Lubrication compensation compressor

A technology of compressors and compression cylinders, applied in mechanical equipment, machines/engines, liquid variable capacity machines, etc., can solve the problems of low reliability, manpower consumption, strong dependence, etc., and achieve the goal of improving purity and improving work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

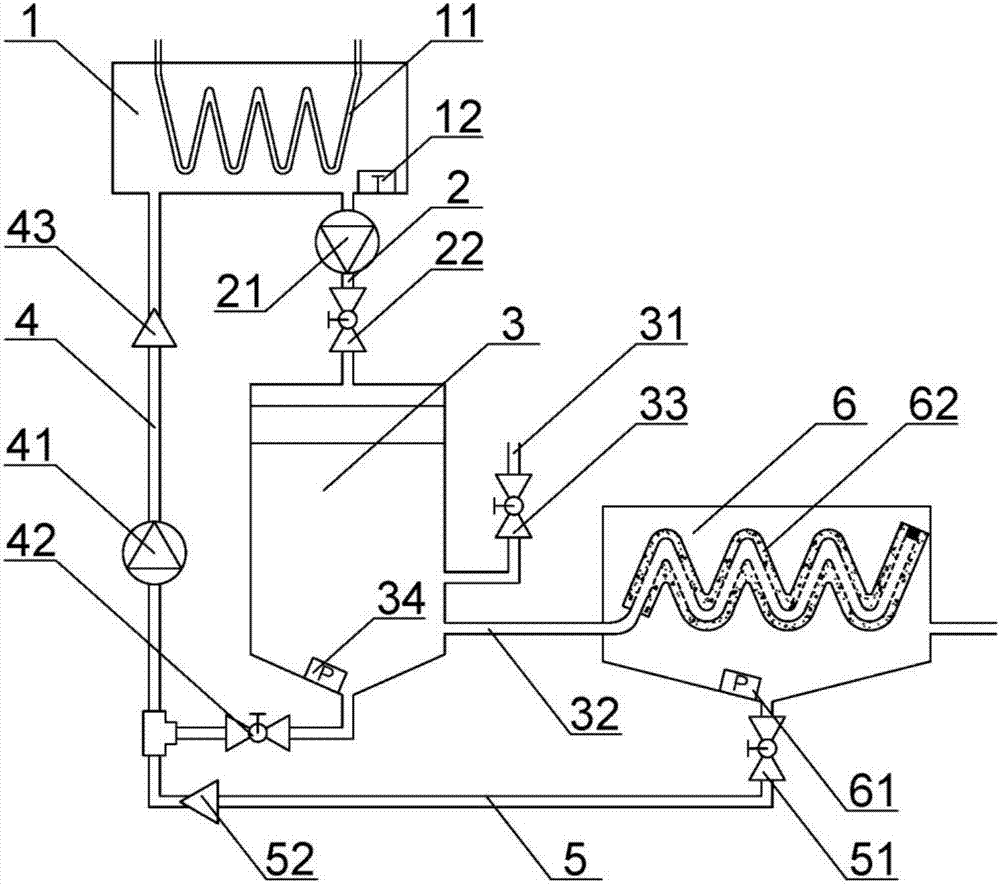

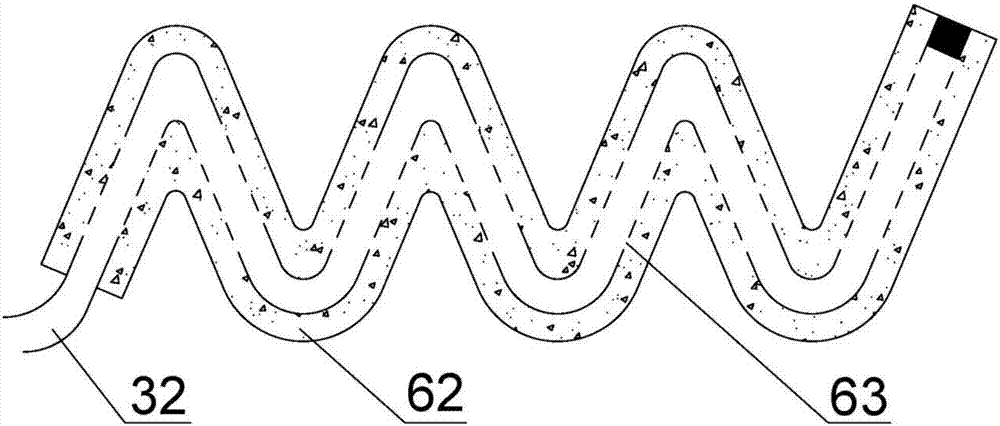

[0018] Such as Figure 1-2 as shown, figure 1 It is a schematic structural diagram of a lubrication compensation compressor proposed by the present invention, figure 2 It is a schematic diagram of the air outlet pipeline of a lubrication compensation compressor proposed by the present invention.

[0019] refer to figure 1 , a lubrication compensation compressor proposed by the present invention, including an oil storage tank 1, an oil inlet pipeline 2, a compression cylinder 3, a first oil return pipeline 4 and a control module, the control module is not shown in the figure; For the piston of compressed gas, the piston moves in the vertical direction. The compression cylinder 3 is provided with an oil inlet hole, a first oil outlet hole, an air inlet hole and an air outlet hole. The oil inlet hole is set on the top of the compression cylinder 3, and the oil outlet hole is set At the bottom of the compression cylinder 3, the oil inlet hole communicates with the oil storage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com