A functional testing machine

A function testing machine and host technology, applied in the direction of sustainable manufacturing/processing, climate sustainability, final product manufacturing, etc., can solve the problems of equipment shutdown and restart, lower production efficiency, equipment instability, etc., to reduce restart The number of times, the effect of ensuring stability and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present application will be described in further detail below through specific embodiments in conjunction with the accompanying drawings.

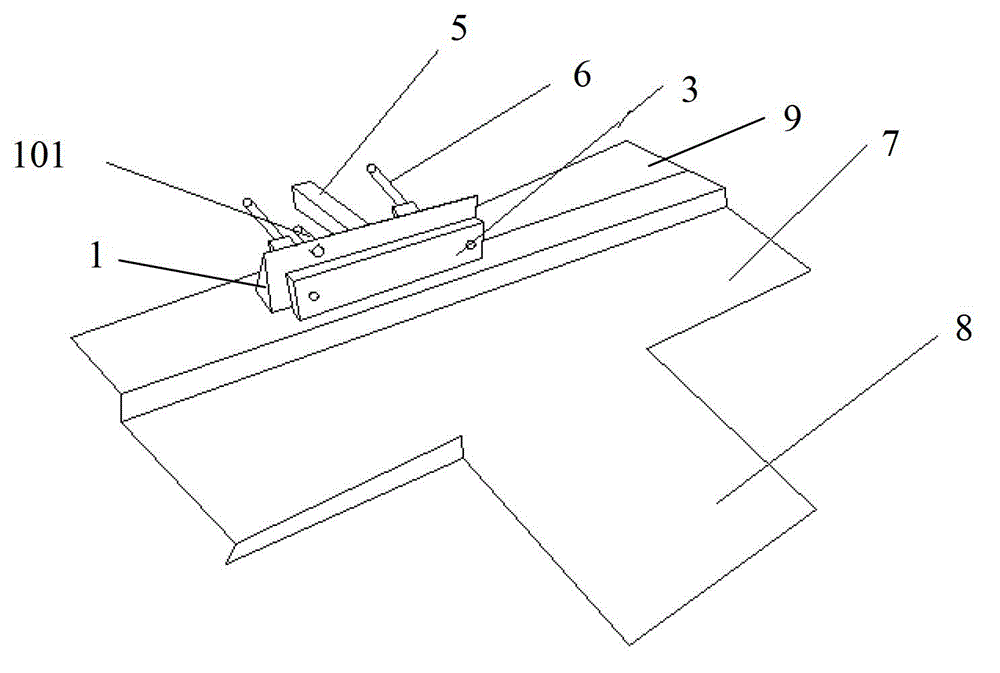

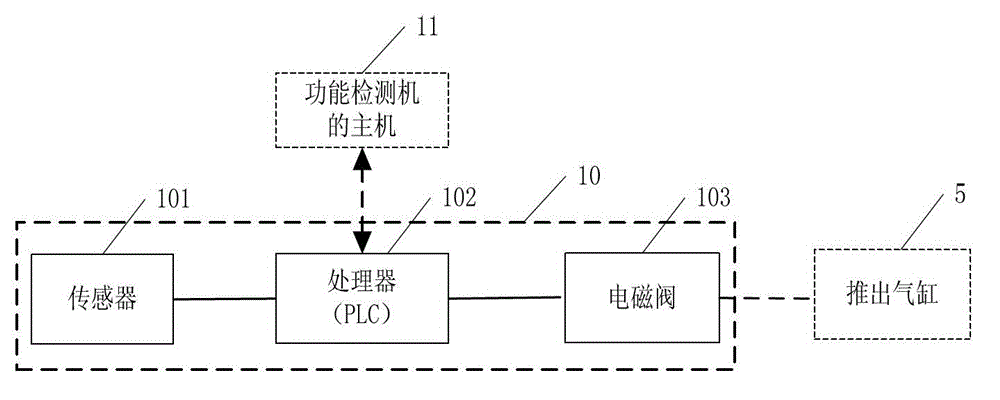

[0016] Please refer to figure 1 , a kind of function testing machine of present embodiment comprises workbench, is positioned at the conveyer belt 7 on workbench, the main engine 11 that battery is detected, and push-out device, and push-out device comprises fixed base 1, pushes out baffle plate 3, pushes out cylinder 5 and processing unit 10 . Wherein the fixed base 1 is installed on the base plate 9, the fixed base 1 has a first track through the fixed base 1 along the direction perpendicular to the conveyor belt 7, the ejection cylinder 5 is fixed on the workbench, and the power output end of the ejection cylinder 5 The first rail passing through the fixed base 1 is connected with the push-out baffle 3, and the control end of the push-out cylinder 5 is connected with the processing unit 10, and the processing unit 10 is also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com