Integral aerial steel wire rope oil removing and lubricating device

A wire rope and oil lubrication technology is applied in the field of integrated high-altitude wire rope degreasing and lubricating devices, which can solve the problems of not being able to automatically cover the entire range of the wire rope, affecting the service life of the wire rope, and having major hoisting, etc. Stable and easy to disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

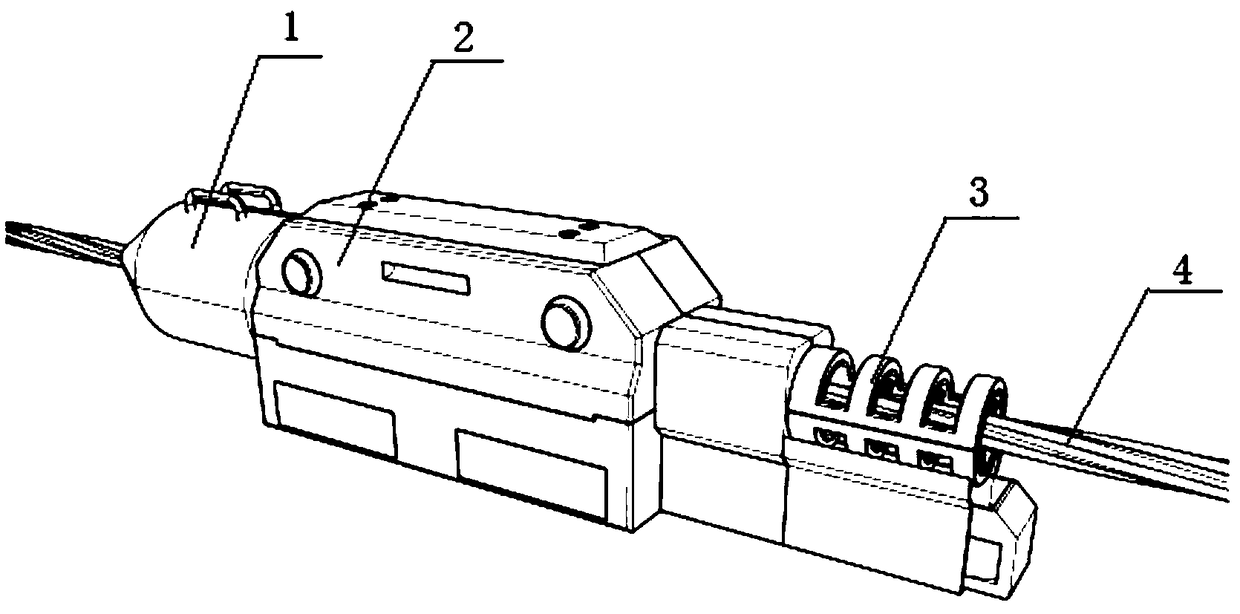

[0035] An integrated high-altitude steel wire rope degreasing and lubricating device, such as figure 1 As shown in , it includes a degreasing mechanism 3, a cable traveling mechanism 2 and an oiling mechanism 1. The degreasing mechanism is located at one end of the cable-holding traveling mechanism, and the oil-applying mechanism is located at the other end of the cable-holding traveling mechanism. The degreasing mechanism, the cable-holding traveling mechanism and the oiling mechanism all adopt buckle-type installation structures, thereby being installed on the steel wire rope 4 conveniently.

