Portal crane gear lubricating structure and lubricating method

A lubricating structure and gear technology, applied in gear lubrication/cooling, belt/chain/gear, mechanical equipment, etc., can solve problems such as potential safety hazards, time-consuming and labor-intensive grease, grease leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

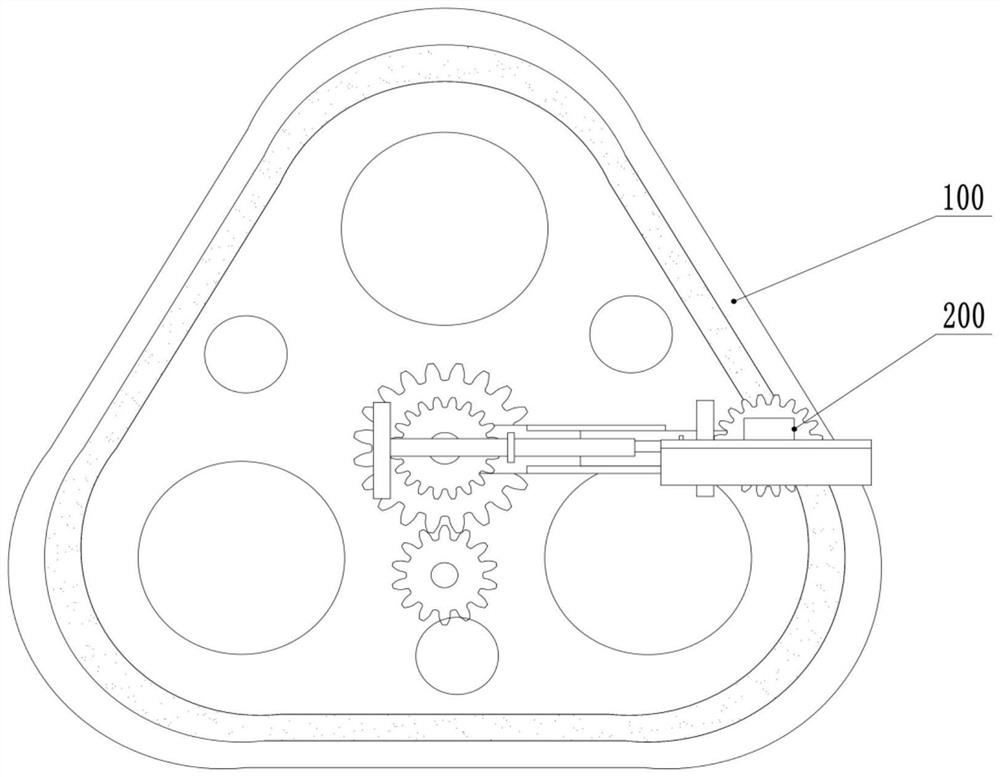

[0052] Such as figure 1 As shown, a gear lubricating structure of a portal machine includes a conveying device 100, an adjusting device 200 installed on the conveying device 100, and an oiler 300 installed on the adjusting device 200 and used for lubricating gears to be lubricated.

