980MPa-grade cold-rolled Q&P steel with excellent plasticity and manufacturing method thereof

A manufacturing method and 980mpa technology, applied in the field of material heat treatment, can solve the problems of high alloy cost, unrealizable continuous production line, and restricted production process window.

Active Publication Date: 2020-06-30

MAANSHAN IRON & STEEL CO LTD

View PDF21 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] At present, there are two problems in the production of Q&P steel: one is that the continuous annealing production line is required to have a high cooling rate according to the traditional distributing process (that is, two-step method of distributing), which cannot be realized by the conventional continuous annealing production line; The process needs to be adjusted in the existing production line. The production process window will be restricted by the equipment and materials of the continuous production line, and the performance cannot be optimal.

At present, the research on the production of Q&P steel by one-step method is only limited to the process improvement after continuous annealing treatment

[0005] The patents with the application numbers 201210092207.7 and 201210429983.1 both proposed the production method of ultra-high-strength steel plate for cold forming, which realized the production of ultra-high-strength steel plate, and added alloy elements such as Mo, Ni, and V to varying degrees in the alloy composition design. Increase the production cost; Patent Publication No. CN110093552A proposes a method for producing 980MPa-grade Q&P using a conventional continuous annealing production line, but it is limited to process adjustment in the continuous annealing production line. Step method Q&P treatment can obtain less paralyzed content, so that better material plasticity cannot be obtained; the patent of publication number CN102766818A is distributed at the quenching temperature. Although the process is relatively strong, relatively high precious metal elements Cr and Mo are added. etc., its alloy cost is higher; the patent of public number CN109988970A and CN109988969A proposes the cold-rolled Q&P980 / Q&P1180 steel and production method thereof with different yield ratios, but its Mn content is higher, can make weldability worse; Publication number CN103361547A The patent discloses a production method of ultra-high-strength steel plates for cold forming and steel plates. The patent adopts a continuous annealing production line + a method of distributing steel plates in a bell annealing furnace to obtain ultra-high-strength steel plates, but this process requires a higher cooling rate To obtain martensitic structure, it is still a process improvement after the continuous annealing process; the Q&P steel manufacturing method proposed by the patents of publication numbers CN110129680A and CN110055465A is except that there is a high Mn content, and the light element Al is also added, which increases the Difficulty in smelting and casting; the patent publication number CN110093564A proposes a 1180MPa-grade ultra-high-strength low-cost cold-rolled quenching and distributing steel and its manufacturing method, which can realize one-step quenching and distributing treatment, but the material needs to be heated to 880-920°C for 240~300s for full austenitization, the maximum heating temperature of conventional continuous annealing production line is only 850℃

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

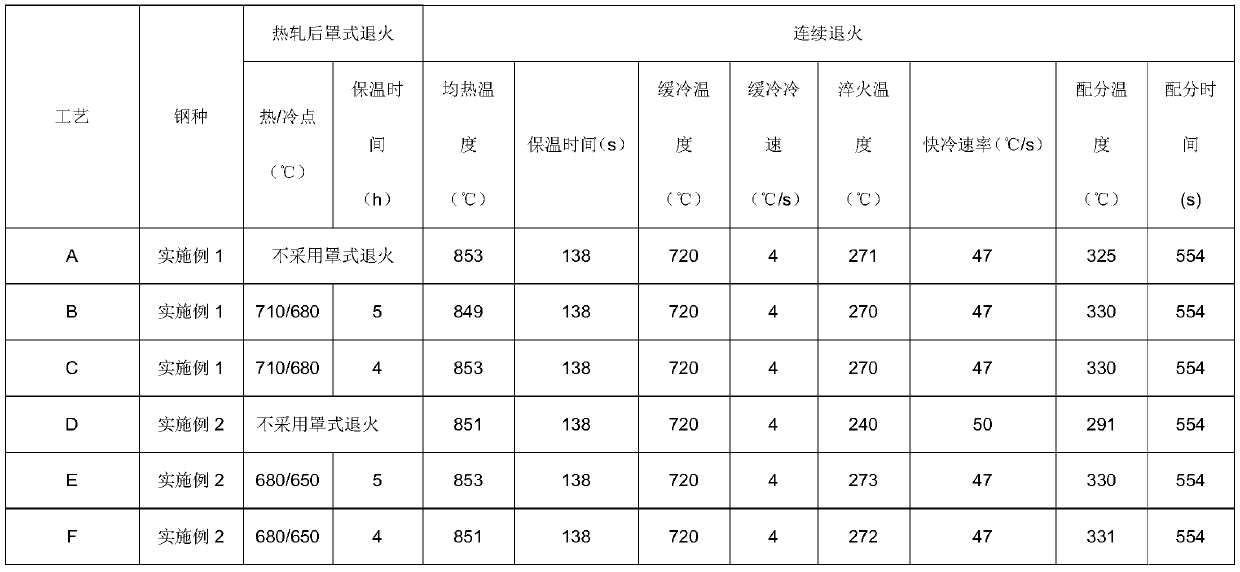

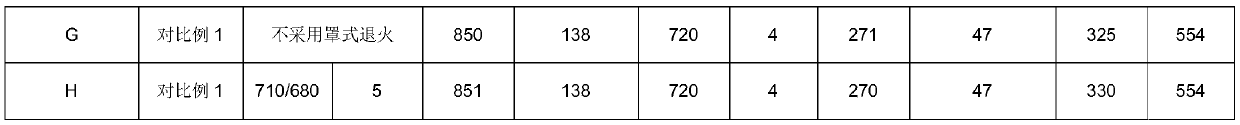

Embodiment 1- Embodiment 2

[0035] A 980MPa grade cold-rolled Q&P steel with excellent plasticity, its smelting composition is shown in Table 1, and the balance not shown in Table 1 is Fe.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Strong plastic product | aaaaa | aaaaa |

