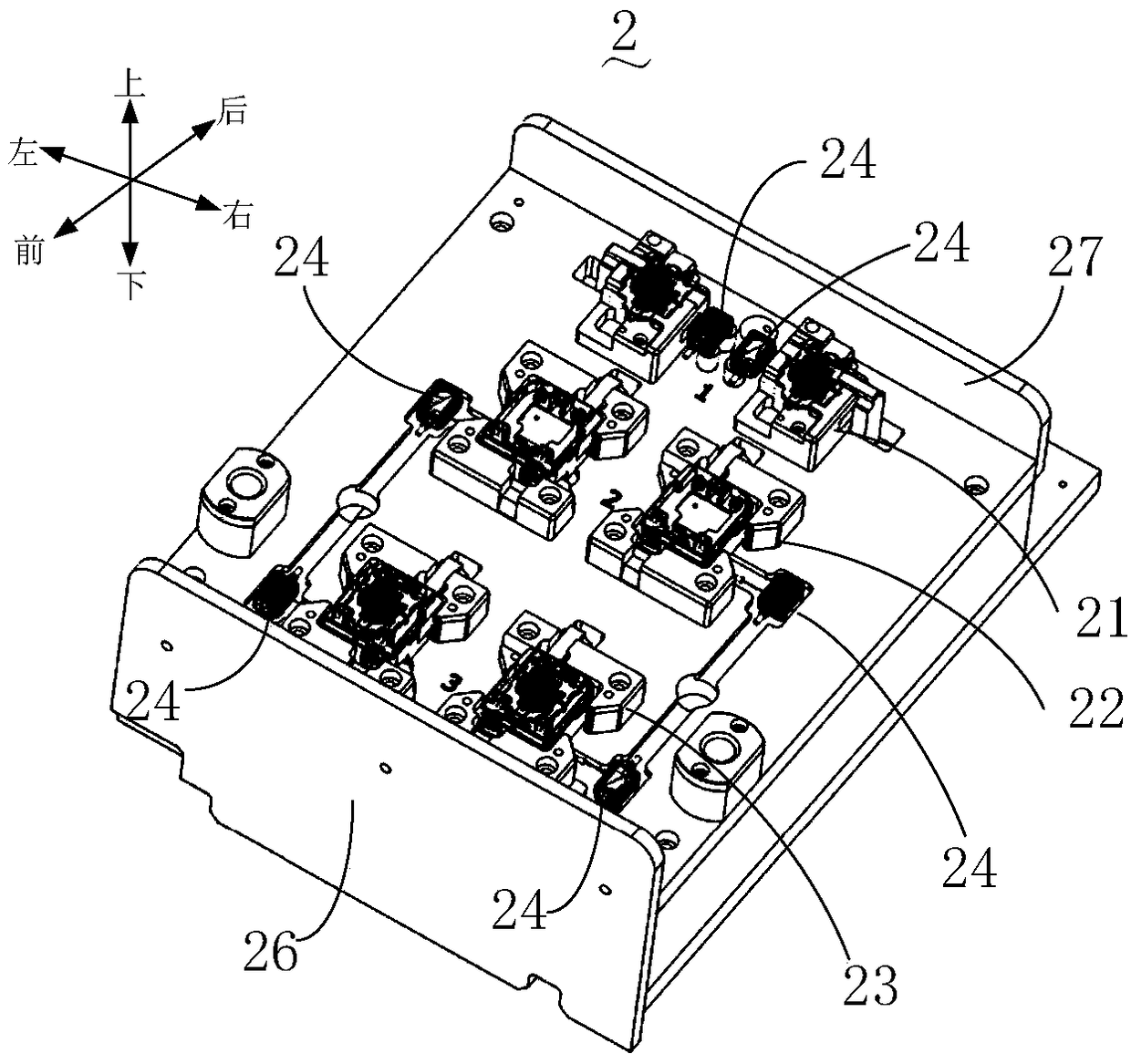

Oiling equipment of automobile window guide frameworks and oiling control method

PendingCN109107847AIncrease productivityEasy to follow upLiquid surface applicatorsSpraying apparatusElectric controlData library

The invention provides an oiling control method of oiling equipment of automobile window guide frameworks. The oiling control method comprises the following steps that the equipment receives a startupcommand, and a workbench is pushed out to the operation position from the initial position; the equipment receives an oiling operation starting command, a camera scans two-dimensional codes on the guide frameworks in the stations, the scanning effects are fed back to a background database, and registration information is generated; and the workbench is pushed back to the initial position from theoperation position, an electric control box controls an oiling mechanism to do oiling work according to the non-vacant information, detected by sensors, of the stations, the oiling condition is detected, oiling qualified information is sent to the background database, and qualified information in the registration information is generated. The invention provides the oiling equipment of the automobile window guide frameworks. By means of the oiling control method of the oiling equipment of the automobile window guide frameworks, oiling is completed automatically, production efficiency is improved, the oiling condition is detected, the qualified information of machining objects is registered one by one, and subsequent tracking is facilitated.

Owner:宁波均普智能制造股份有限公司

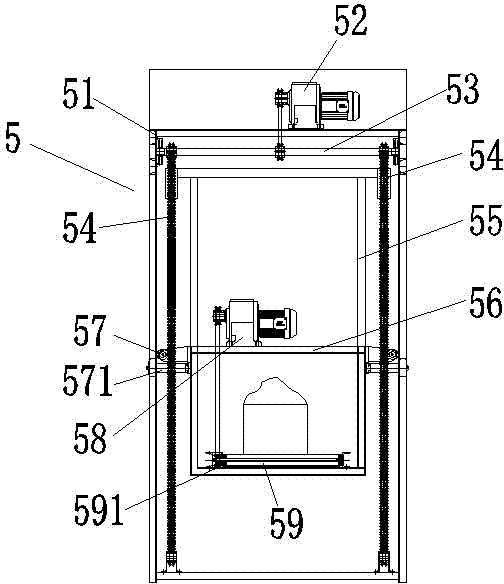

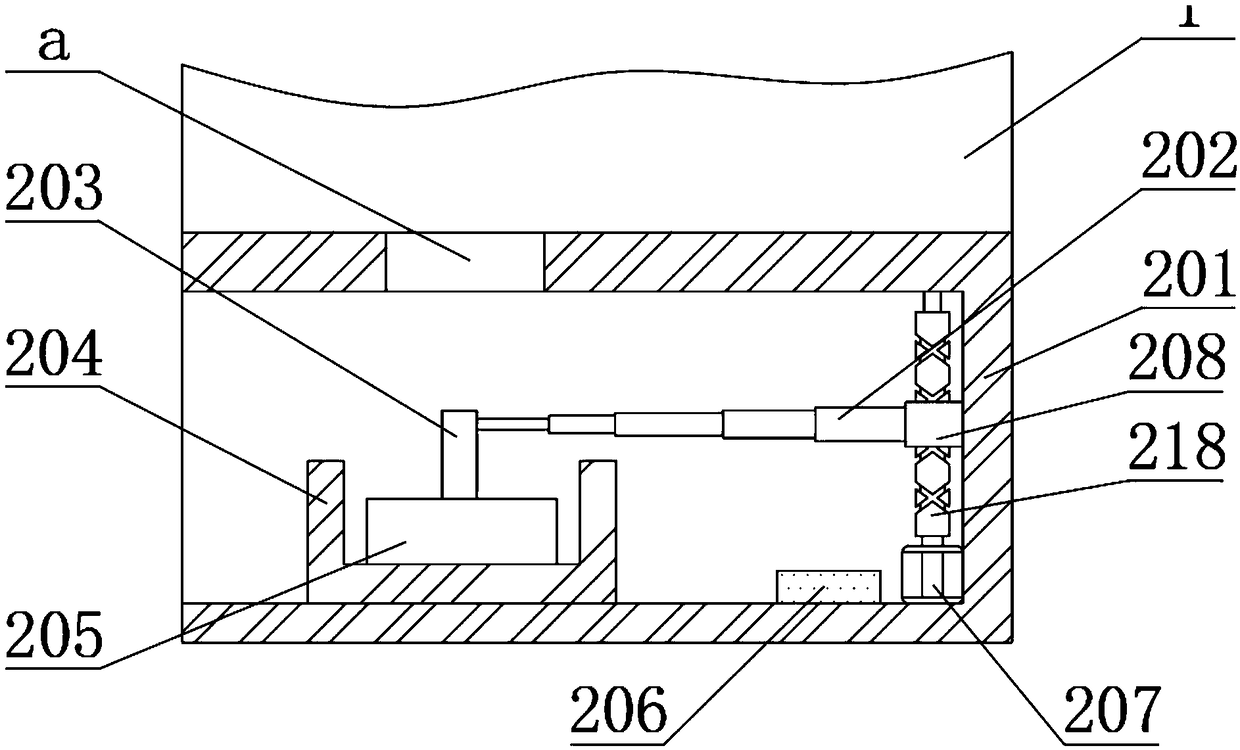

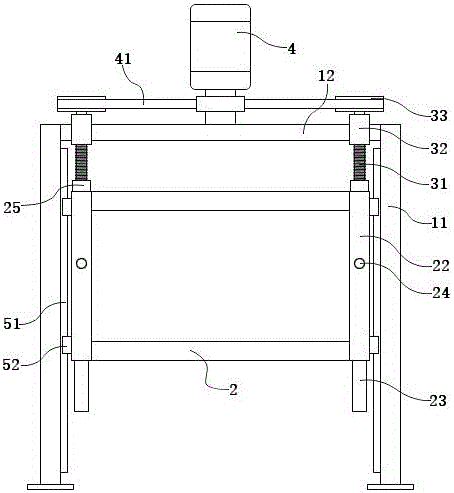

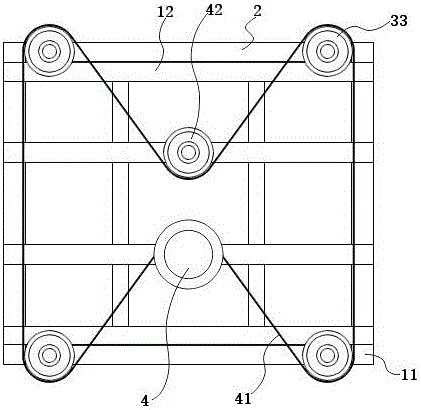

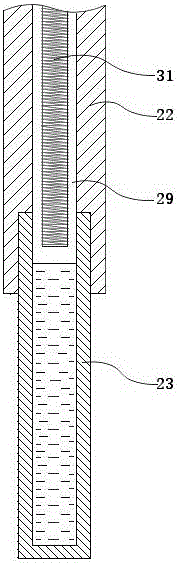

Upper box body foaming equipment driven by screw rods

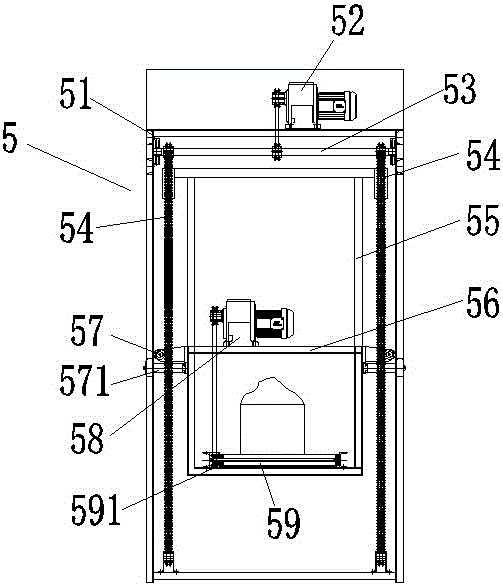

ActiveCN106044620AReduce occupancyImprove securityLifting framesEngine lubricationFuel tankPetroleum engineering

