Intelligent machining control system for numerically-controlled machine tool

An intelligent processing and control system technology, applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of simple structure, waste of working time, low work efficiency, etc., to increase space utilization and reduce replacement frequency, the effect of reducing the frequency of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

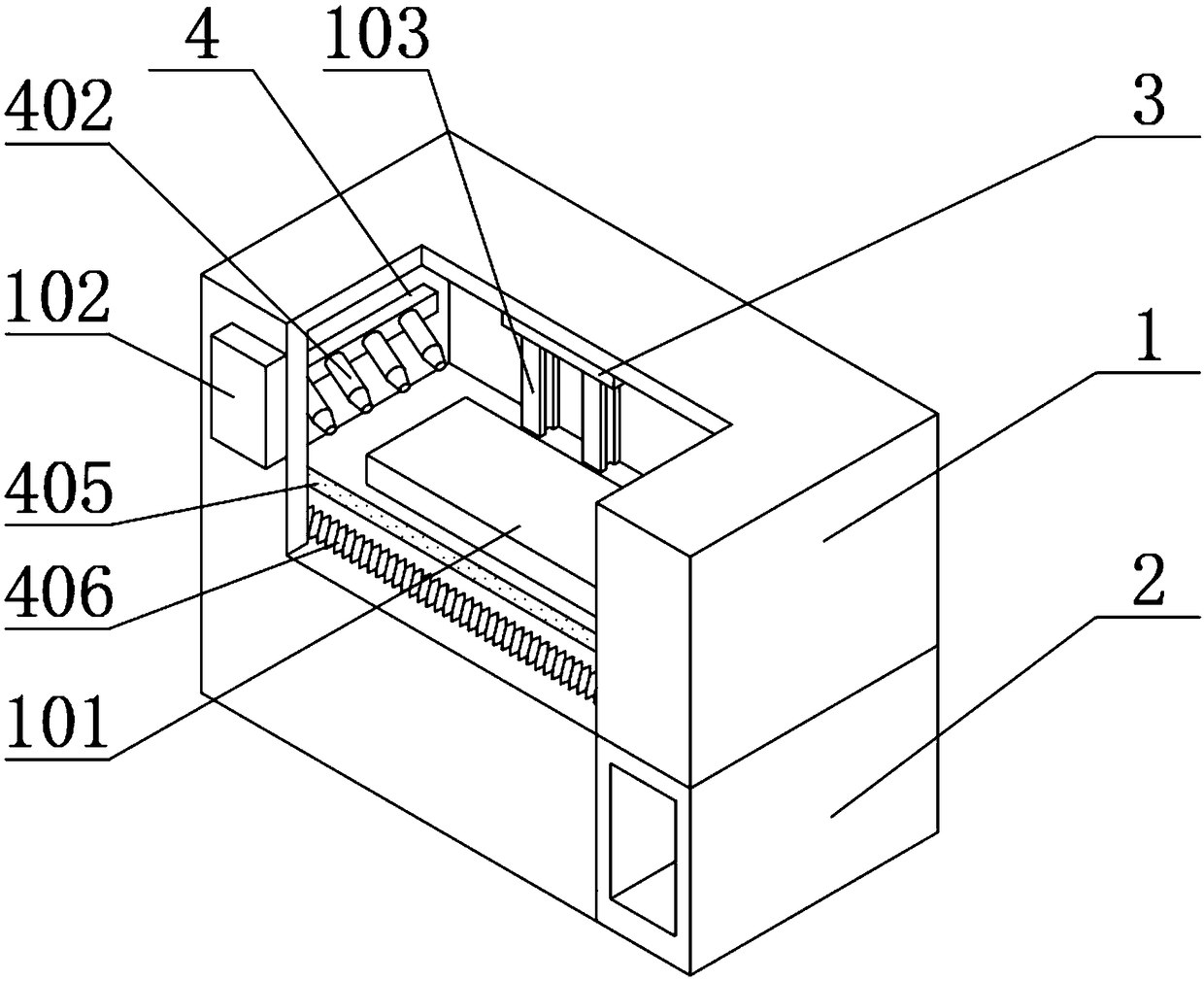

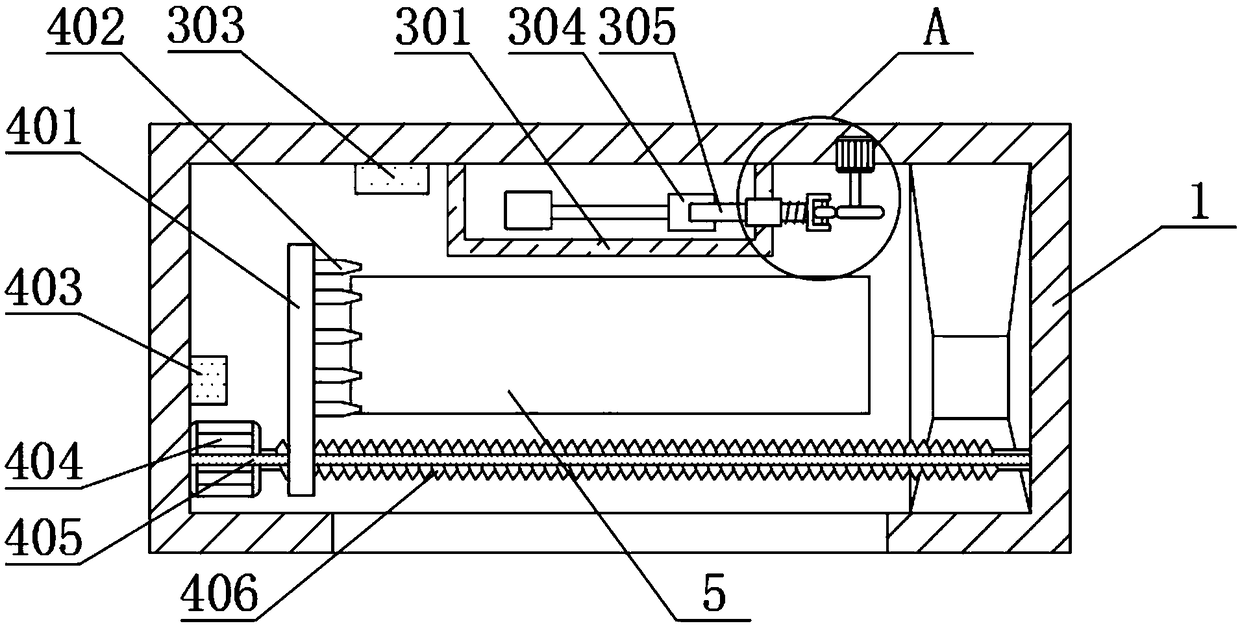

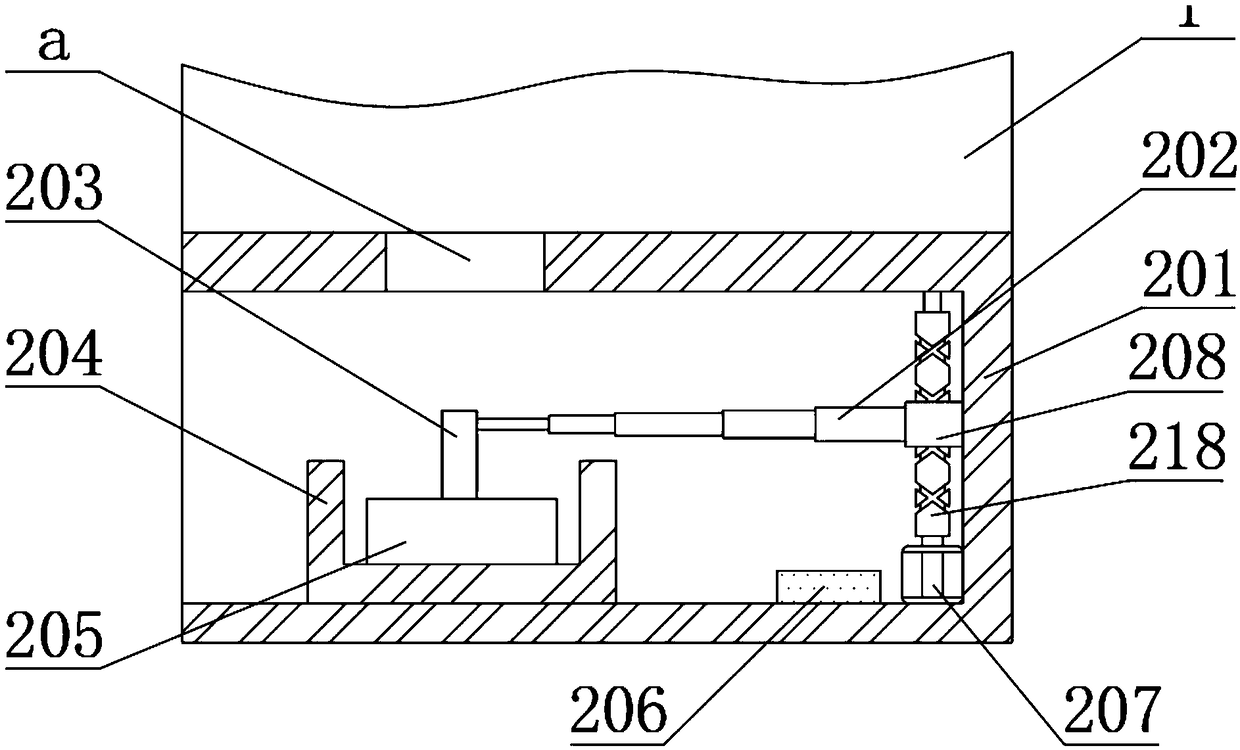

[0031] see figure 1 , figure 2 , image 3 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 , the present invention provides a technical solution:

[0032]An intelligent processing control system for a CNC machine tool, comprising a main device 1, a collecting device 2, an oiling device 3, and a chip cleaning device 4. Chip device 4, the inner rear end of main housing 104 is fixedly connected with refueling device 3, main body device 1 includes loading plate 101, control panel 102, slide rail 103 and main housing 104, the inner side of main housing 104 is fixedly connected with The loading plate 101 arranged horizontally, the front left side of the main casing 104 is fixedly connected with a vertically arranged control panel 102, the inner rear end of the main casing 104 is fixedly connected with a vertically arranged slide rail 103, and the collecting device 2 includes The first protective shell 201, the electric telescopic rod 202, the conn...

Embodiment 2

[0035] see figure 1 , figure 2 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 , the present invention provides a technical solution:

[0036] An intelligent processing control system for a CNC machine tool, comprising a main device 1, a collecting device 2, an oiling device 3, and a chip cleaning device 4. Chip device 4, the inner rear end of the main unit 1 is fixedly connected with a refueling device 3, the main unit 1 includes a loading board 101, a control panel 102, a slide rail 103 and a main housing 104, and the inner side of the main housing 104 is fixedly connected with a horizontal The provided loading board 101, the front left side of the main housing 104 is fixedly connected with a vertically arranged control panel 102, the inner rear end of the main housing 104 is fixedly connected with a vertically arranged slide rail 103, and the collecting device 2 includes a second Two protective shells 209, a second collection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com