Efficient drying room for drying EPP product

A high-efficiency and product technology, applied in drying, dryer, drying of solid materials, etc., can solve the problems of inconsistent drying time, reducing product drying efficiency, disturbing hot air, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

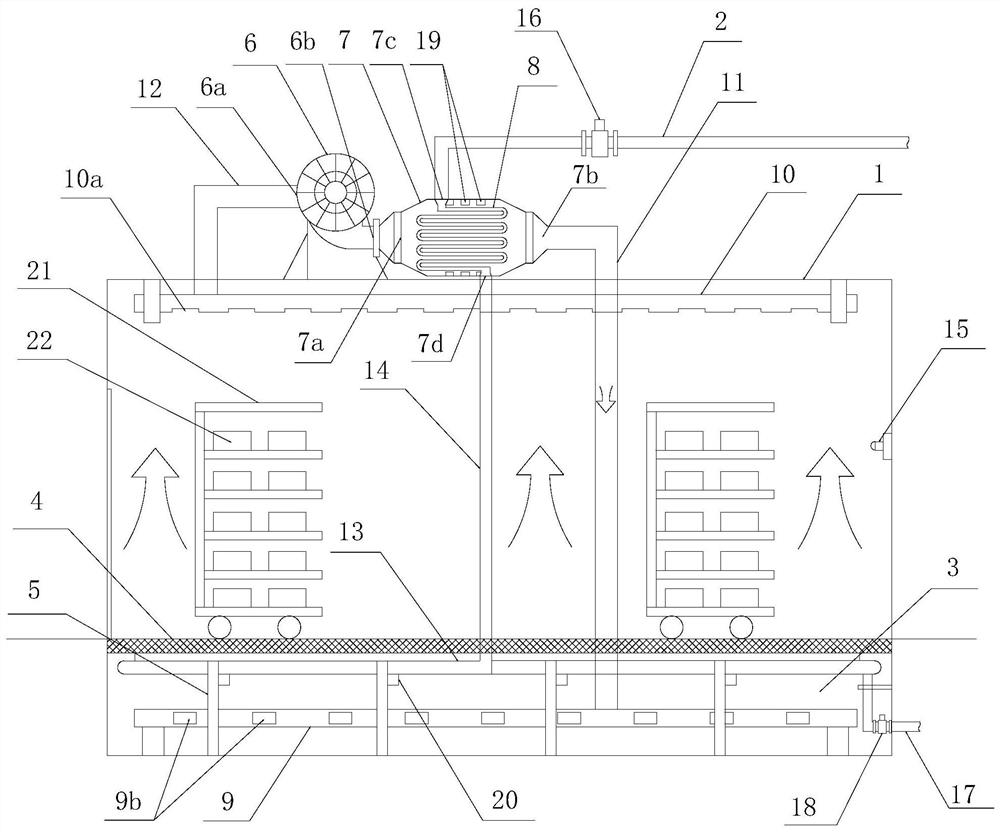

[0042] Example: Combine Figure 1~Figure 4 Shown this EPP product drying provided by the present invention is described as follows with the specific embodiment of high-efficiency drying room:

[0043] combine first figure 1 As shown, this high-efficiency drying room for drying EPP products is the same as the conventional technology. It has a room body 1 built on the ground and a steam supply pipeline 2 that transmits steam to the room body 1 from a steam supply source. The room body 1- The side is equipped with a rolling door (not marked in the figure), for the cart 21 of loading EPP product 22 to enter and exit. The steam supply pipeline 2 is connected with the steam output pipeline of the thermal power plant, and the steam is supplied by the thermal power plant.

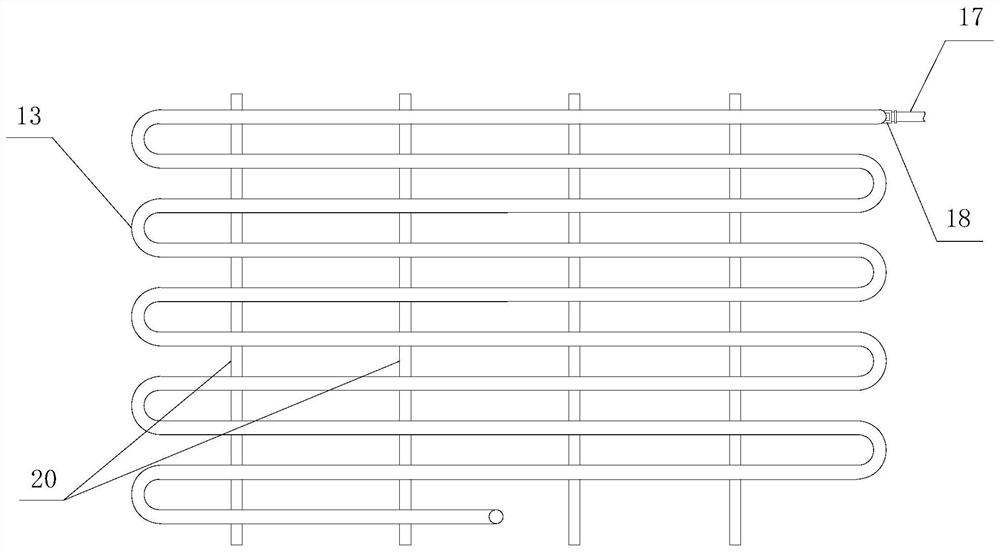

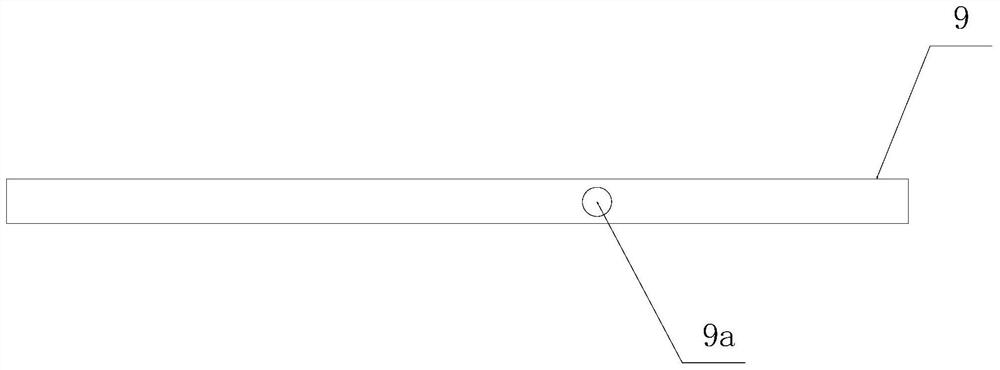

[0044] The core improvement of the present invention is: a cavity 3 is dug on the ground in the room body 1, a cover plate 4 with a mesh is covered on the cavity 3, and the cover plate 4 is supported by a bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com