The invention discloses upper box body foaming equipment driven by screw rods. The upper box body foaming equipment comprises a rack, a box frame, the screw rods and a motor, wherein the motor is arranged on a top platform of the rack; the number of the screw rods is four; and the four screw rods are suspended on the top platform through screw rod bearings and are connected with the motor through a driving mechanism arranged on the top platform. Four cavity columns are arranged at four corners of the box frame and are provided with screw taps connected with the screw rods; a cavity is arranged in each cavity column, and a lubricating oil tank is arranged below each cavity column; the cavity in each cavity column communicates with the corresponding lubricating oil tank; the screw rods penetrate into the corresponding cavities and the lower ends of the screw rods can be immersed in lubricating oil of the corresponding lubricating oil tanks when the box frame ascends; and a lifting guide mechanism is arranged between the box frame and the rack.

Owner:江苏天辰智能装备有限公司

Riveting machine

The invention discloses a riveting machine. The riveting machine comprises a pressure welding piece, a trigger piece, an oil storage piece, an oil conveying pipe, an air conveying pipe, a driving pressure welding piece, and a pushing piece, wherein the pressing welding piece includes a main body part, a pressure head and an assembly part, the main body part is cylindric and the pressure head is columnar, the main body part forms a cavity and an oil transportation hole; the pressure head is provided with an oil outlet which runs through the pressure head and extends to the cavity and is communicated with the oil transportation hole; the oil transportation hole is connected with the oil storage piece through the oil conveying pipe; an airflow switch is arranged on an air conveying pipe and one end of the air conveying pipe is connected with the oil storage piece; pushing piece includes a rod part and a rotating shaft; the trigger piece includes a fixed end and a support end, the fixed end is fixedly connected to the rod part, one end of the assembly part far away from the main body part is fixedly connected to the rod part; the trigger piece corresponds to the airflow switch; the support end is driven by the pushing piece to trigger the airflow switch to ensure that air enters the oil storage piece so as to convey the oil in the oil storage piece to the oil outlet, and the support end of the trigger piece is separated from the airflow switch to ensure that the airflow switch is switched off to prevent the oil in the oil storage piece from flowing into the oil outlet. The riveting machine can realize automatic oil removal and has high production efficiency.

