Upper box body foaming equipment driven by screw rods

A foaming equipment, top-mounted technology, used in mechanical equipment, engine lubrication, lifting devices, etc., can solve the problems of motor occupying ground space, screw lubrication inconvenient, etc., to reduce occupation, avoid swing, and improve safety performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

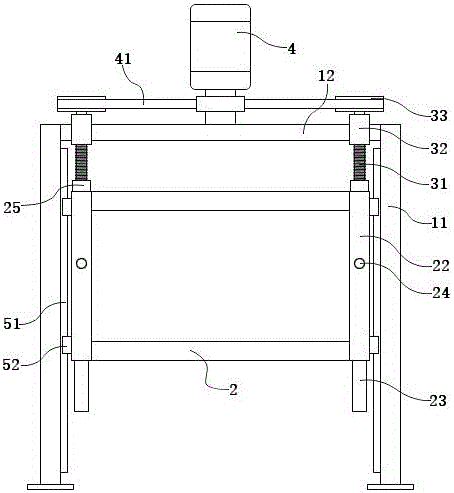

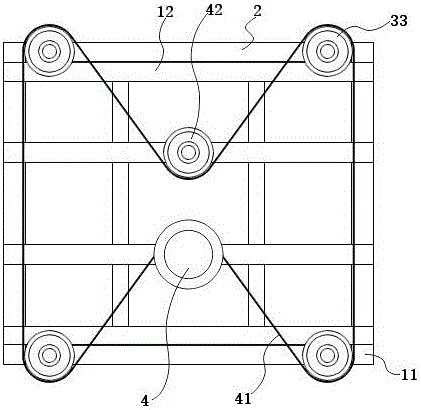

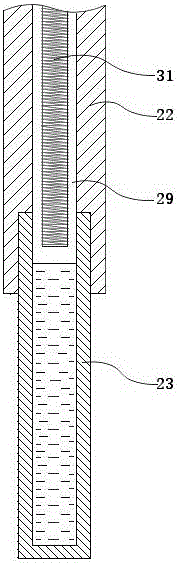

[0019] Such as figure 1 As shown, a box foaming equipment driven by an upper-mounted screw rod includes a frame, a box frame 2, a screw rod 31 and a motor 4. The frame includes a vertical column 11 and a top platform 12 on the top of the column 11 . There are four columns 11 in a square layout, and the columns 11 are located at the four corners of the square. Case frame 2 is used for installing foam case, or is exactly foam case itself. The four corners of the box frame 2 are provided with four cavity columns 22 . There are four screw mandrels 31, which are suspended on the top platform 12 by screw mandrel bearings 32. The lower end of the screw mandrel 31 is suspended to form a free end. The positions of the four screw rods 31 correspond to the four cavity columns 22 one by one. A wire sleeve 25 engaged with the screw rod 31 is provided on the cavity c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com