Cofferdam type pipe rod conveying and discharging device

A discharge device and cofferdam technology, applied in the direction of drill pipe, drill pipe, casing, etc., can solve problems such as complex work procedures, heavy work, and unsafety, and achieve the effects of reduced safety risks, simple assembly, and compact and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to further disclose the technical solutions of the present invention, the following will be described in detail through examples in conjunction with the accompanying drawings:

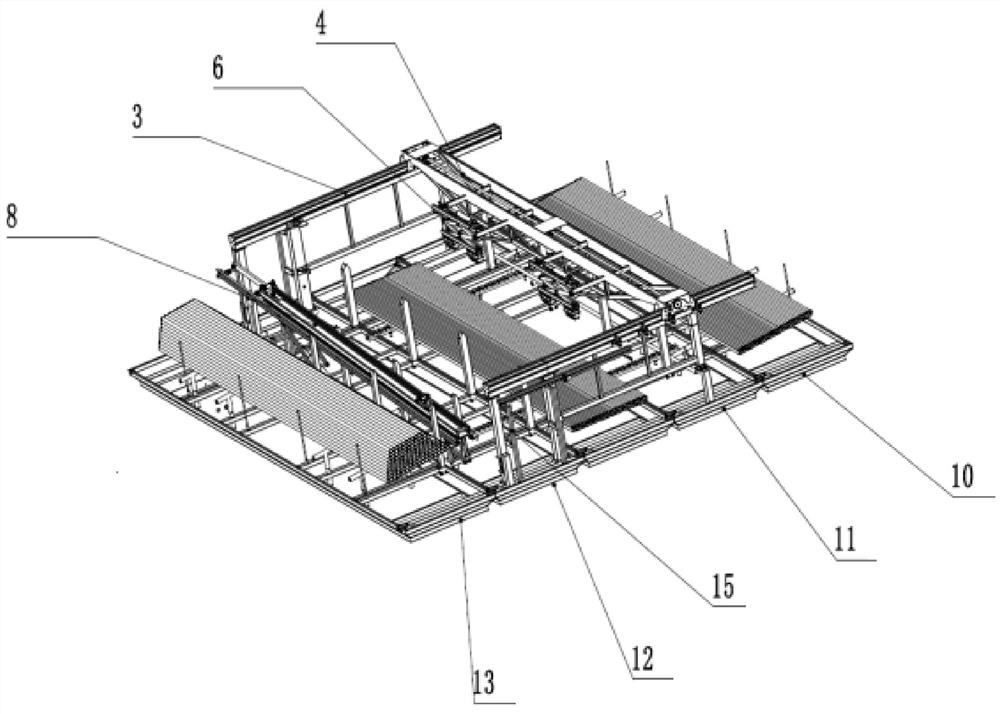

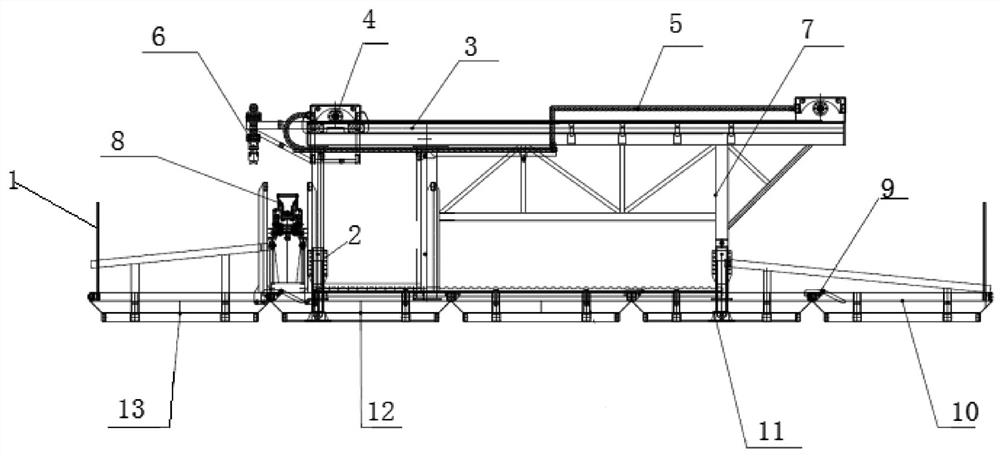

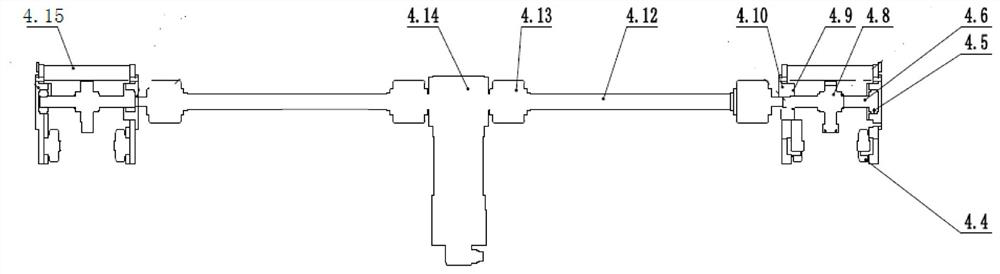

[0055] Such as figure 1 , 2 As shown, a cofferdam type pipe rod conveying and discharging device includes a near-end auxiliary material rack 13, a main material rack 12, an auxiliary material rack 11, a far-end auxiliary material rack 10, a retaining rod 1, a lifting regulator 2, a guide rail 3, a drag Chain 5, cart 4, manipulator 6, lift 8, pillar 7, quick buckle 9, control cabinet and remote control, characterized in that the near-end auxiliary material rack and main material composed of cofferdams are arranged sequentially from left to right Rack, auxiliary material rack, and remote auxiliary material rack are respectively set as environmental protection cofferdams of rectangular blocks, and are fixed by quick buckles 9 each other. Equivalent and parallel four pillars 7, a rectangu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com