Geometric model of new elongater for skew rolling tubular products

A geometric model, skew rolling technology, used in rolling mill control devices, metal rolling, metal rolling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0095] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

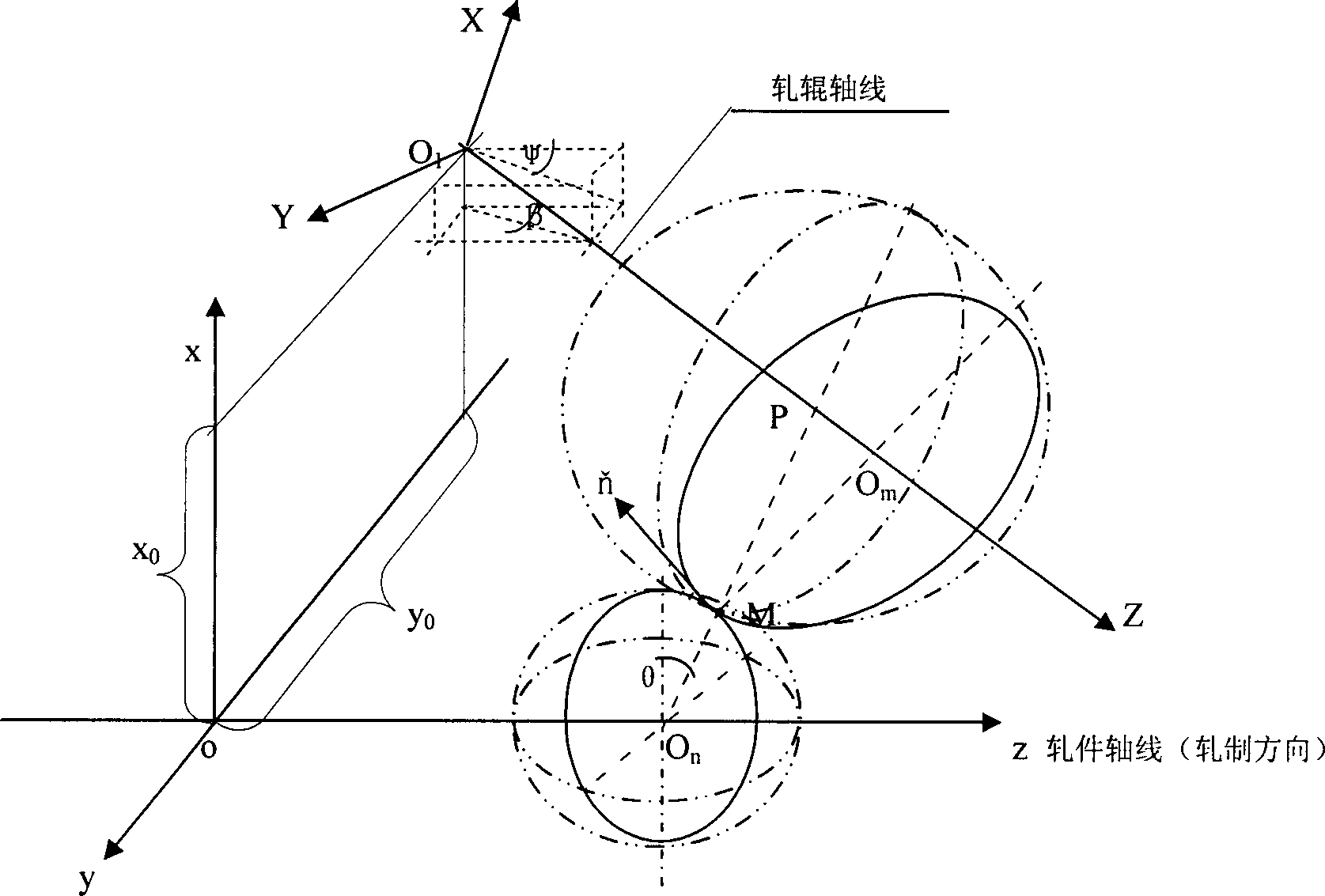

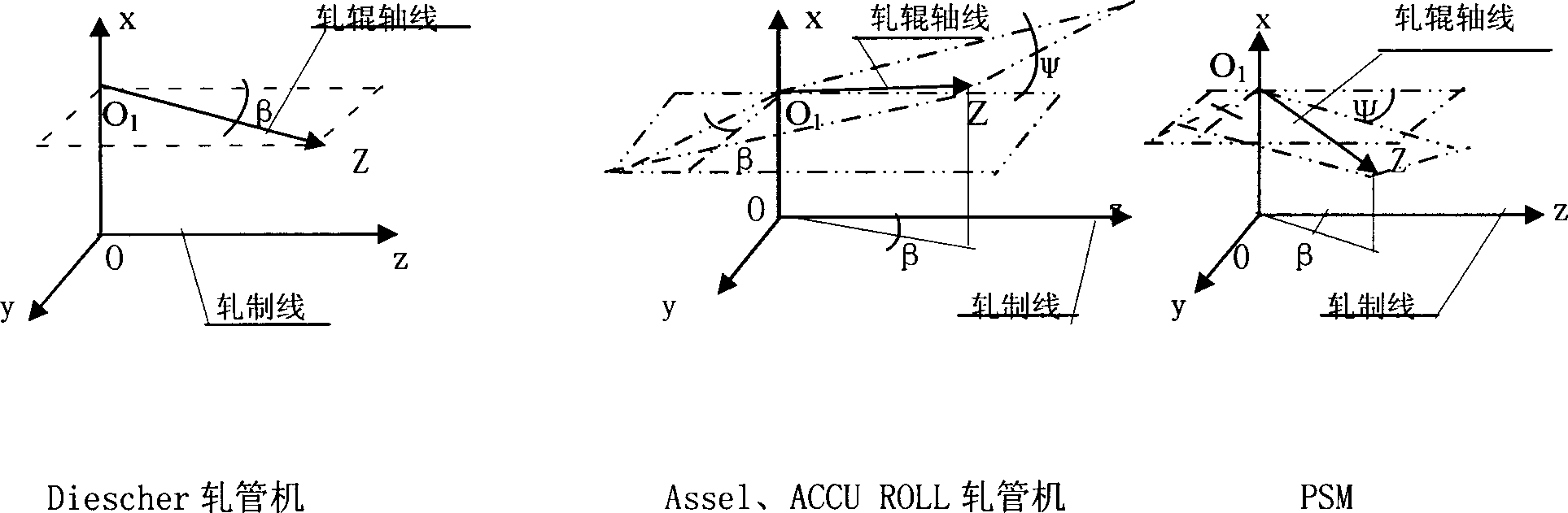

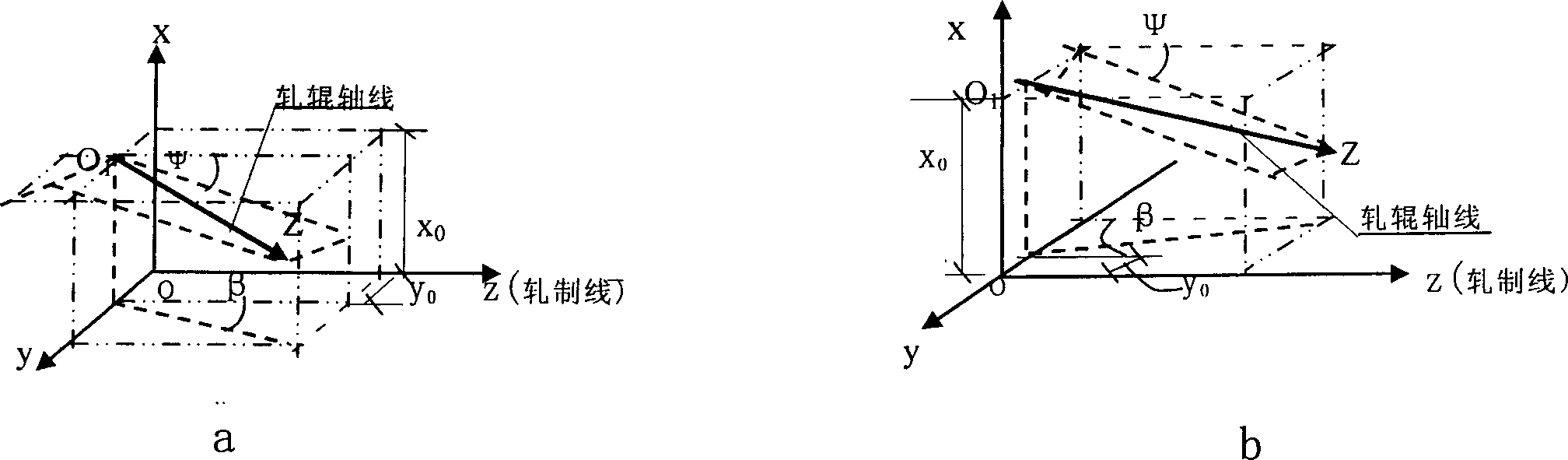

[0096] First draw up a geometric model of a cross-rolled pipe extension machine: the feed angle β=8°, the axis of the roll adjusts the center point of rotation O 1 The distance to the datum plane of the rolled piece axis, that is, the movement amount x of the roll axis on the x-axis 0 =290mm, rolling angle ψ=-20°, offset y 0 =-80mm.

[0097] Other calculation conditions are the same as those of the existing cross-rolled pipe extension machine in the background technology, that is: the calculation of the deformation zone starts from the section where the wall reduction and diameter reduction begin, until the wall reduction and diameter reduction end, the calculated deformation zone length is 120mm, and the beginning of the reduction The capillary outer circle radius r=82.92mm on the cross-section where the wall and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com