UV oven penetrating rod conveying chain

A technology for conveying chains and rods, which is applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., which can solve problems such as increased labor intensity, loose chains, and delays in conveying time, and achieve the effect of automatic oiling and automatic tensioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

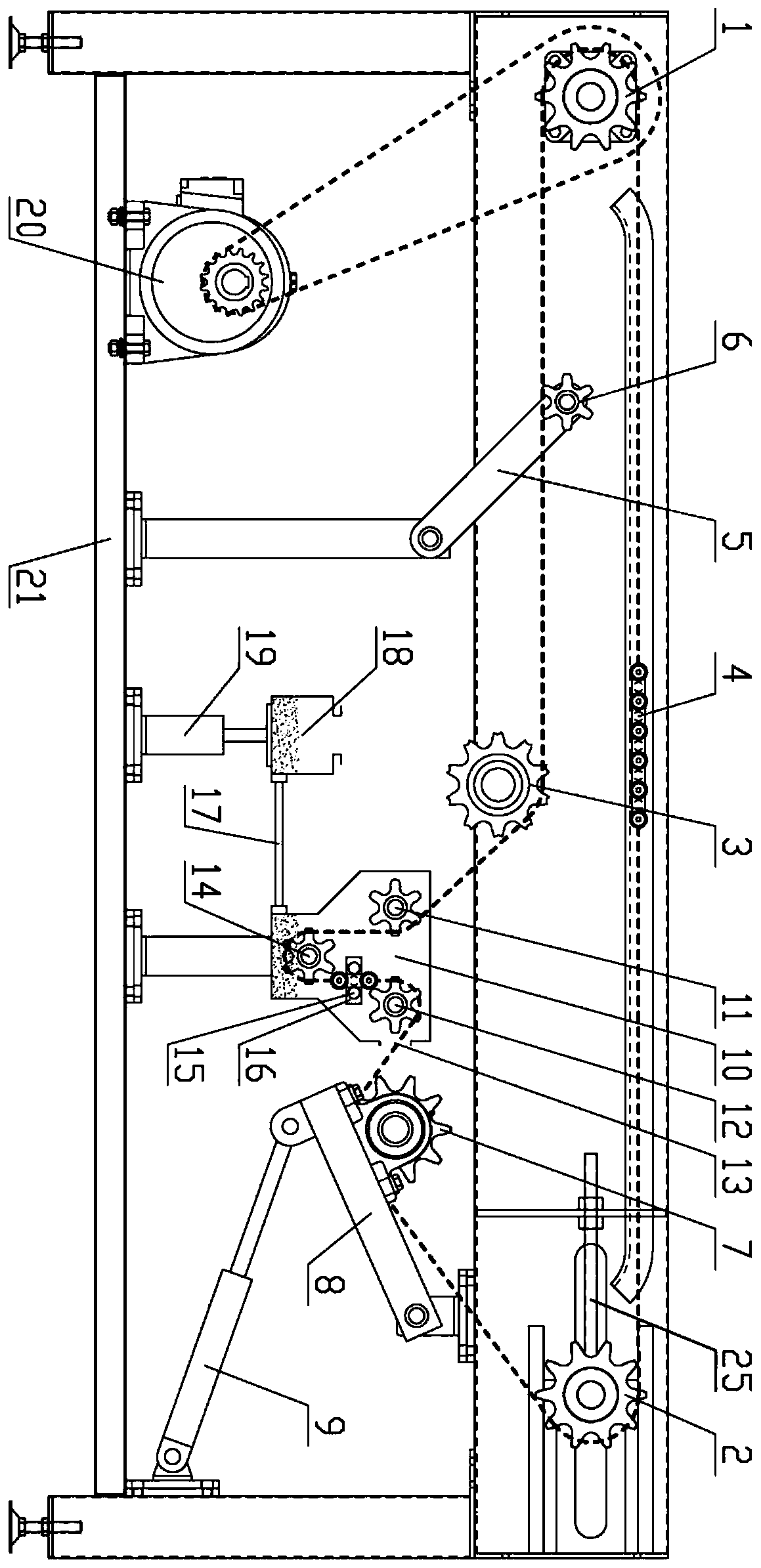

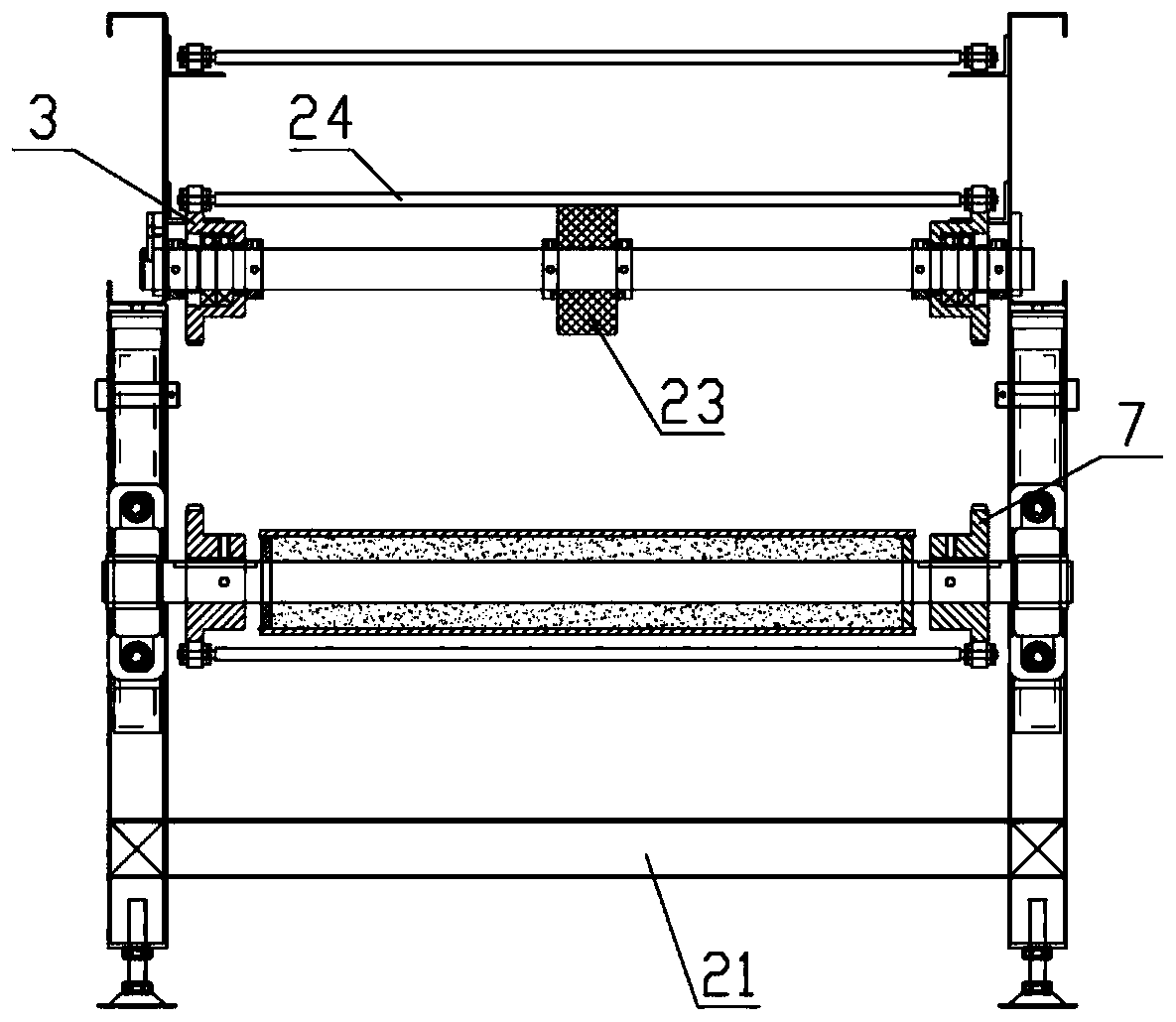

[0036] Such as Figures 1 to 4 As shown, a UV oven rod-through conveyor chain includes a frame 21, the front end of the frame 21 is equipped with a driving sprocket 1, and the rear end is equipped with a driven sprocket 2; the driving sprocket 1 is installed on the front end of the conveyor belt. On the driving shaft, the driving shaft rotates driven by the driving motor 20, and the driven sprocket 2 is installed on the driven shaft at the rear end of the conveyor belt. The driving sprocket 1 and the driven sprocket 2 are established by a roller chain 4 transmission relationship.

