Patents

Literature

66results about How to "Exempt from modification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Styrene-butadiene copolymer chemical foaming composition containing polystyrene micro-blocks, preparation method and application method thereof

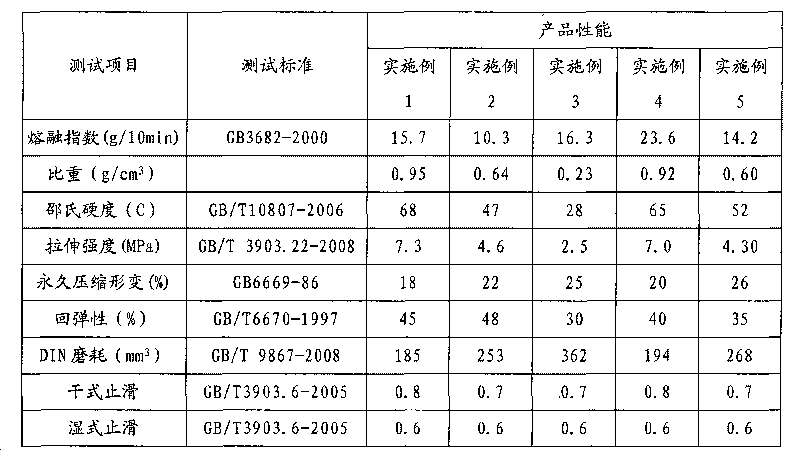

The invention discloses a styrene-butadiene copolymer chemical foaming composition containing polystyrene micro-blocks, a preparation method and an application method thereof. The preparation method takes styrene-butadiene copolymer mixing random structure with block structure as base material, and adds flow modifier or softener to regulate the fluidity of rubber. Rubber compositions manufactured by the method have good fluidity and can be molded directly through injection. Chemical foaming agents added reduces product density and effectively achieves the aim of obtaining lightweight material. Post partial chemical crosslinking can be performed so as to improve the stress cracking resistance and wear resistance of the material. Meanwhile, as the partial physical crosslinking of the styrene-butadiene copolymer allows the material to overcome the defect that all-chemical crosslinked rubber cannot be regenerated, the material can be recycled and regenerated.

Owner:浙江仕峰实业有限公司

Cell reselection for improving network interconnection

InactiveCN101044783AImprove quality experienceReduce the number of timesAssess restrictionRadio/inductive link selection arrangementsCell selectionInterconnection

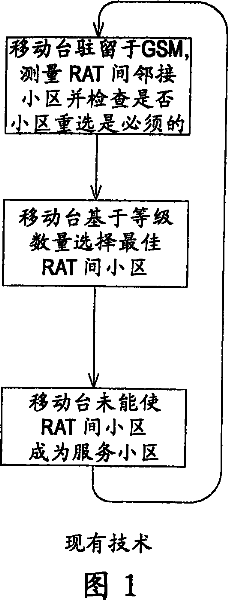

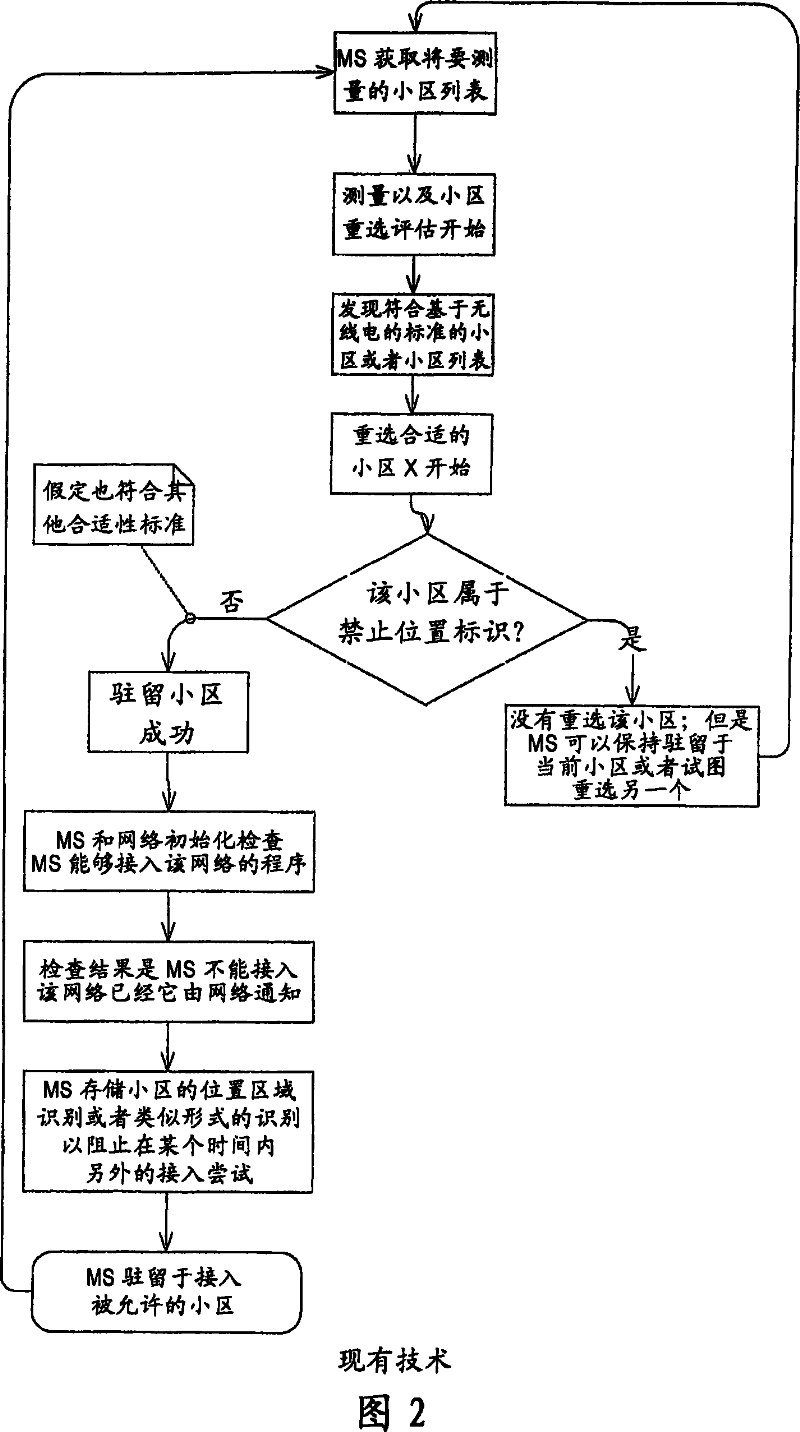

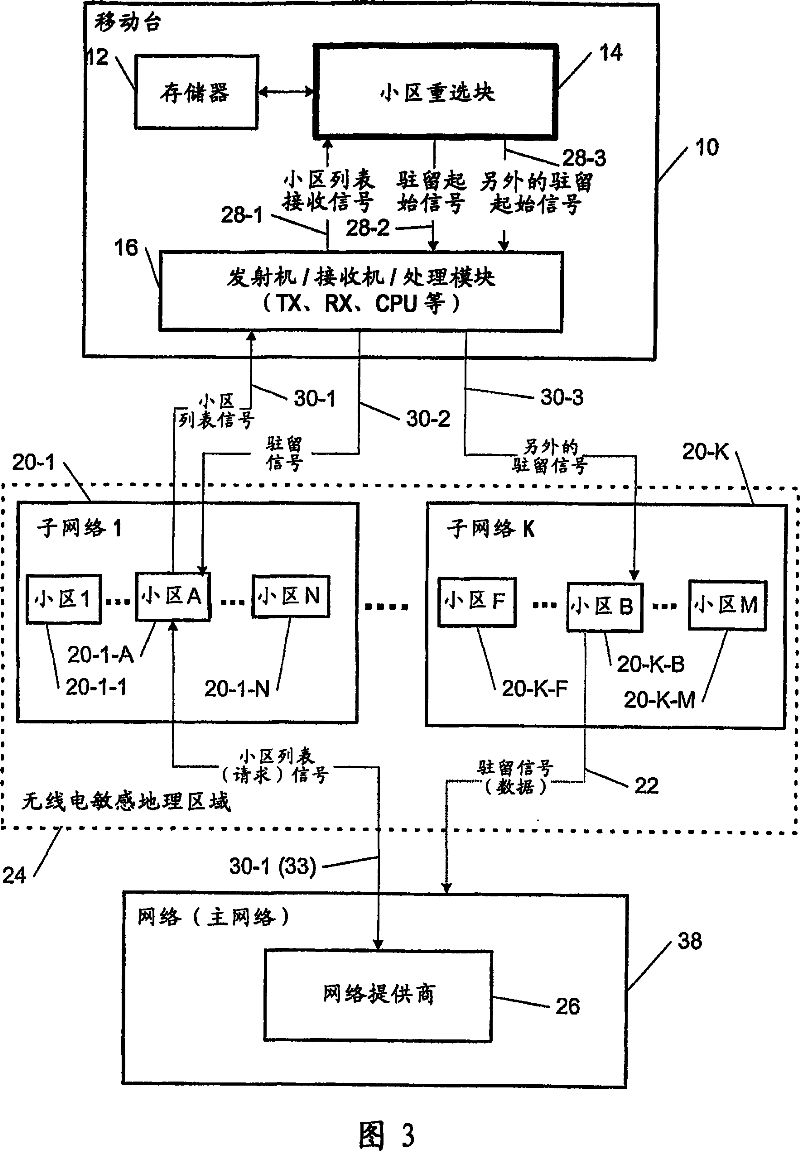

This invention describes a new methodology for a cell reselection by a mobile station (MS) for improving network interconnection and interoperability in a limited mobile access environment. The invention is applicable to any kind of networks and their interconnections. The invention describes how the MS can better recover from failed intersystem cell reselection attempts so that there are fewer subsequent failed attempts using two major improvements. First, the MS takes into consideration during cell reselection evaluation and candidate-cell selection, whether the MS had previously been unsuccessful in reselecting the considered cell. This means treating neighbor cells to which the MS had failed reselection before with a lower priority in subsequent cell reselection evaluations. Second, the MS is allowed to stop monitoring and thus, to stop evaluating cells if it was earlier found that the access to those cells is forbidden.

Owner:NOKIA CORP

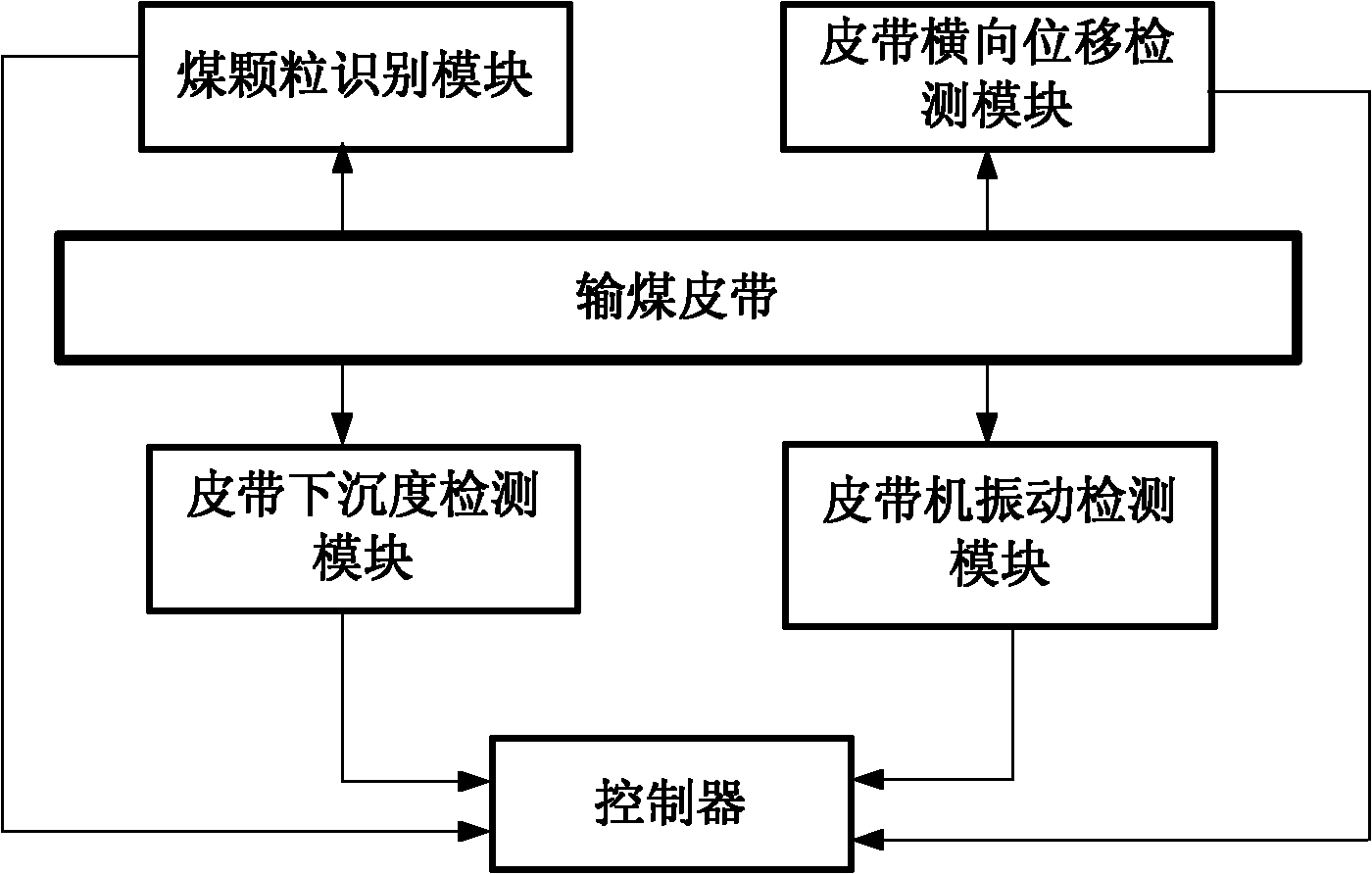

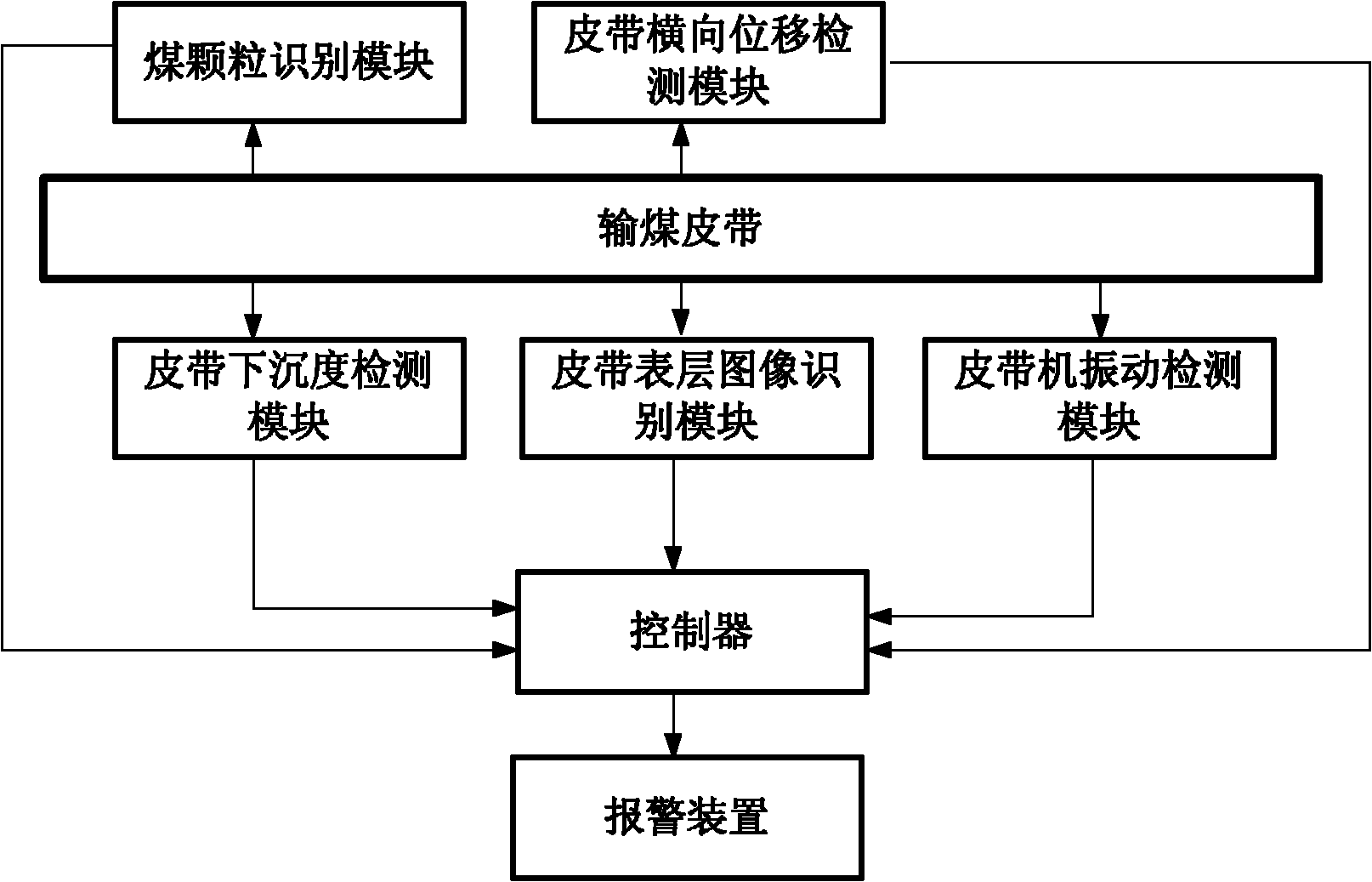

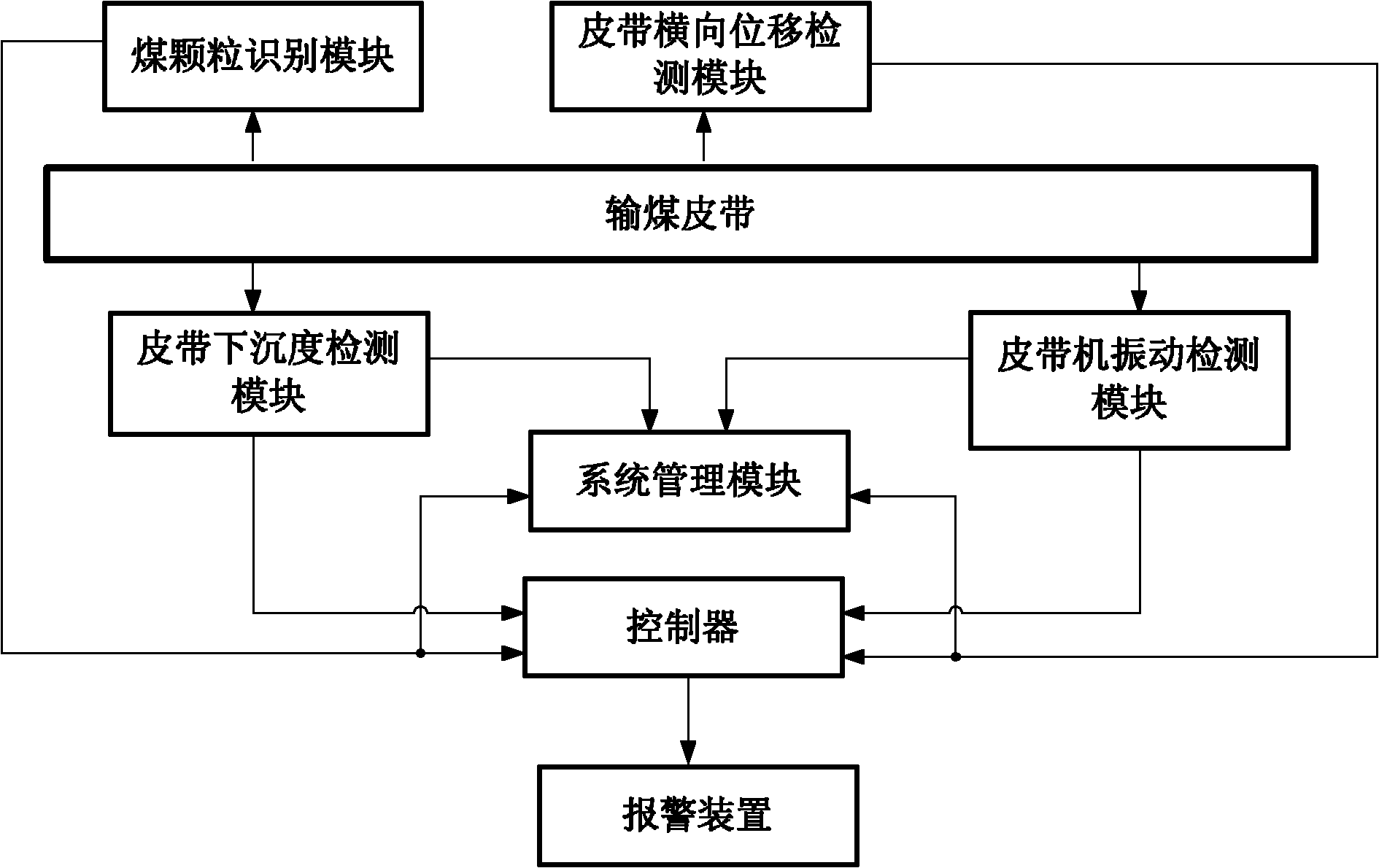

Method for monitoring coal conveying belt of coal conveying system by intelligent monitoring system

InactiveCN102424257AReduce the risk of being tornExtend your lifeControl devices for conveyorsMonitoring systemEngineering

The invention relates to a method for monitoring a coal conveying belt of a coal conveying system by an intelligent monitoring system. The intelligent monitoring system comprises a coal particles identifying module, a belt sinkage detecting module, a belt lateral displacement detecting module, a belt conveyor vibration detecting module and a controller, wherein the controller is connected with each module in a wired way or in a wireless way. The method comprises the following steps of: monitoring whether large-sized coal is existed on the coal conveying belt by the coal particles identifying module; monitoring whether the large-sized coal is existed on the coal conveying belt by the belt sinkage detecting module; monitoring the status of the coal conveying belt by the belt lateral displacement detecting module; monitoring the belt conveyor vibration condition of belt conveyor caused by the vibration of the coal conveying belt throughby the belt conveyor vibration detecting module; and braking athe belt conveyor by the controller, wherein the controller receives the instruction that the belt conveyor needs to be braked and sends out the braking instruction, so that the belt conveyor is braked.