Owner:KANGZHUN ELECTRONICS TECH KUNSHAN +1

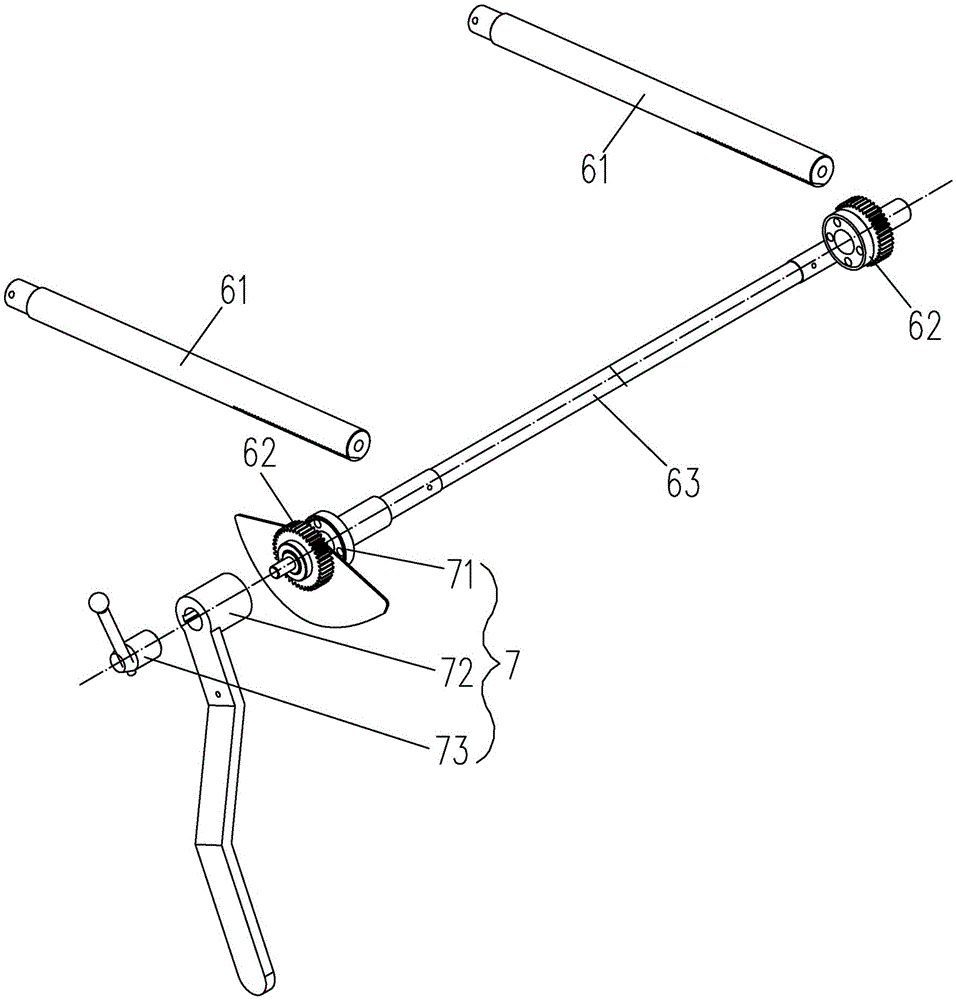

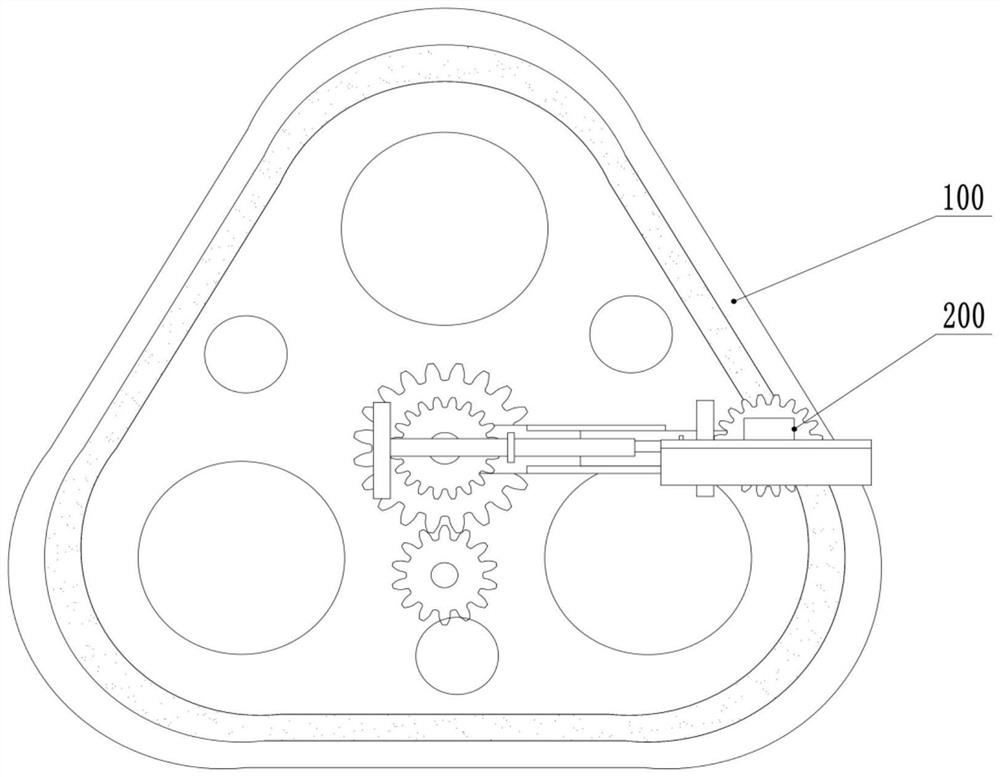

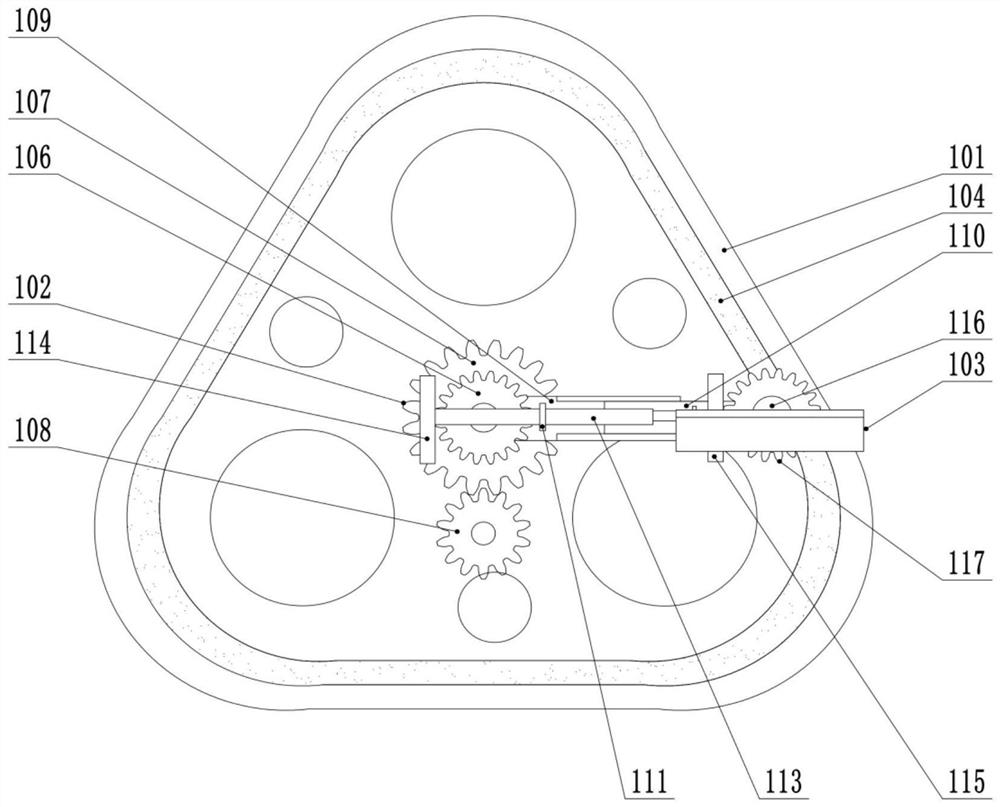

Portal crane gear lubricating structure and lubricating method

PendingCN112855911ASolve the problem of different additionsRealize automatic oilingGear lubrication/coolingOil and greaseMarine engineering

The invention discloses a portal crane gear lubricating structure and a lubricating method. The portal crane gear lubricating structure comprises a conveying device, an adjusting device installed on the conveying device and an oiling device installed on the adjusting device and used for oiling a gear needing to be lubricated; the conveying device comprises a fixing plate, a transmission assembly installed on the fixing plate and a flat plate which is installed on the transmission assembly, surrounds the outer contour of the fixing plate and is always parallel to the horizontal plane in the moving process; and the adjusting device comprises a fixing base, a first adjusting assembly, a second adjusting assembly installed on the first adjusting assembly and a third adjusting assembly installed on the second adjusting assembly. The device is driven by the adjusting device and a driving device to move, automatic oiling is achieved, the problems that grease needs to be smeared manually, and time and labor are wasted in existing portal crane exposed gear lubrication are solved, and manual high-altitude operation is not needed. and by means of the oiling device, the problem that due to different personal operation methods, the grease adding amount of an existing portal crane exposed gear is different is solved.

Owner:ZHENJIANG PORT GRP CO LTD

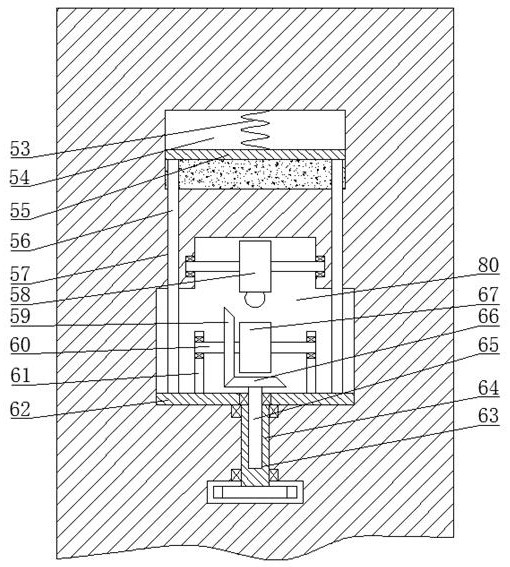

Wafer processing method

ActiveCN106826406AAchieve grindingRealize automatic recyclingGrinding machinesWork carriersEngineeringDrive motor

The invention relates to the technical field of optoelectronics information, and discloses a wafer processing method. The wafer processing method includes the following steps that S1, a wafer is placed on a wafer carrying table, and a pressing mechanism drives grinding heads to press the wafer on the wafer carrying table at a certain pressure; and S2, a driving motor above the grinding heads and a motor of a first driving mechanism are started, the grinding heads are driven by the driving motor to make rotating motion, the motor of the first driving mechanism is slowed down through a speed control gear, then a driven gear is driven to rotate through a rotating shaft, and accordingly the wafer carrying table installed on the rotating shaft can be driven to rotate, the turning direction of the wafer carrying table is opposite to that of the grinding heads, and the grinding heads can grind the wafer. The wafer processing method is provided, powdered scraps generated in grinding can be absorbed in the wafer grinding process, and meanwhile a cooling and lubricating effect on equipment can be achieved.

Owner:重庆晶宇光电科技有限公司

Pressure roll forming device on plastic sheet production line

The invention discloses a pressure roller molding device on a plastic sheet material production line. The device comprises a frame. A lower pressure roller and an elevation upper pressure roller which cooperate with each other are arranged on the frame. A liquid pool matching the lower pressure roller is arranged on the lower part of the frame. An upper auxiliary roller and a lower auxiliary roller respectively cooperating with the upper pressure roller and the lower pressure roller are arranged on the frame. A liquid tank is arranged on the frame and positioned above the upper auxiliary roller. A liquid outlet is provided on the bottom wall of the liquid tank along the axial direction of the upper auxiliary roller. According to the invention, with the added upper and lower auxiliary rollers, and the liquid pool and liquid tank used for accommodating oil, oil in the liquid pool and liquid tank is respectively coated on surfaces of two sides of a PET sheet material, such that an automatic oiling purpose is realized, and labor intensity is reduced. With the upper and lower auxiliary rollers, oil amount and distribution can be well controlled, such that coatings formed after oiling are uniform.