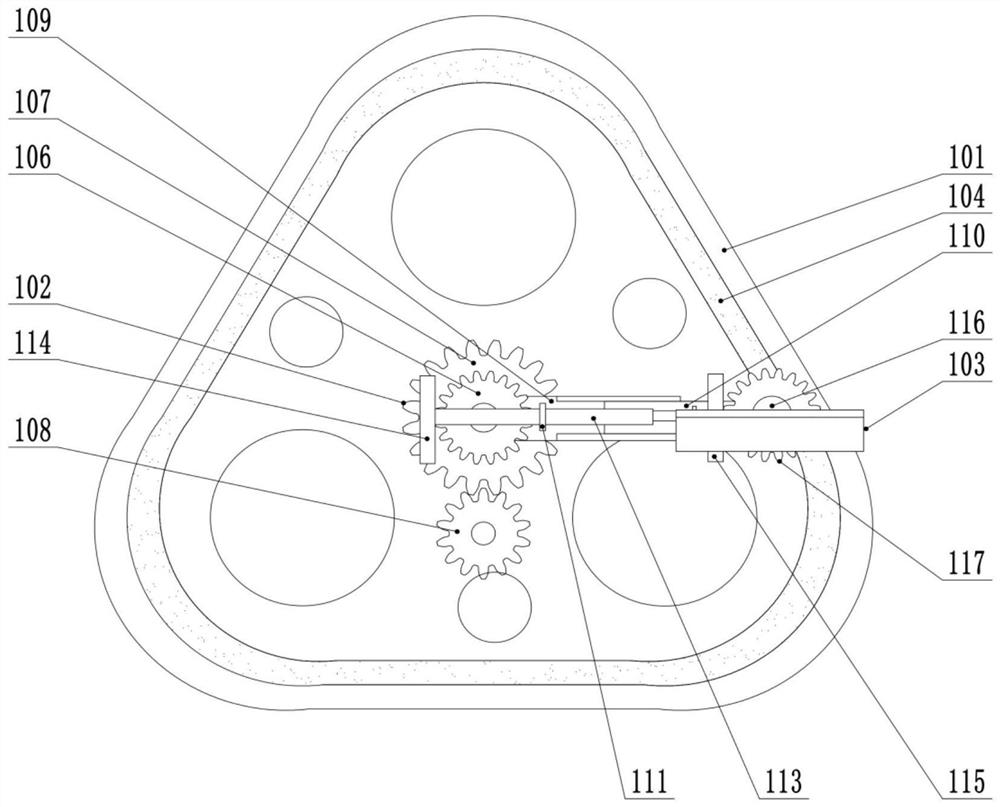

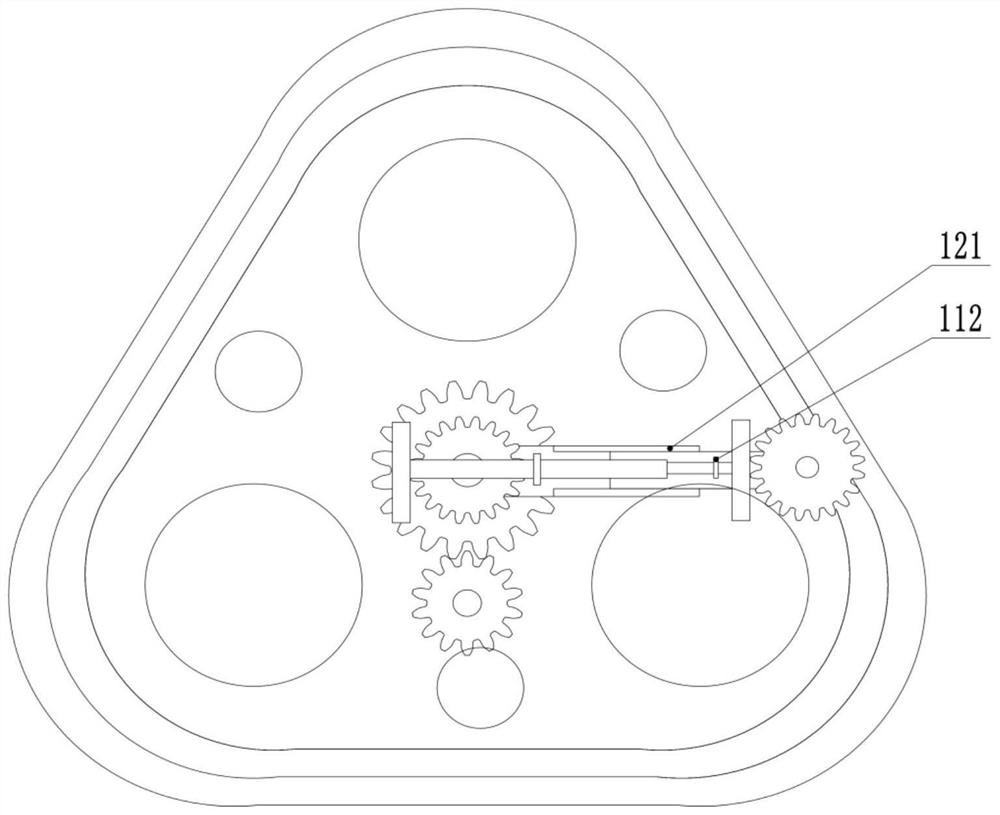

[0053] Such as figure 2 , image 3 , Figure 4 As shown, the conveying device 100 includes a fixed plate 101, a transmission assembly 102 installed on the fixed plate 101, a flat plate 103 installed on the transmission assembly 102 and surrounding the outer contour of the fixed plate 101, and always parallel to the horizontal plane during movement;

[0054] The fixed plate 101 is in the shape of an equilateral triangle, and the three corners of the fixed plate 101 are arc transitions; the fixed plate 101 is equipped with sliding edges 104 distributed around the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com