Method for preparing Mo-Si-Al-K cold-rolling thin molybdenum plate band

A technology of mo-si-al-k and molybdenum plate, which is applied in the field of Mo-Si-Al-K cold-rolled thin molybdenum plate strip and its preparation, can solve the problems of not meeting the requirements of use, low high-temperature strength, easy deformation, etc. Problems, to achieve the effect of easy control of production process, high temperature strength, not easy to bend and brittle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

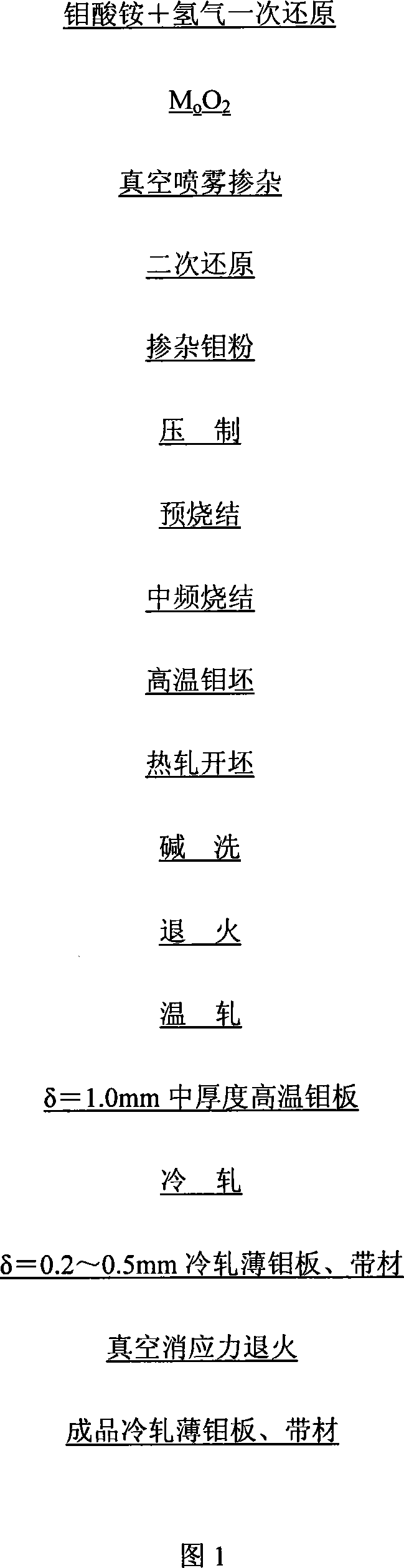

Image

Examples

Embodiment 1

[0014] Take ammonium dimolybdate as raw material and add hydrogen to carry out a reduction to obtain molybdenum dioxide, and take 30kg of molybdenum dioxide for later use; according to the weight percentage, it is 0.2% K 2 O, 0.13% SiO 2 、Al 2 o 3 0.001% weighed 100gK 2 SiO 3 , 6.5g Al(NO 3 ) 3 9H 2 O is dissolved for standby; molybdenum dioxide and K 2 SiO 3 , Al(NO 3 ) 3 The solution is doped in a double-cone vacuum drying doping pot. The pressure of the air compressor pump is 0.2MPa, the drying temperature of the doping pot is 70°C, and the vacuum degree inside the doping pot needs to be controlled above 0.06MPa. 29.0kg of molybdenum dioxide was obtained after mixing; the molybdenum dioxide was subjected to secondary hydrogen reduction in a four-tube high-temperature muffle furnace, and the hydrogen flow rate was 5.0M 3 / H, the loading capacity is 1.0kg / boat, and the speed of pushing away the boat is 4 boats / 60min, obtains Mo-Si-Al-K doped molybdenum powder 21.0k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com