Owner:江苏民扬塑胶科技有限公司

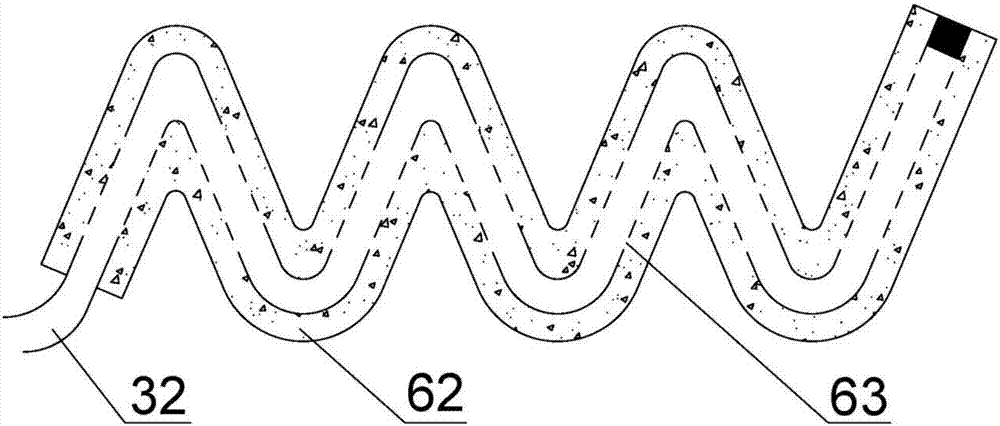

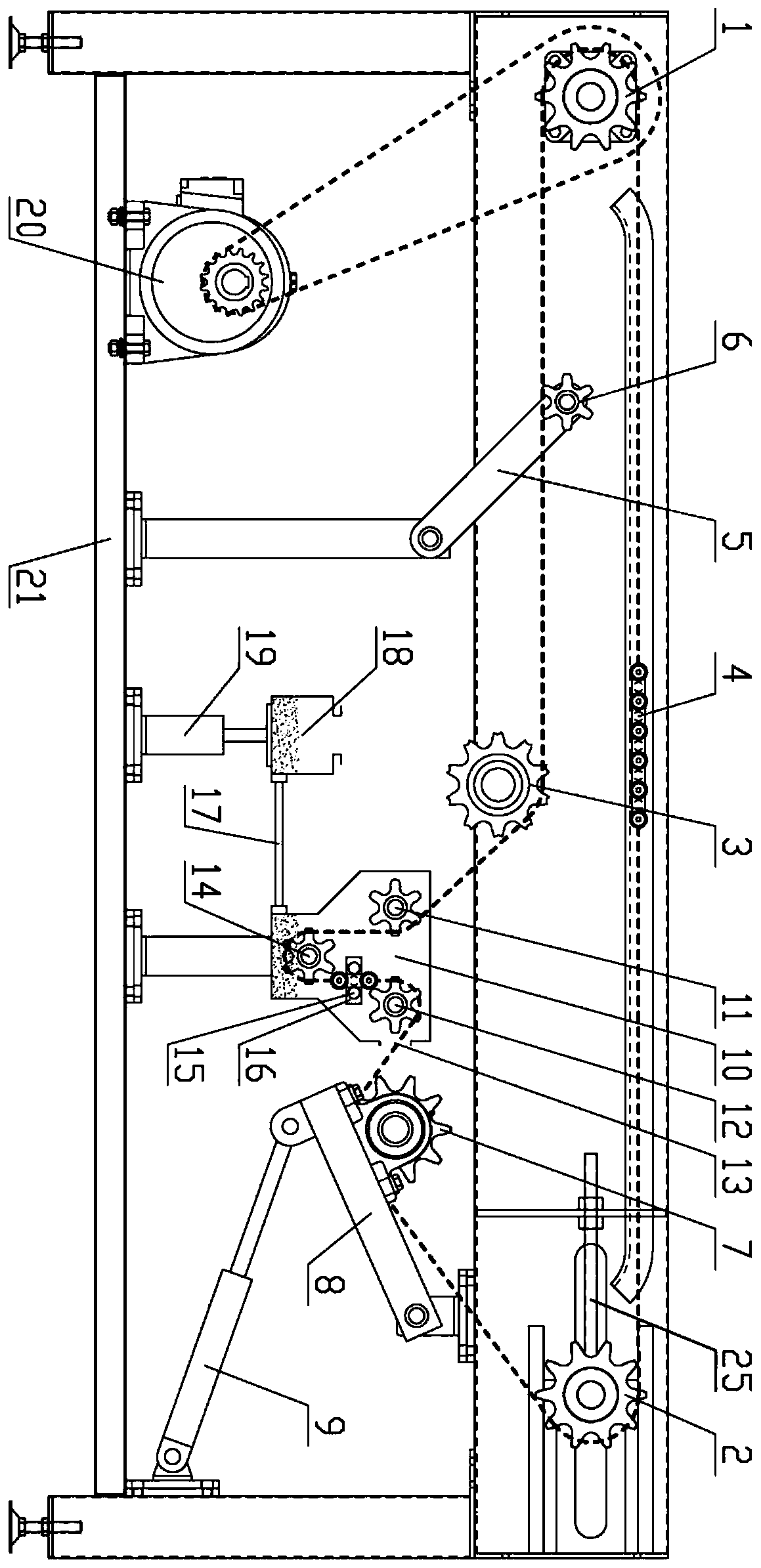

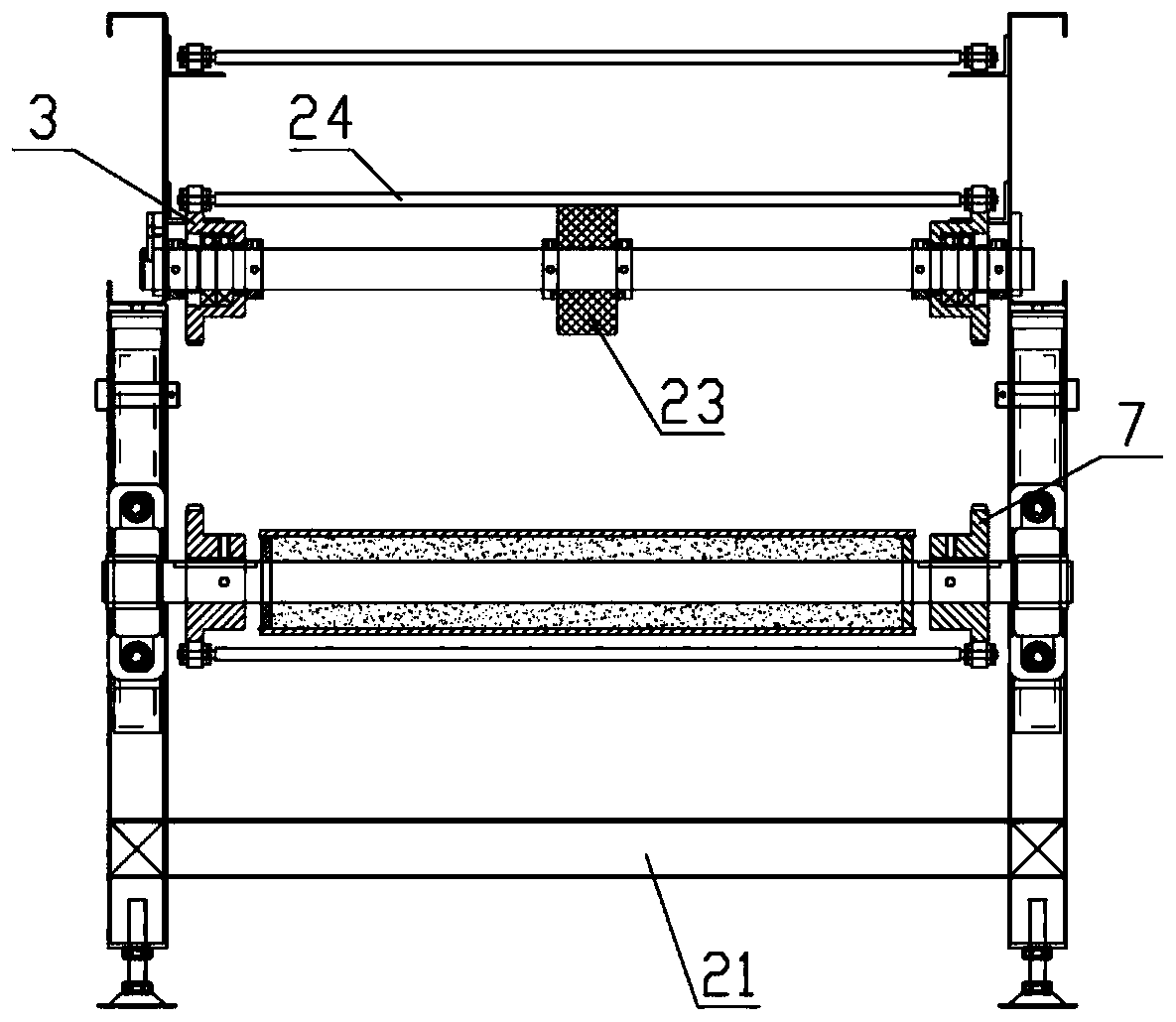

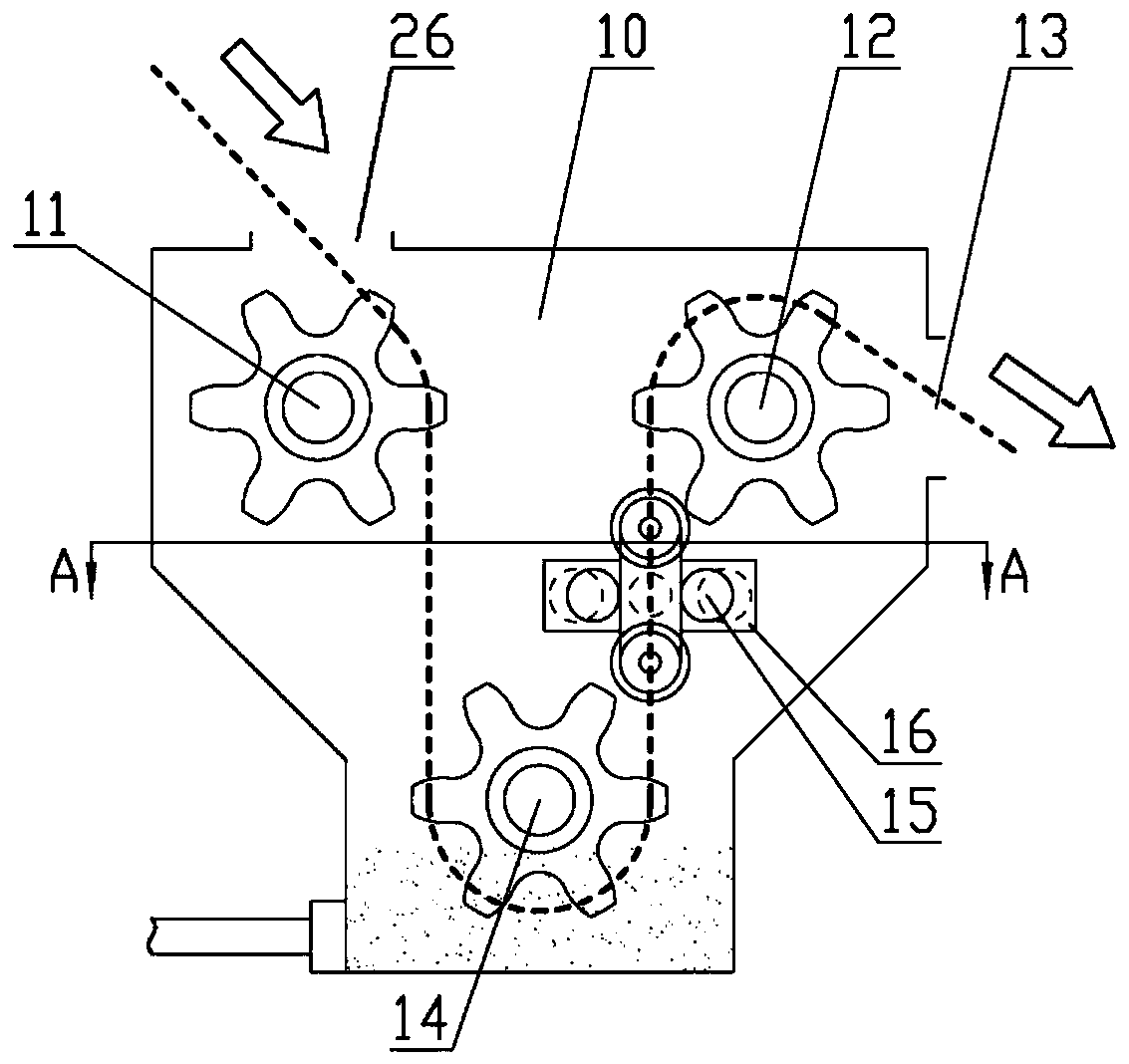

UV oven penetrating rod conveying chain

InactiveCN109748037ARealize automatic oilingRealize automatic tensioningConveyorsControl devices for conveyorsFuel tankDrive motor

The invention discloses a UV oven penetrating rod conveying chain. The UV oven penetrating rod conveying chain comprises a machine frame, driving sprockets are mounted at the front end of the machineframe, and a driven sprocket is mounted at the rear end of the machine frame; the driving sprockets and the driven sprocket are connected in a drive mode by a roller chain, and rotating shafts of where the driving sprockets are located are driven by a drive motor; the UV oven penetrating rod conveying chain further comprises an intermediate sprocket and an oiling device mounted on the machine frame, the oiling device comprises an oiling box and an oil tank, and the oiling box is provided with a chain inlet and a chain outlet; an inlet sprocket, an outlet sprocket and an oiling sprocket are rotatably mounted in the oiling box, and the height of the inlet sprocket and the outlet sprocket are higher than that of the oiling sprocket; and the oil tank is arranged on the machine frame through alifting device in an adjustable height mode, and the bottom of the oil tank communicates with the bottom of the oiling box through a hose. The UV oven penetrating rod conveying chain has the beneficial effects that automatic oiling and automatic tensioning can be achieved in the non-stop state.

Owner:KUNSHAN RUI PU XIN COATING MACHINERY

Riveting machine

The invention discloses a riveting machine. The riveting machine comprises a pressure welding piece, a trigger piece, an oil storage piece, an oil conveying pipe, an air conveying pipe, a driving pressure welding piece, and a pushing piece which triggers the trigger piece to move; the end face of the pressure welding piece is provided with oil outlets; the oil outlets are connected with the oil storage piece through the oil conveying pipe; an airflow switch is arranged on an air conveying pipe and one end of the air conveying pipe is connected with the oil storage piece; the trigger piece corresponds to the airflow switch; and the trigger piece is driven by the pushing piece to trigger the airflow switch to ensure that air enters the oil storage piece so as to convey the oil in the oil storage piece to the oil outlets, and the trigger piece is separated from the airflow switch to ensure that the airflow switch is switched off to prevent the oil in the oil storage piece from flowing into the oil outlets. The riveting machine can realize automatic oil removal and has high production efficiency.

