A chain oiling system

An oil system and chain technology, applied in the field of chain production technology, can solve the problems of inconsistent oil thickness on the chain surface, time-consuming and physical strength, etc., and achieve the effects of improving oiling quality, improving work efficiency and reducing manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

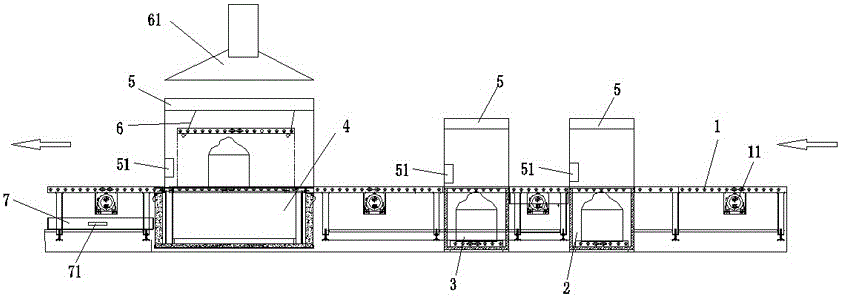

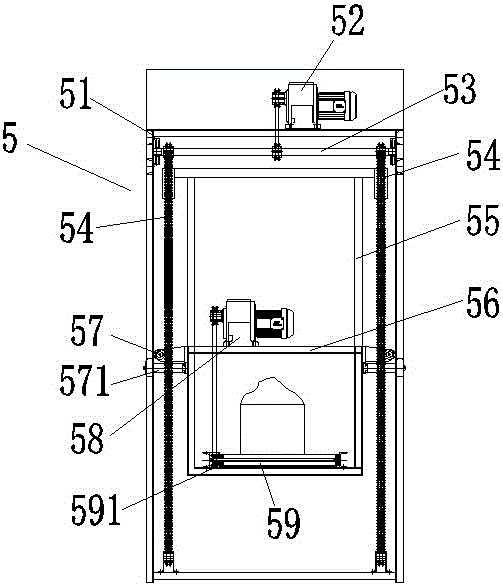

[0018] Below in conjunction with accompanying drawing, the novel of the present invention is further described with embodiment.

[0019] according to Figure 1-2 As shown, a chain oiling system includes a conveying platform 1, power equipment 11, an upper oil tank 4, a sub-conveyor platform 59 arranged on the upper oil tank 4, a lifting device 5 and a smoking device 61, and also includes a controller 511; The lifting device 5 includes a guide rail frame 51, on which a longitudinal motor 52 is arranged, and the longitudinal motor 52 is connected to a rotating shaft 53 by transmission, and a transmission chain 54 is respectively connected to both sides of the rotating shaft 53, and the transmission The chain 54 is connected with a lifting frame 55, and a platform 56 is arranged in the lifting frame 55, and a transverse motor 58 is arranged on the platform 56, and the driving roller 591 on the transmission platform 59 of the transverse motor 58 is connected to the subsection....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com