Wafer processing method

A chip processing and chip technology, applied in the field of optoelectronic information, can solve the problems of low processing efficiency, easy chipping of the edge of the chip, and difficult cleaning, so as to save energy and avoid dust flying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

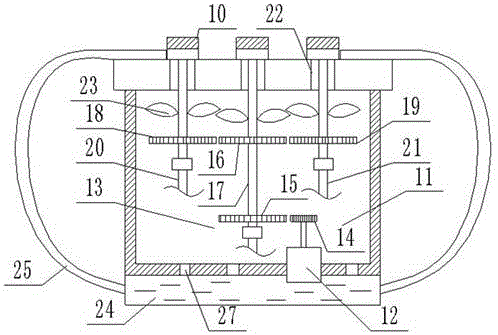

[0021] Wafer processing method, comprising the steps of:

[0022] S1: Place the wafer on the wafer holder, and the pressurizing mechanism drives the grinding head to press the wafer on the wafer holder; S2: Start the driving motor above the grinding head and the motor of the first driving mechanism, and the grinding head is driven by the driving motor. Rotational movement, the motor of the first driving mechanism realizes deceleration through the speed regulating gear, and then drives the driven gear to rotate through the rotating shaft, thereby driving the wafer holder mounted on the rotating shaft to rotate, the steering of the wafer holder is opposite to that of the grinding head, and the grinding The head grinds the wafer;

[0023] Wherein, at the same time as step S2, the fan blades arranged on the rotating shaft follow the rotation of the rotating shaft to rotate, and the fan blades drive the air inside the cavity of the workbench to accelerate to flow, forming a negativ...

Embodiment 2

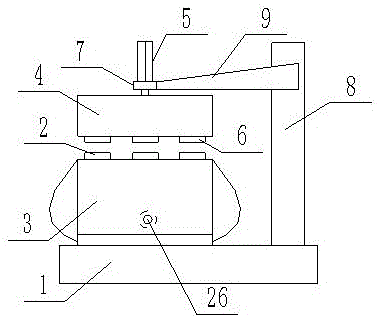

[0030] The used equipment of the wafer processing method in embodiment 1 is basically as figure 1 Shown:

[0031] Wafer grinding equipment, including a base 1 for supporting the grinding equipment, a wafer holder 2 for fixing the wafer, a workbench 3, a grinding mechanism 4 above the workbench 3 and a pressurizing mechanism 5 above the grinding mechanism 4, The pressurizing mechanism 5 adopts an air pressure device; the grinding mechanism 4 includes a grinding head 6, a connecting piece 7 for fixing the grinding head 6, and a drive motor (not shown) arranged above the grinding head 6; the connecting piece 7 includes a movable support 8 And support arm 9, one end of support arm 9 is fixedly connected on the movable support 8, and grinding head 6 is distributed and arranged on the support arm 9, and the coverage area of grinding head 6 is less than wafer 10 surface, makes edge grinding time slightly less than inside, guarantees The surface of the entire wafer is evenly ground...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com