Patents

Literature

30results about How to "Ensure locking function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

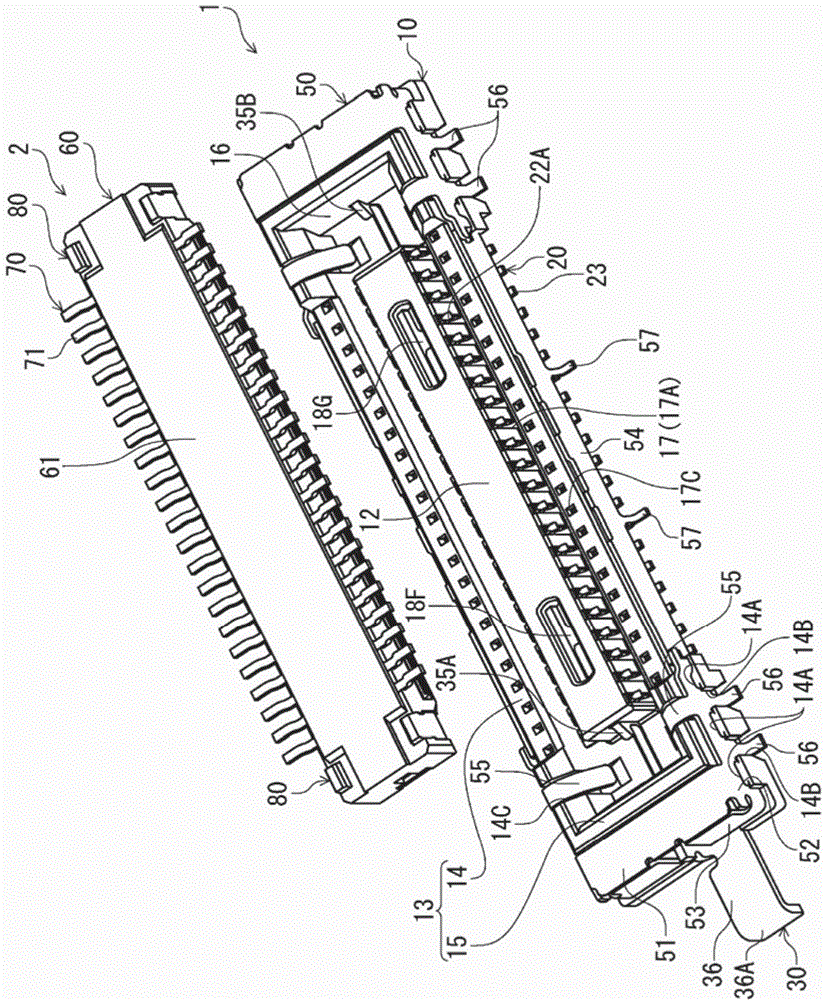

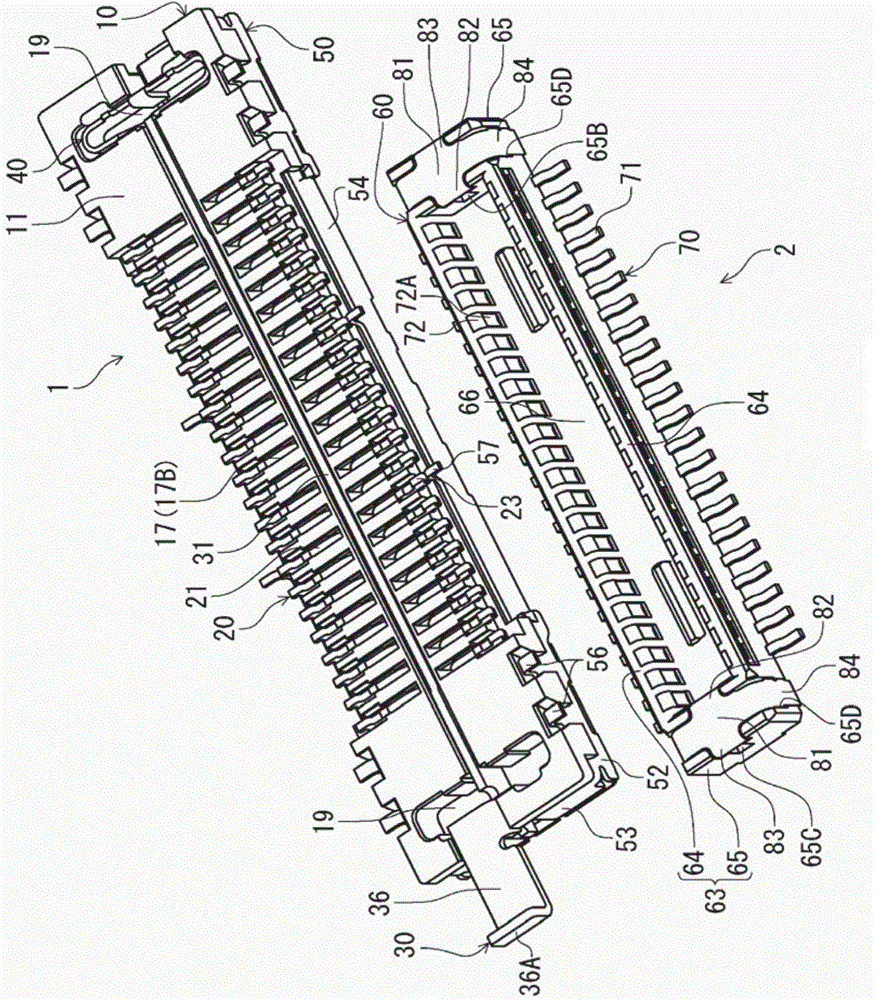