Login to View More

Abstract

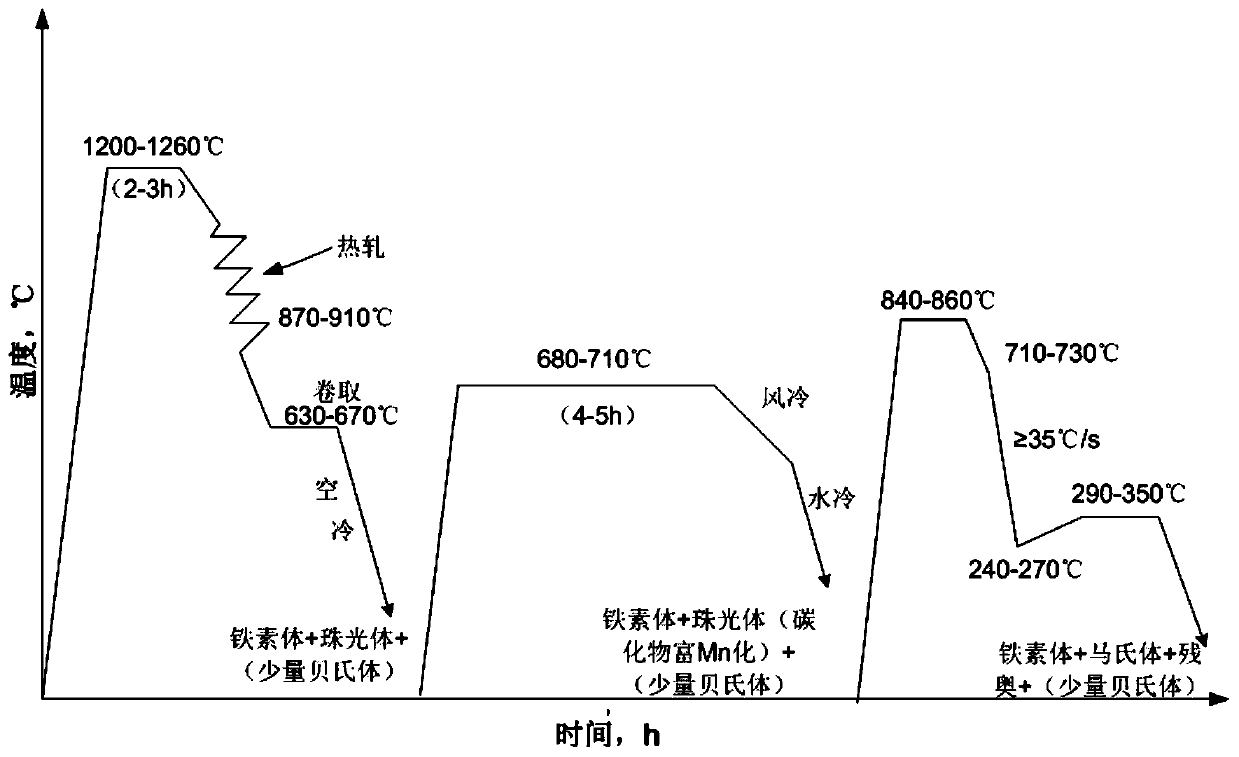

The invention provides 980MPa-grade cold-rolled Q&P steel with excellent plasticity and a manufacturing method thereof. The 980MPa-grade cold-rolled Q&P steel comprises the following components of 0.18%-0.21% of C, 1.4%-1.6% of Si, 1.8%-2.1% of Mn, 0.04%-0.06% of Nb, 0.02%-0.05% of Al, less than or equal to 0.01% of P, less than or equal to 0.01% of S and the balance Fe. According to the 980MPa-grade cold-rolled Q&P steel with the excellent plasticity, compared with the prior art, noble metal elements such as Al, Ni and Mo are not added, the content of Mn is relatively low, the Mn element is mainly used for enriching and stabilizing austenite in the austenite, the plasticity of the material is obviously improved, and the product of strength and elongation can reach 25 GPa%; two-phase region annealing is adopted, the annealing temperature is low, and quenching partition treatment can be implemented on an existing continuous annealing production line through adopting an approximate one-step method; and on the other hand, through annealing treatment of the hot-rolled coil, the influence of the alloy element Mn on the material performance is improved, and equipment does not need to betransformed and invested.

Description

technical field [0001] The invention belongs to the technical field of material heat treatment, and in particular relates to a 980MPa grade cold-rolled Q&P steel with excellent plasticity and a manufacturing method thereof. Background technique [0002] In order to meet the increasingly stringent requirements of energy, environmental protection and safety regulations in the automotive industry, research institutes and steel enterprises at home and abroad have carried out research and development of third-generation automotive steel products with higher strength and better formability. As a typical representative of the third-generation automotive steel, Q&P (Quenching Partition) steel has attracted much attention because of its excellent strong plasticity and the most commercial production possibility. [0003] The basic process route of Q&P steel is: first, austenitization is carried out, and the high-temperature austenite structure is rapidly cooled to a certain temperatur...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C21D8/02C21D1/26C21D1/18C22C38/02C22C38/04C22C38/06C22C38/12

CPCC21D8/0226C21D8/0236C22C38/02C22C38/04C22C38/12C22C38/06C22C38/002C21D1/26C21D1/18C21D2211/005C21D2211/009

Inventor 冷德平肖洋洋崔磊景宏亮詹华刘永刚谷海容张军潘红波彭梦都晋家春卢茜倩马二清邓宗吉王宇雁

Owner MAANSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com