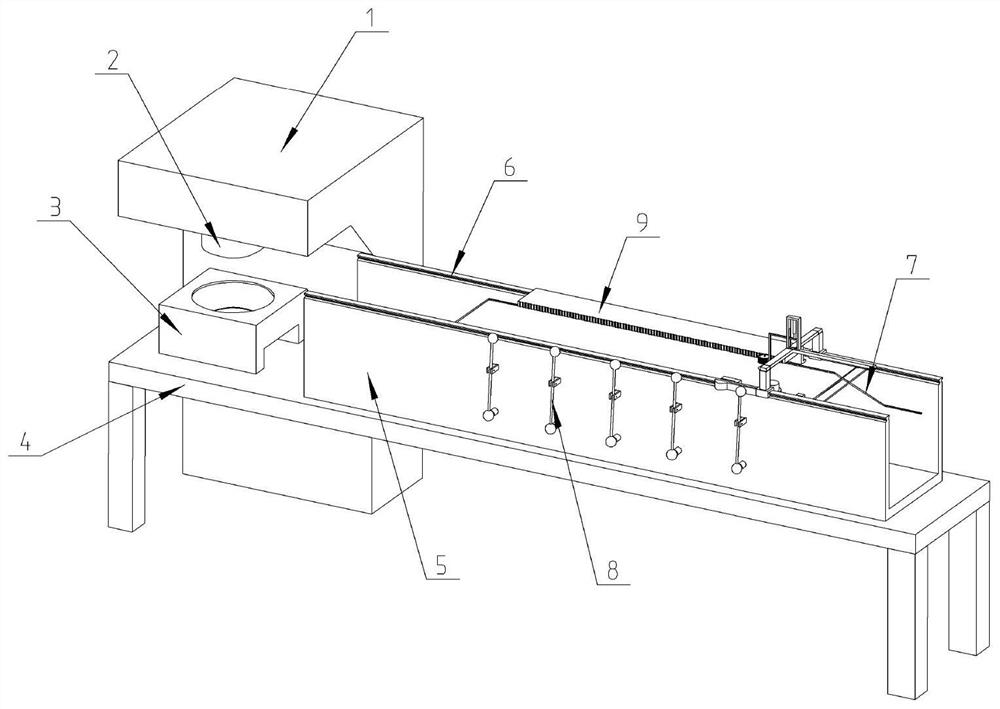

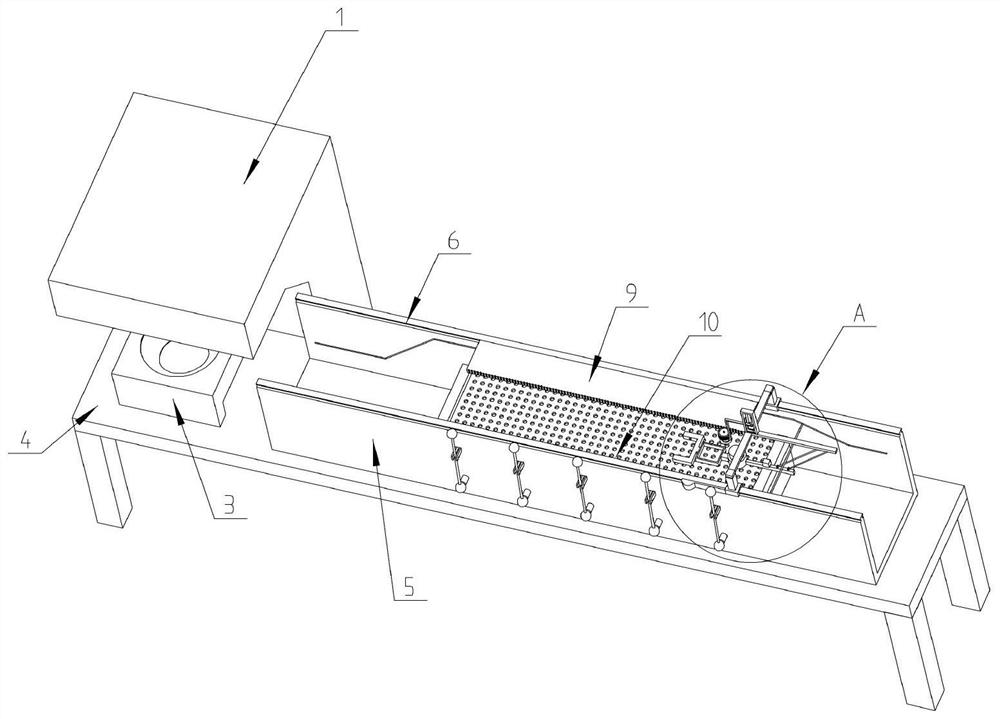

Stamping system for vehicle silencing element

A technology for muffler components and vehicles, applied in the field of machining, can solve problems such as cumbersome steps, and achieve the effect of improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