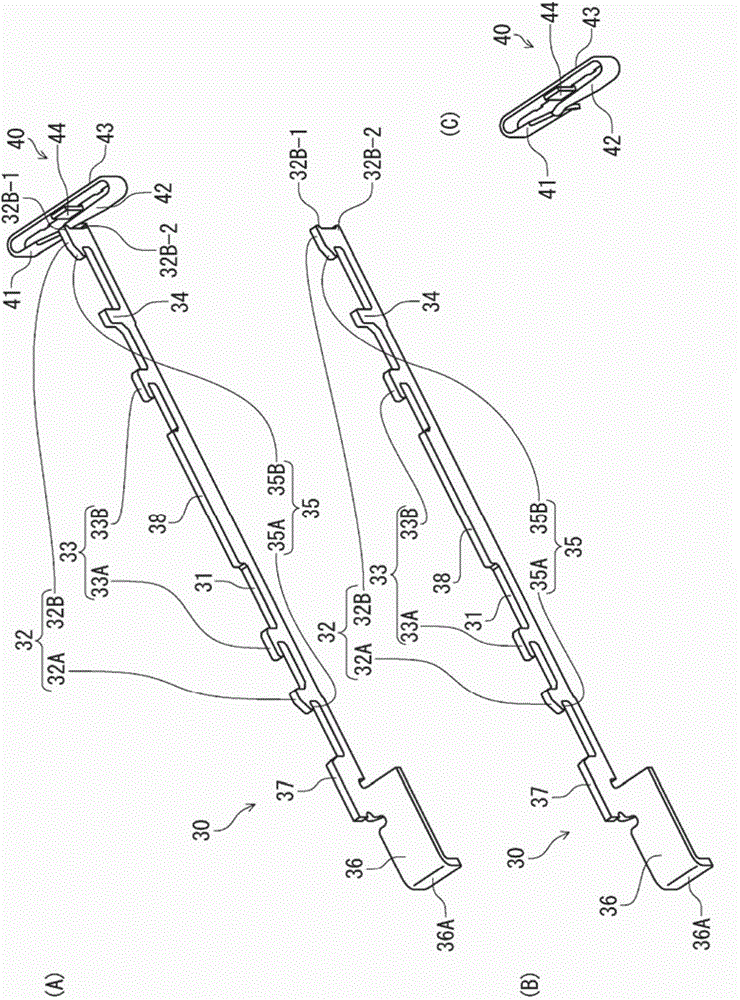

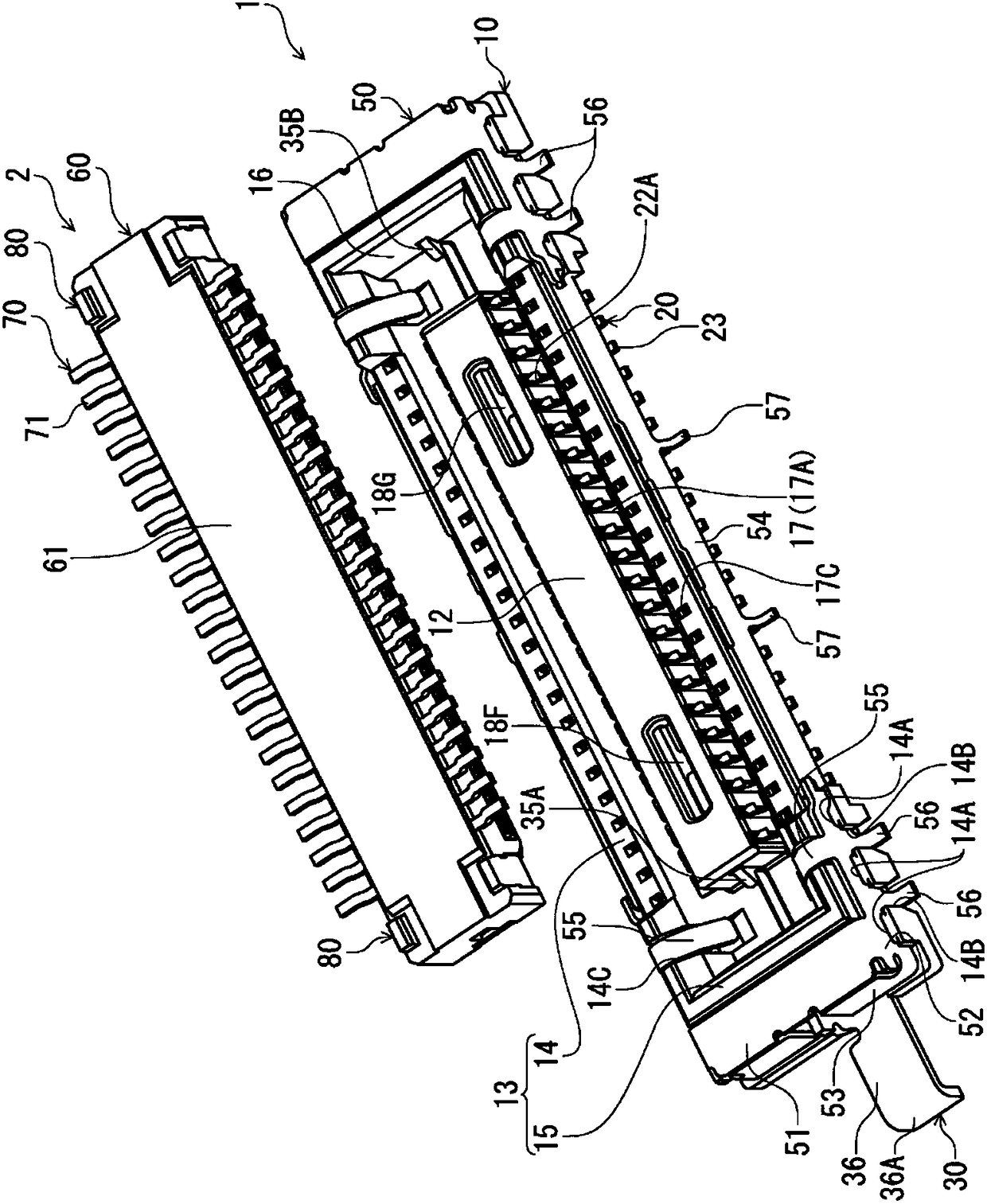

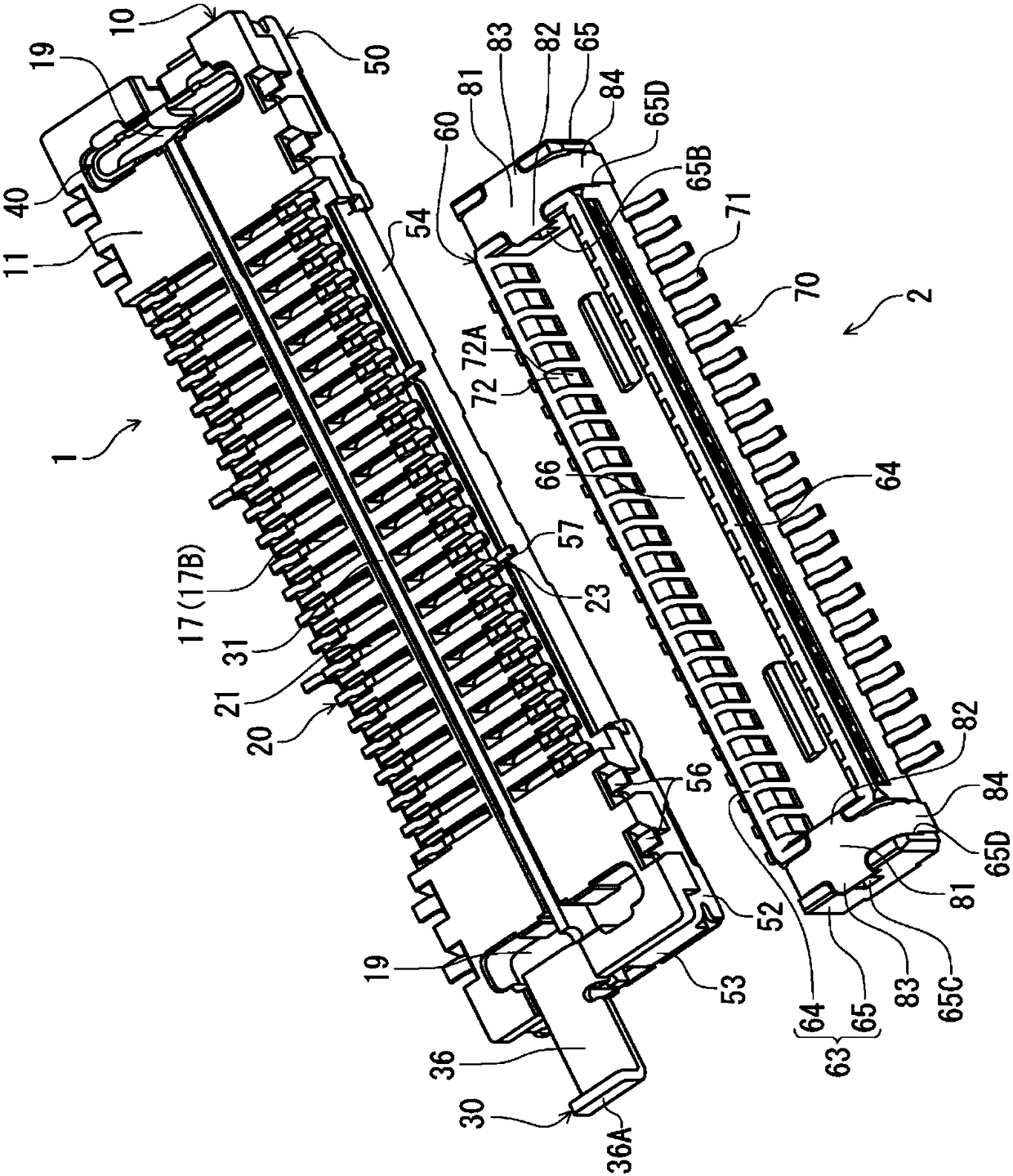

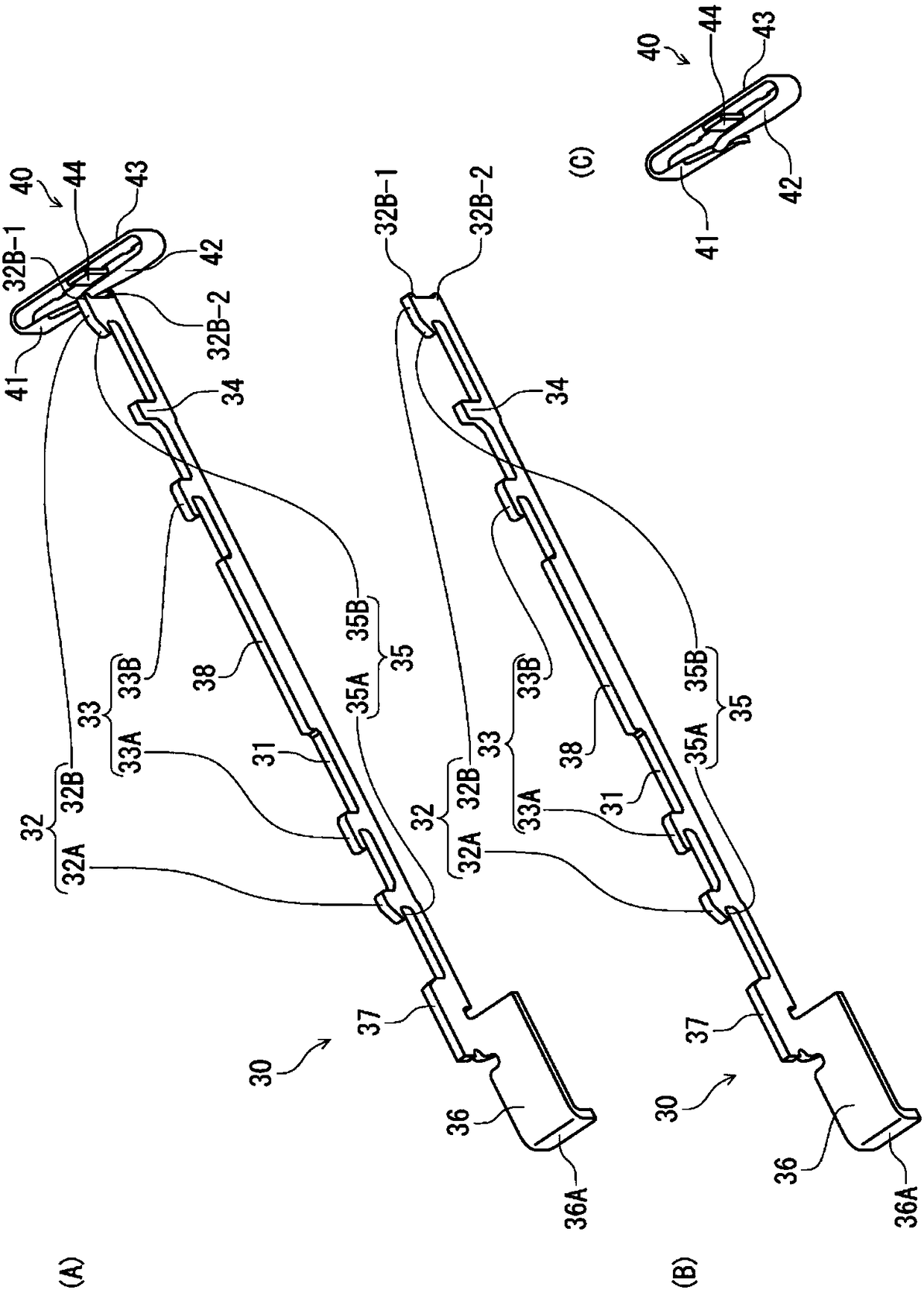

Electric connector