Owner:北京纵横兴业科技发展有限公司 +3

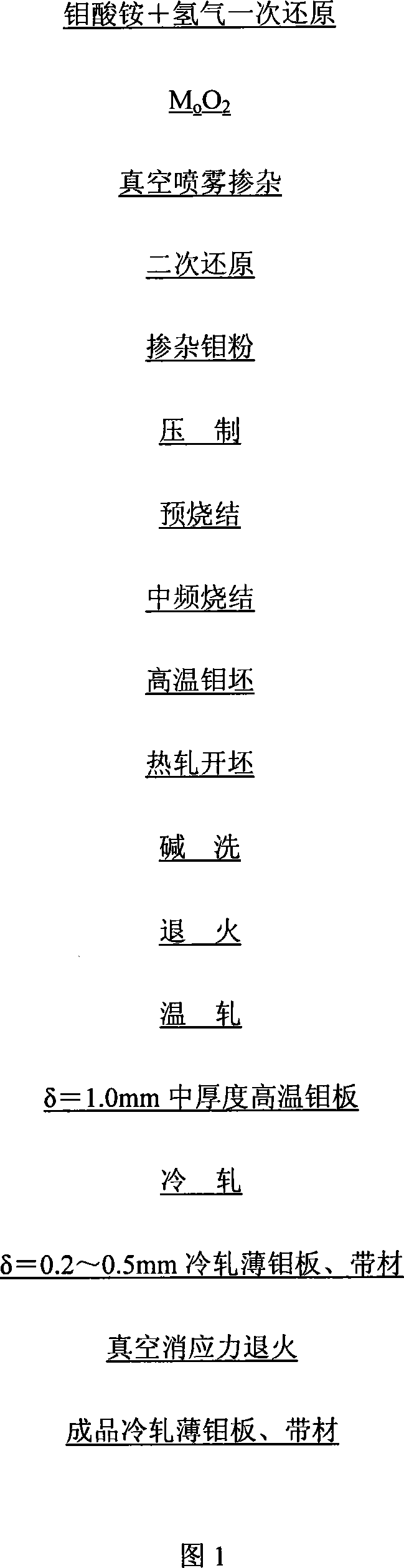

Method for preparing Mo-Si-Al-K cold-rolling thin molybdenum plate band

The invention relates to a Mo-Si-Al-K cold rolling thin molybdenum strip and a preparation method thereof. The invention is characterized in that the preparation process is: sintering the Mo-Si-Al-K into high temperature molybdenum billet; pre-annealing before the rolling at the temperature of 1300-1400 DEG C; implementing the hot rolling cogging processing on the high temperature molybdenum billet with the first pass deformation of 20 to 30 percent; implementing the intermediate annealing, the alkali washing and the warm rolling at the temperature of 900-1100 DEG C when the rolling deformation reaches to 70 to 75 percent to obtain a middle thick molybdenum strip; cold cooling the middle thick molybdenum strip into the specification of a finally finished product; implementing the vacuum stress relief annealing on the finished product at the temperature of 800-850 DEG C. And then the high temperature cold rolling thin molybdenum strip required by the invention is obtained. The product obtained through the invention is provided with strong high temperature strength and high recrystallization temperature. The cold rolling thin molybdenum strip product has the good properties of surface quality, high size precision, strong high temperature strength, good plasticity, long service life, etc. and can be widely used to produce molybdenum crucibles, boats, anodes of transmitting tubes with large power (U type), gate molybdenum tubes, heating unit, heat shields and other structural parts.

Owner:JINDUICHENG MOLYBDENUM CO LTD

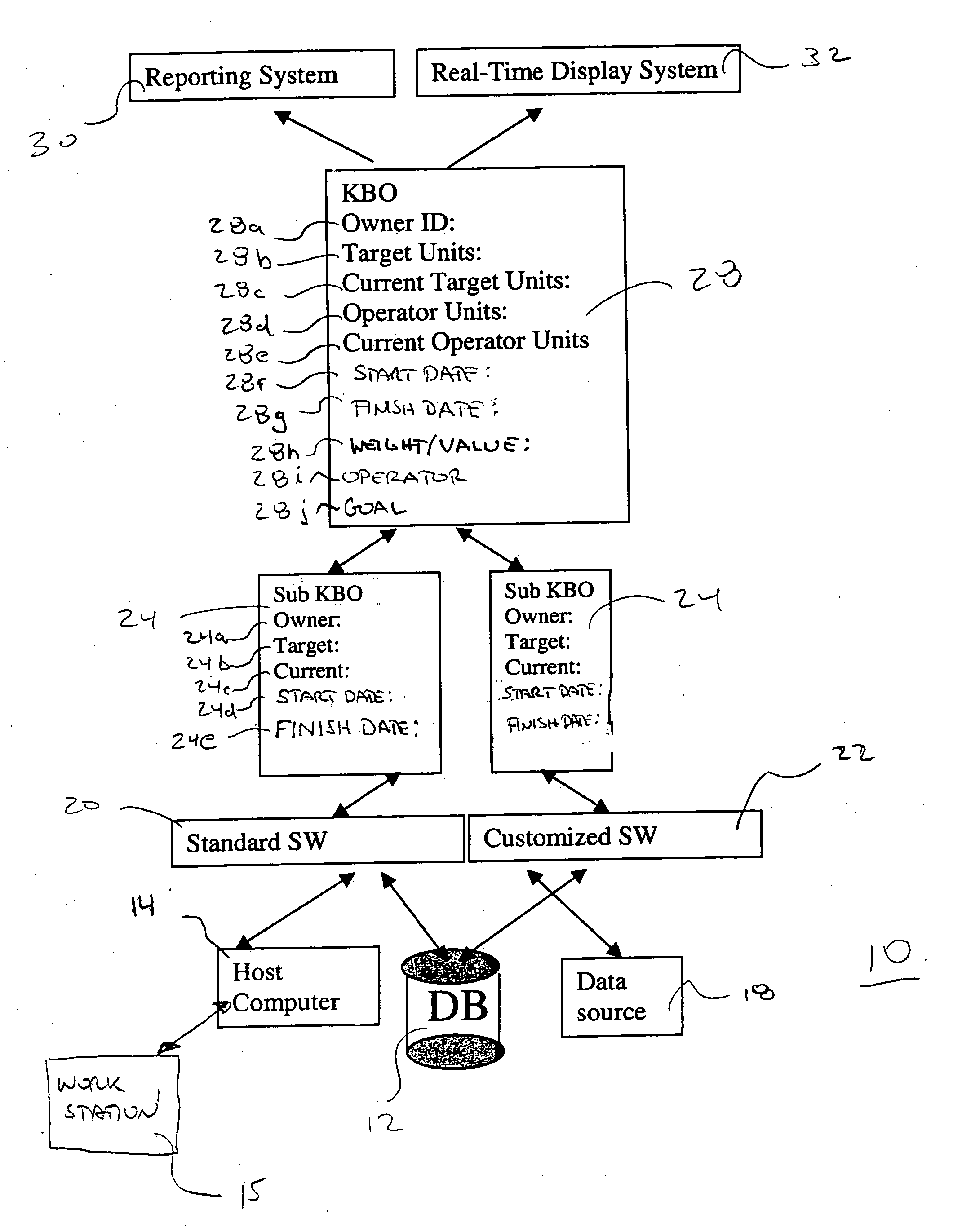

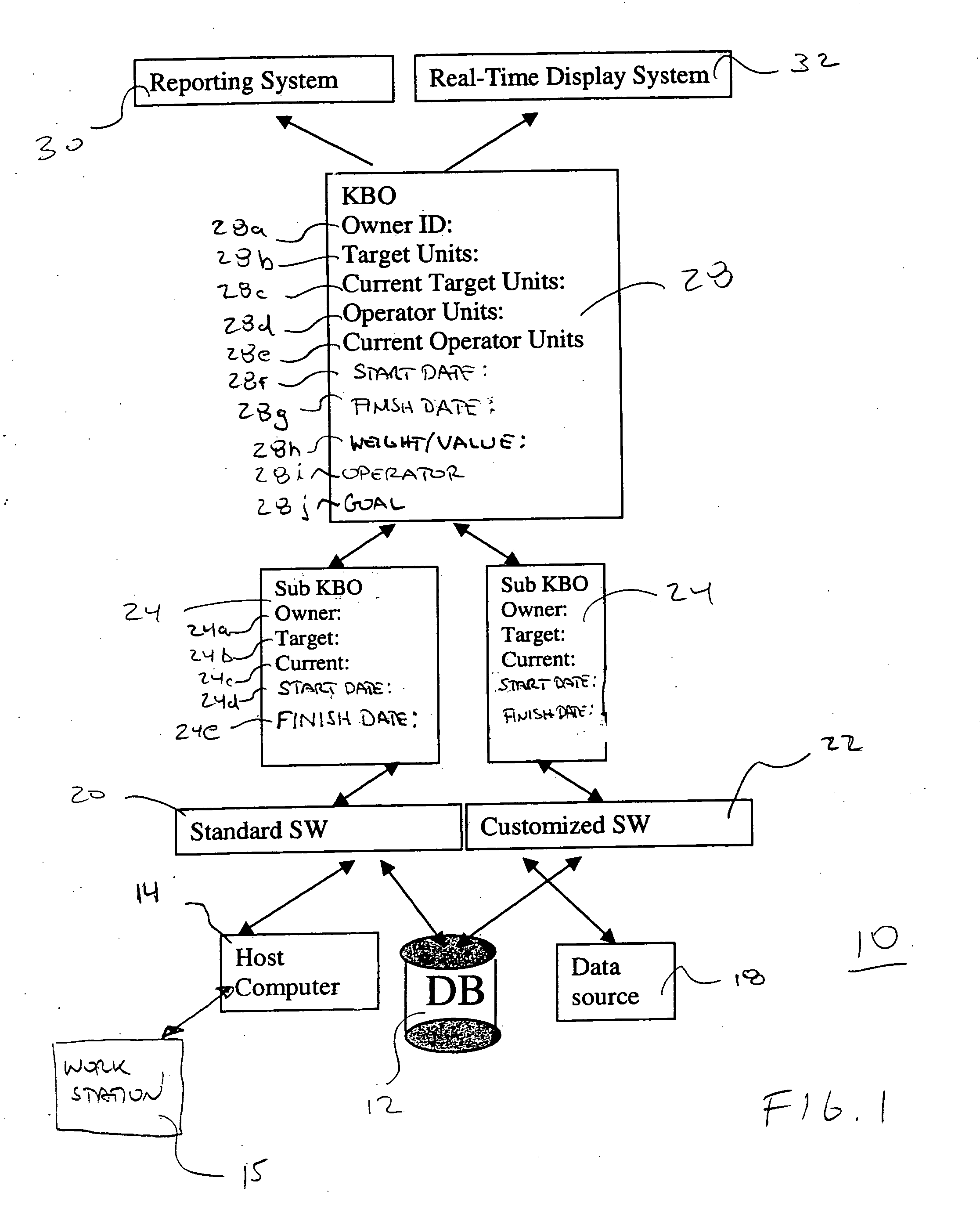

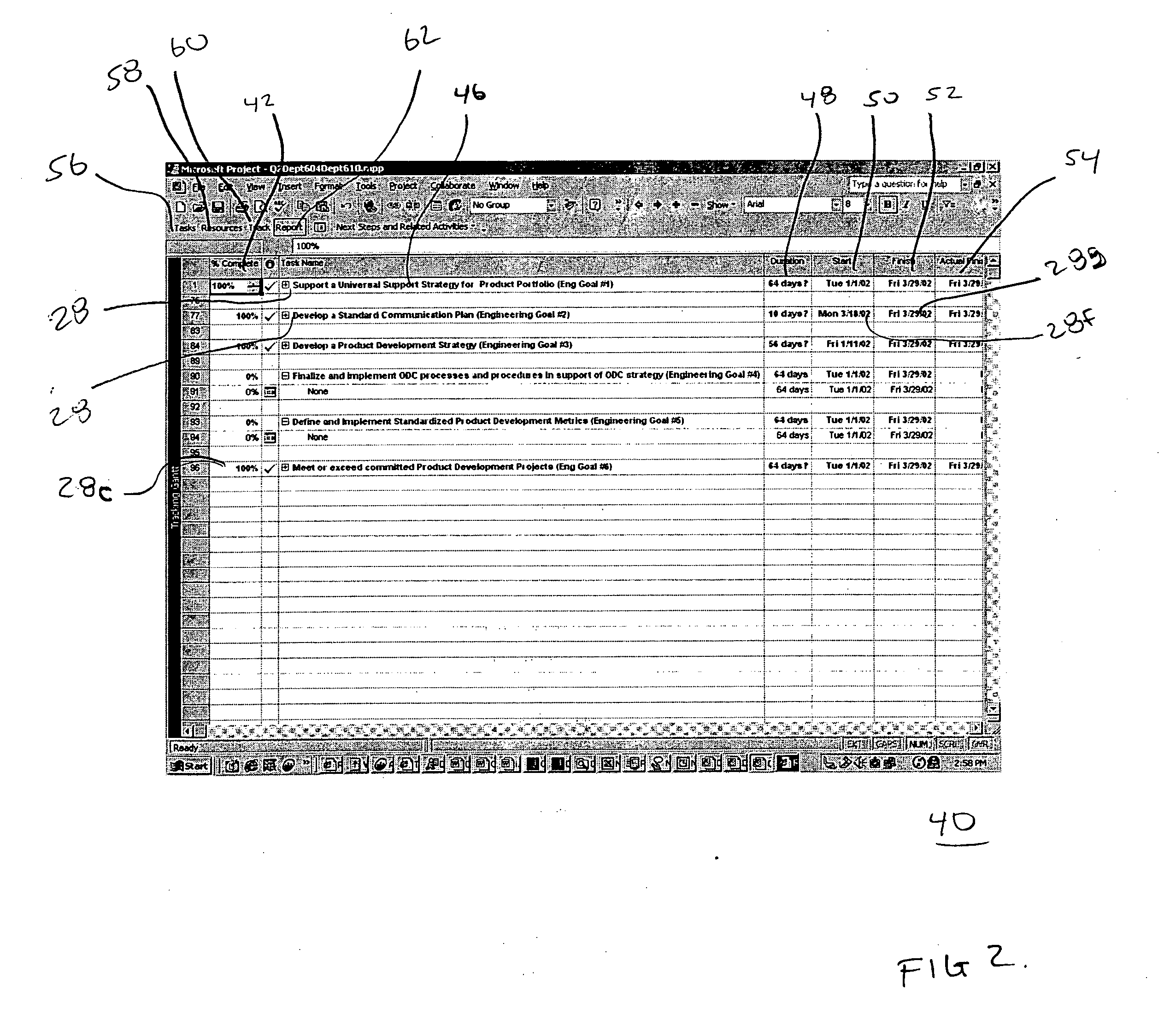

Goal tender system and method

An improved system and method for monitoring the progress performed toward identified key business objectives. First, the objectives are defined and identified as tasks. Then, employees are assigned to each task and the employees are also defined as tasks. Sub key business objectives are assigned to each employee and are also identified as tasks. As data regarding the completion status of each task is entered into the system, a real time comprehensive report on the overall status of key business objectives is realized.

Owner:ROCKWELL ELECTRONICS COMMERCE TECH LLC +1

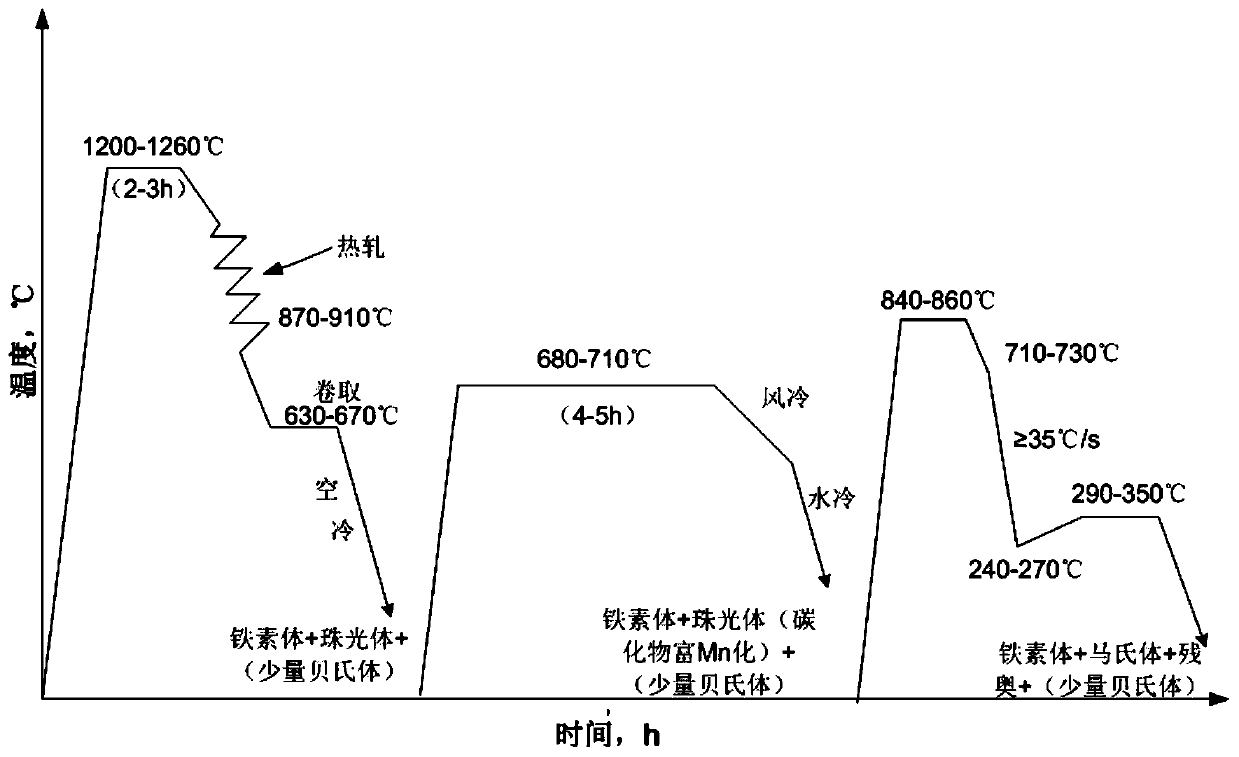

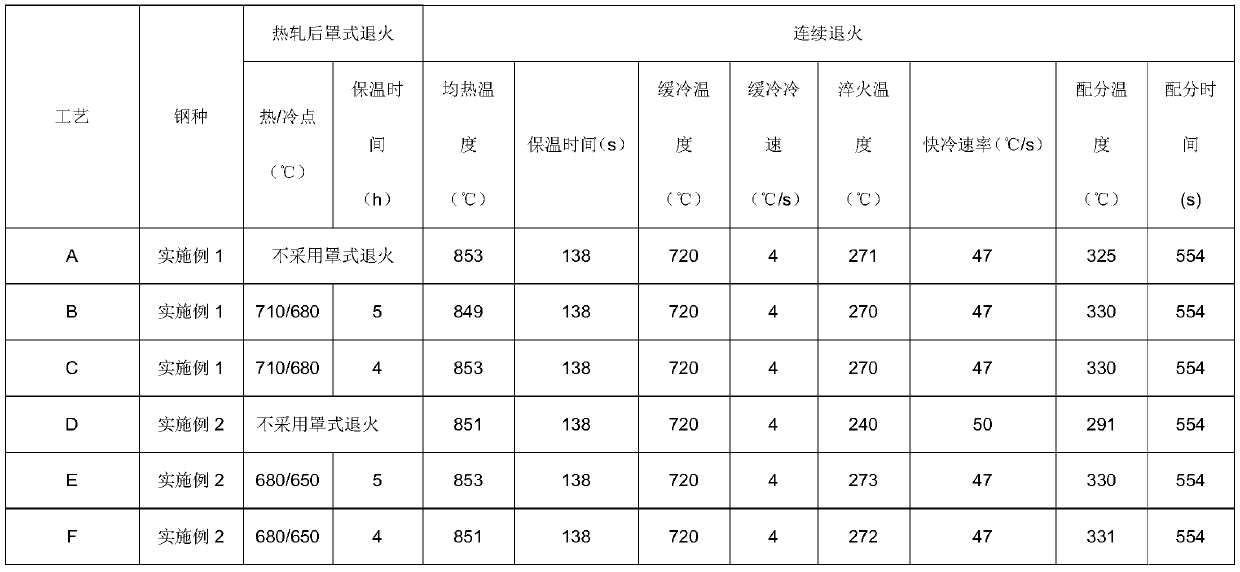

980MPa-grade cold-rolled Q&P steel with excellent plasticity and manufacturing method thereof

The invention provides 980MPa-grade cold-rolled Q&P steel with excellent plasticity and a manufacturing method thereof. The 980MPa-grade cold-rolled Q&P steel comprises the following components of 0.18%-0.21% of C, 1.4%-1.6% of Si, 1.8%-2.1% of Mn, 0.04%-0.06% of Nb, 0.02%-0.05% of Al, less than or equal to 0.01% of P, less than or equal to 0.01% of S and the balance Fe. According to the 980MPa-grade cold-rolled Q&P steel with the excellent plasticity, compared with the prior art, noble metal elements such as Al, Ni and Mo are not added, the content of Mn is relatively low, the Mn element is mainly used for enriching and stabilizing austenite in the austenite, the plasticity of the material is obviously improved, and the product of strength and elongation can reach 25 GPa%; two-phase region annealing is adopted, the annealing temperature is low, and quenching partition treatment can be implemented on an existing continuous annealing production line through adopting an approximate one-step method; and on the other hand, through annealing treatment of the hot-rolled coil, the influence of the alloy element Mn on the material performance is improved, and equipment does not need to betransformed and invested.

