Method for producing rolling stock rolled in a rolling train of a rolling mill, control and/or regulation device for a rolling mill for producing rolled rolling stock, rolling mill for producing rolled rolling stock, machine-readable program code and storage medium

A rolling equipment and closed-loop control technology, applied in the field of rolling equipment for rolling stock, open-loop and/or closed-loop control devices, and program code storage media, can solve problems such as damage to production rolling equipment, production losses, etc., to achieve Increased rolling speed, flexible handling, increased spacing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

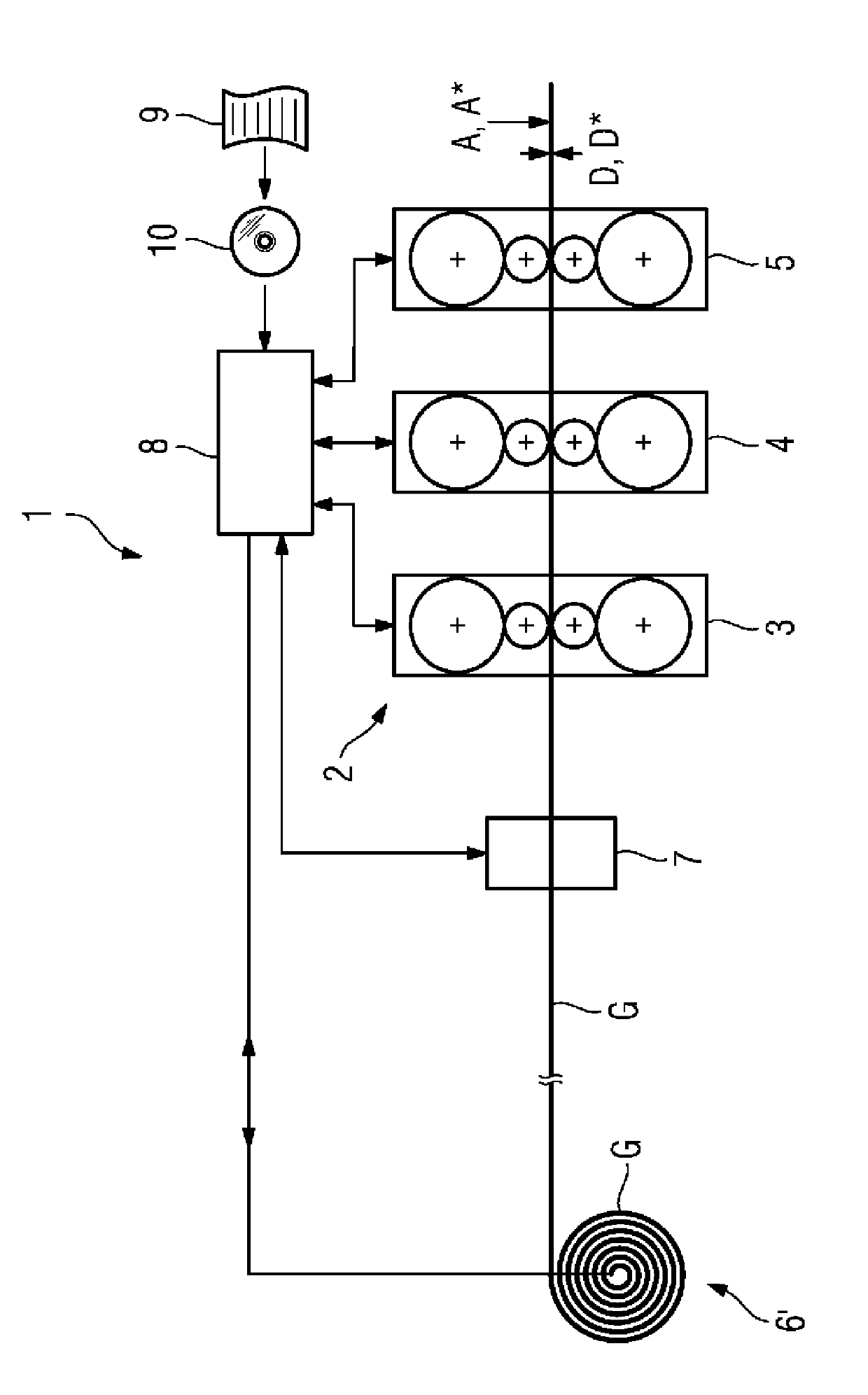

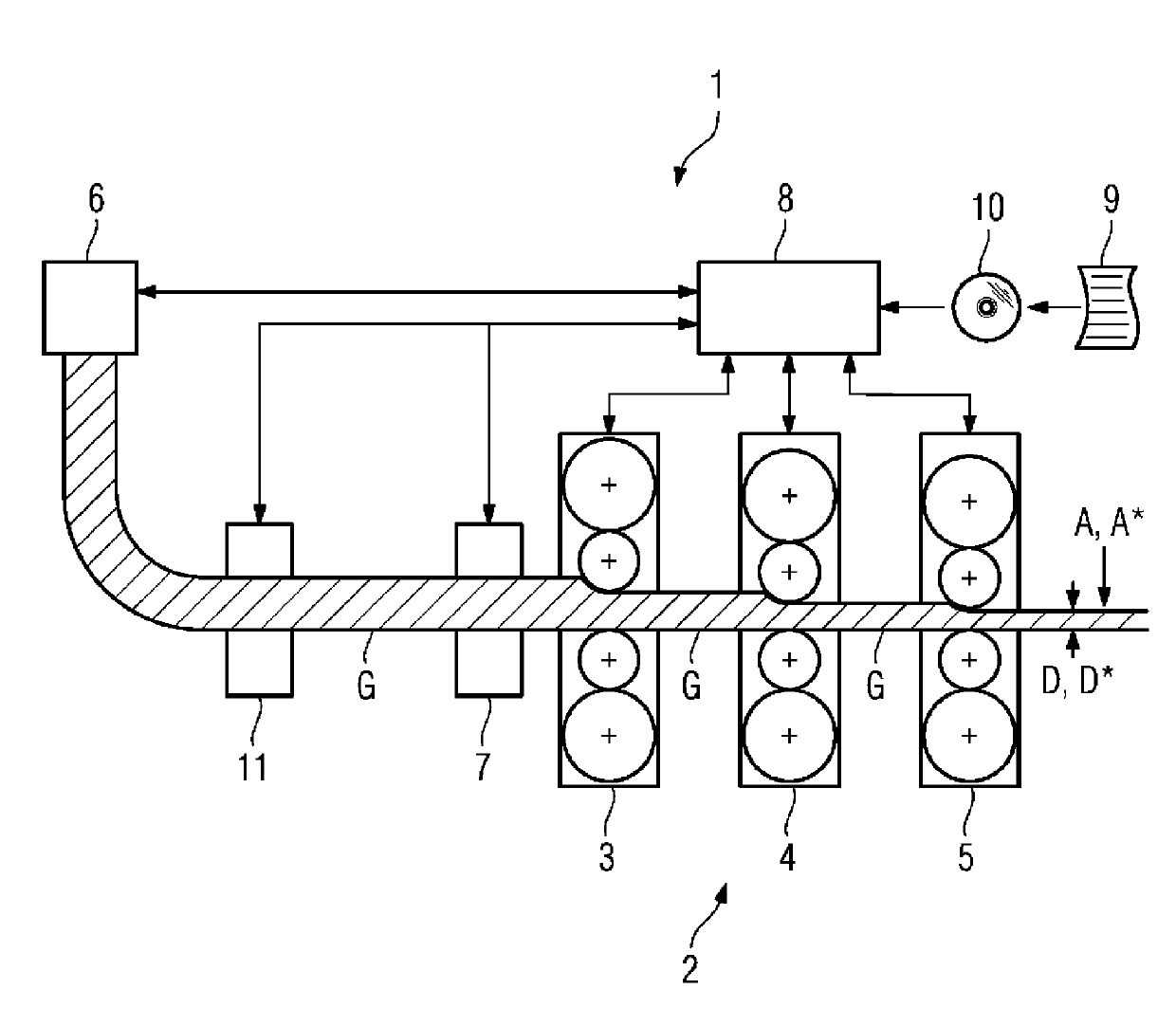

[0026] exist figure 1 The rolling plant 1 shown in the figure is designed as a combined cast-rolling plant and comprises a casting device 6 with which a metal, referred to below as rolling stock G, is cast, which is subsequently subjected to a rolling process.

[0027] In the exemplary embodiment here, the rolling process is illustrated with the aid of a three-stand rolling train 2 , which schematically represents the finishing rolling train 2 .

[0028] The casting device 6 can be designed, for example, as a crystallizer. The casting device 6 can likewise be designed as a roller casting machine. There are no restrictions regarding the casting devices that can be used.

[0029] During planned operation, the rolling plant 1 is operated in what is known as endless operation, ie metal is cast continuously and fed directly to a rolling process, in particular a finish rolling process. The rolling stock thus runs continuously from the casting device 6 to the finishing train 2 dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com