Owner:HIROSE ELECTRIC GROUP

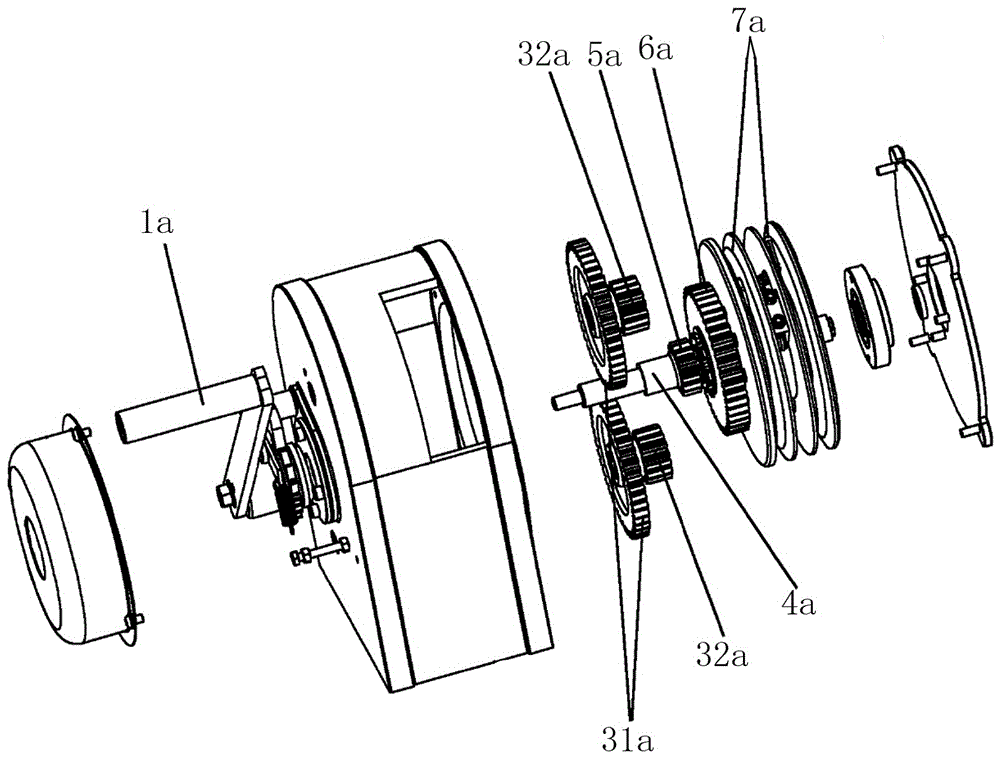

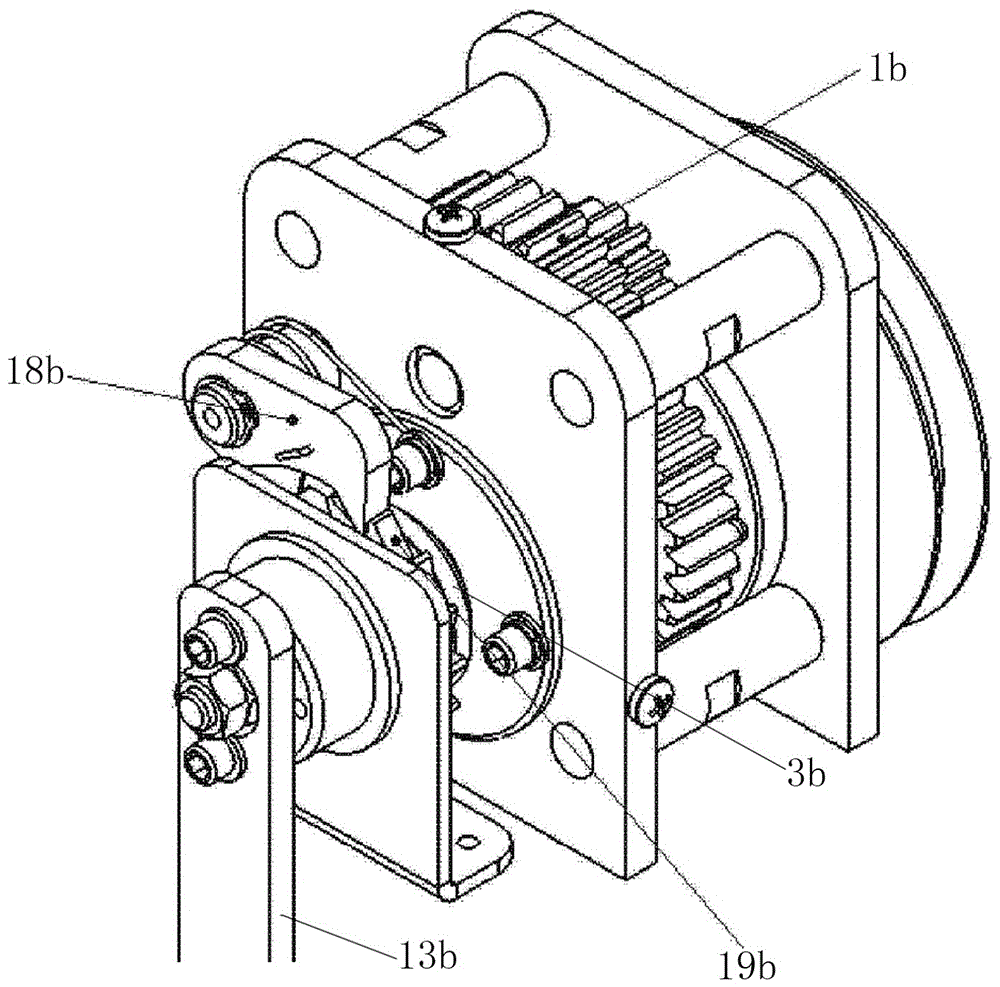

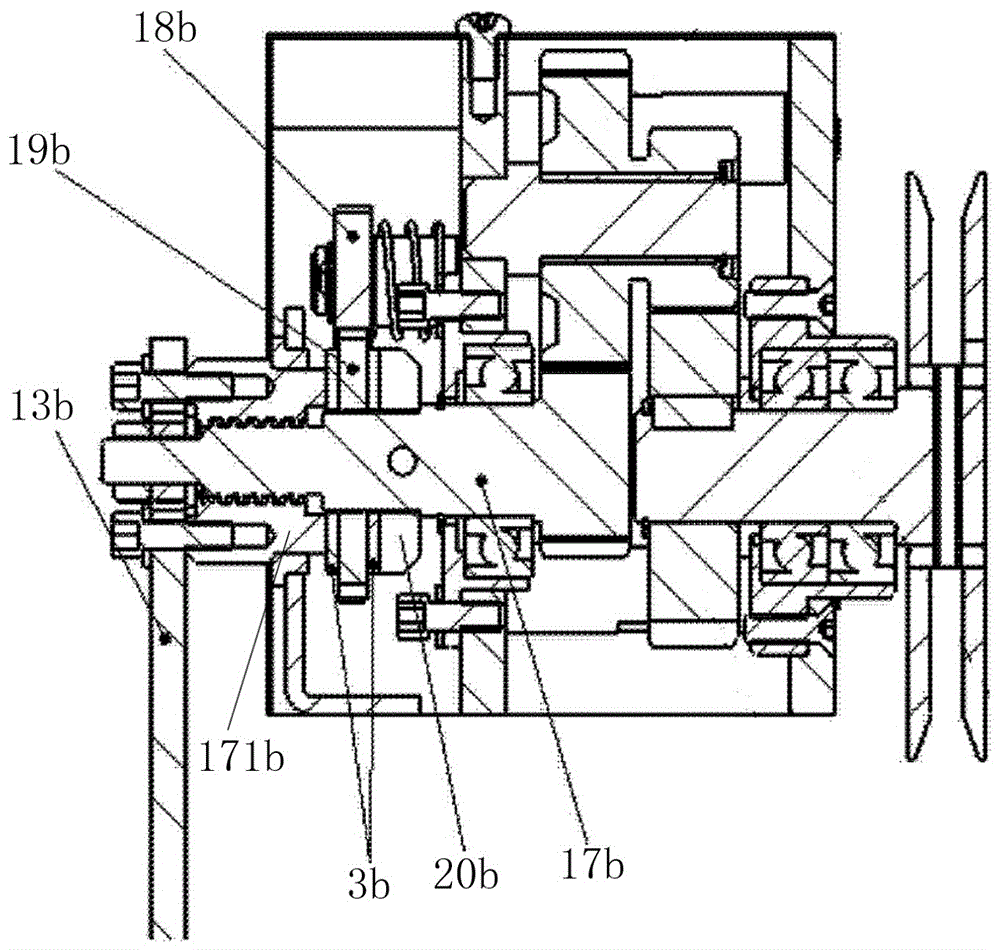

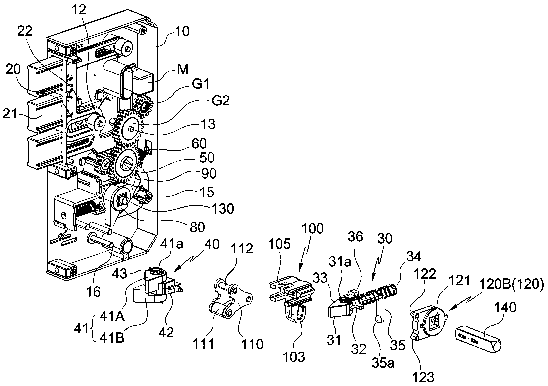

