Vertical axis rotor propeller and hydrogen production ship using the propeller

A thruster and vertical axis technology, which is applied in the direction of rotary propellers, hydroelectric power generation, special-purpose ships, etc., can solve the problems of reducing the power generation efficiency and power of the impeller behind, the effect is difficult to achieve ideal, and the voltage and frequency of power generation are unstable. , to achieve high propulsion efficiency and power generation efficiency, simplify the power generation control system, and reduce procurement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

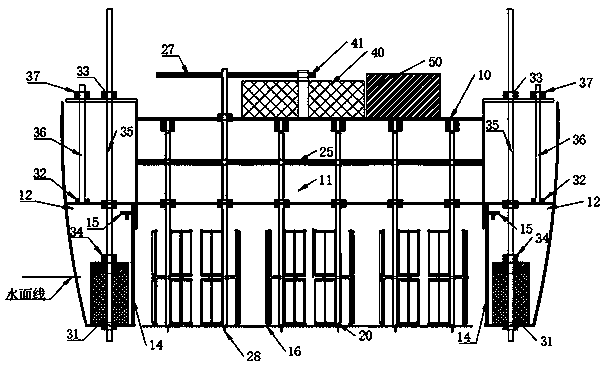

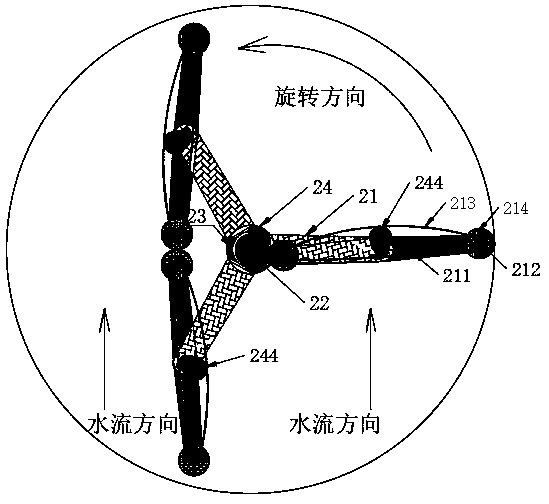

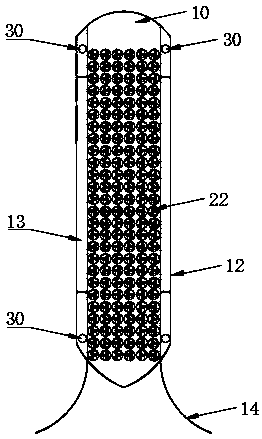

[0014] Such as Figure 1-3 As shown, a hydrogen production ship for power generation includes a cabin 11, a buoy cabin 12, a water turbine passage floor 16, a deflector 14, a buoy cabin lifting support device 30, a vertical axis runner propeller 20, a power generation system 40, and an electrolysis water system. The hydrogen system 50, the buoy cabin 12 is a part of the whole hull 10, which is installed on both sides of the cabin 11, the buoy cabin 12 is provided with a buoy cabin water tank 13, and the two sides of the buoy cabin water tank 13 are provided with a buoy cabin lifting support device 30 The buoy cabin lifting support device 30 includes a deck locking device 33 fixedly installed on the upper deck of the hull 10, installed on the top of the buoy cabin 12, fixed relative to the upper and lower positions of the buoy cabin, but can relatively rotate The buoy locking device 32 is installed on the buoy The bottom of the cabin 12, the upper and lower positions are fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com