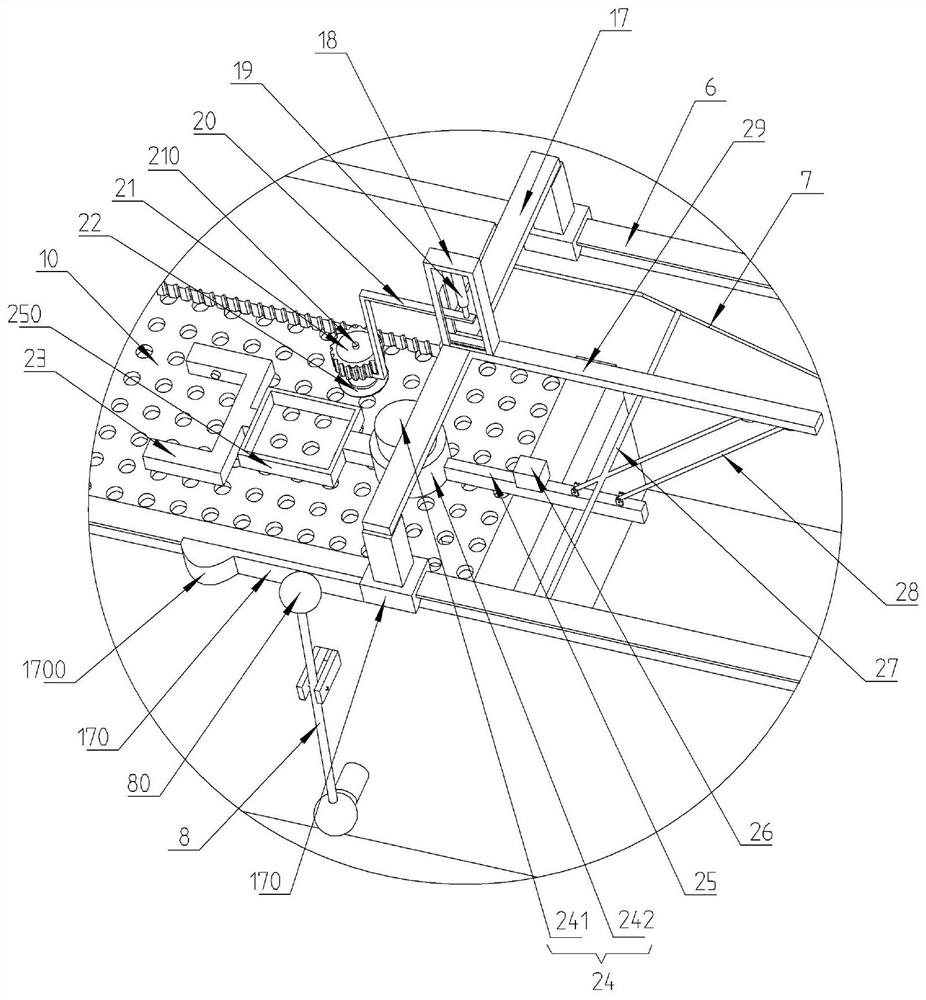

[0045] First place the workpiece to be punched under the vacuum chuck 22, the vacuum chuck 22 will absorb the upper surface of the workpiece, and then push the portal frame 17 to walk on the first slideway 6, while the portal frame 17 is walking, it also drives oiling frame walking, the driving rod 27 on the oiling frame walks along the first horizontal section 71, the first transition section 72, the second horizontal section 73, the second transition section 74 and the third horizontal section 75 successively, when the driving rod 27 is positioned at the first When in the first horizontal section 71, the vacuum chuck 22 is separated from the support core 241, which is convenient for the workpiece to be placed on the vacuum chuck 22. When the driving rod 27 is located in the second horizontal section 73, the vacuum chuck 22 and the support core 241 are close to each other, and the two The one is in the concentric position vertically, and the two clamp the workpiece.

[0046] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com