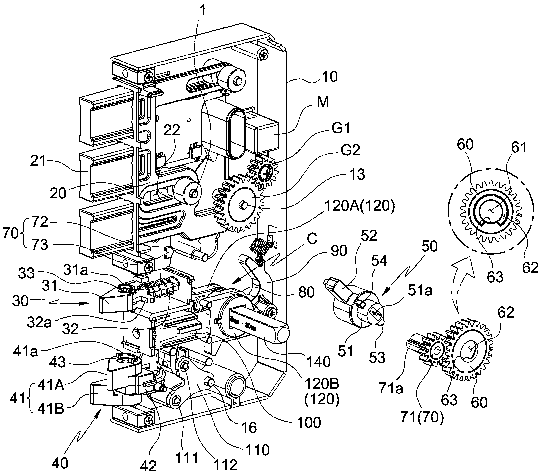

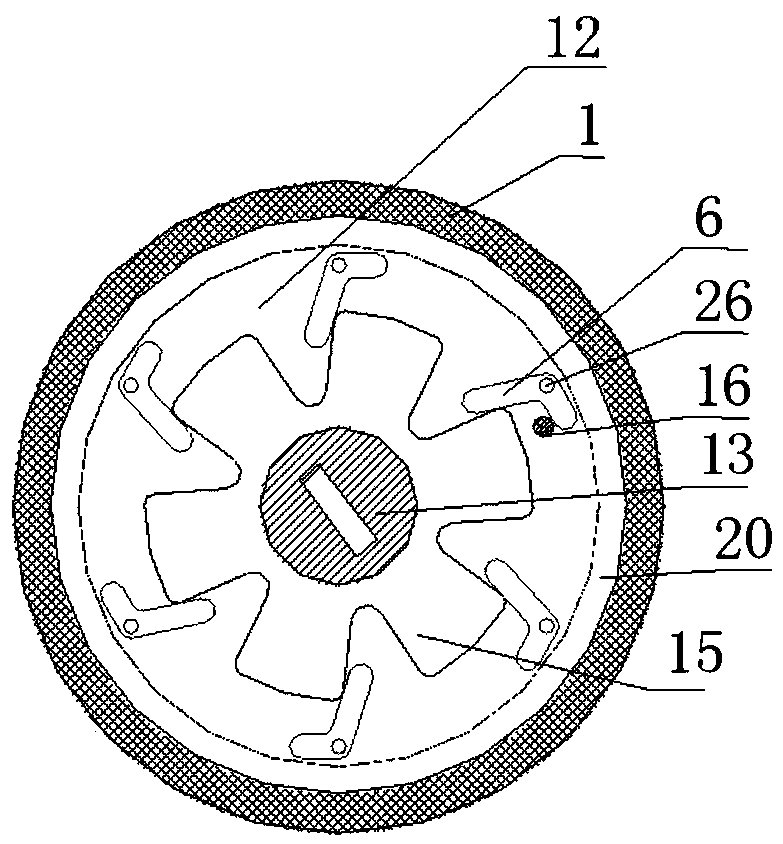

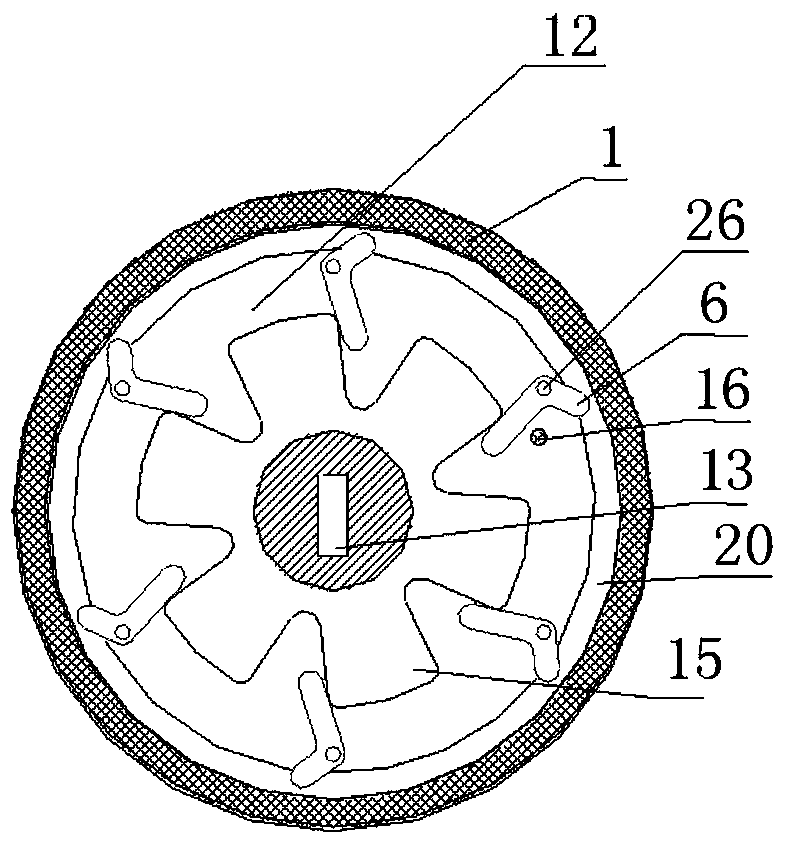

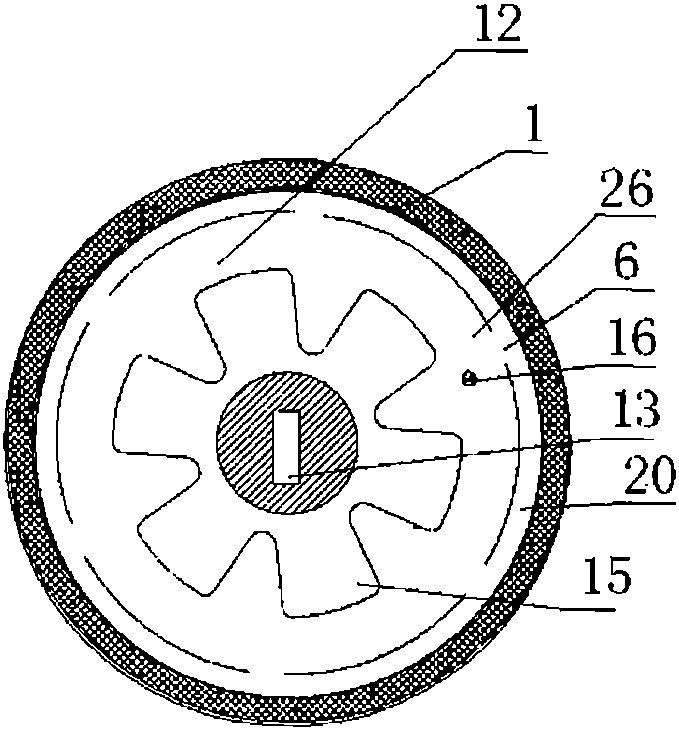