Owner:MAANSHAN IRON & STEEL CO LTD

Femto positioning method and device

The invention discloses a Femto positioning method and device. The Femto positioning method includes: receiving a frequency sweep report message reported by the Femto, wherein the frequency sweep report message carries signal intensity information of at least one same-system macro cell and frequency point information used by each same-system macro cell; determining location information of the Femto according to the signal intensity information of the same-system macro cell and the frequency point information used by the same-system macro cell carried in the frequency sweep report message.

Owner:CHINA MOBILE GROUP SHAIHAI

Method for activating and floating sulfide minerals suppressed by cyanide ions

ActiveCN102319629ASimplify the operation processSave time and process costsFlotationThiosulfateMetal

The invention relates to a method for activating and floating sulfide minerals suppressed by cyanide ions during separation of non-ferrous multi-metal sulfide ores and comprehensive recovery of valuable elements in gold ore cyanide tailings. The method comprises the following steps of: (1) adding a soluble salt into ore slurry, and / or filling O2-containing gas and / or SO2-containing gas into the ore slurry to activate suppressed target minerals; and (2) floating to obtain target sulfide mineral concentrate, wherein the soluble salt in the step (1) is one or a mixture of more than two of inorganic sulfite, pyrosulfite or thiosulfate. According to the method disclosed by the invention, procedures for densely dehydrating and removing reagents with active carbon are eliminated, agents such as sulfuric acid and the like are not added into the ore slurry, activation and floatation of sulfide minerals are realized, a high-quality sulfide mineral concentrate product is obtained, and the recovery rate of the sulfide mineral concentrate product is increased greatly.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

