Automobile control panel assembly equipment and control method thereof

A technology for assembly equipment and automobile control, applied in metal processing equipment, manufacturing tools, metal processing, etc., can solve problems such as low work efficiency, affecting work efficiency, inaccurate oil control, etc., to improve production efficiency and improve production efficiency and yield, the effect of avoiding waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

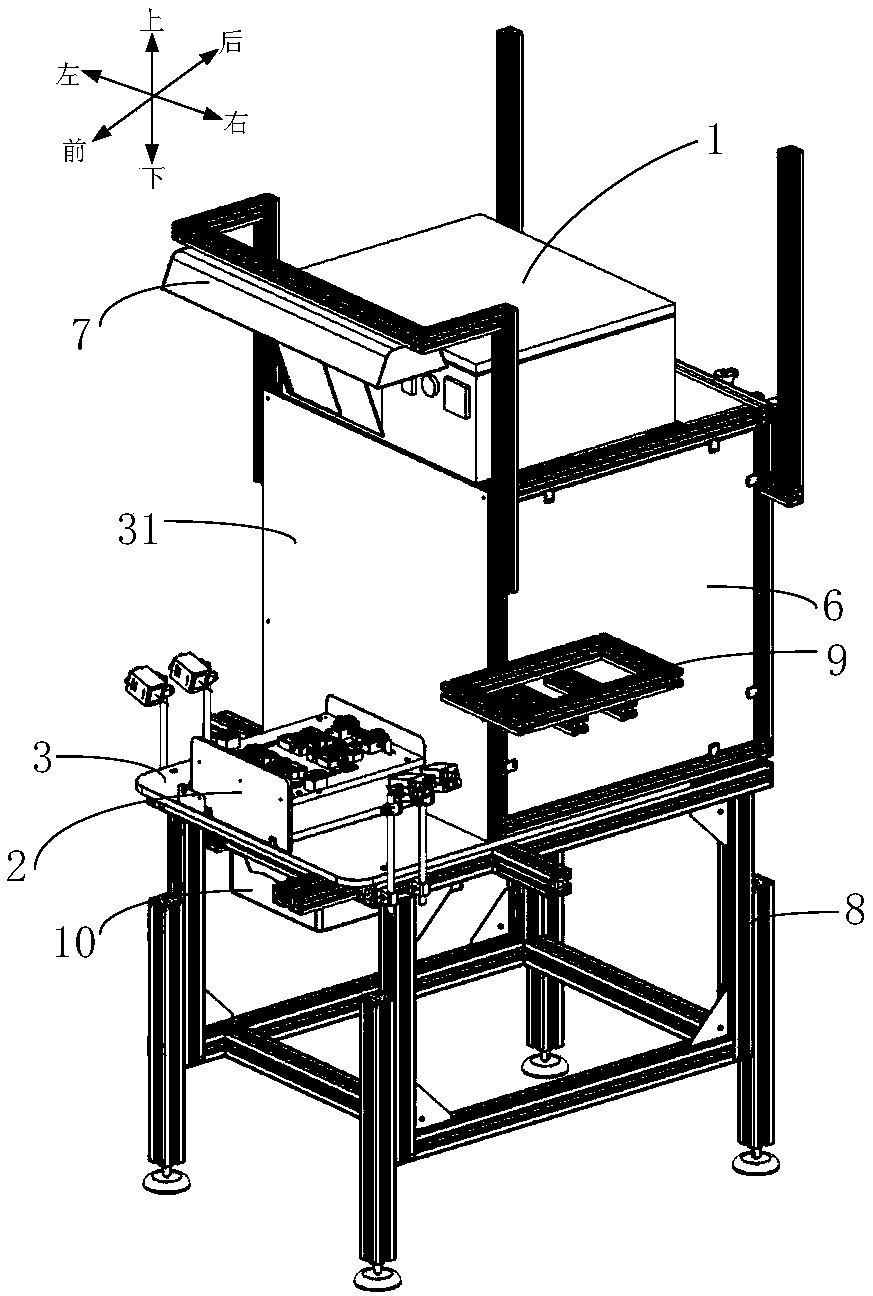

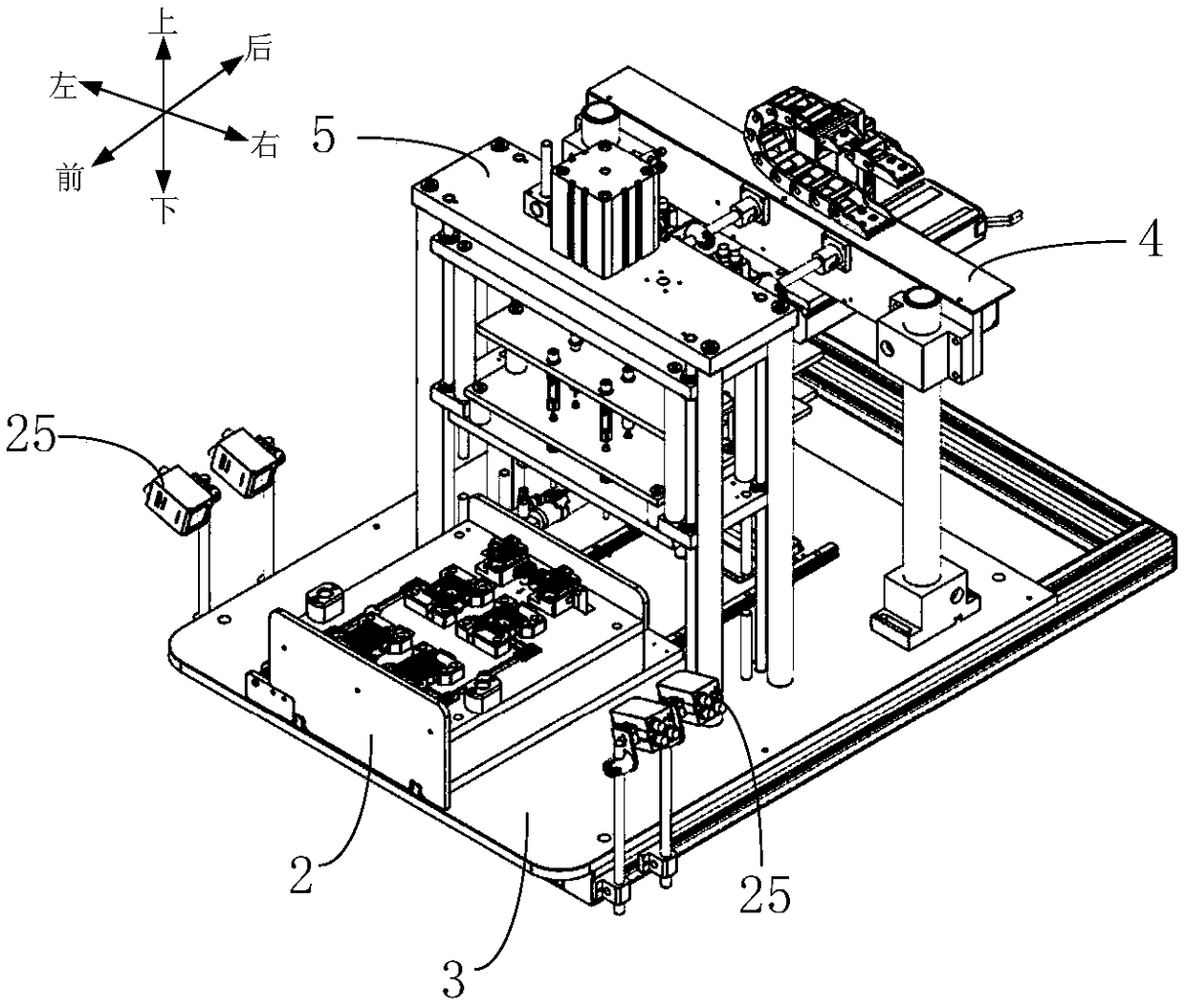

[0039] see figure 1 and figure 2 As shown, they are respectively the overall schematic diagram and the internal schematic diagram of the automobile control panel assembly equipment of the present invention.

[0040] combine figure 1 and figure 2 As shown, an automobile control panel assembly equipment includes an electric control box 1, a workbench 2, a base plate 3, an oiling mechanism 4 and a pressing mechanism 5 connected to the base plate 3, and the workbench 2 is provided with an oiling process tool position and pressing process station, the workbench 2 is slidably connected to the bottom plate 3 to realize the movement of the workbench 2 between the initial position and the operating position. In the initial position, the oiling process station is located directly below the oiling mechanism 4 , The pressing process station is located directly below the pressing mechanism 5, and the workbench 2, the oiling mechanism 4 and the pressing mechanism 5 are all electrically...