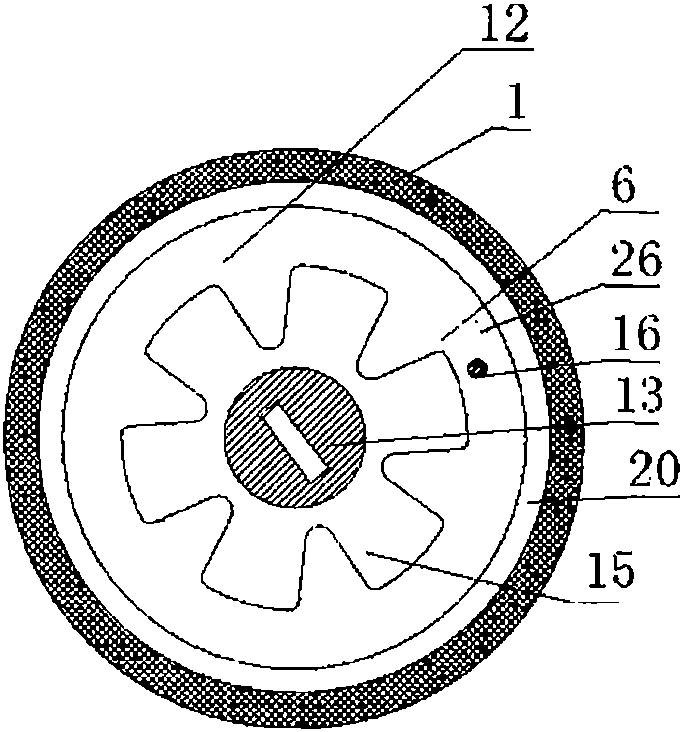

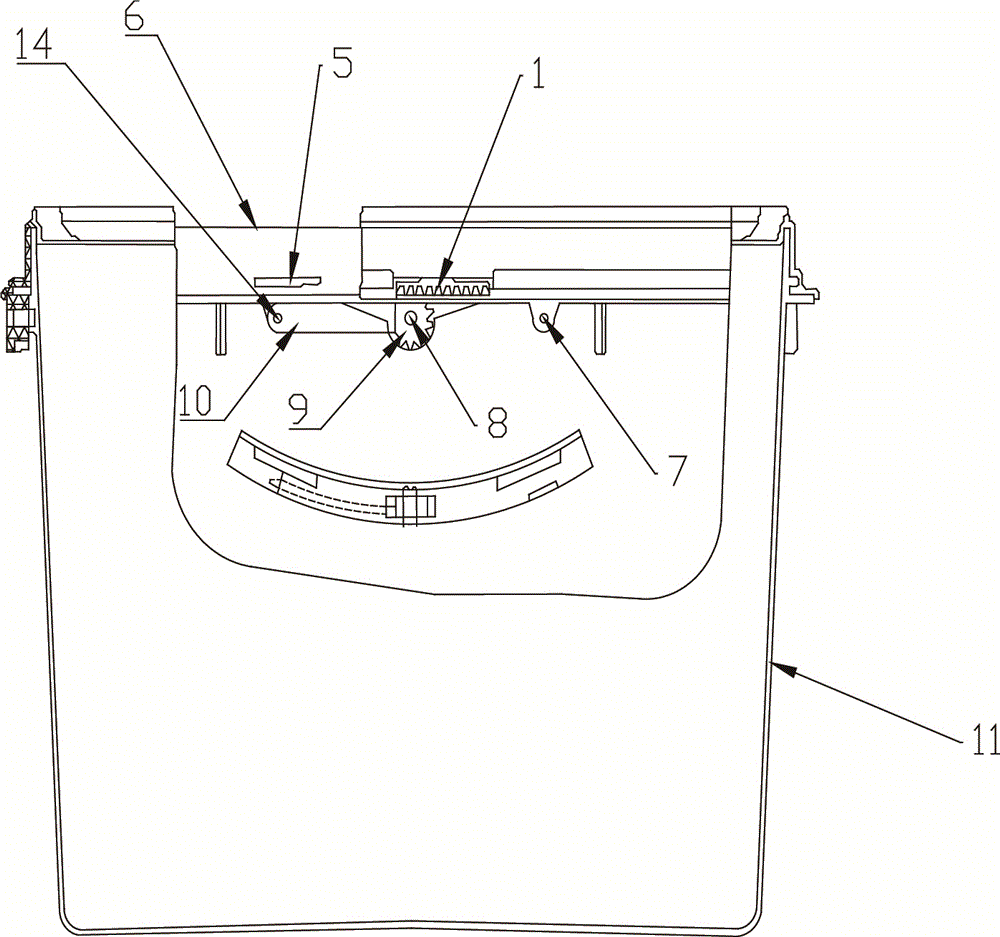

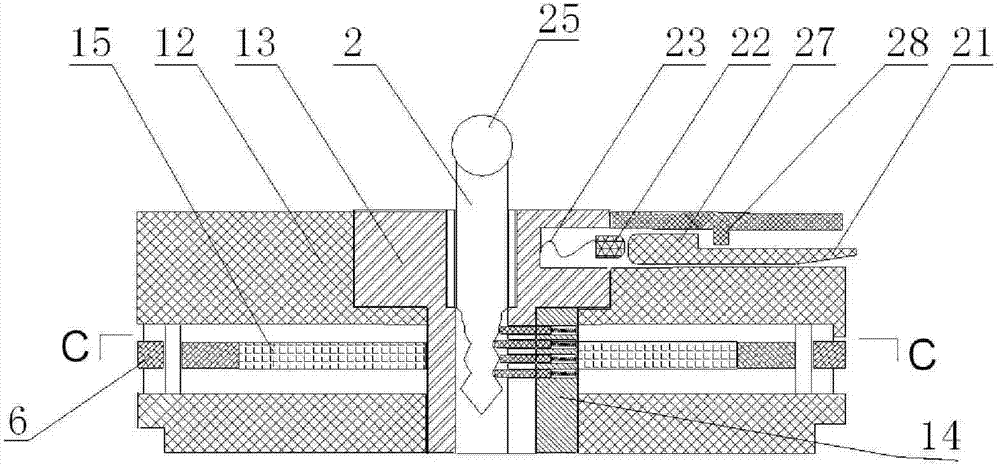

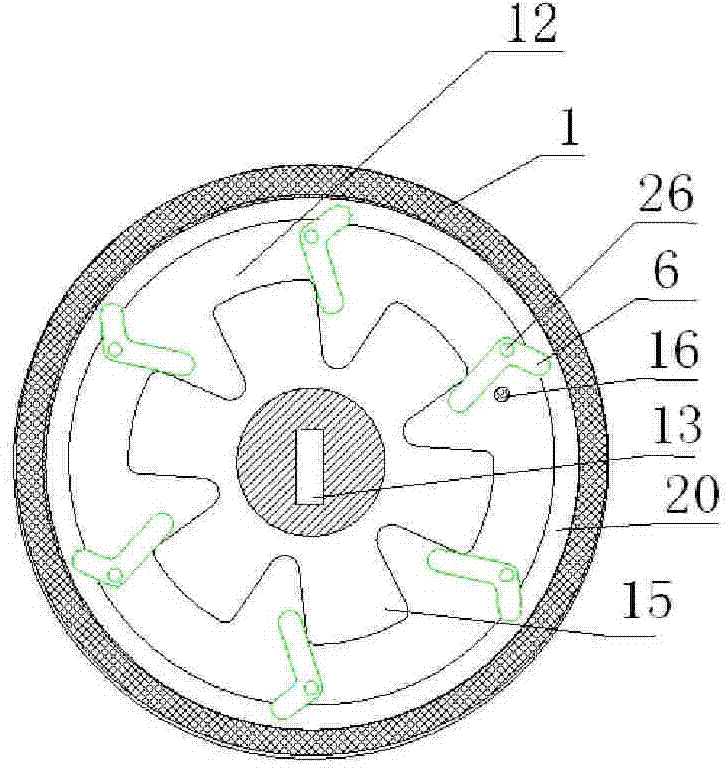

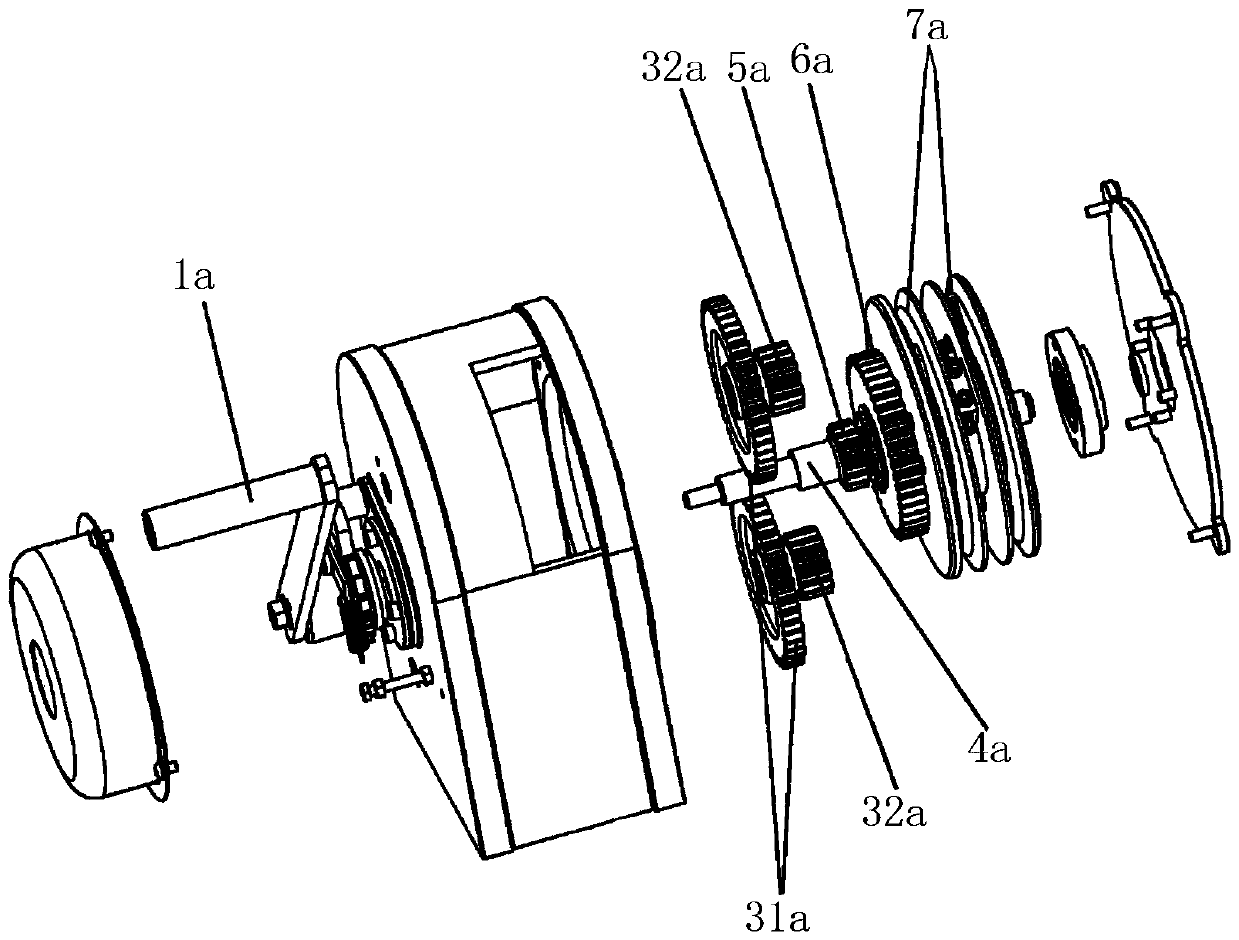

Improved locking device for main rotating shaft and application

ActiveCN105972201AAchieve brakingRealize the locking functionGearing controlHoisting equipmentsEngineeringCentrifugal force