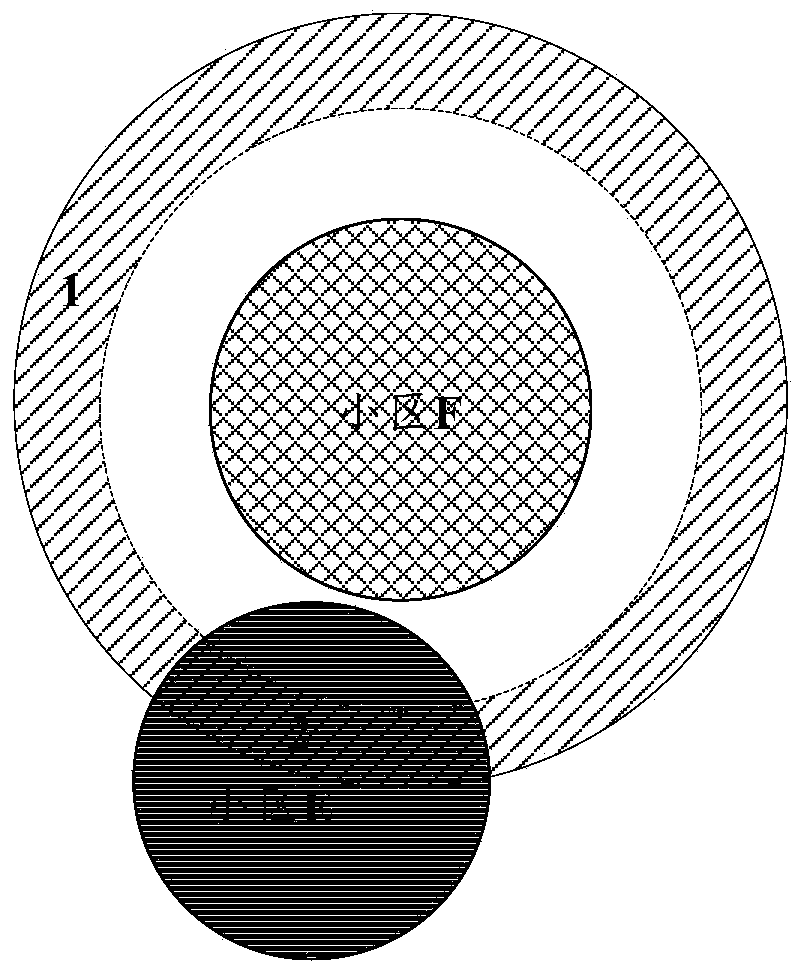

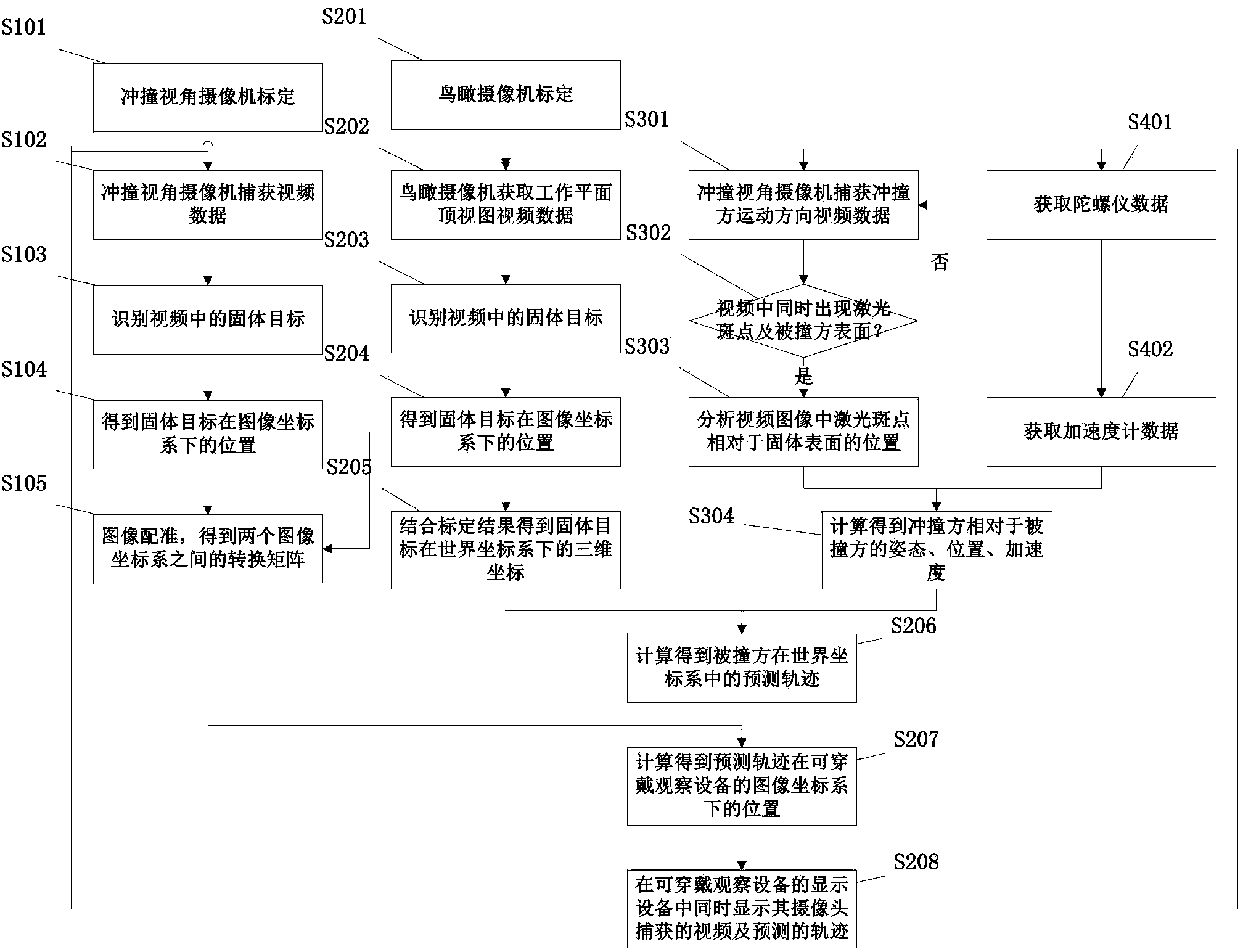

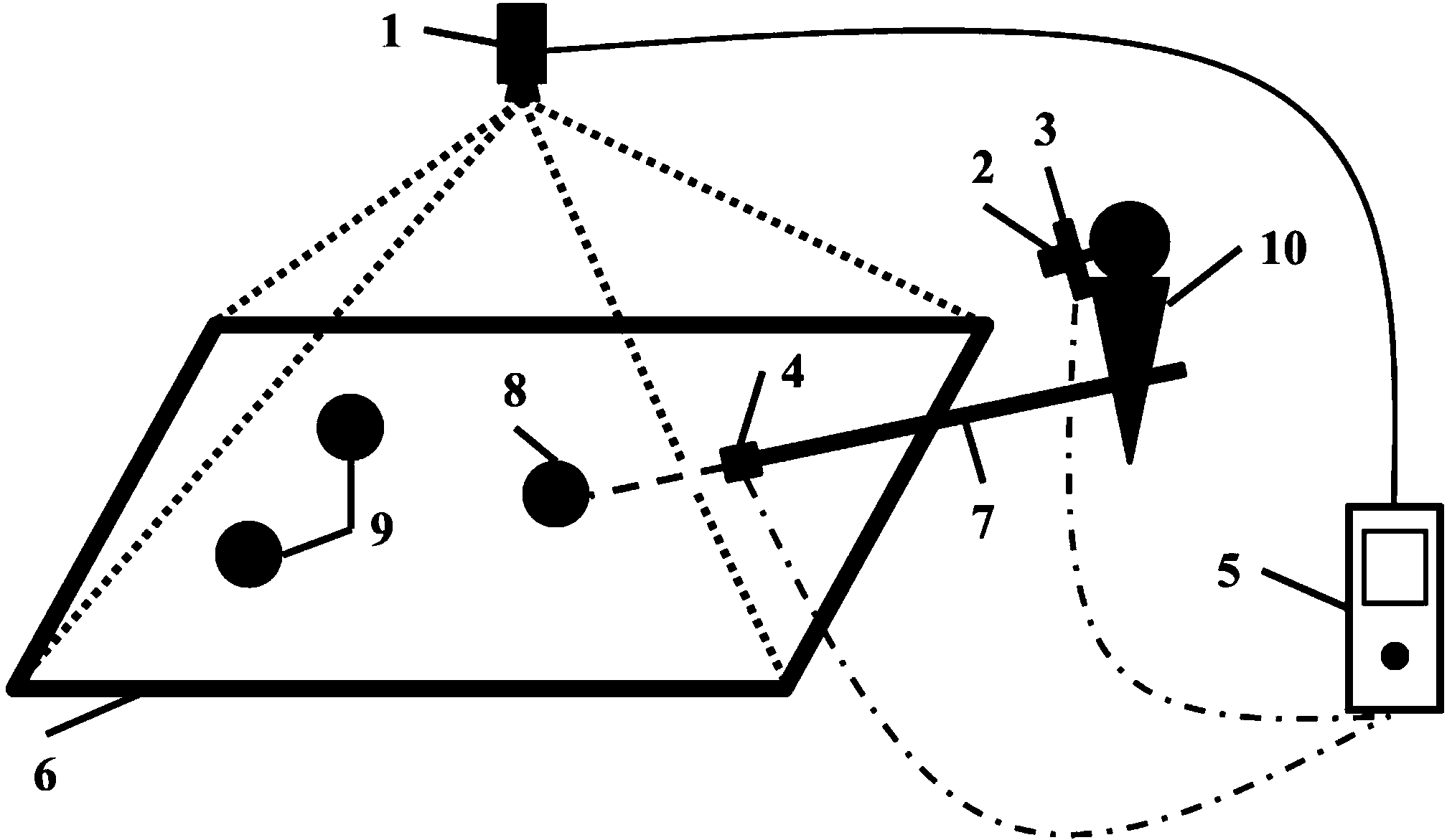

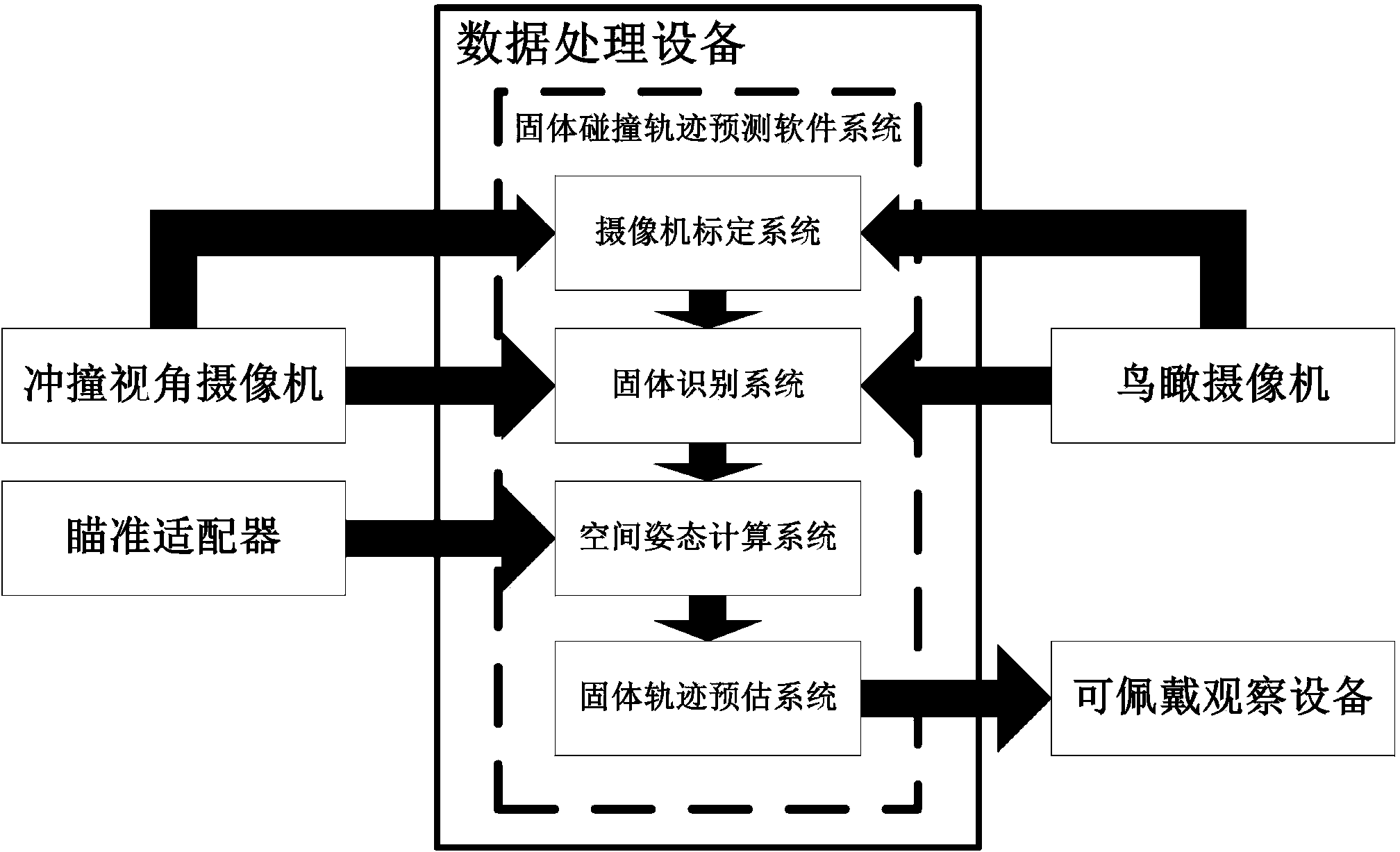

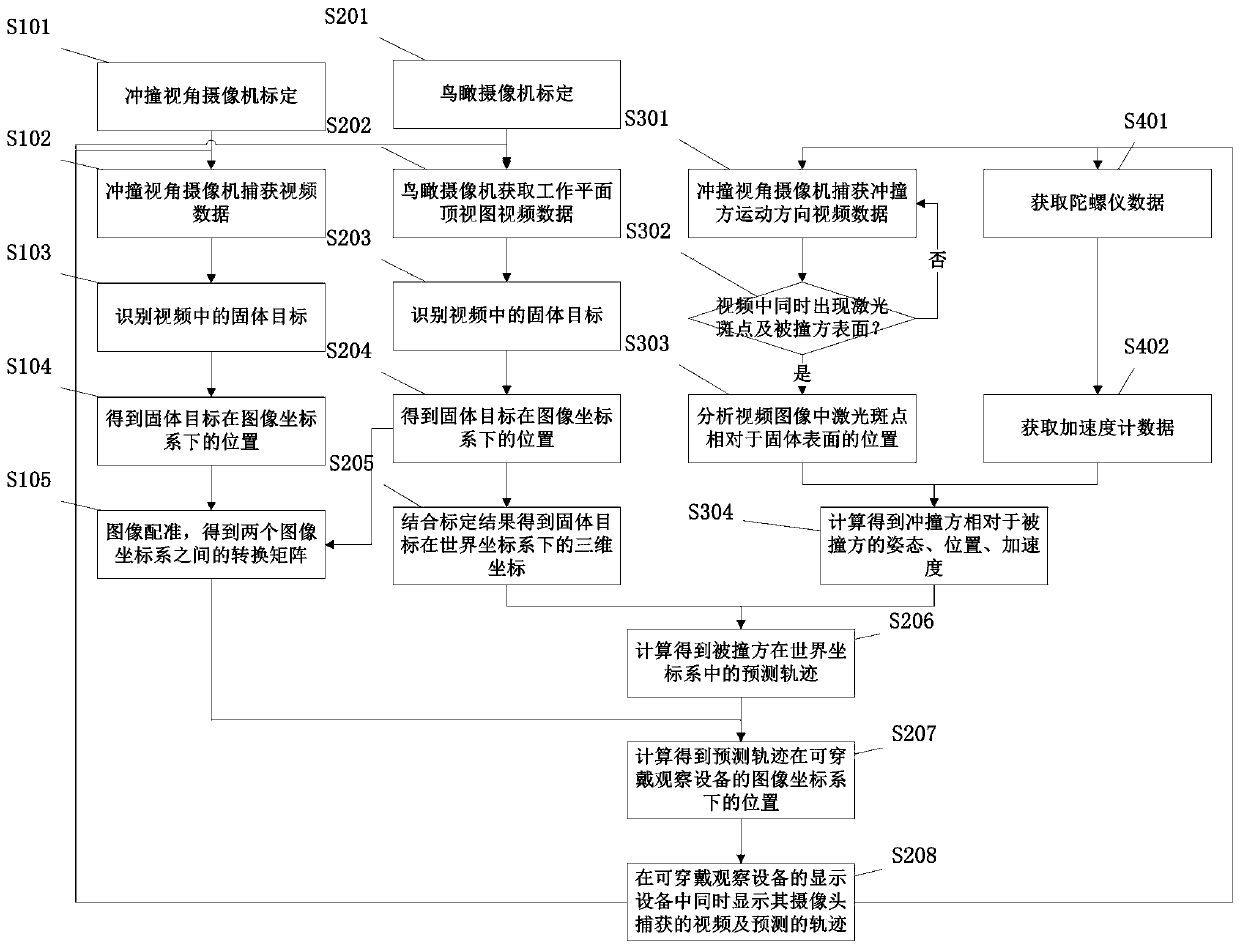

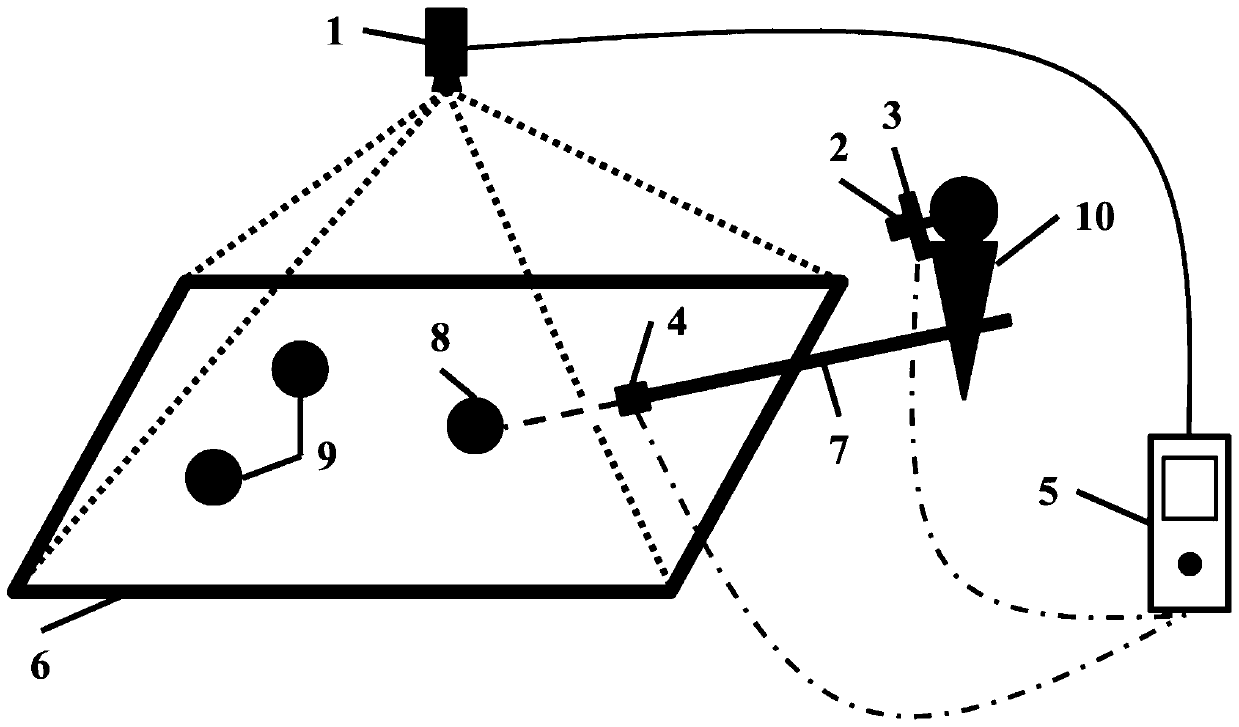

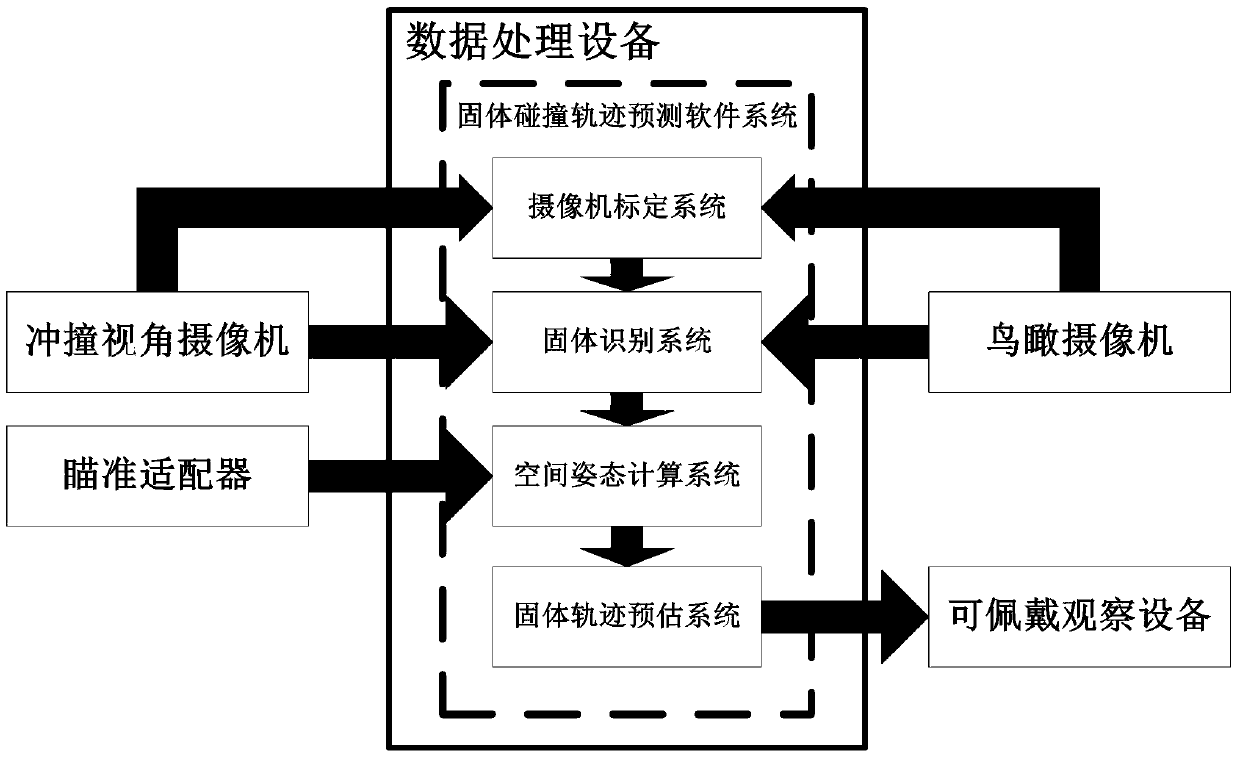

Rigid-body collision track prediction display unit

ActiveCN104376154AQuick calibrationExempt from modificationSpecial data processing applicationsSoftware systemGoal recognition

The invention provides a rigid-body collision track prediction display unit. The rigid-body collision track prediction display unit is composed of an aerial camera, a collision view angle camera, a wearable observation device, an aiming adapter, data processing equipment and a rigid-body collision track prediction software system. The rigid-body collision track prediction software system is configured in the data processing equipment, and is divided into a camera calibration system, an object identification system, a spatial posture calculating system and a rigid-body track estimation system. The spatial positions of rigid bodies on the working plane and the posture and force of the colliding party are obtained by analyzing video data transmitted by the aerial camera and the collision view angle camera by combination with spatial pose information transmitted by the aiming adapter, so that possible movement tracks generated after the colliding party and the collided party collide are obtained through calculation, and the tracks and actual scenes are overlapped to be displayed on a display screen of the wearable observation device. The collision tracks can be predicted and displayed in real time, and users can adjust the positions and movement states of the rigid bodies before collision happens.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

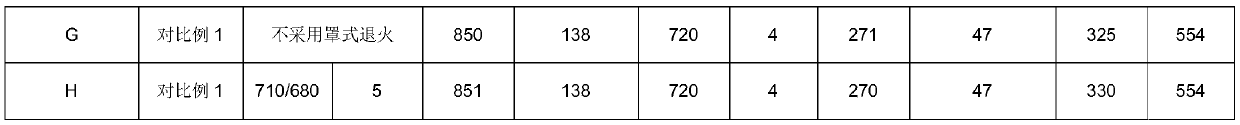

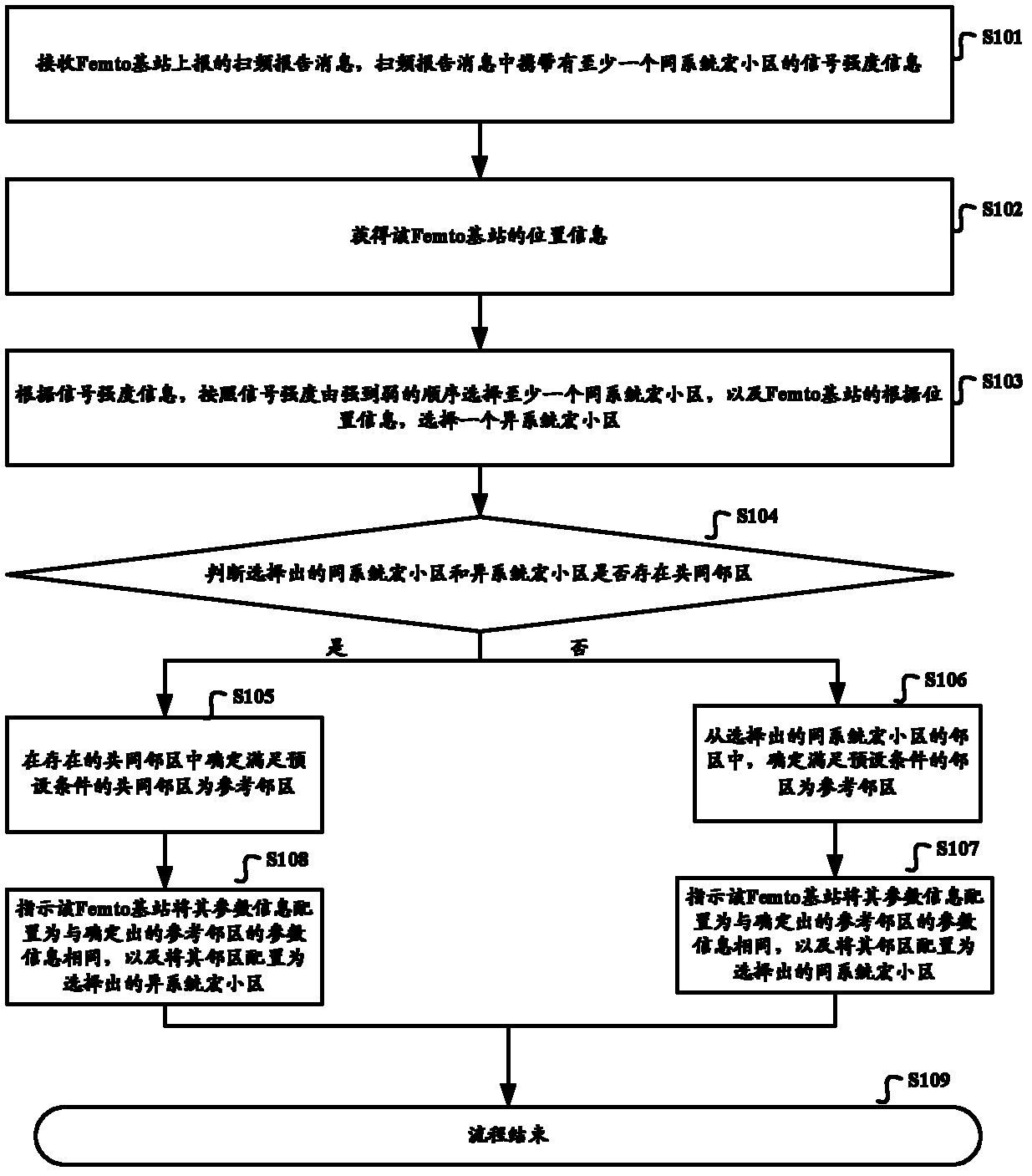

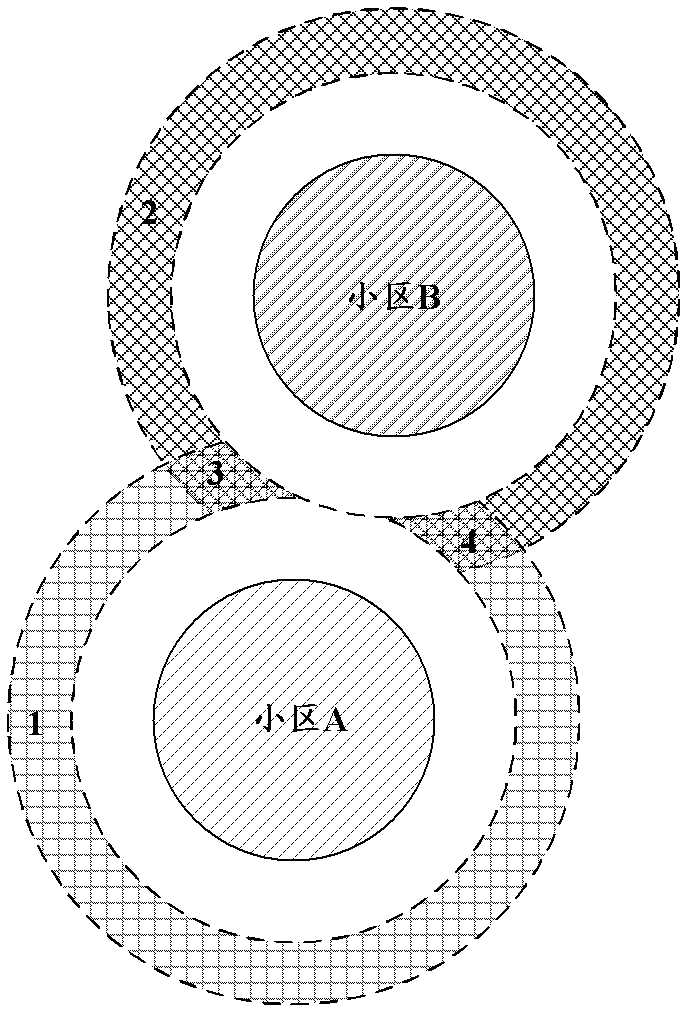

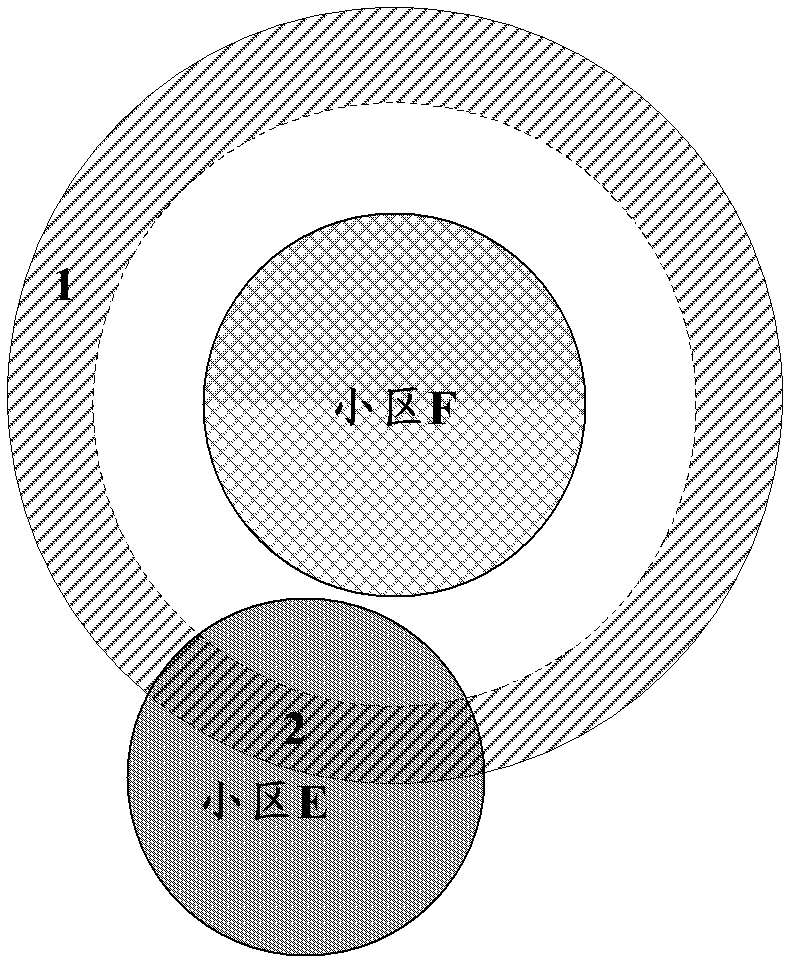

Configuring and positioning method of Femto and relevant device

The invention discloses a configuring and positioning method of a Femto and a relevant device, which are used to realize two-way reselection and switching between a Femto cell and an inter-system macro cell on the premise of not reconstructing the Femto of the existing network. The configuring method of the Femto comprises the steps of receiving frequency sweep report information reported by the Femto, obtaining position information of the Femto, selecting at least one co-system macro cell according to signal intensity information carried in the frequency sweep report information, selecting at least one inter-system macro cell according to the position information of the Femto, judging whether a common neighboring area exists between the co-system macro cell and the inter-system macro cell, and indicating the Femto to configure parameter information and the neighboring area of the Femto according to a judgment result.

Owner:CHINA MOBILE GROUP SHAIHAI

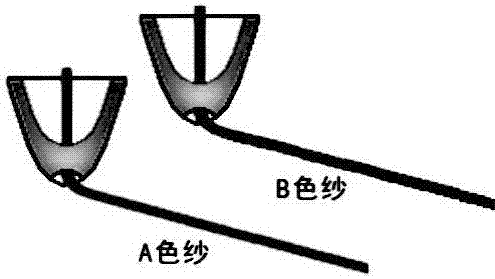

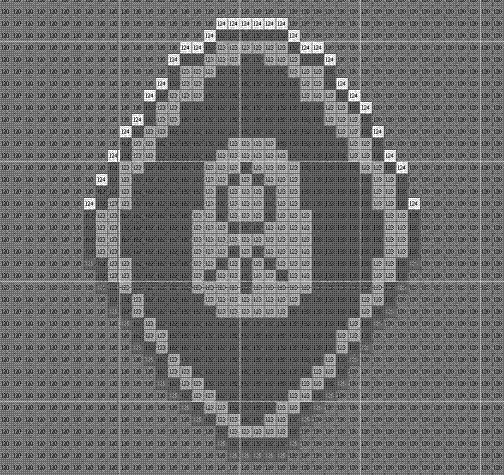

Method for knitting colorful tassel patterns

The invention provides a method for knitting colorful tassel patterns. The method comprises the following steps that S1, a tassel zone effect is achieved, wherein according to the tassel flower pattern requirements, a front needle bed does not execute knitting, a yarn guiding nozzle brings a color-A yarn to pass through, and a rear needle bed performs normal knitting to drive a color-B yarn nozzle, wherein loops woven normally by the rear needle bed form a basic ground structure, the front needle bed does not perform knitting, and the yarn guiding nozzle brings the color-A yarn to pass throughthe knitting zone of the rear needle bed to form tassels; S2, a colorful pattern zone effect is achieved, wherein according to the pattern color requirements, the front needle bed knits colorful patterns, the rear needle bed performs knitting in a needle spacing mode, and a speckled effect is formed on the bottom face of a fabric. By adopting the method, the fabric has the special flower patterneffects of tassels and colorful patterns. In addition, flower pattern structures of knitted fabrics can be also increased, and required tassels and colorful patterns can be also freely designed by combining with a computerized flat knitting machine.

Owner:HUIZHOU UNIV

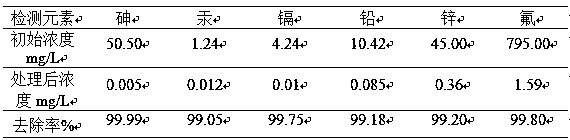

Method for treating potassium chloride cyanide-free cadmium plating wastewater

ActiveCN108164031AEasy to handleEffective precipitationWater contaminantsWaste water treatment from metallurgical processPotassiumCadmium Cation

The invention belongs to the field of wastewater treatment, and concretely to a method for treating potassium chloride cyanide-free cadmium plating wastewater. The method comprises the following steps: S1, adjusting the pH value of the wastewater, and adding an aqueous solution of sodium pyrosulfite; S2, adding an aqueous solution of sodium diethyldithiocarbamate, and adjusting the pH value of thewastewater; S3, adding a flocculant to make precipitated particles aggregate, and separating the precipitated particles from the wastewater; S4, adding hydrogen peroxide to the wastewater; and S5, adjusting the pH value of the wastewater treated in step S4. The method significantly reduces the content of cadmium and chromium in the potassium chloride cyanide-free cadmium plating wastewater to make the wastewater discharge meet the requirements of national standards, and is suitable for original wastewater treatment and discharge systems in existing electroplating workshops of enterprises.

