Biochemical method for removing impurities in Baijiu

A biochemical and biochemical reaction technology, used in the field of removing impurities in liquor, can solve problems such as inability to solve technical problems, no obvious removal effect, and insignificant effect, achieves low technical threshold, low equipment requirements, and reduces uncomfortable reactions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Take 2kg of raw eggs, remove the egg shells, put them into a container, stir them evenly with an electric mixer, add them into 22.5L of 60% white wine (old-fashioned sorghum shochu) base wine, and stir them well until they are even. At room temperature of 25°C, a light yellow precipitate gradually formed, which was left standing for 4 days. When a large amount of flocculent precipitate appears at the bottom of the container, filter the light yellow precipitate with a filter cloth to obtain the filtrate, put the filtrate into a wine still for distillation, take the wine whose distillation temperature is below 90 degrees, and obtain the processed wine of 75 degrees base wine.

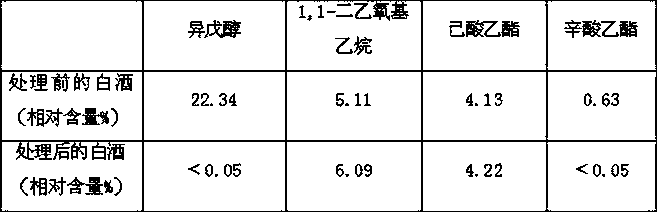

[0021] The analysis results of some trace components by gas chromatography are shown in Table 1.

[0022] Table 1 Analysis results of some trace components of liquor before and after treatment (comparison of liquor quality)

[0023]

[0024] Note: *Under the same gas chromatographic measuremen...

Embodiment 2

[0025] Example 2: Take 1.5kg of raw eggs, remove the shells, put them into a container, stir them evenly with an electric mixer, add them into 1.8L of 45% white wine (old-fashioned corn shochu) base wine, and stir them well until they are even. At room temperature of 30°C, a light yellow precipitate gradually formed, which was left standing for 6 days. When a large amount of flocculent precipitate appears at the bottom of the container, filter the light yellow precipitate with a fine gauze to obtain the filtrate, put the filtrate into a wine still for distillation, take the wine whose distillation temperature is below 90 degrees, and obtain the processed wine of 75 degrees base wine.

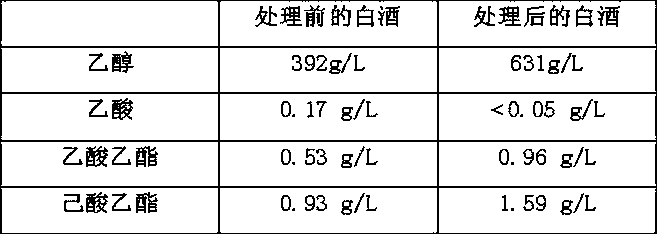

[0026] The main component index analysis results of gas chromatography analysis are shown in Table 2.

[0027] Table 2 Analysis results of main component indexes of liquor before and after treatment (comparison of liquor quality)

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com