Control method and system for improving wind energy utilization rate of wind turbine generator

A technology for a wind turbine and a control method, which is applied to the control of wind turbines, wind energy power generation, wind turbines, etc., can solve problems such as being unable to identify and eliminate faults at the first time, increasing the number of restarts of pitch drives, and reducing the operating safety of the unit. , to achieve the effect of improving the key real-time attention and real-time detection rate, reducing the safety risk of unit operation, and expanding the dimension of stuck propeller identification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0038] A control method for improving the utilization rate of wind energy of a wind turbine, wherein the wind turbine mainly includes blades and a pitch system, and the pitch system mainly includes a pitch driver and a pitch driver main control system, including the following steps:

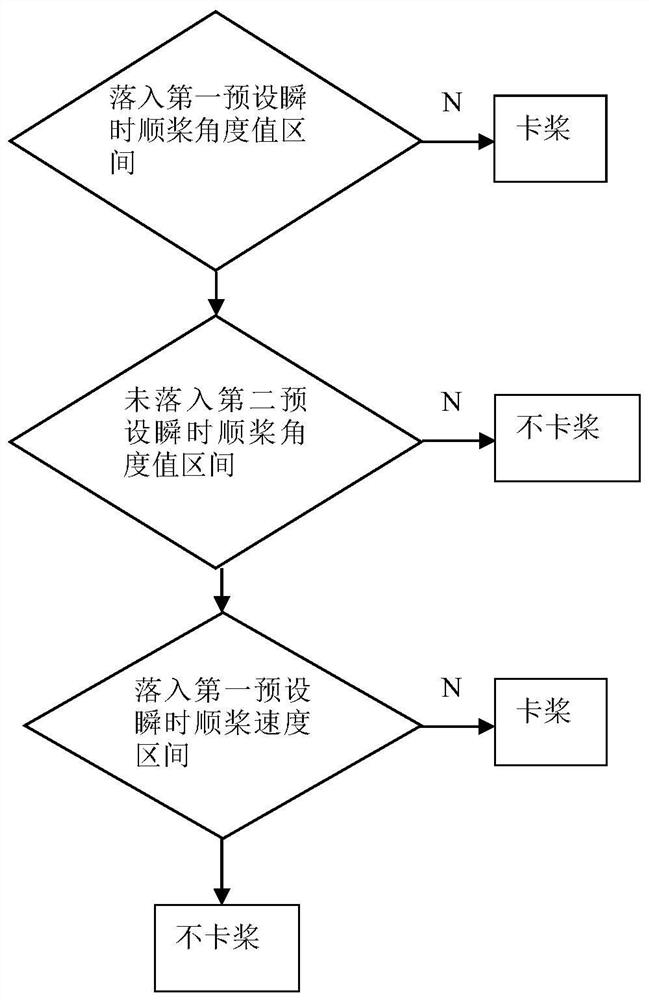

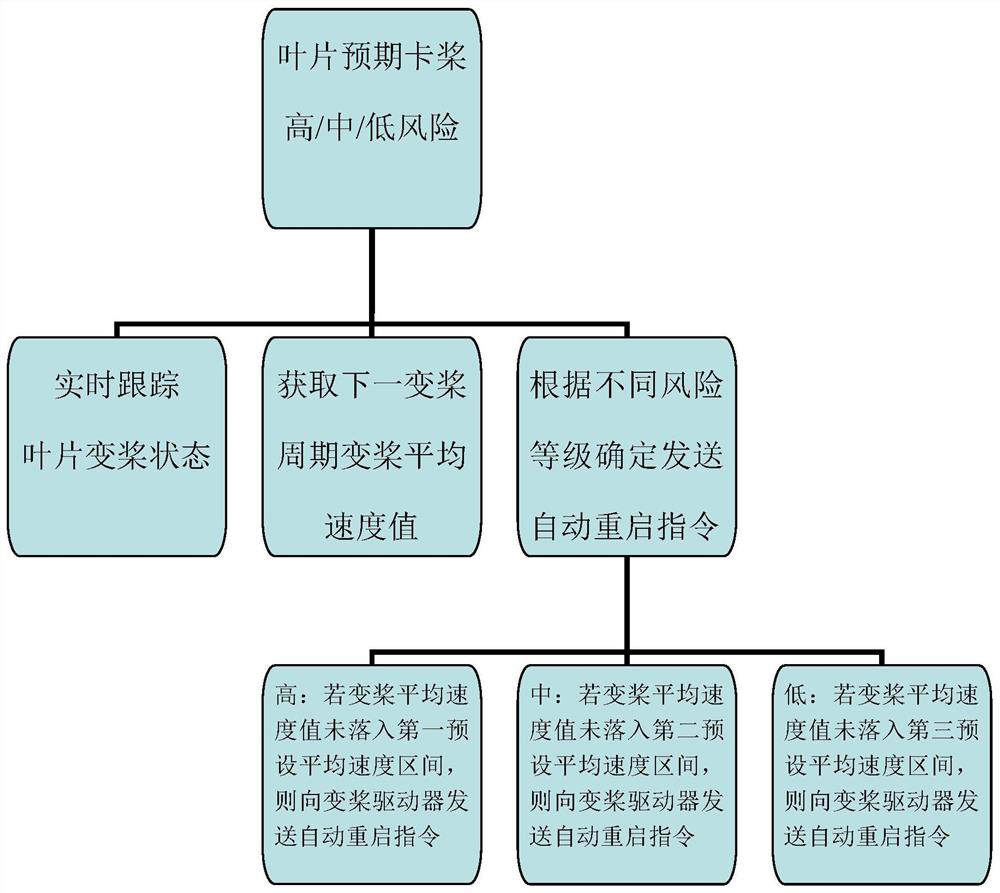

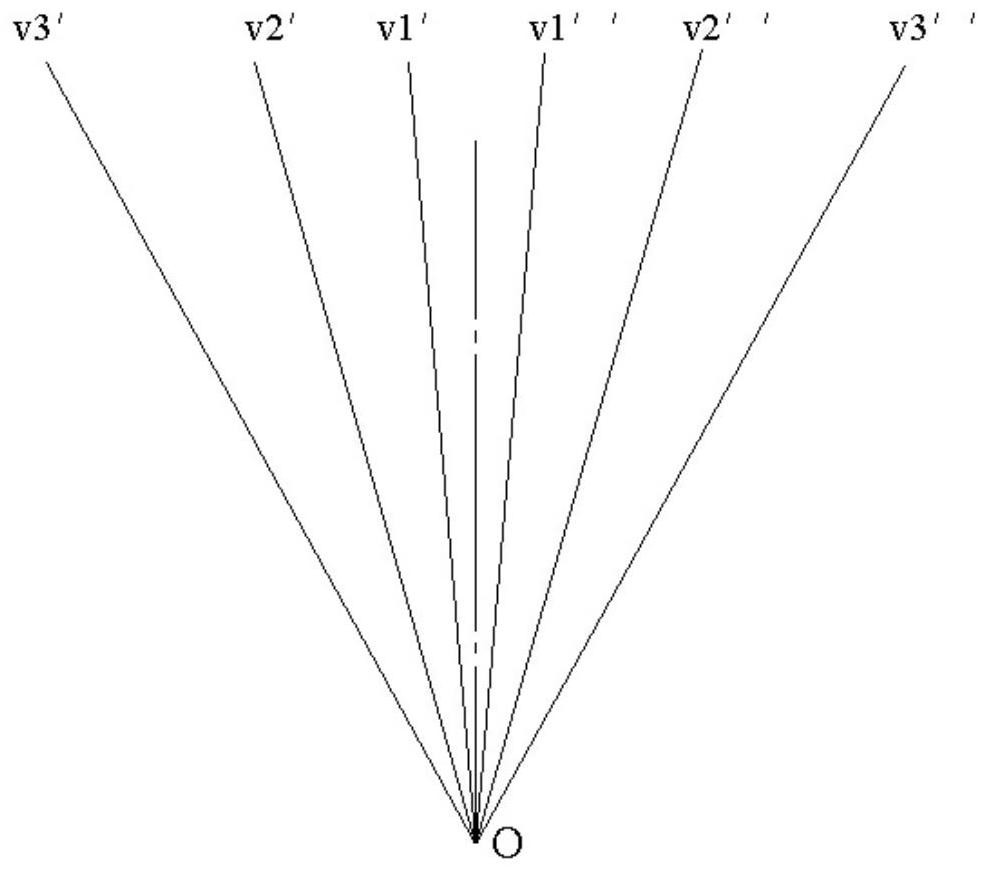

[0039] Determination of blade jamming: If the pitch angle α of at least one blade does not fall within the first preset instantaneous feathering angle value interval [α1, α2], that is, αα2, then it is determined that the blade is A propeller stuck fault occurs; if the pitch angle of the blade falls into the first preset instantaneous feathering angle value range [α1, α2], but does not fall into the second preset instantaneous feathering angle value range [β1, β2 ], that is, αβ2, then determine whether the feathering speed value v at the current moment falls into the first preset instantaneous feathering speed interval [v1,v2], if the feathering speed value v at the current moment does not Falling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com