Embodiment 2

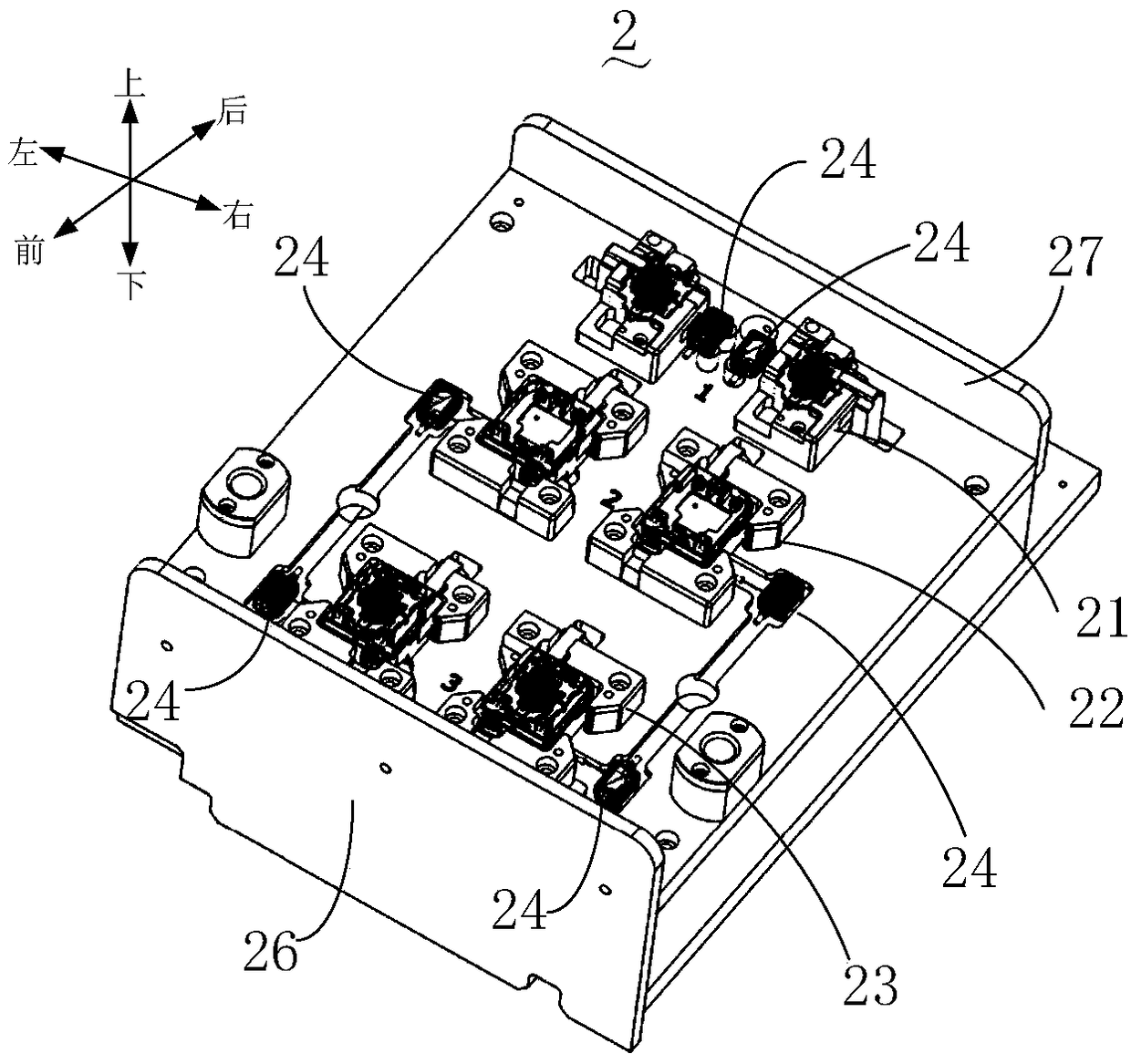

[0051] see image 3 As shown, it is a schematic structural diagram of the workbench of the automobile control panel assembly equipment of the present invention.

[0052] The automobile control panel assembly equipment as described in Embodiment 1, the difference of this embodiment is that, as image 3 As shown, the oiling process station includes a first group of stations 21 and a second group of stations 22, and the pressing process station includes a third group of stations 23, the first group of stations 21, the second group of stations 22 and The third group of stations 23 includes two stations on the left and right, and each station is provided with a sensor 24 , that is, in this embodiment, the number of sensors 24 is 6, and the sensors 24 are electrically connected to the electric control box 1 .

[0053] Among them, the left and right stations of the first group of stations 21 are respectively used to place two rollers, and the left and right stations of the second gr...

Embodiment 3

[0057] see Figure 4 As shown, it is a structural schematic diagram of the pressing mechanism of the automobile control panel assembly equipment of the present invention.

[0058] As the automobile control panel assembly equipment described in Embodiment 2, the difference of this embodiment is that, as Figure 4 As shown, the pressing mechanism 5 is provided with a plurality of pressing rods 51. In the present embodiment, the number of the pressing rods 51 is 4, and two stations corresponding to the left and right stations of the third group of stations 23 are respectively provided with two A lower pressing rod 51, two lower pressing rods 51 located on the same side are distributed forward and backward to ensure that the roller can be effectively pressed into the shell to achieve the assembly effect; each lower pressing rod 51 is provided with a displacement sensor, a displacement sensor and an electric motor. The control box 1 is electrically connected to detect the pressing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com