Owner:KANGZHUN ELECTRONICS TECH KUNSHAN +1

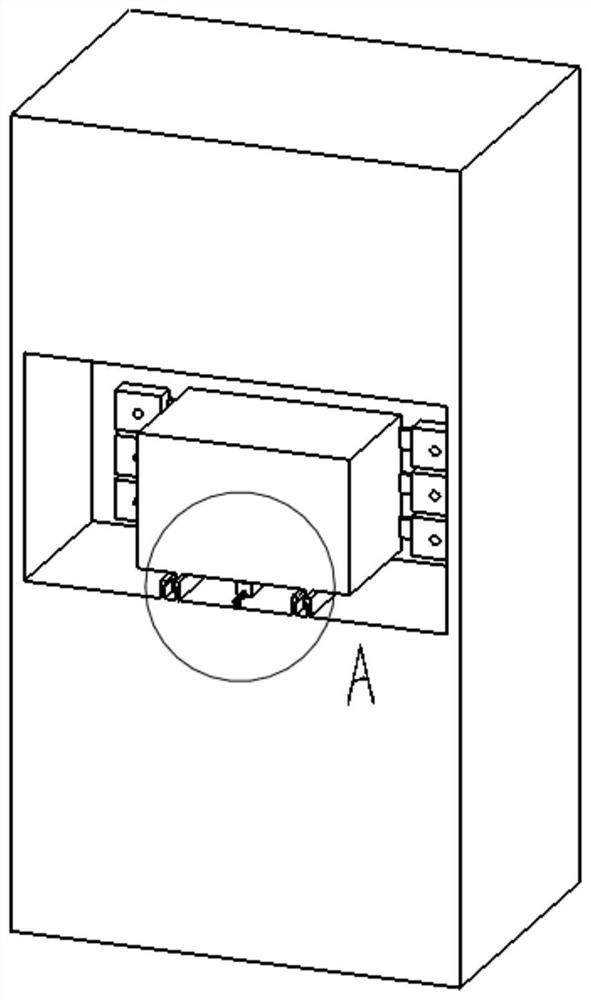

Power distribution module worm connection type intelligent wire outlet cabinet

PendingCN111697450AEasy to disassembleDisassembly safetySubstation/switching arrangement detailsControl theoryMechanical engineering

The invention discloses a power distribution module worm connection type intelligent outgoing line cabinet, and the cabinet comprises an outgoing line cabinet body and a power distribution module; thepower distribution module is connected in a cavity of the outgoing line cabinet body, and the power distribution module is connected in the cavity of the outgoing line cabinet body through a worm structure. The problems that in the prior art, a power distribution module is difficult to disassemble and low in disassembly safety are solved.

Owner:GUIZHOU CHANGTONG ELECTRIC

Cofferdam type pipe rod conveying and discharging device

PendingCN113846980AReduce operational security risksReduce manual interventionDrilling rodsDrilling casingsHydraulic cylinderCoupling

The invention discloses a cofferdam type pipe rod conveying and discharging device. The conveying and discharging device is composed of five cofferdams and comprises a near-end auxiliary material frame, a main material frame, an auxiliary material frame and a far-end auxiliary material frame, the five cofferdams are each arranged to be a rectangular block, are sequentially arranged from left to right and are mutually fixed through rapid buckles, four stand columns with lifting adjusters are arranged at the bottoms of the four corners of the outer sides of the main material frame and the auxiliary material frame, the upper top ends of the front stand column and the rear stand column are each provided with a rectangular guide rail, the middle of the top face of each rectangular guide rail is provided with a rack, the front rectangular guide rail and the rear rectangular guide rail are each provided with a rectangular traveling mechanism matched with the guide rails to move, two output shafts of a speed reducer are respectively connected with couplings of two rolling mechanisms arranged on the two guide rails, and the rolling mechanisms are provided with drag chains which are mutually hinged with drag chain rods; grabbing manipulators consisting of manipulator support frames, hydraulic cylinders, shear fork frames and electric permanent magnets are respectively arranged below the front middle part and the rear middle part of the traveling mechanism; and a lifting machine for receiving and sending a pipe rod to a wellhead is longitudinally arranged on the right side of the near-end auxiliary material frame.

Owner:东营市天合工贸有限责任公司

A tinplate oiling device

InactiveCN103962272BRealize automatic oilingSimple structureLiquid surface applicatorsWelding/cutting auxillary devicesDrive wheelTin

The invention provides a tinplate oiling device, and belongs to the technical field of metal tin making. The tinplate oiling device comprises an oiling mechanism and an oil brushing mechanism; the oiling mechanism and the oil brushing mechanism are arranged just above tinplate and are both fixed on a rack; the oil brushing mechanism is arranged on the front end of the oiling mechanism, and the oiling mechanism comprises an oil storage groove, a rear baffle, a front baffle, a driving wheel and an oiling wheel; the driving wheel is rotatably arranged in the oil storage groove; the oiling wheel is rotatably arranged on the rack and is tangential with the driving wheel; the lower end of the oiling wheel is tangential with the upper end of a tinplate; the oil brushing mechanism comprises a support, a fastening screw and an oil brushing pen; the support is fixed on the rack and is internally provided with a pen passing hole; the oil brushing pen is inserted into a pen passing hole in the support and is fixed by the fastening screw; the front end of the oil brushing pen is provided with a hair-shaped object which is in contact with the tinplate. The tinplate oiling device provided by the invention is simple in structure, can oil the tinplate automatically, and improves the production efficiency.

Owner:TONGXIANG XILIANG TIN CANS

Stamping system for vehicle silencing element

ActiveCN113319177ARealize automatic oilingAchieve extrusionShaping toolsMetal-working feeding devicesMachiningStamping press

The invention discloses a stamping system for a vehicle silencing element. The invention relates to the field of machining, and particularly discloses a stamping system which comprises a stamping machine body, a workbench, a lower die and an upper die, wherein the workbench is further provided with an oil coating mechanism, and the oil coating mechanism comprises a conveying oil-coating frame and an oil coating groove; the middle section of the oil coating groove is an oil storage section in which hydraulic oil is stored, an oil coating assembly used for spraying the hydraulic oil upwards is arranged in the oil storage section, and a first slide way and a second slide way are formed in the positions, above the oil coating assembly, of the two side walls of the oil coating groove; the conveying oil-coating frame comprises a conveying frame and an oil-coating frame, the conveying frame is slidably connected into the first slide way, and the oil-coating is slidably connected into the second slide way. By the adoption of the stamping system, automatic oil-coating before workpiece stamping can be achieved, and the automation degree of workpiece stamping is improved.

Owner:CHONGQING ZHIMAO MACHINERY MFG

Liquid diet feeding device for anti-infection critical nursing

InactiveCN114129452AImprove feeding efficiencyRealize the function of automatic food supplementFeeding-bottlesFeeding-tubesNursing careLiquid diet

The invention belongs to the technical field of medical feeding equipment, and discloses an anti-infection type critical care liquid food feeding device which comprises an injection tube, a first round block is fixedly mounted at the right end of the injection tube, a first piston is movably sleeved with the injection tube, a transverse tube is fixedly mounted at the right end of the first piston, and a second round block is fixedly mounted at the right end of the transverse tube. And the right end of the transverse pipe penetrates through the first round block and is fixedly provided with a second round block. By arranging a transverse pipe, a vertical block, a second circulating groove and a second piston, food in a food box enters an injection pipe through the vertical block due to the fact that the transverse pipe moves leftwards, and when the first piston moves rightwards, the food in the transverse pipe enters the left end of the first piston through the second circulating groove; compared with the traditional equipment, the automatic feeding device has the advantages that manual food filling is avoided, and the feeding efficiency of medical staff is improved.

Owner:PEOPLES HOSPITAL OF HENAN PROV

A chain oiling system

ActiveCN103752761BRealize automatic oilingPrecise time controlMetal chainsControl engineeringElectric machinery

The invention discloses a chain oiling system, comprising a conveying platform, a power device, an oiling slot, a subpart conveying platform and a lifting device arranged on the oiling slot, and a controller, wherein the lifting device comprises a longitudinal motor and a transverse motor, so that the subpart conveying platform can move up and down and left and right. The system achieves the automatic oiling of a chain through the automatic lifting device and the controller. A worker only needs to put the chain on the conveying platform, and subsequent machining processes can be automatically completes, so that the labor is greatly saved, the work efficiency is improved, and the oiling time and pressure of the chain can be accurately controlled, and the oiling quality is improved.( / b).

