Method for splicing arc-shaped space truss

A space truss and arc technology, applied in the processing of building materials, construction, building structure, etc., can solve the problems of material waste, high operating height, and difficult to ensure safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

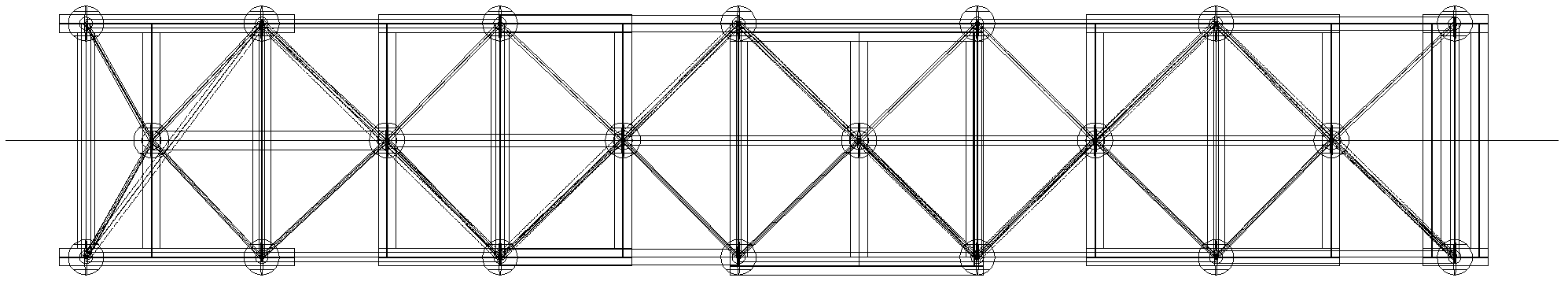

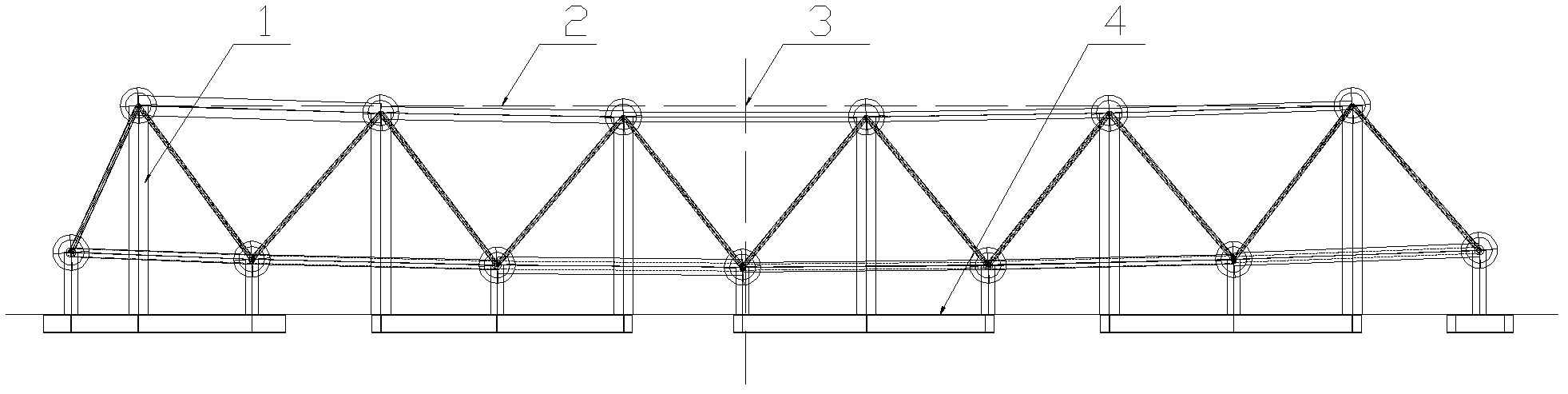

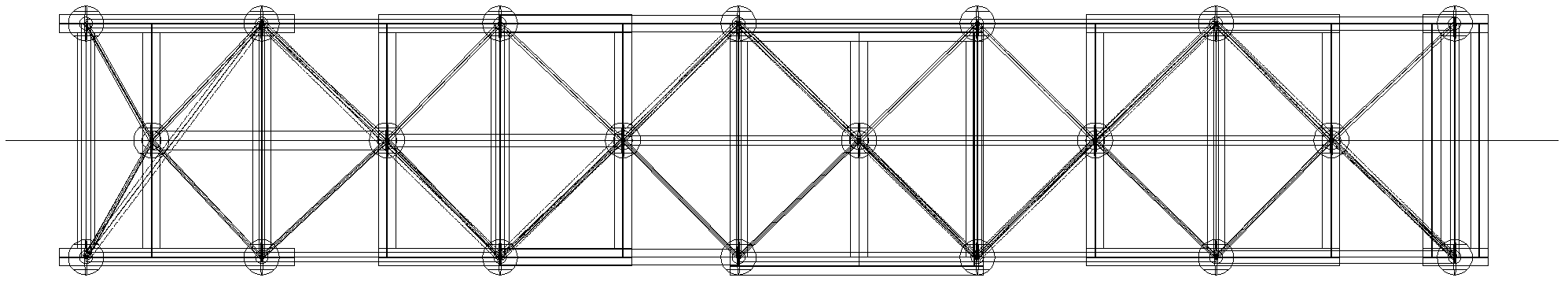

[0018] As shown in the figure: an assembly method for arc-shaped space trusses, which is completed in accordance with the following steps:

[0019] 1. According to the design drawing, find out the radius r of each node ball, and perform three-dimensional transformation of the assembled inverted triangular truss into a regular triangular truss;

[0020] 2. Make the connecting line between the two ends of the equilateral triangular truss as the auxiliary line, and make the vertical bisector of the auxiliary line, with the midpoint as the origin, the auxiliary line and the bisector respectively establish the coordinate system for the X and Y axes;

[0021] 3. Mark the three-dimensional coordinates (x, y, z) of the center of each node ball according to the coordinate system;

[0022] 4. Determine the maximum value of y (y max ) ball node support height h, the difference between each node and the radius of the ball node here r - , determine the support height y of each ball node ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com