Owner:GUANGZHOU ULTRA UNION CHEM LTD

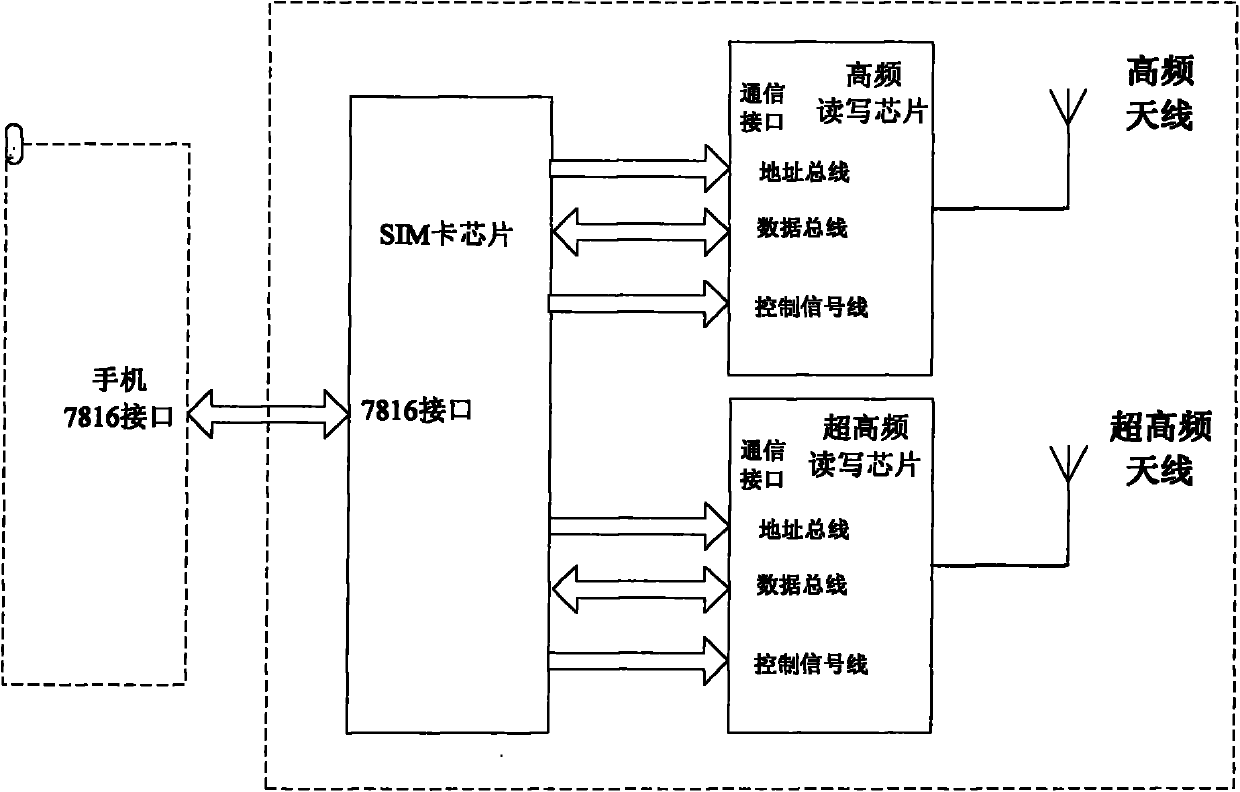

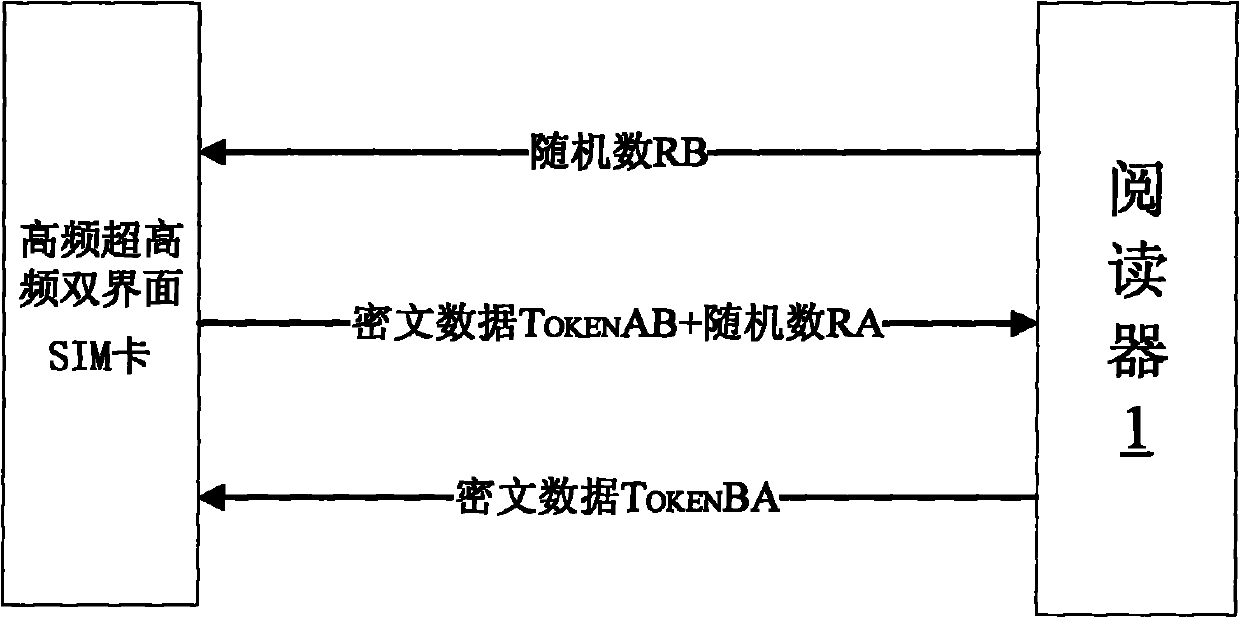

High-frequency and ultrahigh-frequency double-interface SIM (subscriber identity module) card and radio-frequency identification system

ActiveCN102202128AImprove securityRealize non-contact proximity radio frequency identificationPayment architectureSubstation equipmentShortest distanceUhf antennas

The invention discloses a high-frequency and ultrahigh-frequency double-interface SIM (subscriber identity module) card and a radio-frequency identification system for mobile payment. The SIM card comprises an SIM card chip, an ultrahigh-frequency antenna, an ultrahigh-frequency read / write chip, a high-frequency antenna and an high-frequency read / write chip, wherein the SIM card chip is connected with the high-frequency read / write chip; the high-frequency read / write chip receives a high-frequency signal sent by a reader through the high-frequency antenna, demodulates the signal and sends the demodulated signal to the SIM card chip. The radio-frequency identification system disclosed by the invention realizes non-contact short-distance radio-frequency identification of the mobile phone by use of the high-frequency and ultrahigh-frequency double-interface SIM card and without replacing a new mobile phone, and avoids misoperation on the other high-frequency and ultrahigh-frequency double-interface SIM cards around.

Owner:SHANGHAI QUANRAY ELECTRONICS

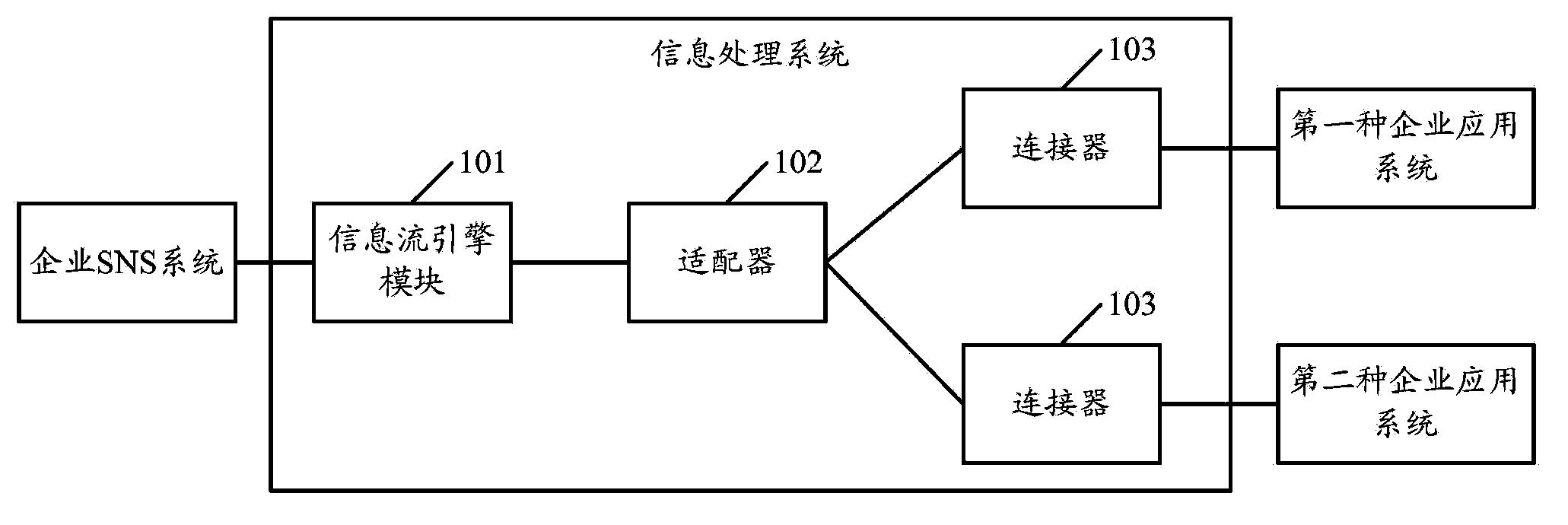

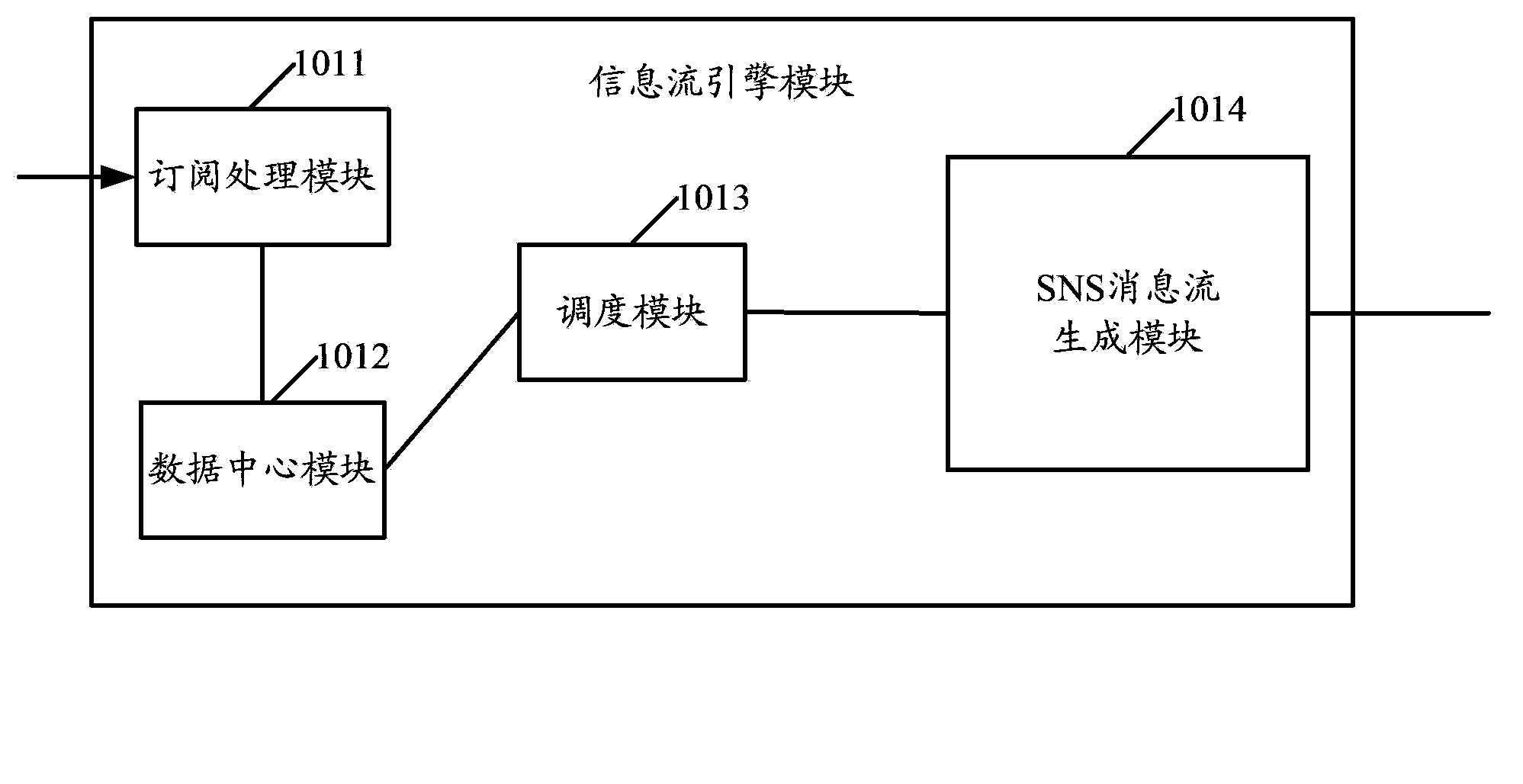

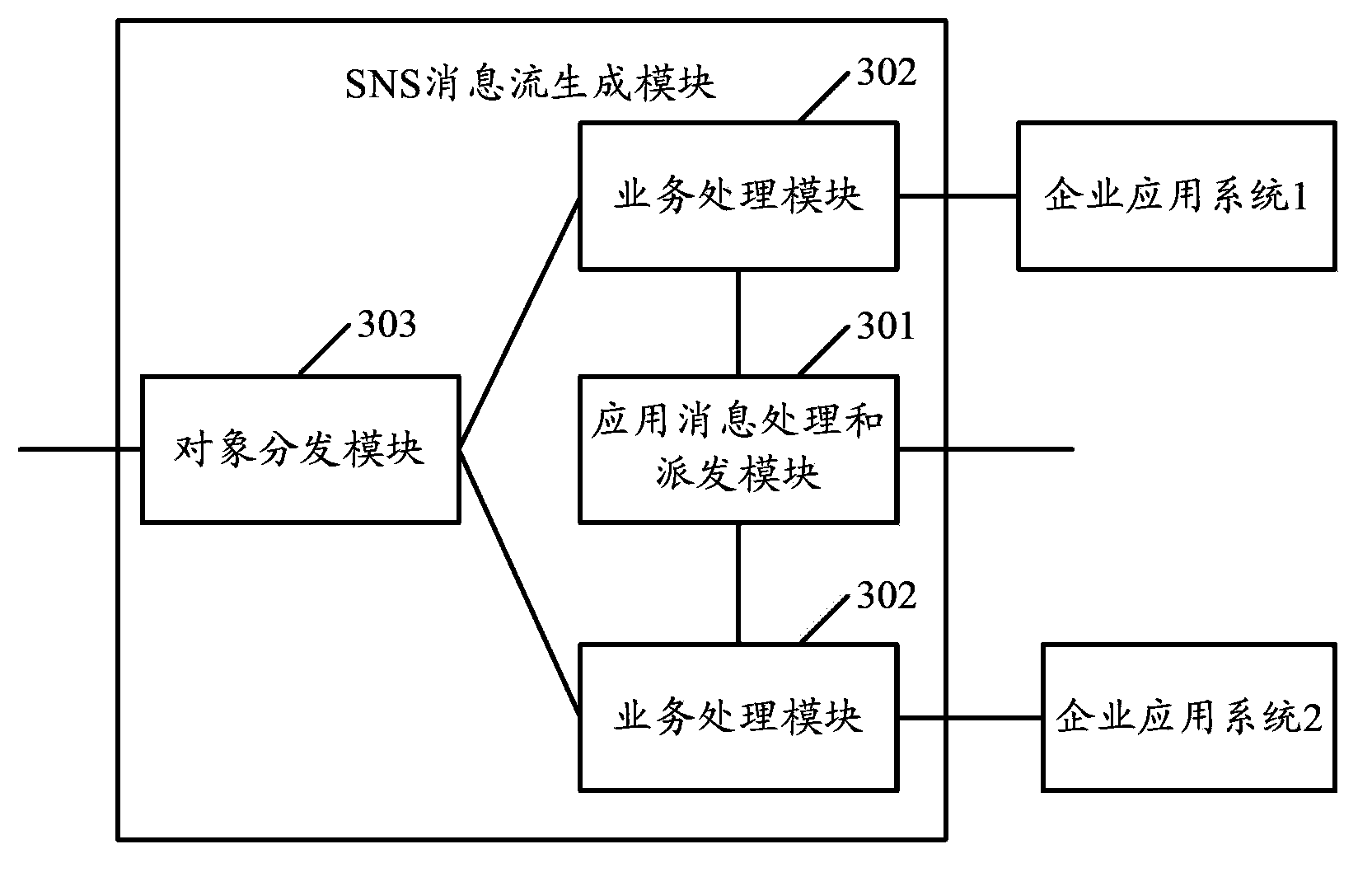

Information processing system and method for network service

ActiveCN103905521ALow retrofit costExempt from modificationTransmissionMessage queueInformation processing

The invention discloses an information processing system and method for a network service. The system comprises an information flow engine module, an adapter and one or more connectors, and the connectors of different kinds are connected with enterprise application systems with different communication modes. The information flow engine module manages subscription relation information of a user and the enterprise application systems, task information for acquiring enterprise application information is generated and is written in a task queue, and uniform application messages in a uniform application message queue are read and are converted into SNS message flow. The connectors are used for being connected with the enterprise application systems, the task information of the corresponding enterprise application system in the task queue is read, enterprise application information is acquired, the enterprise application information is written into the enterprise application message queue. The adapter is used for reading the enterprise application messages from the enterprise application message queue and converting the enterprise application messages into uniform application messages, and the uniform application messages are written into the uniform application message queue. According to the system and method, the cost for achieving enterprise socialization network services can be saved.

Owner:CHINA MOBILE COMM GRP CO LTD

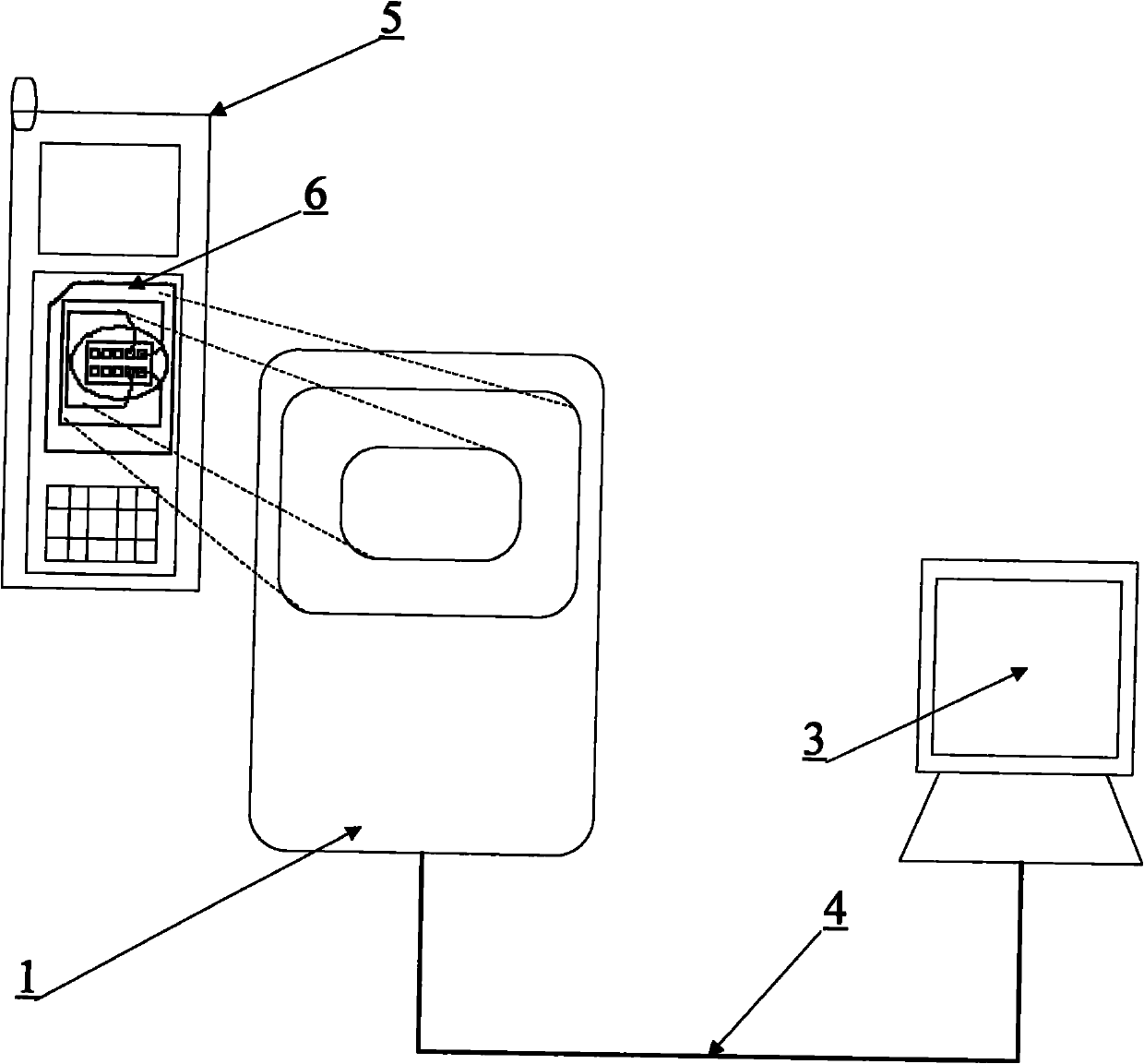

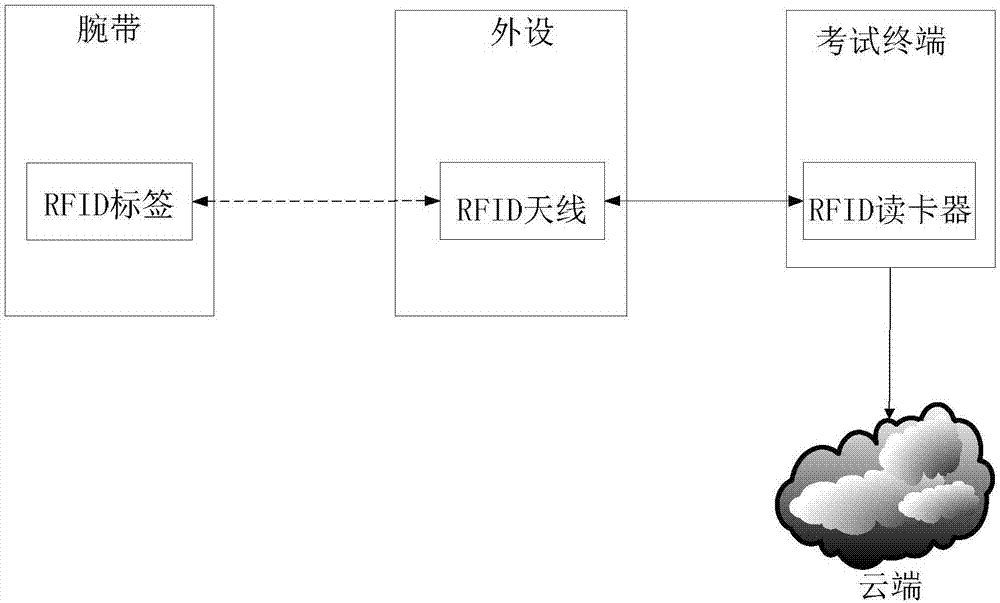

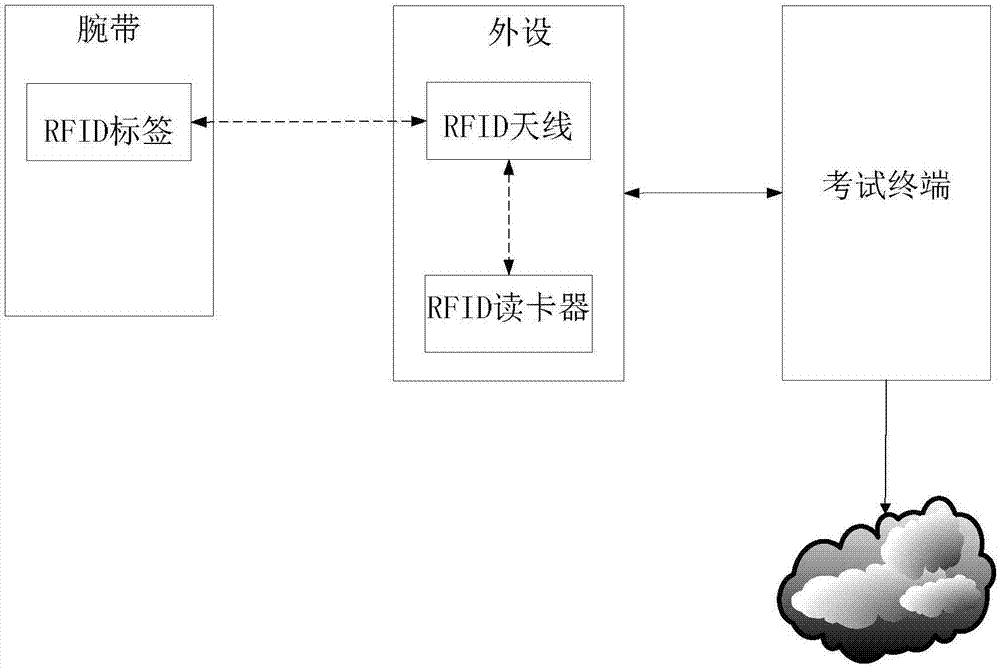

Computerized surrogate exam-taker prevention system

InactiveCN107424098ALow implementation costImprove reliabilityData processing applicationsElectronic waste recyclingEmbedded systemUpgrade

The present invention provides a computerized surrogate exam-taker prevention system which comprises a wristband, a peripheral and an exam terminal. The wristband is internally provided with an RFID tag which stores a unique ID. The peripheral is internally provided with an RFID antenna matched with the RFID tag, and a mouse pad is electrically connected with the exam terminal. The invention provides the computerized surrogate exam-taker prevention system, the RFID technology is only used for an examination management end, the monitoring of an implementing identity can be solved and the upgrade or transformation of a whole examination system is not needed, and the system has low cost and high reliability.

