Full-automatic shoe-cleaning machine

A shoe polisher, a fully automatic technology, applied in the direction of cleaning boots and shoes, cleaning equipment, household appliances, etc., can solve the problem that the cleaning roller brush and the upper cannot be completely fitted, cannot meet the use requirements, and the feet must be placed on the The above problems can achieve the effect of good wiping effect, uniform force and short shoe-shine time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments and illustrations.

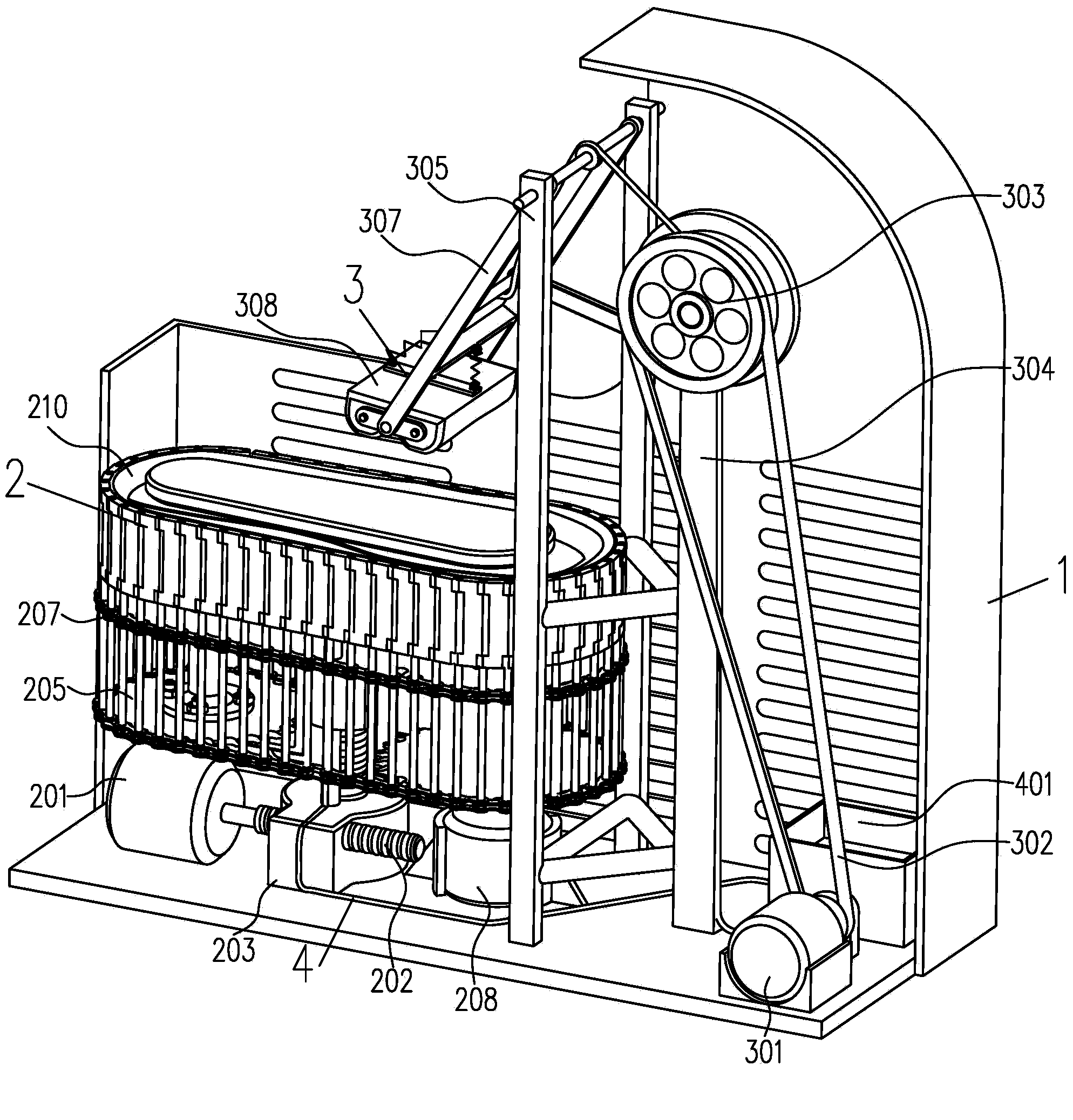

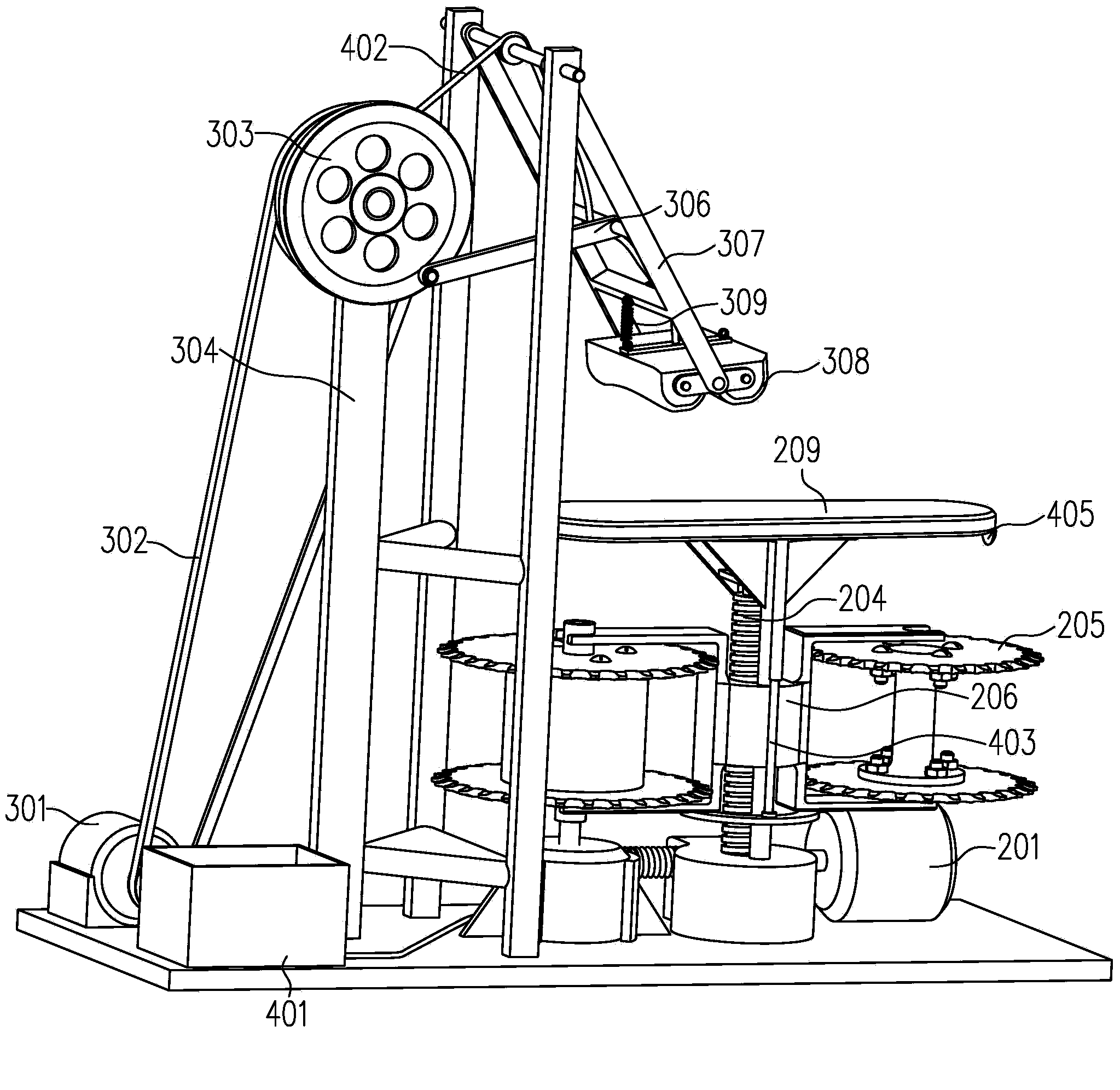

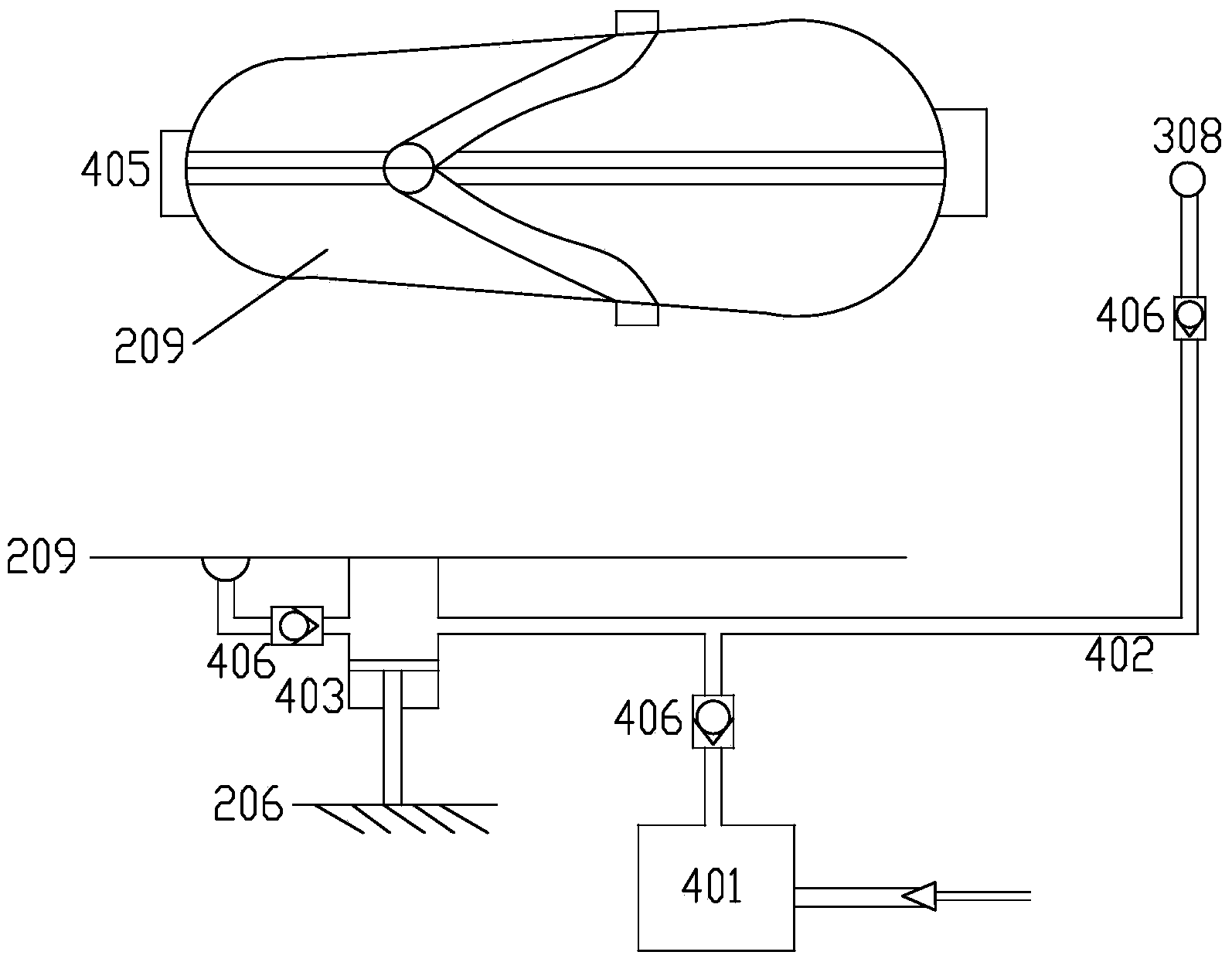

[0028] Such as figure 1 and Figure 7 As shown, a fully automatic shoe polishing machine is composed of a casing 1, an upper wiping device 2, a vamp wiping device 3 and a refueling system 4. The upper surface wiping device 2, the vamp wiping device 3 and the refueling system 4 are all built in the casing 1, and the casing 1 is provided with a switch button.

[0029] Such as figure 1 , figure 2 and Figure 5 As shown, the upper surface wiping device 2 includes a motor A (201), a worm I (202), a worm gear box 203, a worm II (204), a sprocket 205, a sprocket frame 206, a chain drive 207, and a motor B (208), foot support 209 and annular air bag hair brush 210, the described worm screw I (202) is connected with the output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com