Riveting machine

A technology for riveting machines and crimping parts is applied in the field of riveting machines that can be automatically oiled, and can solve problems such as low production efficiency, affecting the quality of riveting, and excessive lubricating oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The riveting machine provided by the embodiment of the present invention will be further described in detail below with reference to specific implementation methods and drawings.

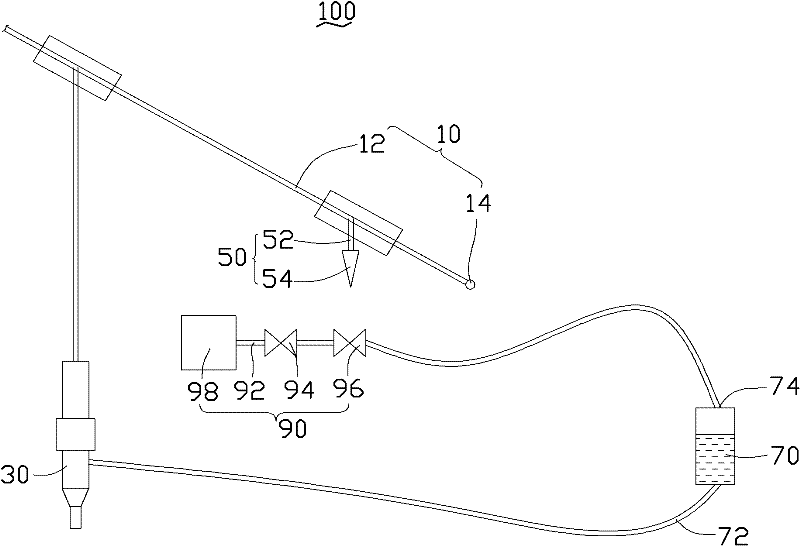

[0045] see figure 1 , The riveting machine 100 according to the embodiment of the present invention includes a pusher 10 , a crimping member 30 , a trigger 50 , an oil storage member 70 and an air delivery assembly 90 .

[0046] The pusher 10 is used to drive the crimping member 30 to move. In this embodiment, the riveting machine 100 is a manual riveting machine, and the pusher 10 is a lever structure, which includes a rod 12 and a rotating shaft 14 at one end of the rod 12 . The rotating shaft 14 is rotatably disposed on the workbench (not shown).

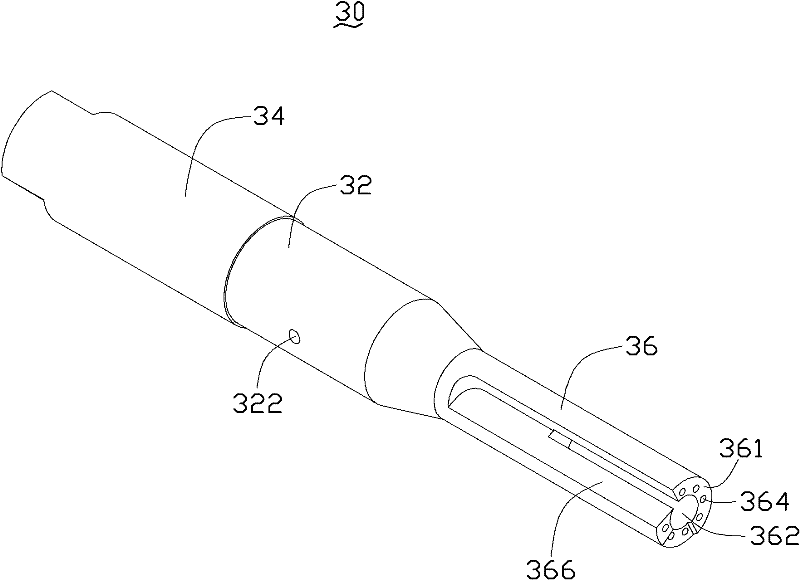

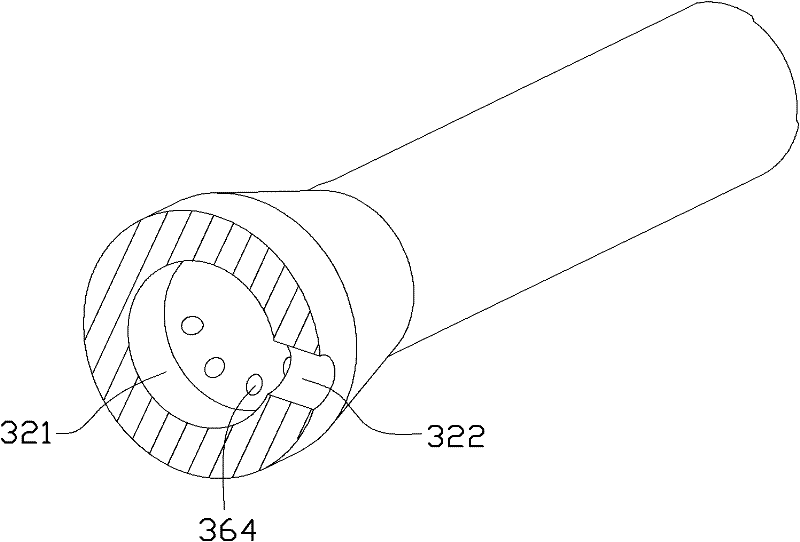

[0047] Please also see figure 2 and image 3 , The crimping member 30 includes a main body portion 32 , an assembly portion 34 and a pressure head 36 . The main body 32 is generally cylindrical, and a cavity 321 is formed therein. The main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com