Method for treating waste acids with iron-based oxide residues

A technology of iron-based oxides and waste residues, applied in metallurgical wastewater treatment, chemical instruments and methods, filtration treatment, etc., to achieve the effect of stable structure, simple operation, and not easy to migrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

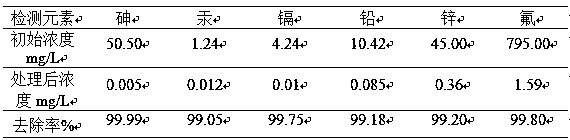

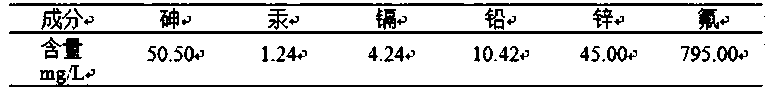

[0021] Embodiment 1: In terms of mass percentage, the main components of the iron-based oxide waste residue in this embodiment are shown in Table 1,

[0022] Table 1 Composition of iron-based oxides

[0023]

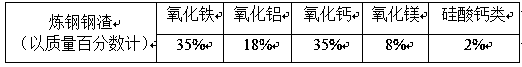

[0024] The polluted acid wastewater of the present embodiment is the polluted acid wastewater produced in the lead smelting process, and the concentration of hydrogen ions in the polluted acid wastewater is 0.15mol / L, and the composition and content are as shown in Table 2 in the polluted acid wastewater,

[0025] Table 2 Composition and content of polluted acid wastewater

[0026]

[0027] A method for treating dirty acid with iron-based oxide waste residue, the specific steps are as follows:

[0028] (1) The iron-based oxide waste slag (steel-making steel slag) was crushed through a 200-mesh sieve, washed three times with deionized water, and dried to obtain the iron-based oxide waste slag powder; Iron oxide content in steel slag) is 35%;

[0029] (2) Add the ...

Embodiment 2

[0034] Embodiment 2: In terms of mass percentage, the main components of the iron-based oxide waste residue in this embodiment are shown in Table 4,

[0035] Table 4 Composition of iron-based oxides

[0036]

[0037] The polluted acid wastewater of the present embodiment is the polluted acid wastewater produced in the copper smelting process, and the concentration of hydrogen ions in the polluted acid wastewater is 0.4mol / L, and the composition and content are as shown in Table 5 in the polluted acid wastewater,

[0038] Table 5 Composition and content of polluted acid wastewater

[0039]

[0040] A method for treating dirty acid with iron-based oxide waste residue, the specific steps are as follows:

[0041] (1) The iron-based oxide waste residue (pyrite slag) was crushed through a 150-mesh sieve, washed three times with deionized water, and dried to obtain the iron-based oxide waste residue powder; in which, the iron-based oxide waste residue was (pyrite slag) iron o...

Embodiment 3

[0047] Embodiment 3: In terms of mass percentage, the main components of the iron-based oxide waste residue in this embodiment are shown in Table 7,

[0048] Table 7 Iron-based oxide components

[0049]

[0050] The polluted acid wastewater of the present embodiment is the polluted acid wastewater produced in the copper smelting process, and the concentration of hydrogen ions in the polluted acid wastewater is 0.6mol / L, and the composition and content are as shown in Table 8 in the polluted acid wastewater.

[0051] Table 8 Composition and content of polluted acid wastewater

[0052]

[0053] A method for treating dirty acid with iron-based oxide waste residue, the specific steps are as follows:

[0054] (1) The iron-based oxide waste residue (iron-containing sediment) was crushed through a 100-mesh sieve, washed twice with deionized water, and dried to obtain the iron-based oxide waste residue powder; in which, in terms of mass percentage, the iron-based oxide waste re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com