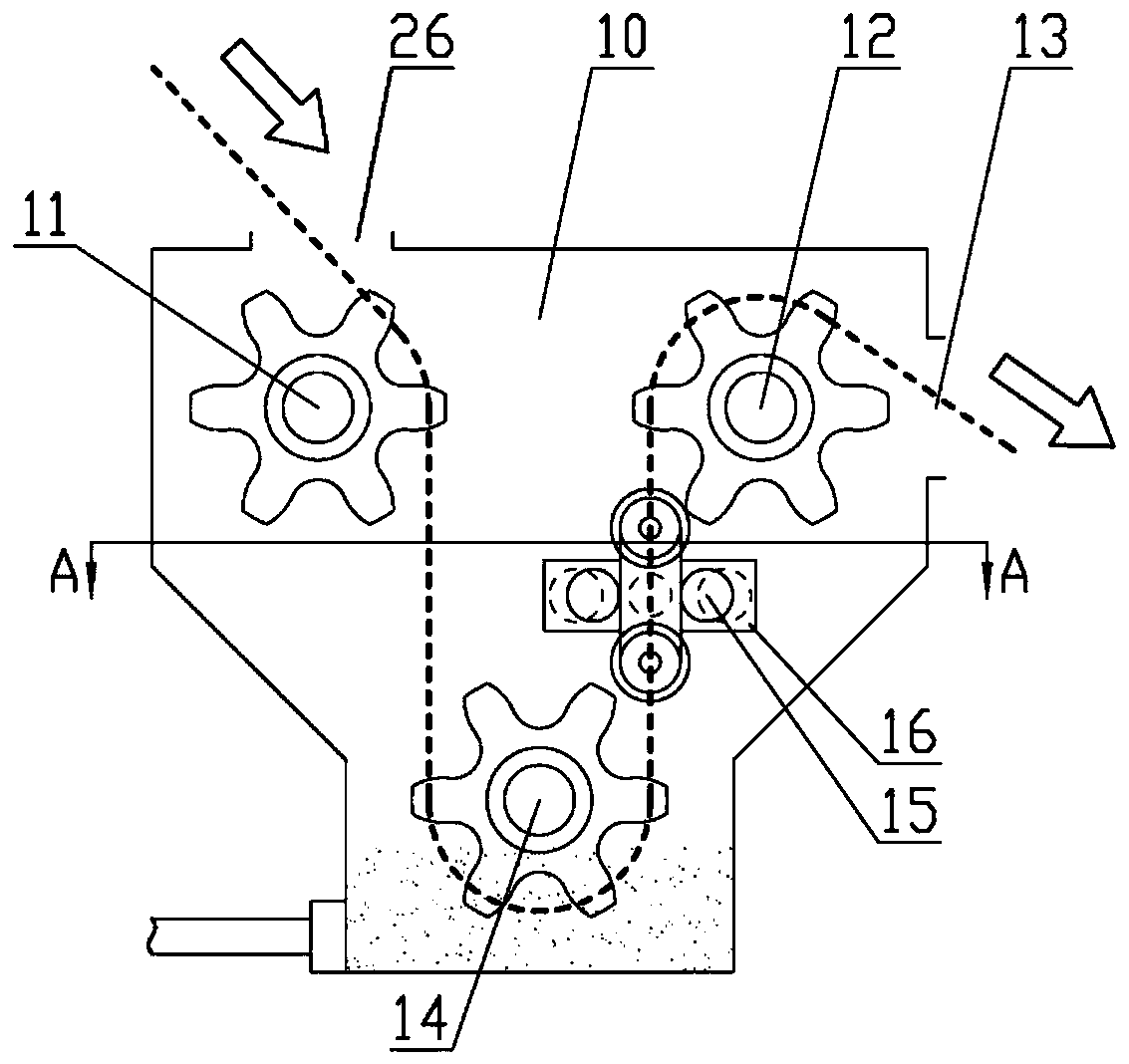

[0037] The UV oven rod conveying chain also includes an intermediate sprocket 3 and an oiling device. The intermediate sprocket 3 is preferably installed in the middle and below the driving sprocket 1 and the driven sprocket 2. On the rotating shaft where the intermediate sprocket 3 is located Support wheels are also provided, whereby the belt surface 24 of the conveyor belt is supported. The inte...

Embodiment 2

[0052] The difference from Embodiment 1 is that in this embodiment, the load-measuring sprocket 6 is installed on a moving base, and the moving base is slidably installed on the frame 21, so that it can move along a straight line; the first sensor can detect the movement of the moving base. moving distance.

[0053] In the present invention, the installation method of each sprocket and the detection means of the sensor are all prior art, so they will not be described in detail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com