Owner:浙江西塘实业有限公司

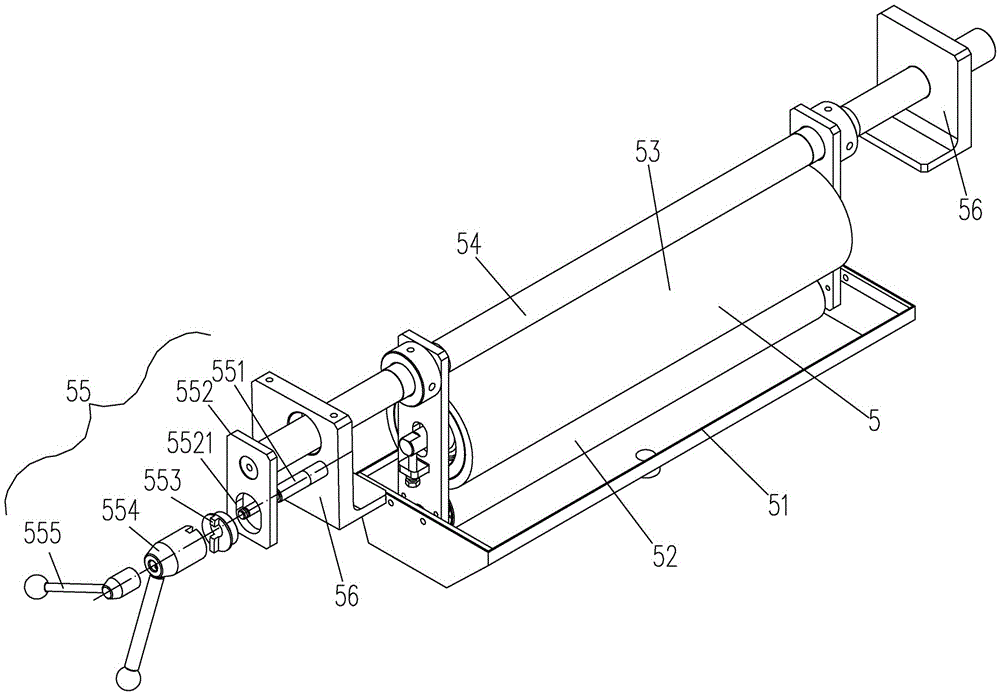

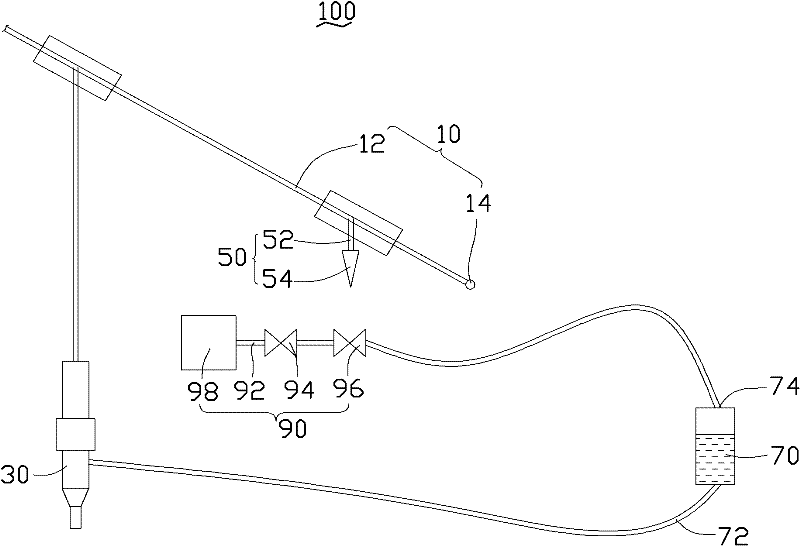

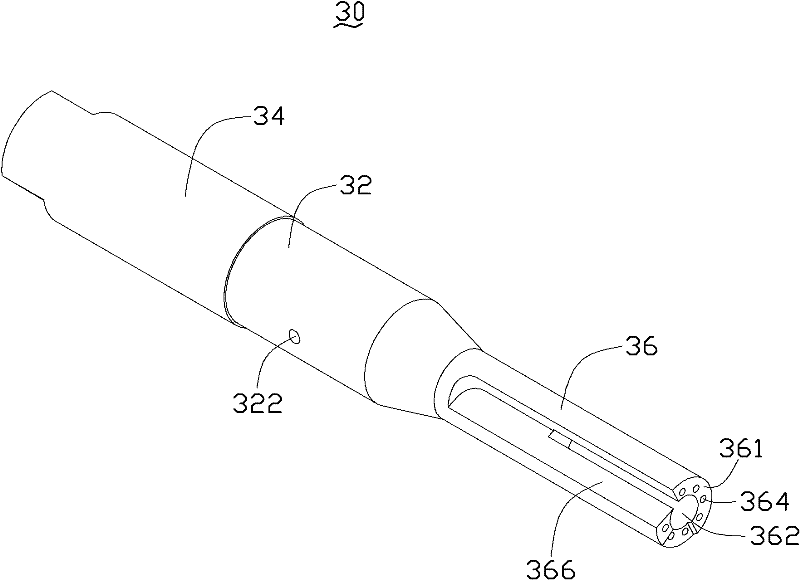

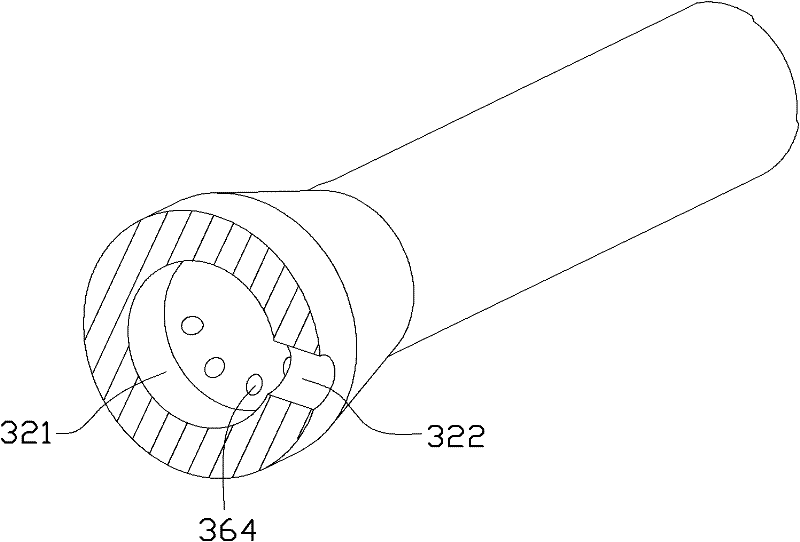

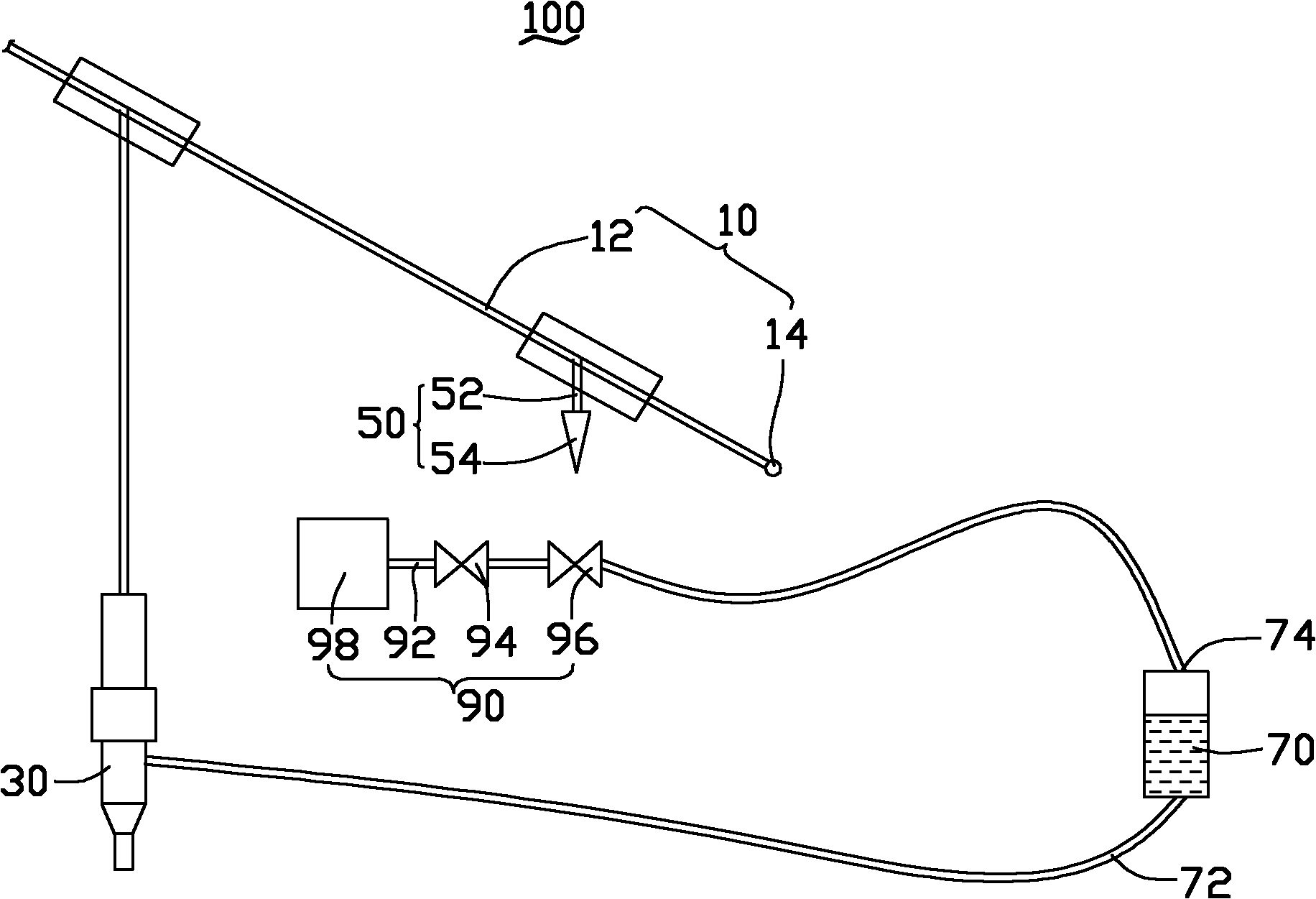

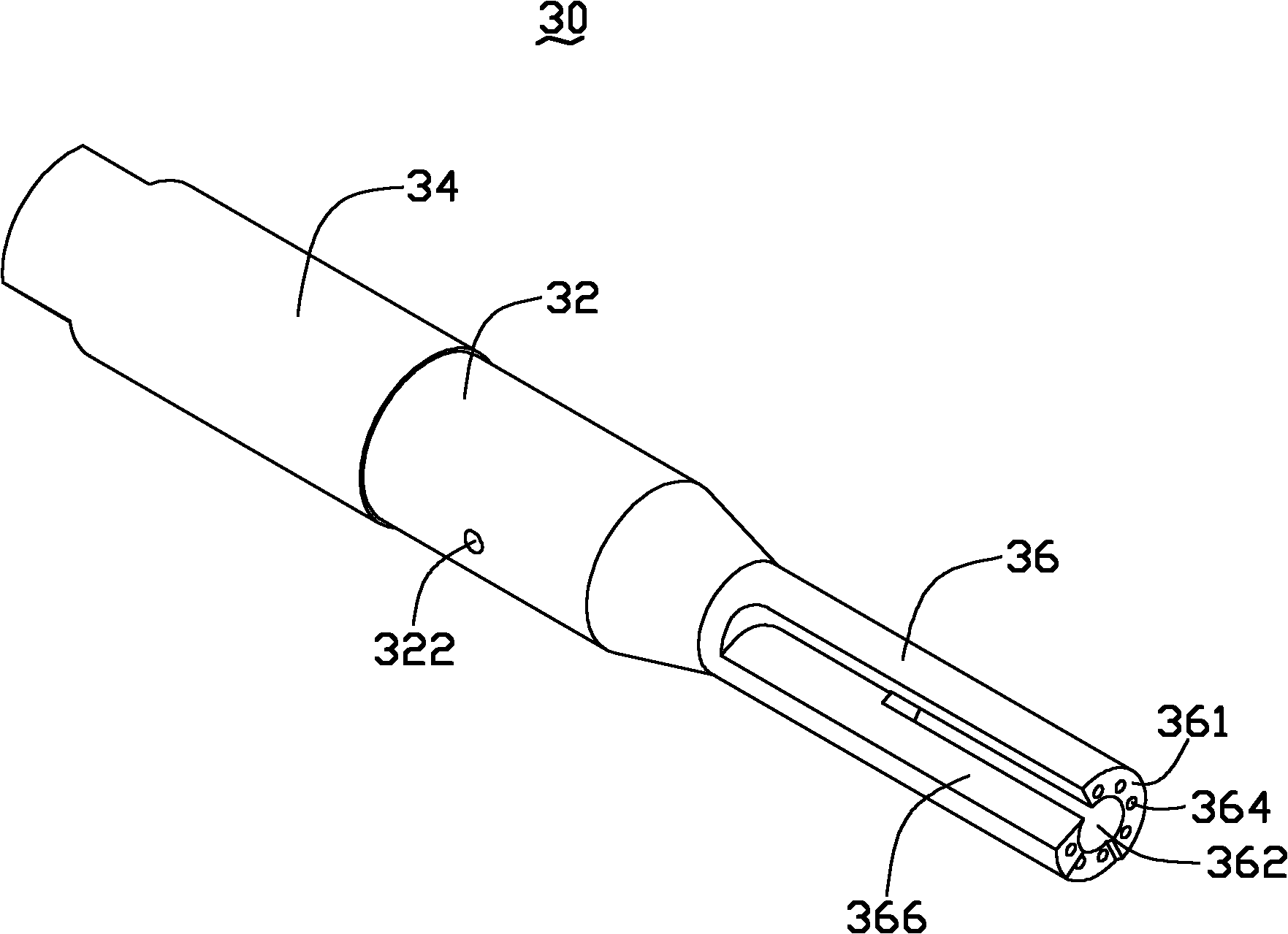

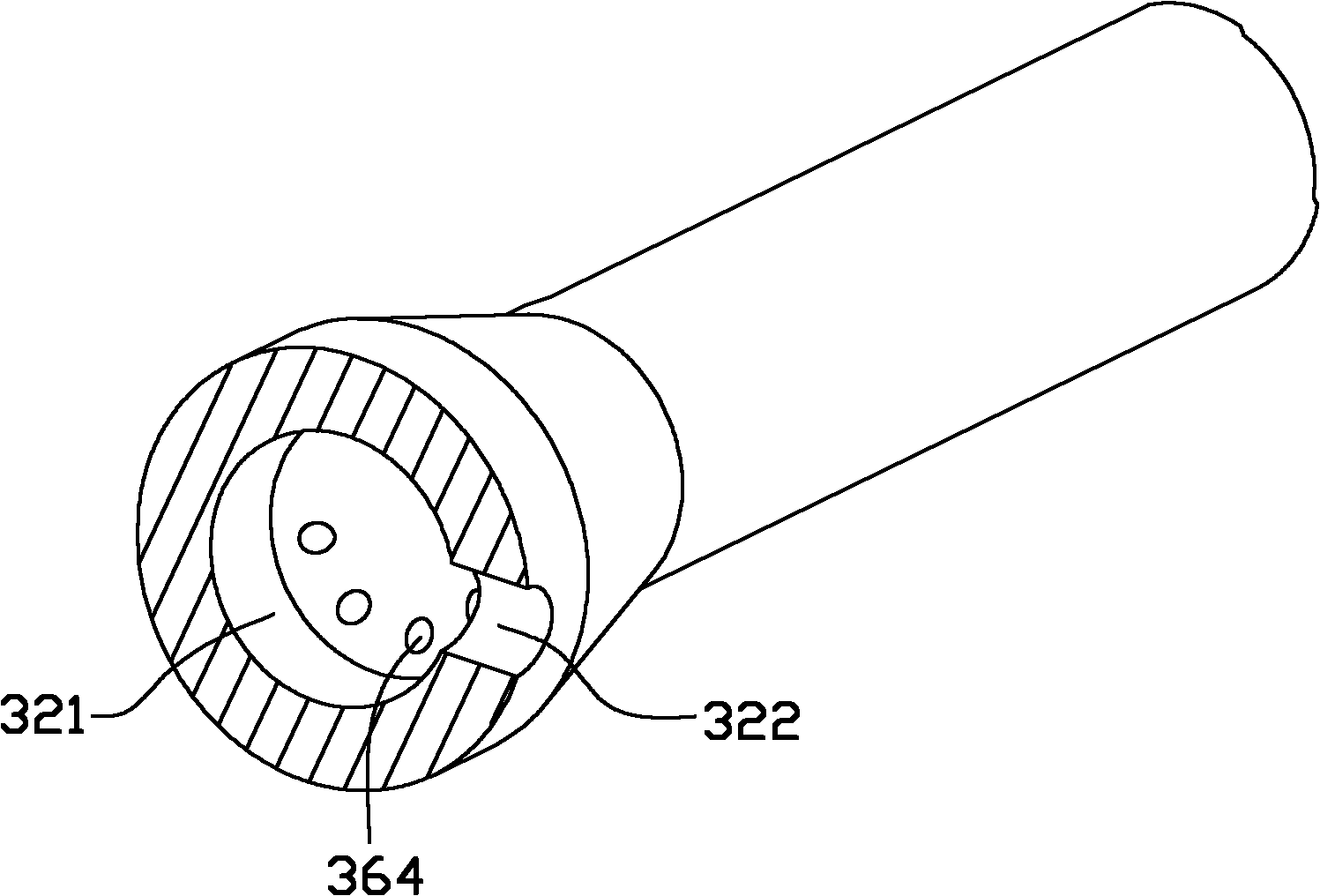

A device for oiling the end of a drill pipe

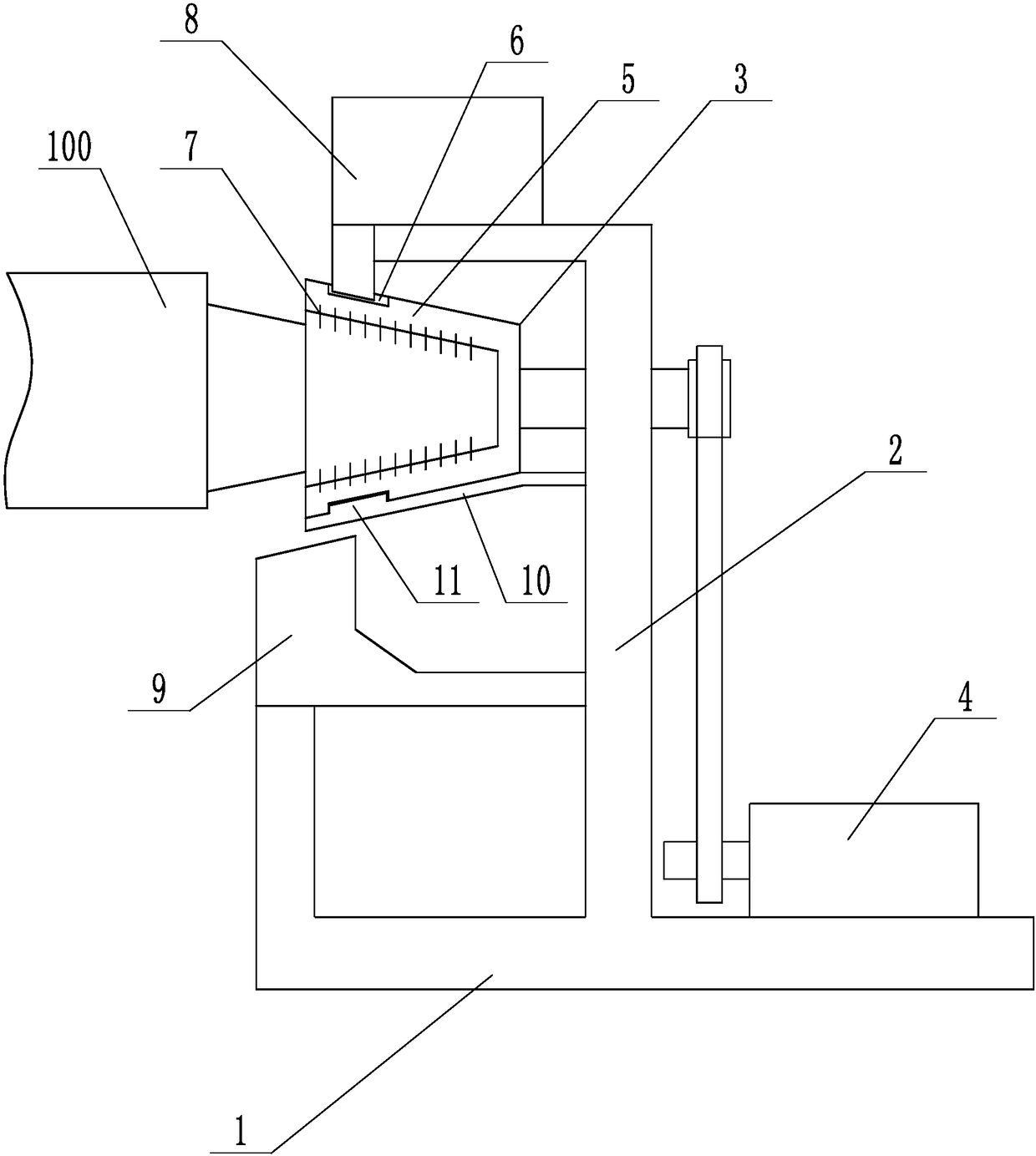

ActiveCN105944914BSimple structureRealize automatic oilingLiquid surface applicatorsCoatingsFuel tankPetroleum engineering

The invention relates to an oil coating device for the end part of a drill rod. The oil coating device comprises a base, wherein an oil coating head horizontally arranged is mounted on the base through a bracket, and the oil coating head is driven through a motor on the base; the oil coating head is in a shape of a conical flaring, the side wall of the oil coating head is hollow and is provided with an oil storing annular gap, one circle of oil inlet annular groove is arranged on the outer wall of the oil coating head, and oil outlet holes are uniformly formed in the inner wall of the oil coating head; an oil storing tank is mounted on the bracket positioned above the oil coating head, an oil return tank is mounted on the base positioned below the oil coating head, and the oil return tank is connected with the oil storing tank through an oil pump and an oil pipe; and an oil deflector is further mounted below the oil coating head, the oil deflector is in a conical arc shape matched with that of the oil coating head, and the inner wall of the oil deflector is provided with an oil blocking projection matched with the oil inlet annular groove.