Owner:QICHEN GUANGZHOU ELECTRONICS TECH CO LTD

Method for treating waste acids with iron-based oxide residues

InactiveCN108947021ANot easy to migrateStable structureWater contaminantsTreatment involving filtrationTherapeutic effectElectric field

The invention relates to a method for treating waste acids with iron-based oxide residues and belongs to the technical field of waste acid treatment. The method comprises the following steps: smashingiron-based oxide residues and screening with a 100-300 mesh sieve, cleaning for 2-3 times with deionized water, distilled water or pure water, and then drying, thereby acquiring iron-based oxide residue powder; adding the iron-based oxide residue powder into the waste acids and uniformly mixing, thereby acquiring a mixed system; regulating pH value to 4-5 with alkali; under an external field condition, heating the mixed system to 60-70 DEG C, shaking for 1-2h, standing for 1.5-2.5h and performing solid-liquid separation, thereby acquiring supernate and solids on bottom, wherein the external field is one or more of ultrasonic field, microwave field, magnetic field, electric field and pressurizing field. The method for treating waste acids with iron-based oxide residues provided by the invention has the advantages that the pipelines and valves are not blocked, the running of the whole system is stable, the treatment effect is excellent, and the like.

Owner:KUNMING UNIV OF SCI & TECH

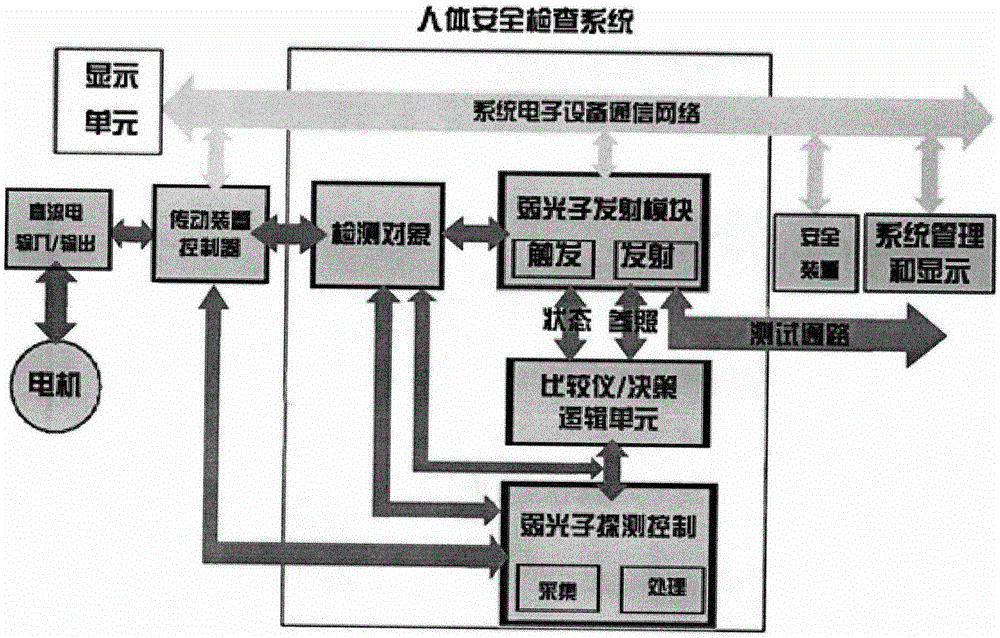

Rapid human body safety inspection system

InactiveCN105223624AAccurate detectionAvoid harmNuclear radiation detectionHuman bodyPhoton emission

The invention provides a rapid human body safety inspection system, which comprises a weak photon emission module, a weak photon detection control module, a logic unit, a safety device, a system management and display module, a transmission device controller, a display unit and a transmission device, wherein the weak photon emission module, the safety device, the system management and display module, the transmission device controller and the display unit are communicated via a system electronic equipment communication network; the transmission device is connected with the transmission device controller; a detected object is automatically transmitted to a detection area via the transmission device; the weak photon emission module emits low dose X rays to penetrate through the detected object; and after the weak photon detection control module acquires the weak photons, data processing is carried out via the logic unit, the weak photons are transmitted back to the system management and display module, and objects hidden inside and outside the detected object body are displayed on the display unit. The fact that body surface characteristics are not displayed by the weak photon detection technology is adopted, the detection dose is low, and foreign bodies inside and outside the human body can be detected accurately.

Owner:安徽合创智诚安全技术有限公司

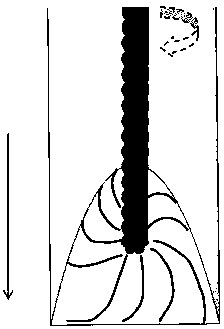

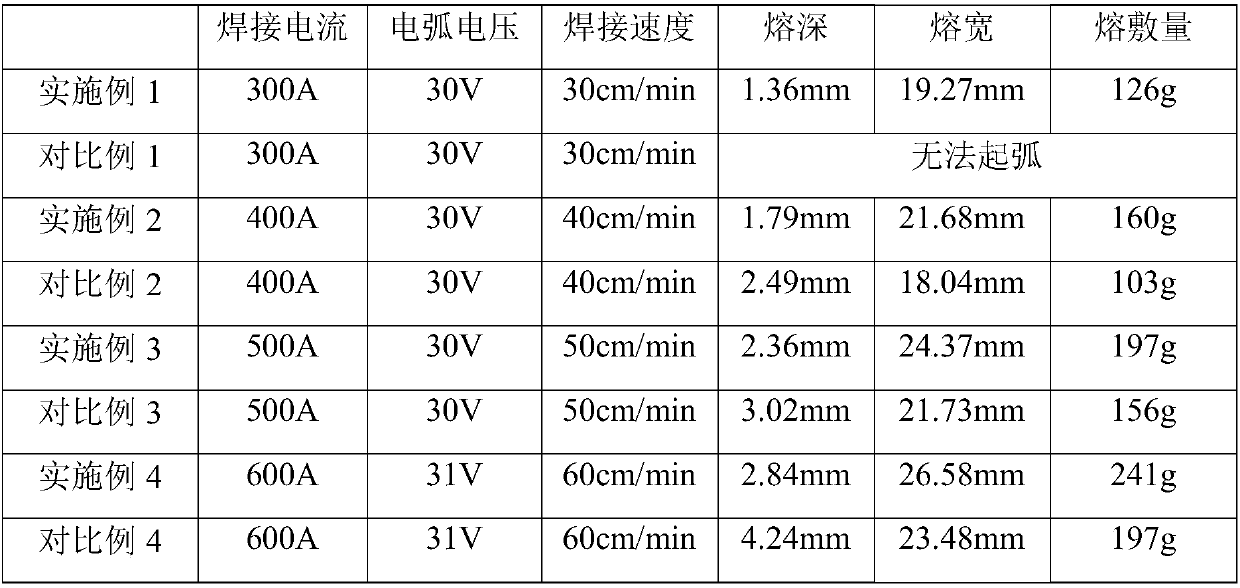

Thick-wire single-power-source shallow-fusion-depth high-efficiency submerged-arc automatic surfacing process method

The invention discloses a thick-wire single-power-source shallow-fusion-depth high-efficiency submerged-arc automatic surfacing process method. The method comprises the following steps that a weldingwire is used for winding six fine welding wires around one center welding wire to be spiraled into a spiral structure; and the prepared welding wire is fed into a welding area of a submerged-arc automatic trolley through a wire guide pipe and is connected with a welding power source to transmit welding current, the submerged-arc automatic trolley can move along the joint of a base material, meanwhile, a flux is applied to the welding area in an assisted mode until surfacing is completed. According to the method, the rotation motion of the welding arc is further driven under the action of mechanical rotation generated during feeding of the spiral-shaped single wires, a liquid molten pool is forced to carry out fluid motion perpendicular to the fusion depth direction so as to reduce the convection motion of the metal in the molten pool to the bottom, so that the heat inside the molten pool is conducted in the width direction of a weld joint, then the melting amount of the root of the molten pool is reduced, and a welding bead is enabled to be expanded in the width direction. According to the process method, the cable type welding wire shallow fusion depth with the diameter of 6.0 mmand wide-bead submerged-arc automatic surfacing are achieved, extremely high surfacing efficiency is realized, meanwhile, the welding cost can be further reduced.

Owner:NANJING INST OF TECH

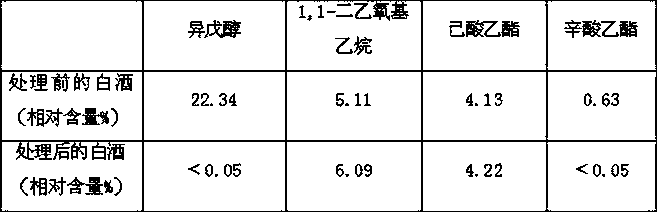

Biochemical method for removing impurities in Baijiu

PendingCN107916205AEfficient removalSoft tasteAlcoholic beverage preparationEggshellHazardous substance

The invention provides a biochemical method for removing impurities in Baijiu and provides a method for removing the impurities in the Baijiu by utilizing a bioactive substance. According to the biochemical method provided by the invention, one bioactive substance (whole egg liquid, i.e., raw eggs without egg shells (containing egg white and yolks)) has a mutual effect with the impurities in the Baijiu to be subjected to biochemical reaction; then filtering and distillation methods are carried out to obtain the treated Baijiu. By adopting the biochemical method provided by the invention, the impurities in the Baijiu can be effectively removed, so that the treated Baijiu has a soft taste, people do not get headache after drinking the Baijiu, the discomfort is reduced and damages, caused byharmful substances in the Baijiu, to human bodies are reduced. The biochemical method provided by the invention has the advantages of low requirements on equipment, low technical threshold, short response time, simplicity in operation and low cost. An old distillery does not need to be transformed in a large scale, so that a lot of funds can be saved.

Owner:孙欧希

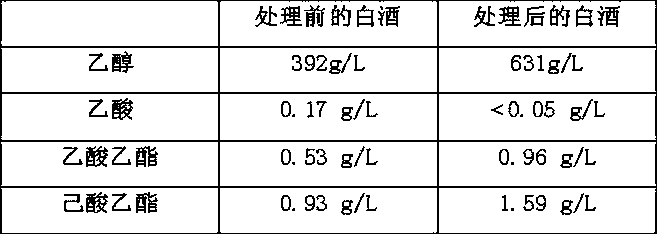

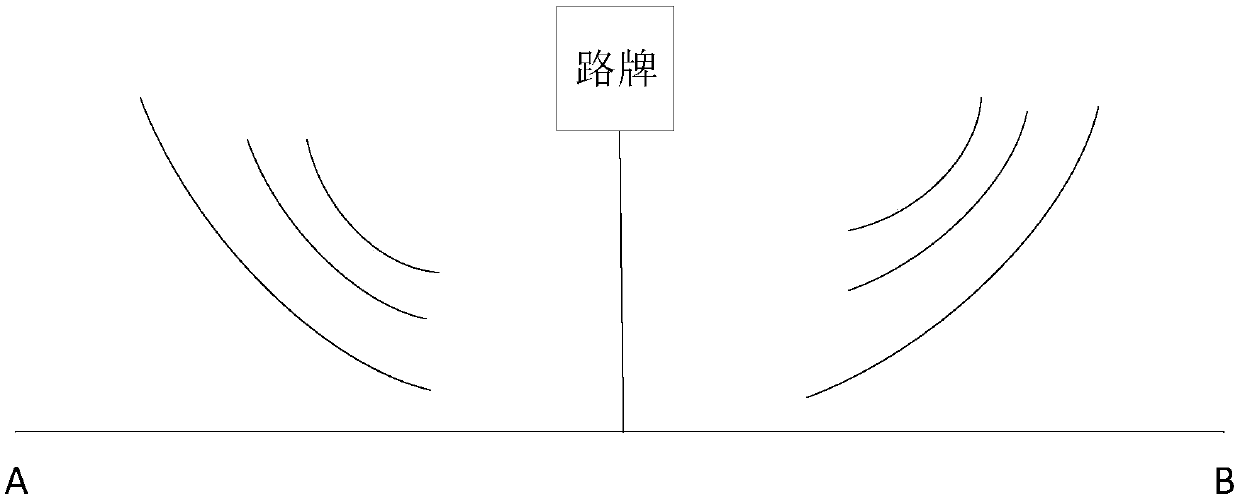

Highway congestion judgment method

InactiveCN107909814ARealization of congestion judgmentExempt from modificationDetection of traffic movementReal-time computingRoad congestion

The invention provides a highway congestion judgment method. The highway congestion judgment method comprises the following steps: periodically sending inquiry data by a guide board; when the guide board receives the response data sent by the driving card for the first time, recording the identity information of the driving card, and starting the timing; determining whether the response data is received in each period or not by the guide board; if yes, continuously and periodically determining whether the response data is received or not in each period; if not, determining whether the number of the periods without receiving the response data is greater than a preset value or not; and if not, continuously and periodically determining whether the response data is received or not in each period; and if yes, stopping the timing; determining whether the timing duration is larger than the preset duration by the guide board, if not, indicating that the road is smooth; if yes, indicating the road congestion; and releasing the storage space. According to the highway congestion judgment method, the highway congestion judgment can be achieved without monitoring equipment and the transformation of a highway.

Owner:胡晓华

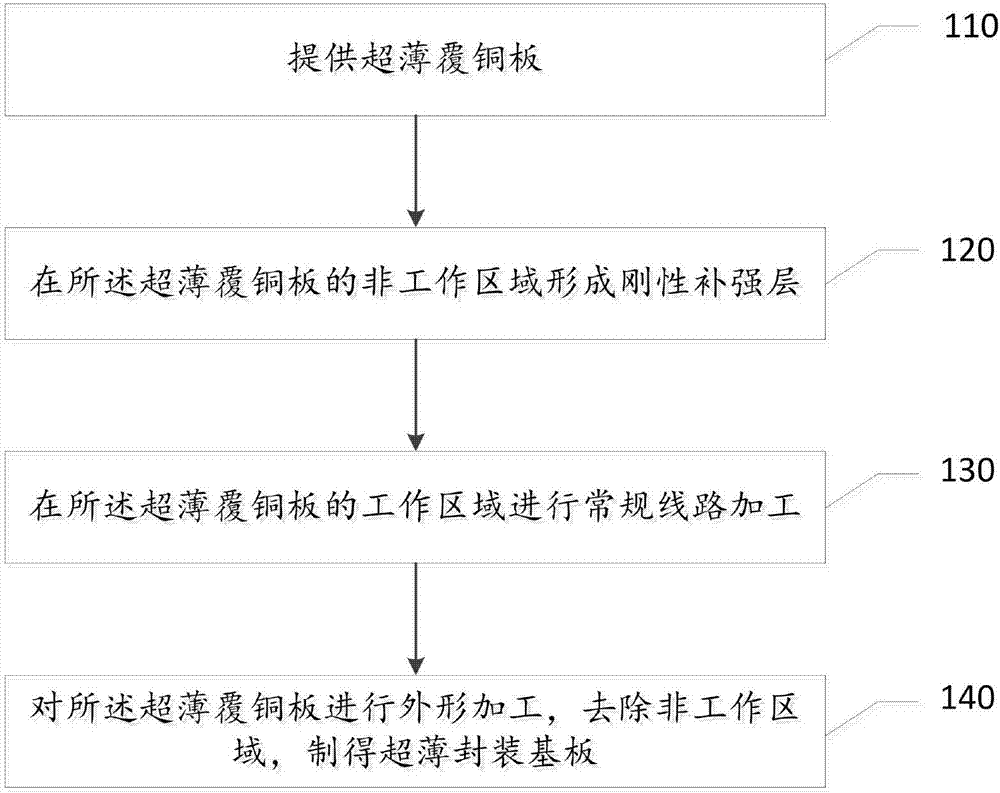

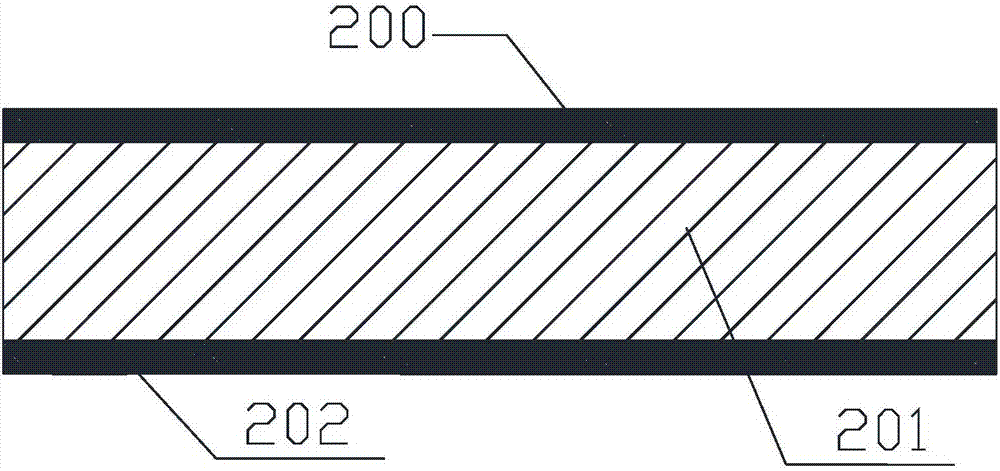

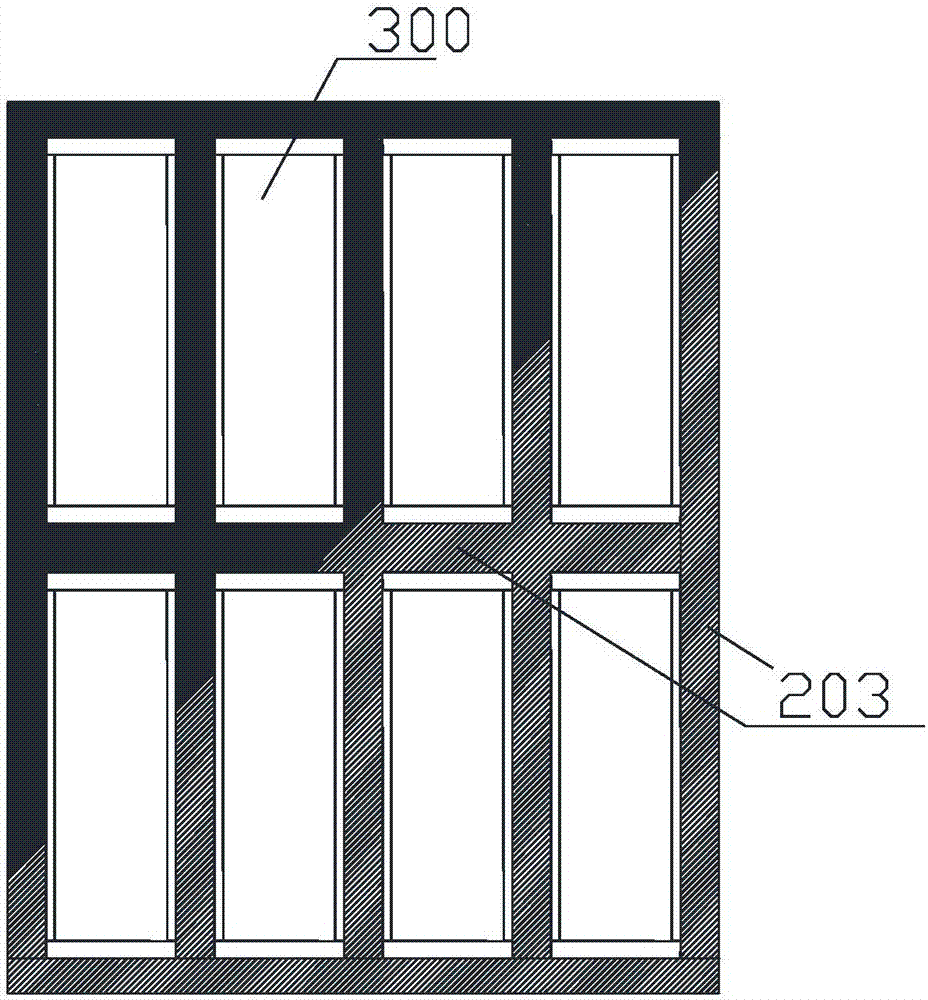

Manufacturing method of ultrathin package substrate and related product

ActiveCN107089641AHigh strengthAvoid deformationDecorative surface effectsSolid-state devicesCopperUltimate tensile strength

The invention discloses a manufacturing method of an ultrathin package substrate and a related product. The manufacturing method can help solve a technical problem that the ultrathin package substrate is low in machinability, each to be injured or damaged in the machining process due to insufficient strength. The method comprises the following steps: providing an ultrathin copper-clad plate; forming a rigid reinforcing layer on a non-working region of the ultrathin copper-clad plate; performing conventional line machining on the working region of the ultrathin copper-clad plate; and performing shape machining on the ultrathin copper-clad plate to remove the non-working region, thereby manufacturing the ultrathin package substrate.