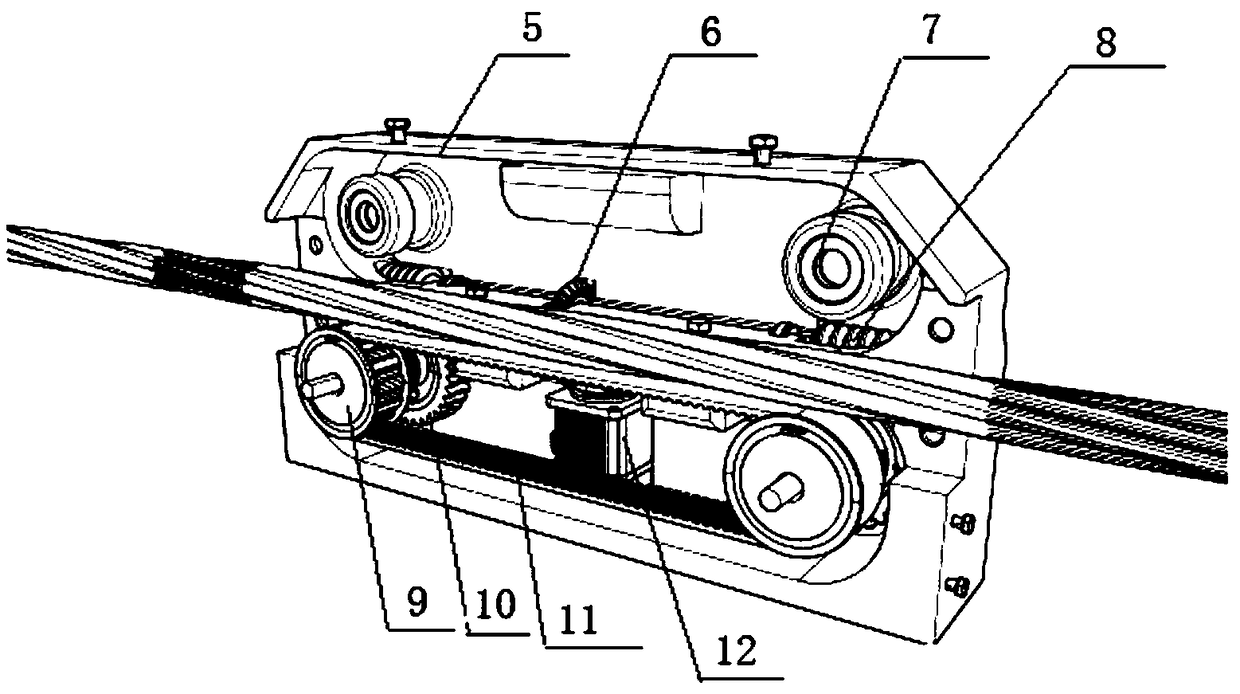

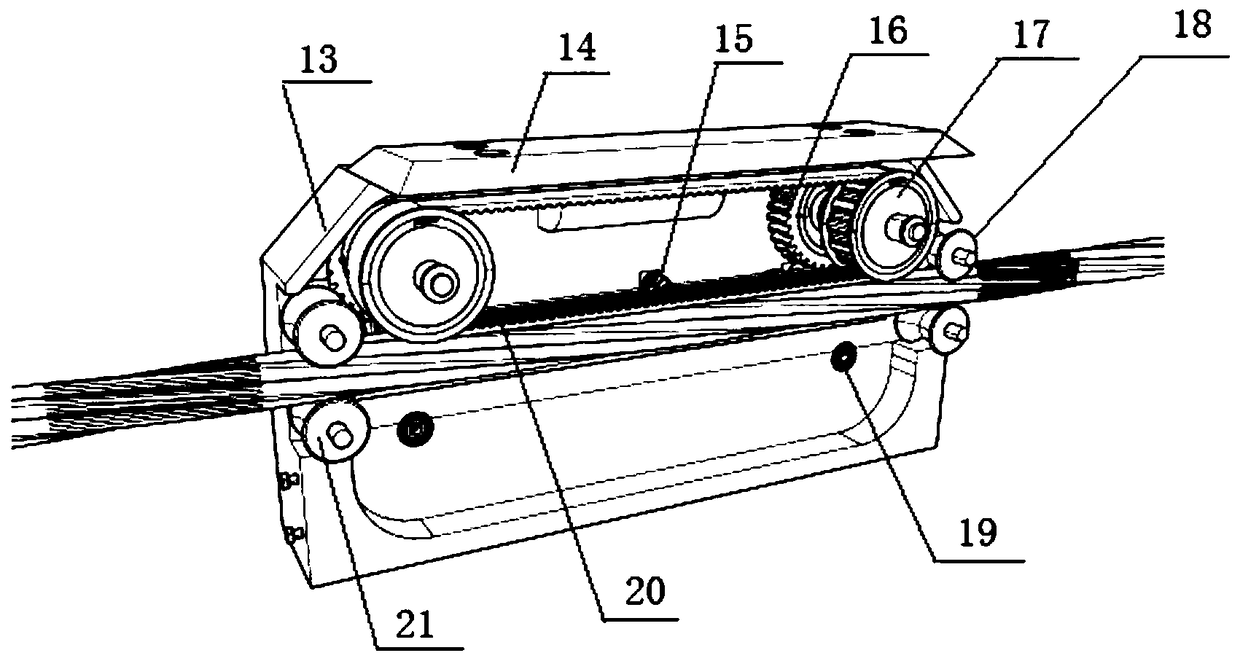

[0036] The cable-holding traveling mechanism includes a shell, a first traveling wheel mechanism and a second traveling wheel mechanism. The casing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com