Owner:邳州市景鹏创业投资有限公司

A steel wire rope oiling maintenance device

ActiveCN110961310BOiled to achieveRealize automatic oilingPretreated surfacesCoatingsWire rodAirframe

The invention relates to the field of wire rod maintenance, in particular to a steel wire rope oiling maintenance device, which includes a fuselage and an oil storage tank for storing protective oil arranged above the fuselage, and is characterized in that the oil storage tank is threadedly connected to the The installation groove provided in the top wall of the fuselage, the oil immersion chamber is arranged in the fuselage, the oil immersion chamber and the installation groove are connected through the oil inlet hole, and the oil immersion chamber is provided in the top wall for The liquid level control device for controlling the protective oil level in the oil immersion chamber, the wire feeding chambers are symmetrically arranged in the left and right end walls of the oil immersion chamber, and the invention provides a steel wire rope oiling maintenance device, which can realize the automatic maintenance of the steel wire rope. Oiling, the equipment adopts immersion oiling, so that the protective oil in the steel wire rope can penetrate more fully and the protective effect is better. At the same time, the equipment cleans the residual oil on the surface of the steel wire rope before applying the protective oil, and at the same time washes away the floating dust on the surface of the steel wire rope, which can Better realize steel wire rope protective oil coating, more practical.

Owner:青岛迪世亚制钢有限公司

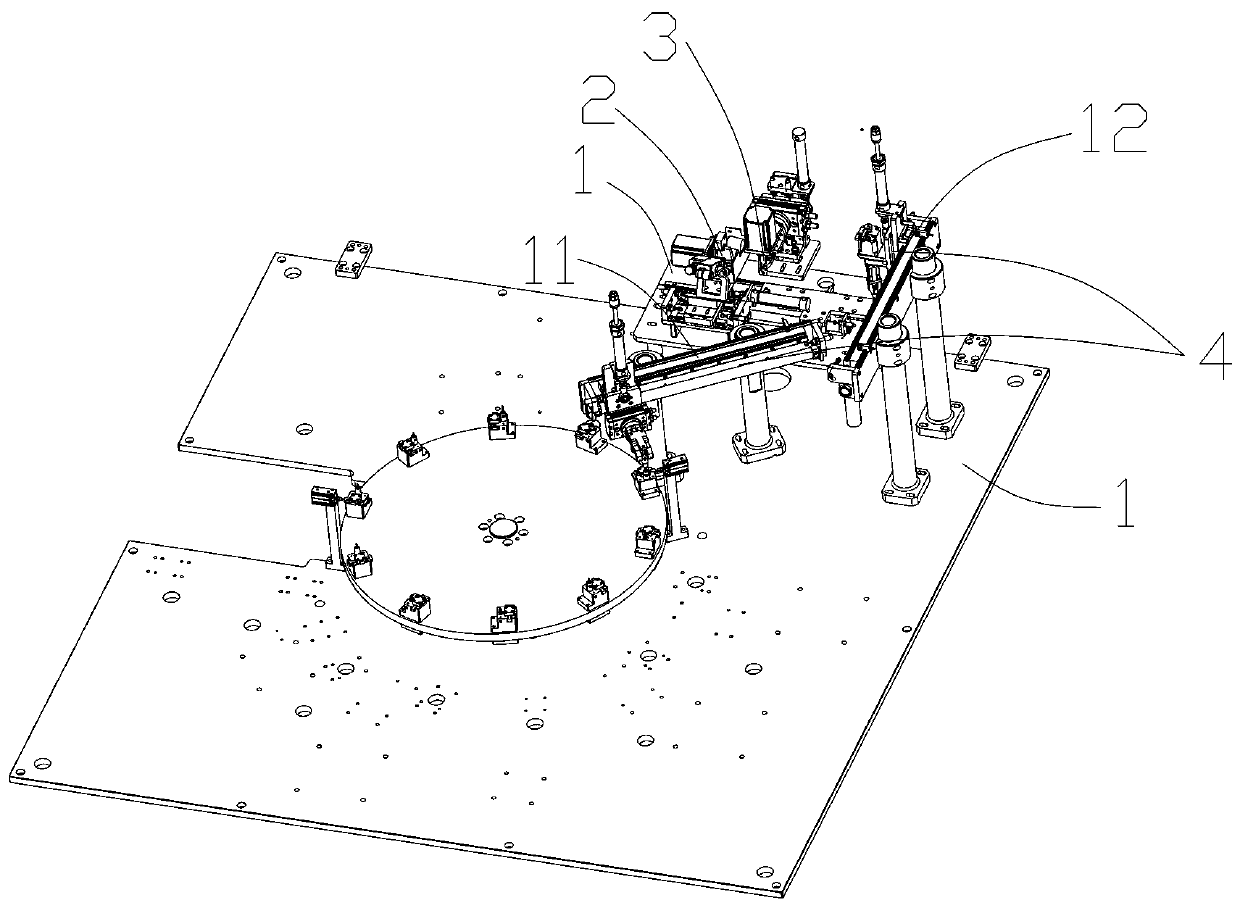

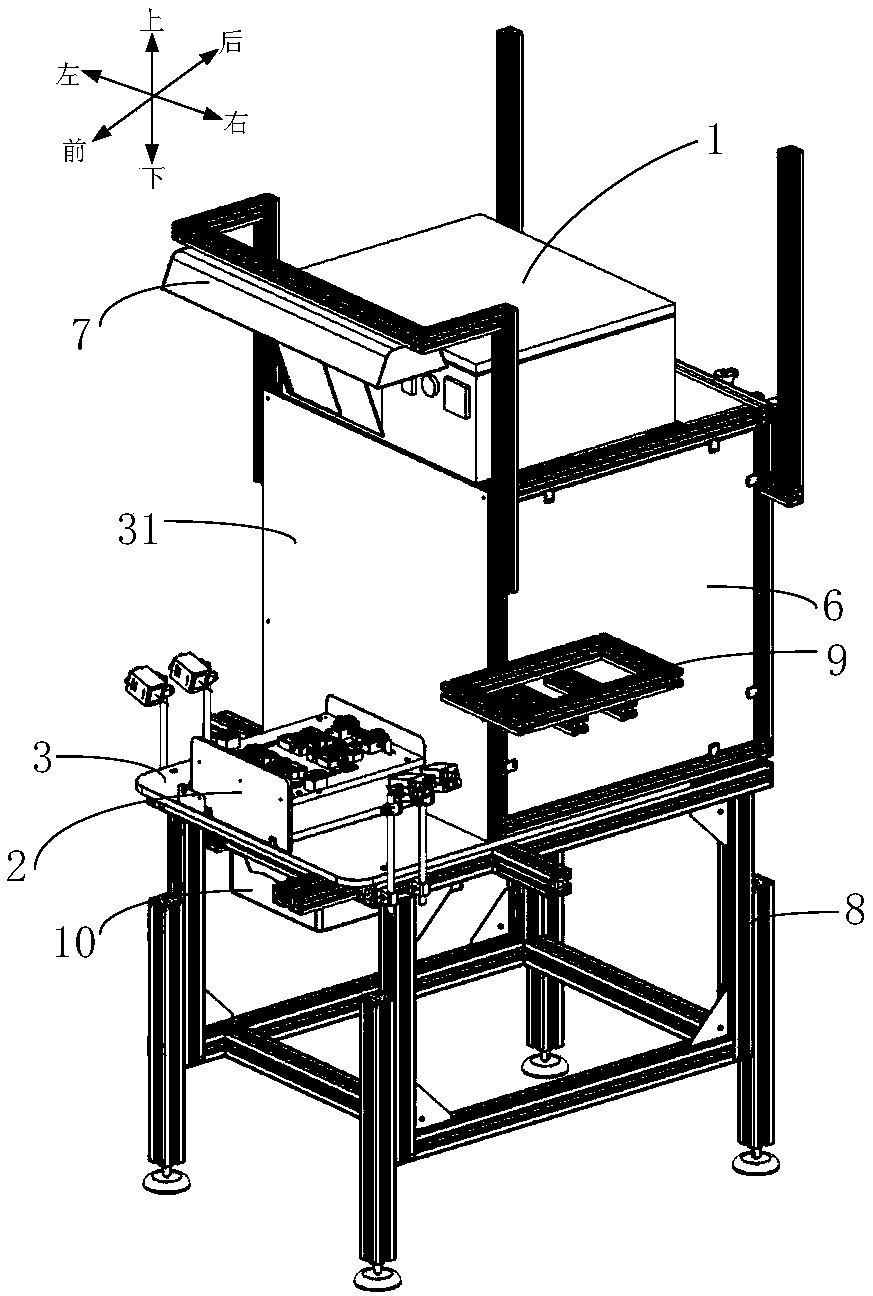

Automobile control panel assembly equipment and control method thereof

PendingCN109175946AIncrease productivityEasy to follow upMetal working apparatusWork in processComputer science

The invention firstly provides a control method of automobile control panel assembly equipment. The control method comprises the following steps that a camera scans parts to be oiled in oiling workingprocedure stations, and feeds back scanning results to a background database so as to generate registration information; according to non-empty station information detected by a sensor, the oiling work is carried out, and qualified oiling information is fed back to the background database to generate first qualified information; semi-finished products to be pressed downwards are formed; another camera scans the semi-finished products to be pressed downwards, and feeds back scanning results to the background database so as to judge the generated first qualified information; and the downward pressing work is carried out according to non-empty station information, and downward pressing qualified information is sent to the background database so as to generate second qualified information. The invention secondly provides the automobile control panel assembly equipment. According to the control method of the automobile control panel assembly equipment, oiling and downward pressing assembling operation can be automatically completed, so that the production efficiency is improved; and the oiling condition and the downward pressing height are detected, and the qualified information of machined objects is registered one by one, so that follow-up traceability is facilitated.

Owner:宁波均普智能制造股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com