Owner:SHENNAN CIRCUITS

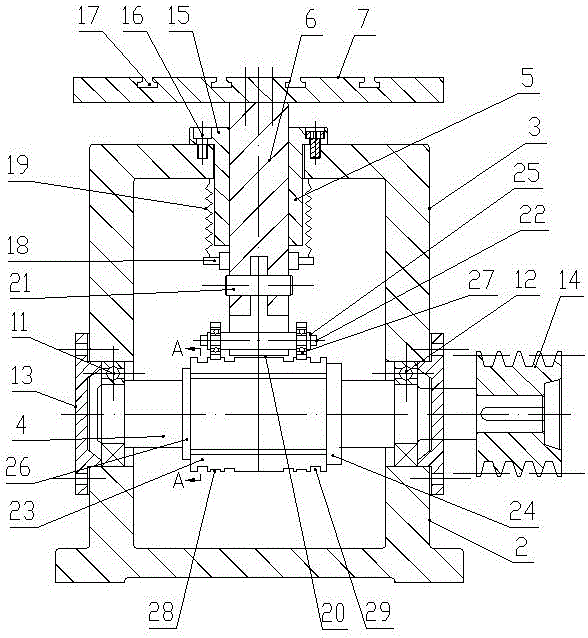

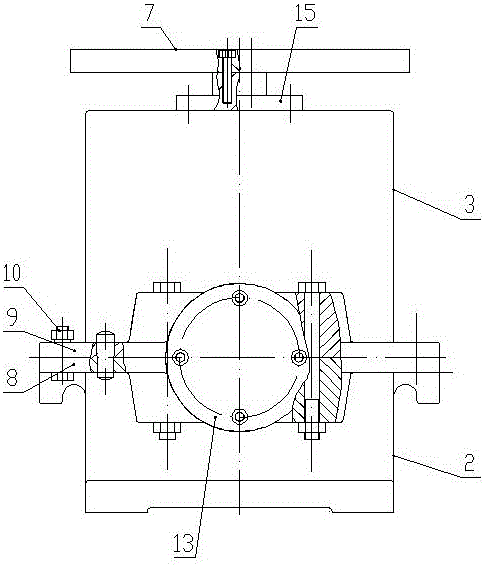

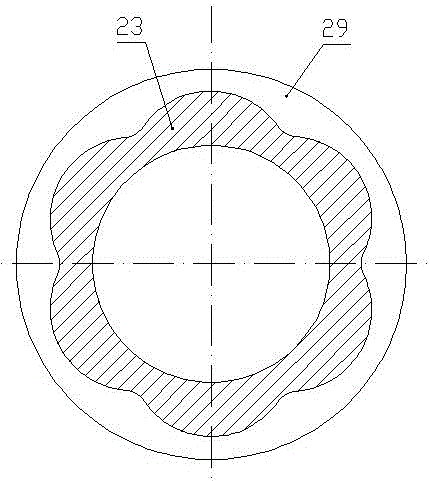

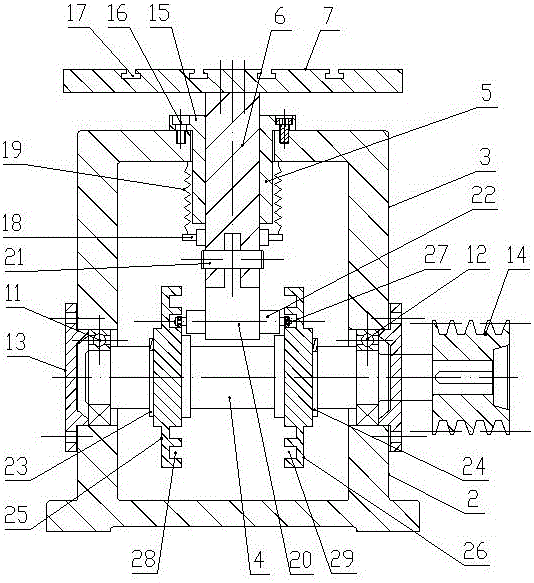

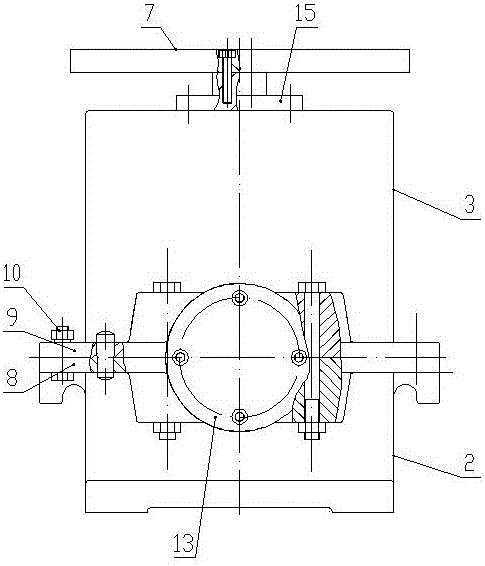

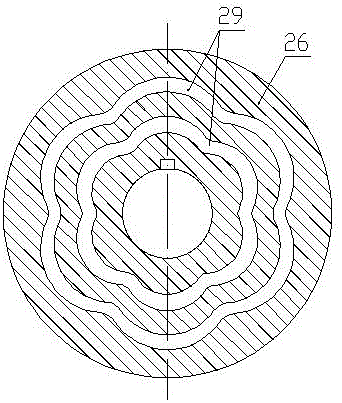

Roller type low-frequency vibrational drilling worktable

ActiveCN106424831ALarge axial vibrationLarge frequency axial vibrationMetal working apparatusBoring/drilling componentsEngineeringDrive motor

The invention provides a roller type low-frequency vibrational drilling worktable which comprises a driving motor, a lower box body, an upper box body, a rotary driving shaft, a linear bearing, a linear driving shaft and a table plate. The upper end of the lower box body abuts and is connected with the lower end of the upper box body by means of fastening bolts. The left end and the right end of the rotary driving shaft are respectively rotationally arranged on the left sides and the right sides of the lower box body and the upper box body. The linear bearing of which the lower end extends into the upper box body is arranged at the top of the upper box body. The linear driving shaft penetrates the linear bearing in a sliding manner. The upper end of the linear driving shaft is fixedly connected with the lower surface of the table plate. A fixed frame is arranged at the lower part of the linear driving shaft. A compression spring is arranged between the lower surface of the top of the lower box body and the fixed frame. The lower end of the linear driving shaft is in transmission connection with the rotary driving shaft through a low-frequency vibration mechanism. The roller type low-frequency vibrational drilling worktable can realize stepless adjustment of the vibration frequency, the low-frequency vibration amplitude can be adjusted, a set of available vibration and drilling parameters can be conveniently found, and processed parts can be processed.

Owner:KEYIZHAN INTELLIGENT EQUIP CO LTD +1

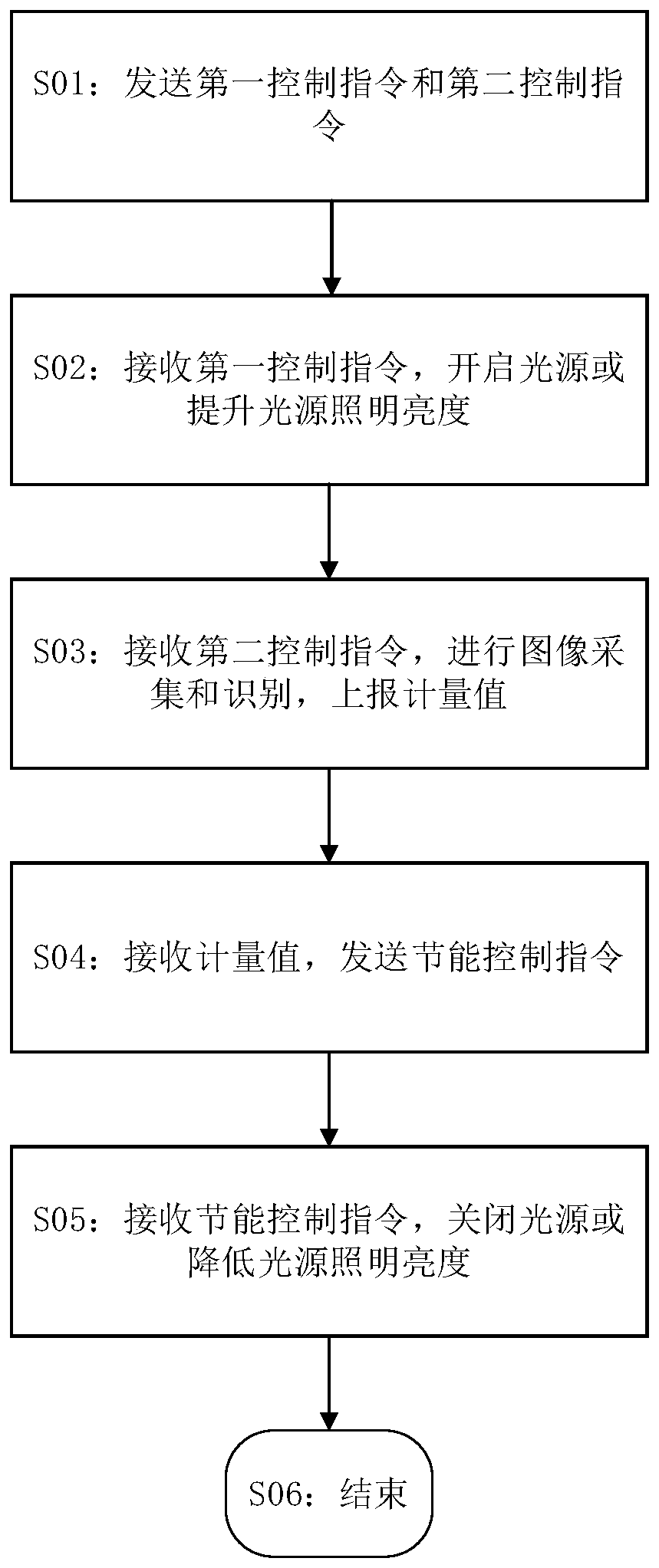

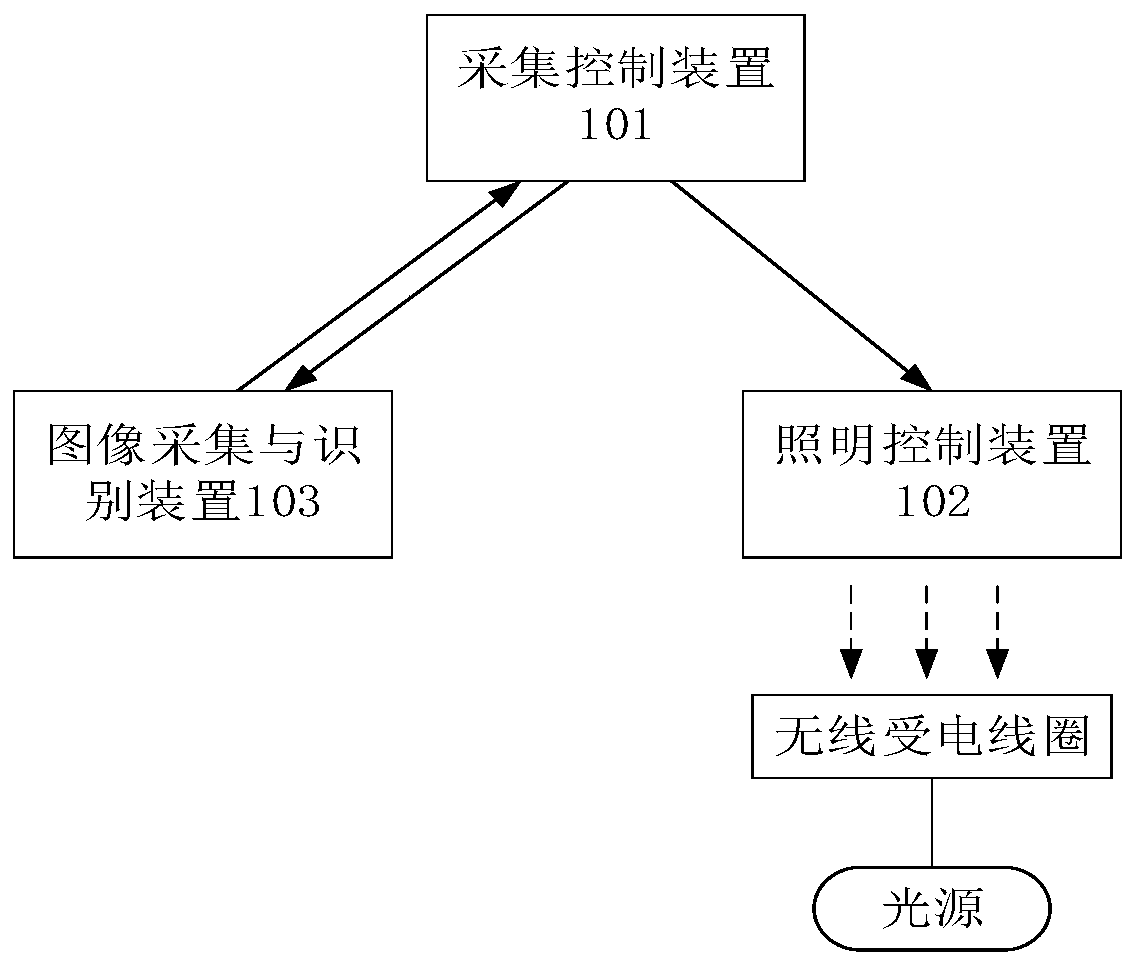

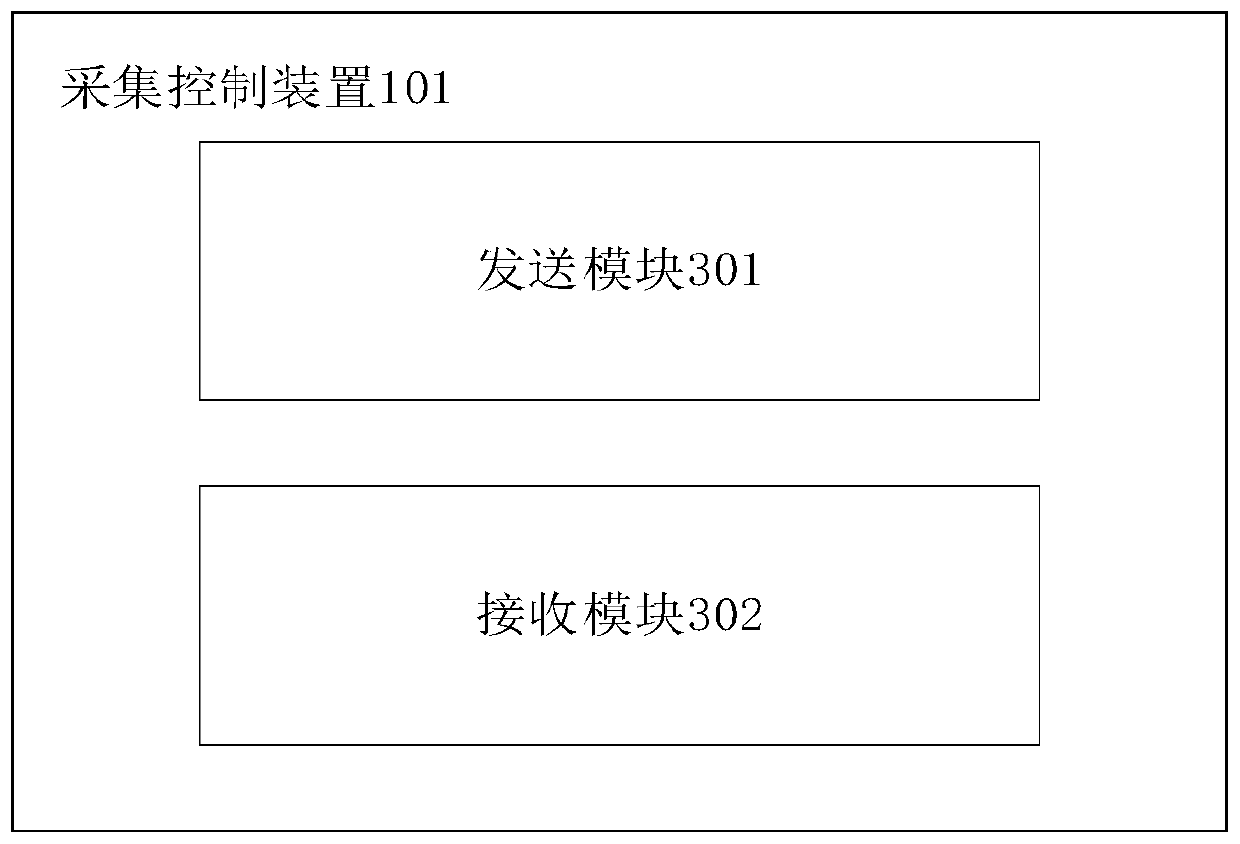

Image data acquisition method and device, computer readable medium and system thereof

InactiveCN109977938AEnsure resolution accuracyExempt from modificationTelevision system detailsCharacter and pattern recognitionData acquisitionIdentification device

The invention provides a measurement value acquisition control method and device for a measurement target, and relates to the field of metering target image data acquisition. The method comprises thesteps of when image acquisition needs to be carried out on a metering target, sending an acquisition instruction to an illumination control device and an image acquisition and identification device ofa light source which are located in an acquisition geographic area corresponding to the image acquisition and identification device and separated from the image acquisition and identification deviceso as to start the image acquisition and identification of the field data; and receiving the metering value identified by the image acquisition and identification device, or the information which is reported by the image acquisition and identification device and indicates the insufficient illumination brightness. According to the present invention, the illumination degree of the image acquisitionis ensured by utilizing the illumination facilities in the surrounding environment, and other equipment or the power supply circuits do not need to be transformed.

Owner:JIANGSU ELECTRIC POWER CO

Groove type low-frequency vibration drilling workbench

ActiveCN106270640AExempt from modificationEasy to useMetal working apparatusBoring/drilling componentsFixed frameEngineering

The invention discloses a groove type low-frequency vibration drilling workbench which comprises a driving motor, a lower box body, an upper box body, a rotary driving shaft, a linear bearing, a linear driving shaft and a platen. The upper end of the lower box body and the lower end of the upper box body are in butt connection through a fastening bolt. The left end and the right end of the rotary driving shaft are rotationally arranged on the left side and the right side of the lower box body and the upper box body respectively. The top of the upper box body is provided with the linear bearing with the lower end stretching into the upper box body. The linear driving shaft penetrates in the linear bearing in a sliding mode. The upper end of the linear driving shaft is fixedly connected with the lower surface of the platen. The lower portion of the linear driving shaft is provided with a fixing frame. A compression spring is arranged between the lower surface of the top of the lower box body and the fixing frame. The lower end of the linear driving shaft and the rotary driving shaft are in driving connection through a low-frequency vibration mechanism. According to the groove type low-frequency vibration drilling workbench, stepless adjustment for the vibration frequency can be achieved, the amplitude of low-frequency vibration can be adjusted, a set of available vibration drilling parameters can be conveniently found, and a to-be-machined part is machined.

Owner:CONPROFE TECH GRP CO LTD +1

A device for predicting and displaying rigid body collision trajectory

ActiveCN104376154BObserve the prediction results in real timeImprove collision effectSpecial data processing applicationsSoftware systemSimulation

The invention provides a rigid-body collision track prediction display unit. The rigid-body collision track prediction display unit is composed of an aerial camera, a collision view angle camera, a wearable observation device, an aiming adapter, data processing equipment and a rigid-body collision track prediction software system. The rigid-body collision track prediction software system is configured in the data processing equipment, and is divided into a camera calibration system, an object identification system, a spatial posture calculating system and a rigid-body track estimation system. The spatial positions of rigid bodies on the working plane and the posture and force of the colliding party are obtained by analyzing video data transmitted by the aerial camera and the collision view angle camera by combination with spatial pose information transmitted by the aiming adapter, so that possible movement tracks generated after the colliding party and the collided party collide are obtained through calculation, and the tracks and actual scenes are overlapped to be displayed on a display screen of the wearable observation device. The collision tracks can be predicted and displayed in real time, and users can adjust the positions and movement states of the rigid bodies before collision happens.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

Method for inhibiting malignant reduction swelling of iron pellets

InactiveCN113073196AInhibition of malignant reduction expansionAvoid a series of problems caused by blast furnace smeltingRoastingSILICONE DIOXIDE

The invention discloses a method for inhibiting malignant reduction swelling of iron pellets. The method comprises the following steps of, (1), determining proper preheating and roasting temperatures through a pellet test, and carrying out fine tuning optimization by controlling the preheating temperature to be 800-850 DEG C and the roasting temperature to be 1200-1220 DEG C; (2) finely grinding iron ore concentrate until the particle size of -500 meshes accounts for more than 70%; (3) adding minerals of which the main component is silicon dioxide or the iron ore concentrate of which a small amount of gangue component is mainly silicon dioxide into pelletizing raw materials as a promoting agent to promote the diffusion of volatile components generated during preheating roasting, so as to effectively inhibit the reduction swelling of the pellets; and (4) taking at least one of the steps (1), (2) and (3) to control the reduction swelling rate of the pellets within 20%. According to the method, the reduction swelling rate of the pellets subjected to malignant reduction swelling can be reduced to be within the normal reduction swelling range.

Owner:包钢集团矿山研究院(有限责任公司) +1

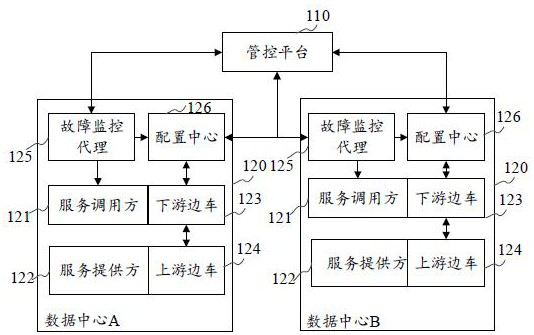

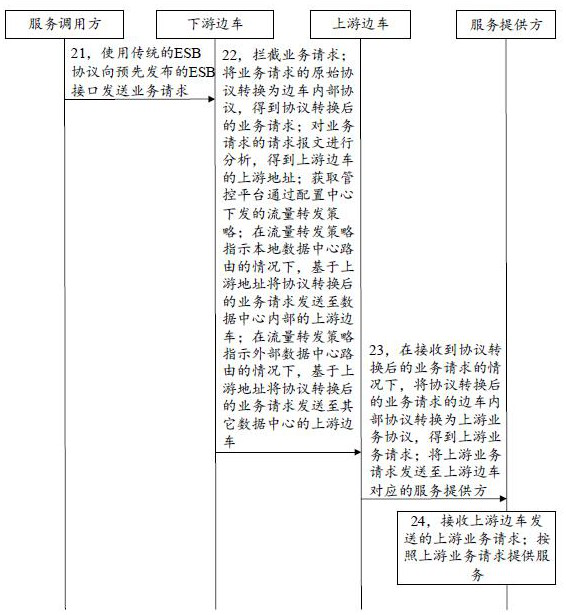

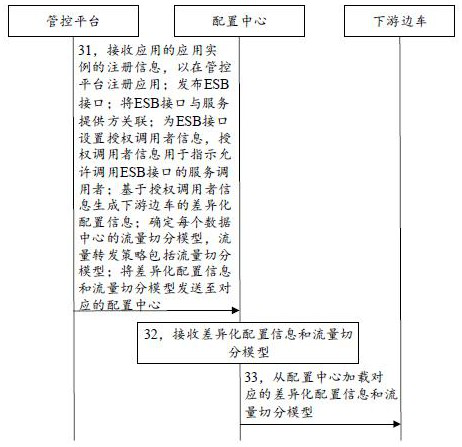

Application multi-activity system under distributed ESB scene based on service grid technology

ActiveCN114024826AThe problem of ensuring that requests are not interruptedSolve maintenance costsTransmissionComputer networkEngineering

The invention relates to a system for realizing application multi-activity in a distributed ESB scene based on a service grid technology, which belongs to the technical field of communication and comprises a management and control platform and at least two data centers, the data centers run a service calling party and a service provider corresponding to the same application, a downstream side vehicle for monitoring the service calling party, an upstream side vehicle which is in communication connection with the downstream side vehicle and is used for monitoring the service provider, a fault monitoring agent for monitoring the fault condition of the service provider, and a configuration center which is in communication connection with the downstream side vehicle; and the management and control platform is in communication connection with the configuration center and the fault monitoring agent. The problem that an ESB cannot achieve addressing of a plurality of data centers and cannot ensure that any data center can flow back to other data centers after a service fault, thereby ensuring that a service request is not interrupted can be solved; addressing to a plurality of data centers can be realized; and multi-data center routing is realized through a downstream side vehicle, and the capabilities of active-active, even multi-active and the like of service applications are ensured.

Owner:江苏博云科技股份有限公司

A method of activated flotation of sulfide minerals suppressed by cyanide ions

The invention relates to a method for activating and floating sulfide minerals suppressed by cyanide ions during separation of non-ferrous multi-metal sulfide ores and comprehensive recovery of valuable elements in gold ore cyanide tailings. The method comprises the following steps of: (1) adding a soluble salt into ore slurry, and / or filling O2-containing gas and / or SO2-containing gas into the ore slurry to activate suppressed target minerals; and (2) floating to obtain target sulfide mineral concentrate, wherein the soluble salt in the step (1) is one or a mixture of more than two of inorganic sulfite, pyrosulfite or thiosulfate. According to the method disclosed by the invention, procedures for densely dehydrating and removing reagents with active carbon are eliminated, agents such as sulfuric acid and the like are not added into the ore slurry, activation and floatation of sulfide minerals are realized, a high-quality sulfide mineral concentrate product is obtained, and the recovery rate of the sulfide mineral concentrate product is increased greatly.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

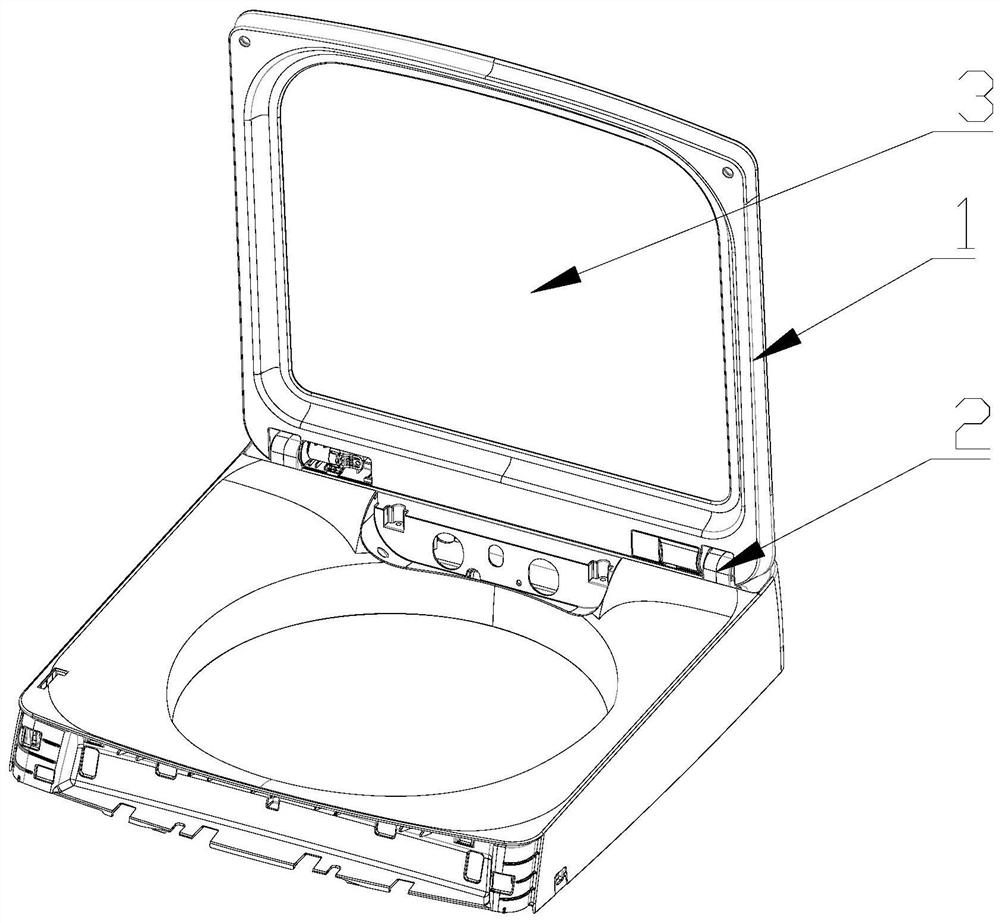

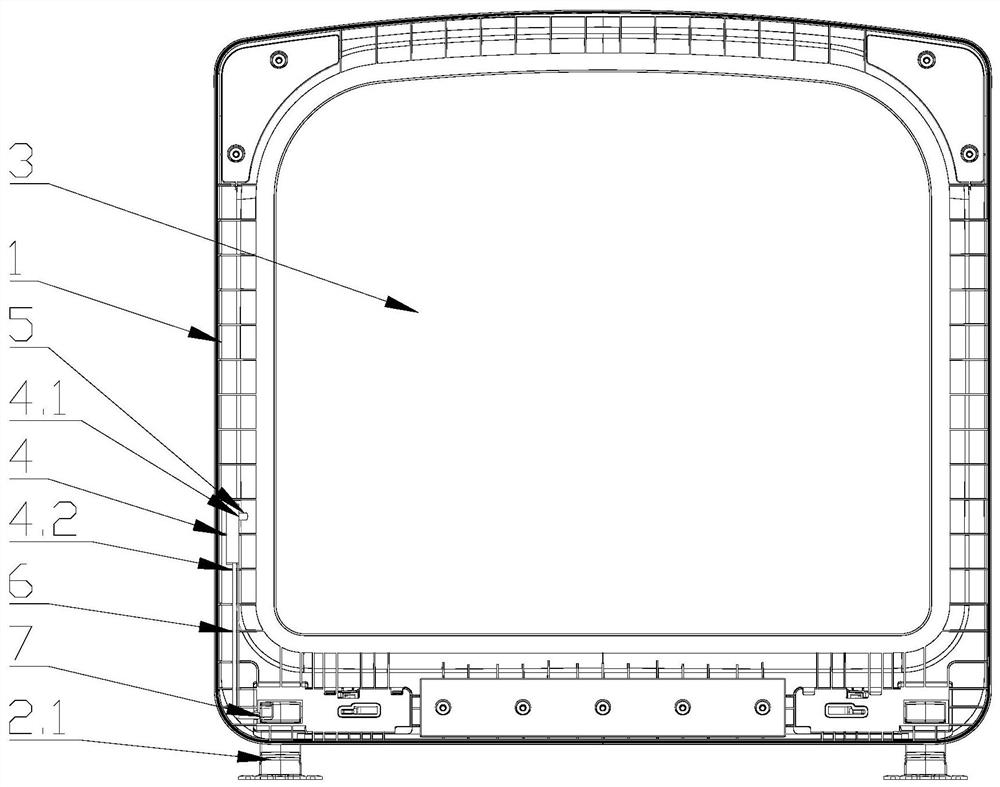

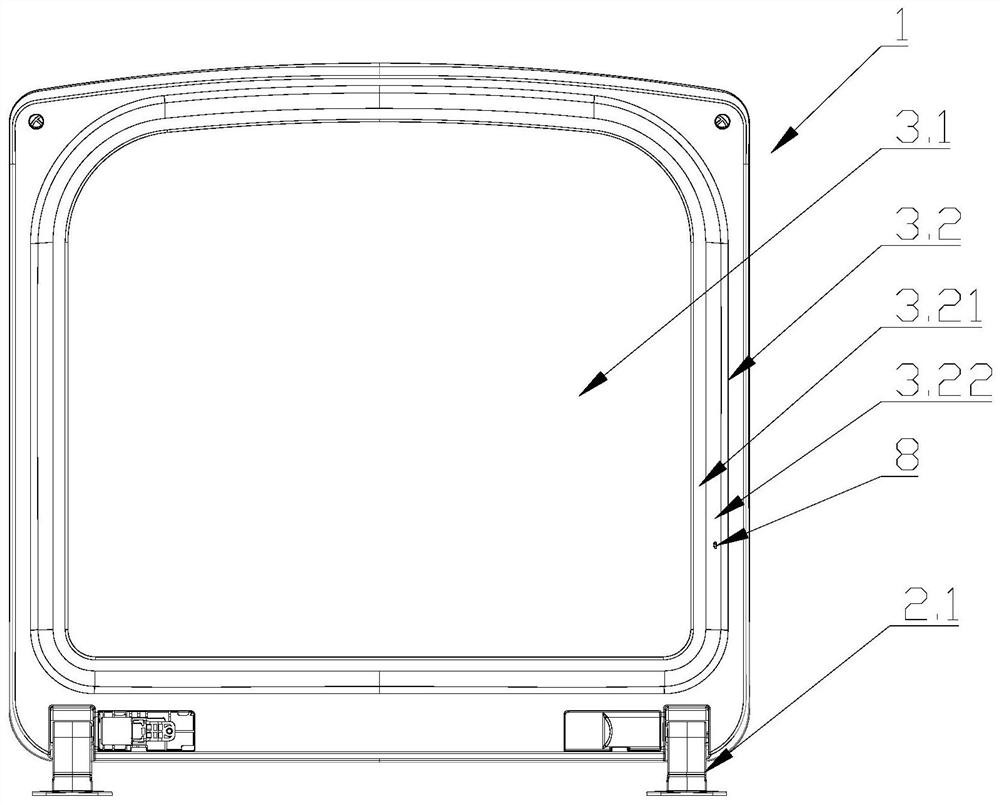

Washing machine and control method thereof

PendingCN113445271AObserve the impactAffect washingOther washing machinesControl devices for washing apparatusLaundry washing machineMachine control

The invention discloses a washing machine. The washing machine comprises a door body and an observation window arranged in the door body; a gas power device is arranged on the door body; the gas power device comprises a gas outlet; the gas outlet is arranged to be communicated with the observation window; and the gas power device blows gas to the observation window through the gas outlet. Meanwhile, the invention further discloses a control method of the washing machine. The control system of the washing machine controls the gas power device to be turned on or turned off according to a received instruction; and / or the control system of the washing machine controls the gas power device to be started or stopped according to the working parameters of the washing machine. According to the washing machine, the gas power device is arranged on the door body to blow gas to the observation window, so that mist and / or attached water drops on the observation window are / is removed, and therefore, the situation that the observation of a user on the washing condition in the washing machine is influenced due to the fact that mist and the attached water drops are generated on the observation window is prevented.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

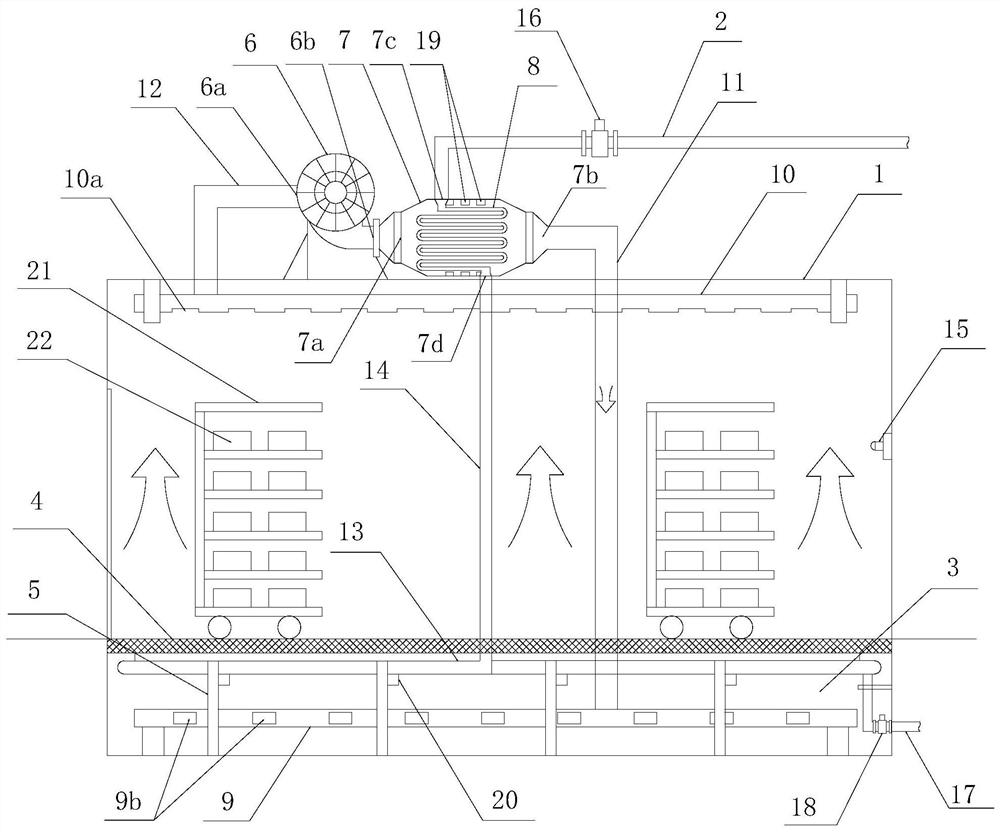

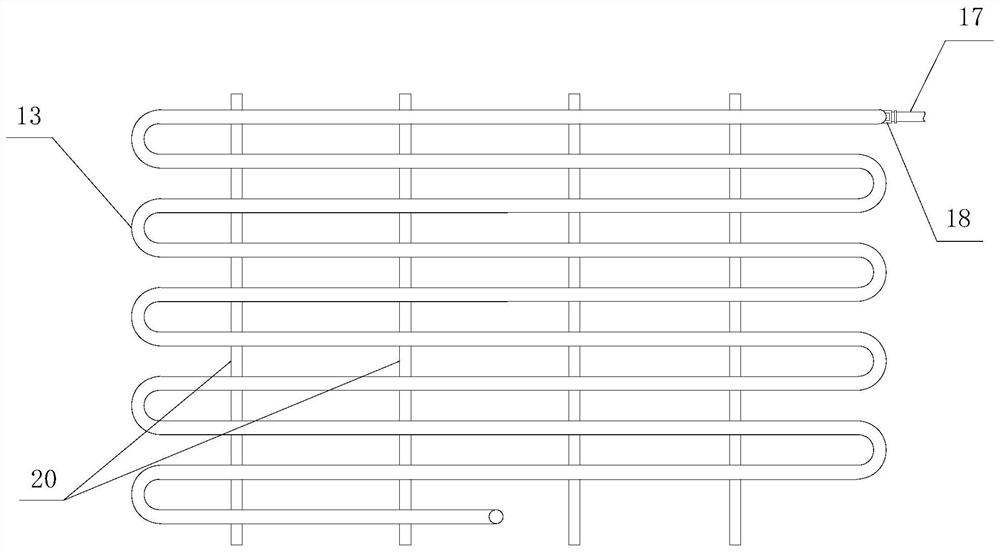

Efficient drying room for drying EPP product

PendingCN111854343AImprove drying uniformityEnsure shipment uniformityGranular material dryingDrying gas arrangementsThermodynamicsEngineering

The invention discloses an efficient drying room for drying an EPP product. The efficient drying room comprises a room body built on the ground and a steam supply pipeline; the steam supply pipeline conveys steam to the room body from a steam supply source; the efficient drying room is characterized in that a concave cavity is dug in the ground in the room body; a cover plate provided with meshescovers the concave cavity; the efficient drying room further comprises an airflow circulation radiating mechanism; the airflow circulation radiating mechanism comprises a draught fan and a radiating air bellow arranged outside the room body, a bottom wind pipe arranged in the concave cavity and provide with an air supply outlet, an S shaped thread radiating pipe below the bottom wind pipe, and a top wind pipe arranged on the top of the interior of the room body and provided with a return air inlet; the radiating air bellow is provided with an air bellow air inlet connected with the air outletof the draught fan and an air bellow air outlet connected with the bottom wind pipe via a pipeline; the air inlet of the draught fan is connected with the top wind pipe via a pipeline; an S shaped radiating copper pipe is arranged in the radiating air bellow; one end of the radiating copper pipe is connected with the steam supply pipeline; and the other end of the radiating copper pipe is connected with the S shaped thread radiating pipe via a pipeline. The efficient drying room is better in drying uniformity for the EPP product, is higher in drying efficiency, saves steam and reduces the production cost.

Owner:苏州祥侯新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com