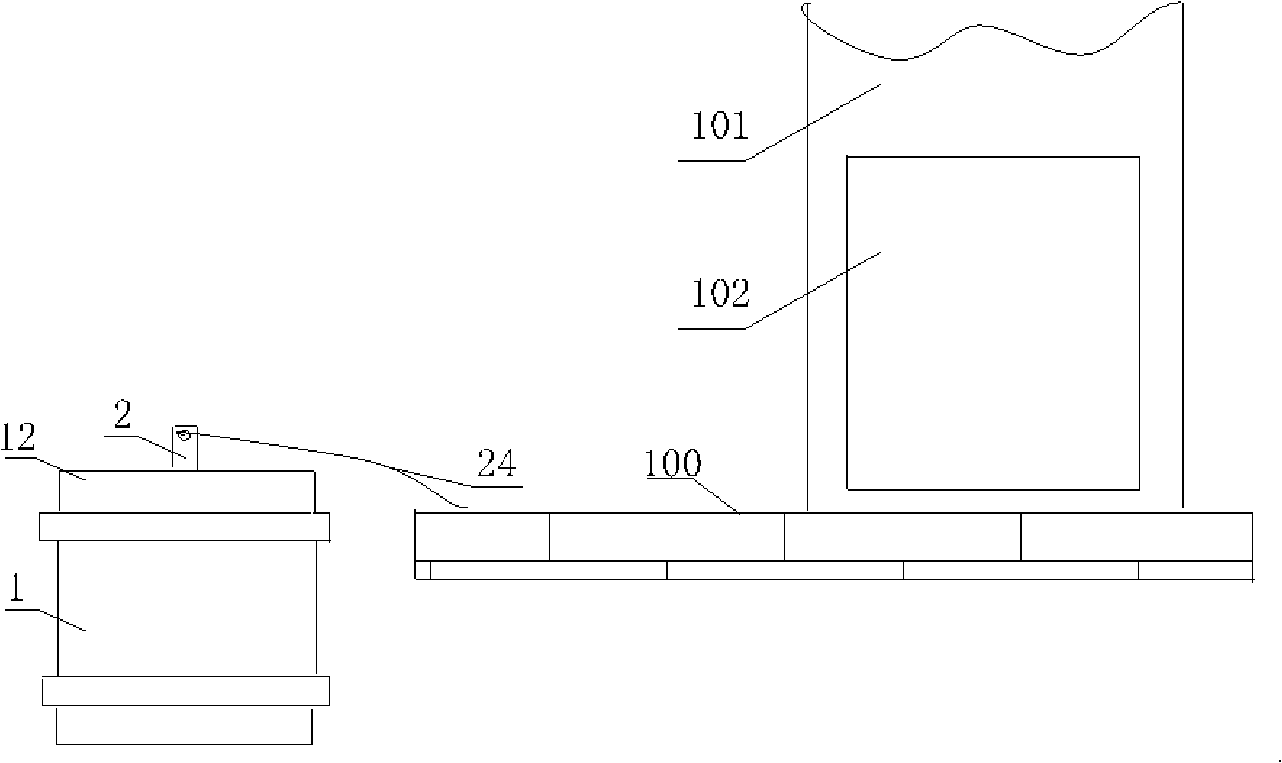

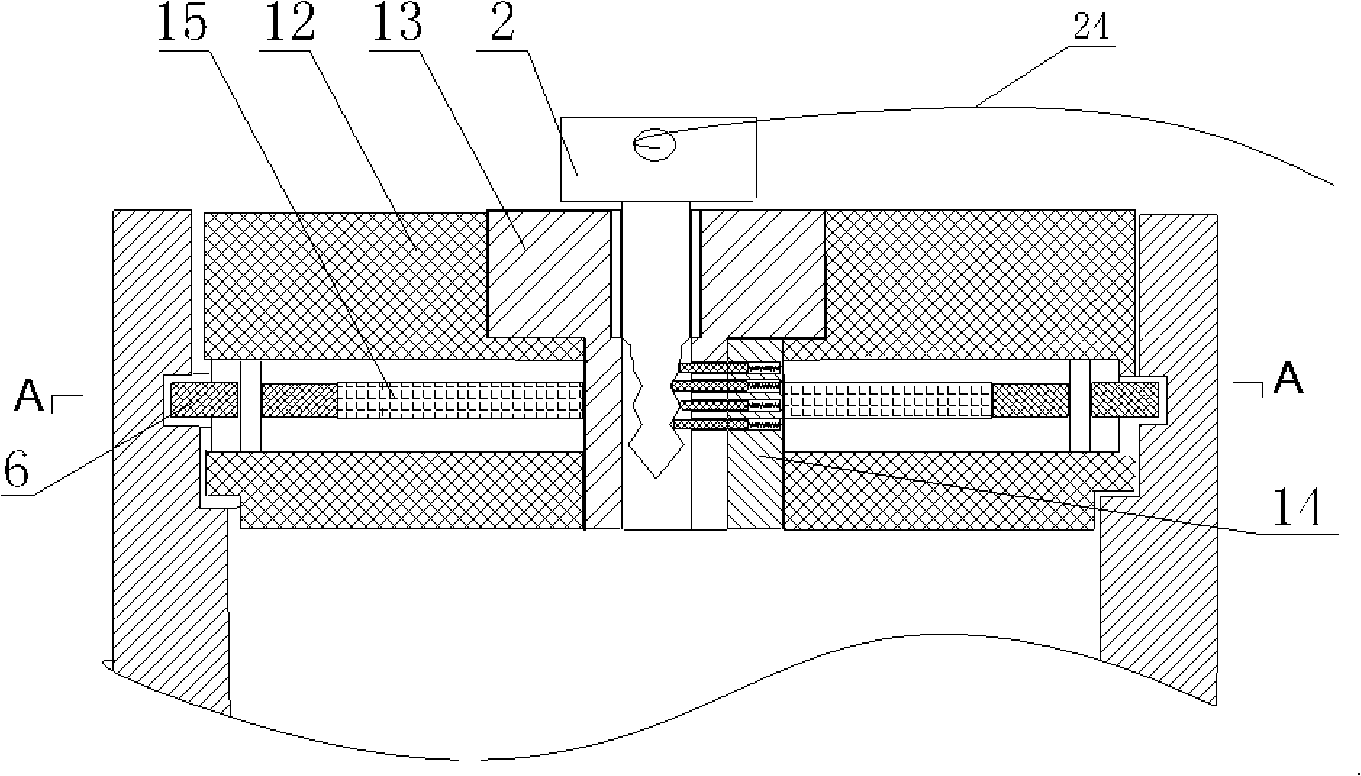

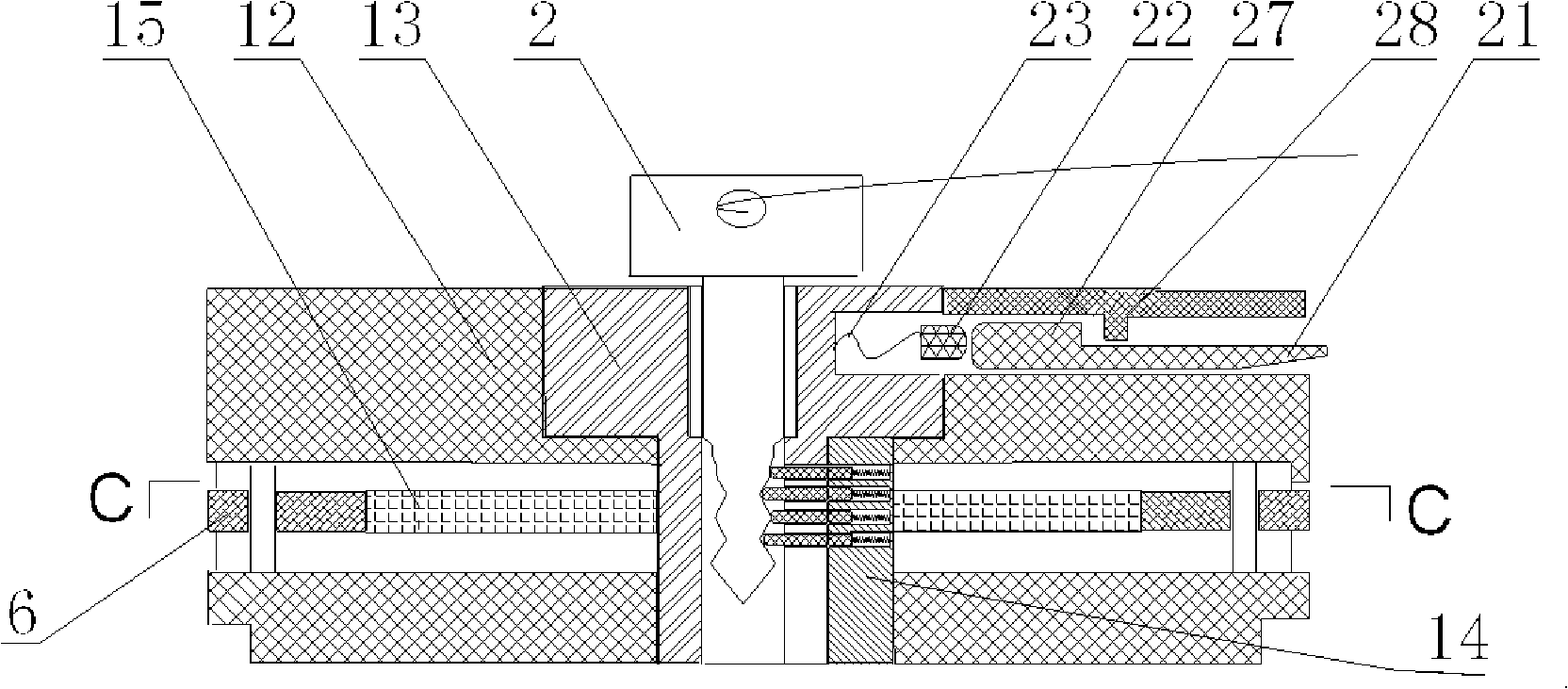

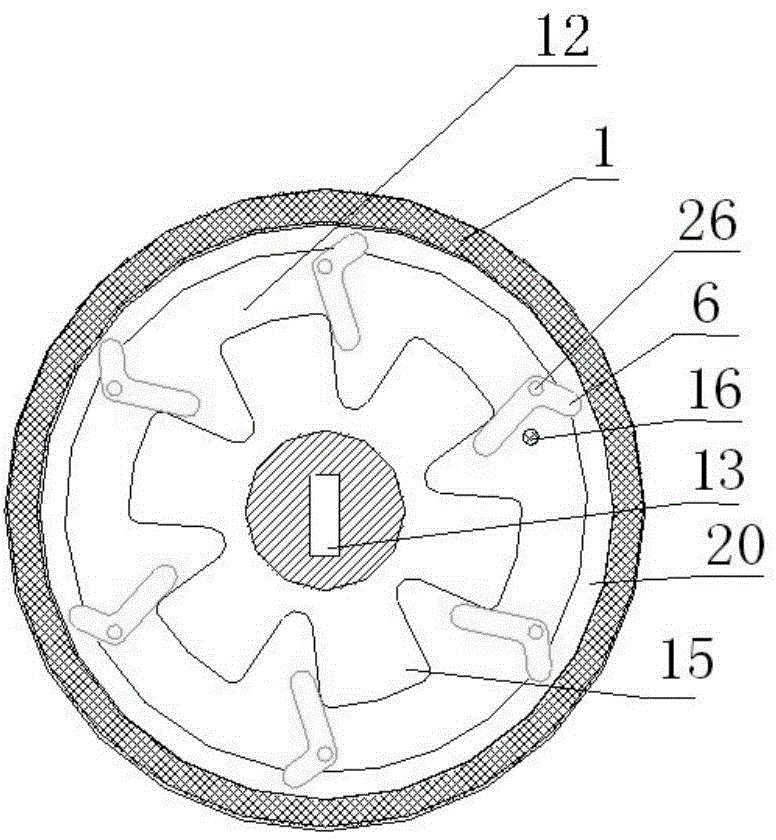

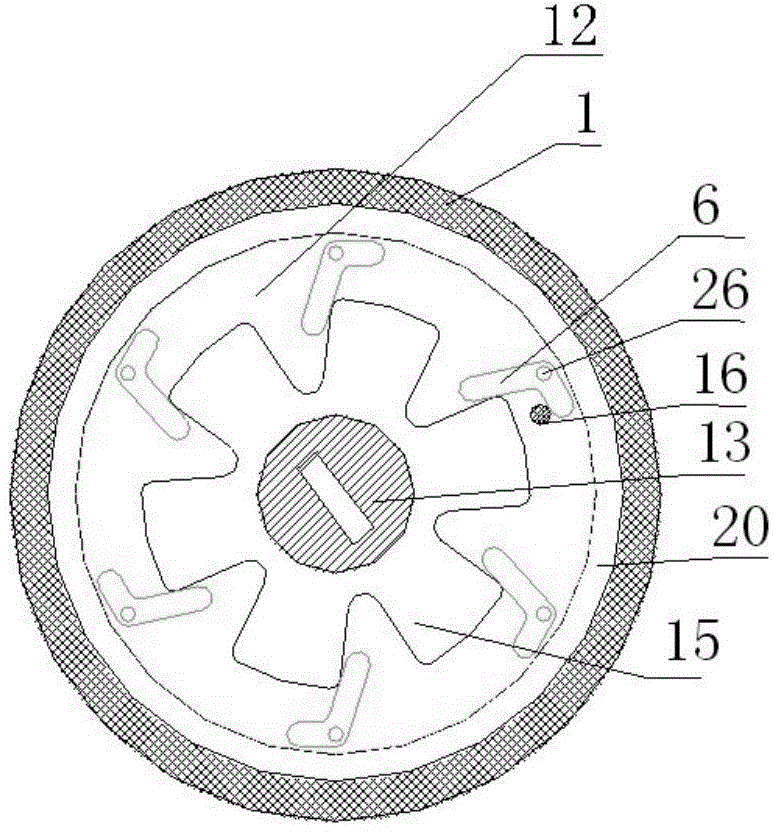

The invention discloses an improved locking device for a main rotating shaft. The device is characterized in that a torsional spring which can overcome screwing frictional resistance between the main rotating shaft and a connecting nut is additionally arranged between the connecting nut and the main rotating shaft so as to prevent the main rotating shaft from uncontrollable high-speed rotating caused by human errors; the connecting nut can overcome the thread frictional force relative to the main rotating shaft under the effect of the inverted torsion of the torsional spring, and thus the connecting nut can be rotated relative to the main rotating shaft, and as a result, the main rotating shaft can be braked. The invention also provides another scheme for locking the main rotating shaft. The scheme is characterized in that an inner pawl which can be limited through an elastic connector is arranged on a flywheel disc; in case that the main rotating shaft is subjected to uncontrollable high-speed rotating, the outward centrifugal force of the inner pawl on the flywheel disc can be utilized to overcome the tensioning force of the elastic connector, thus the inner pawl can be locked to an inner ratchet wheel, and as a result, the function of locking the main rotating shaft can be further achieved.

Owner:施耐德电气(厦门)开关设备有限公司

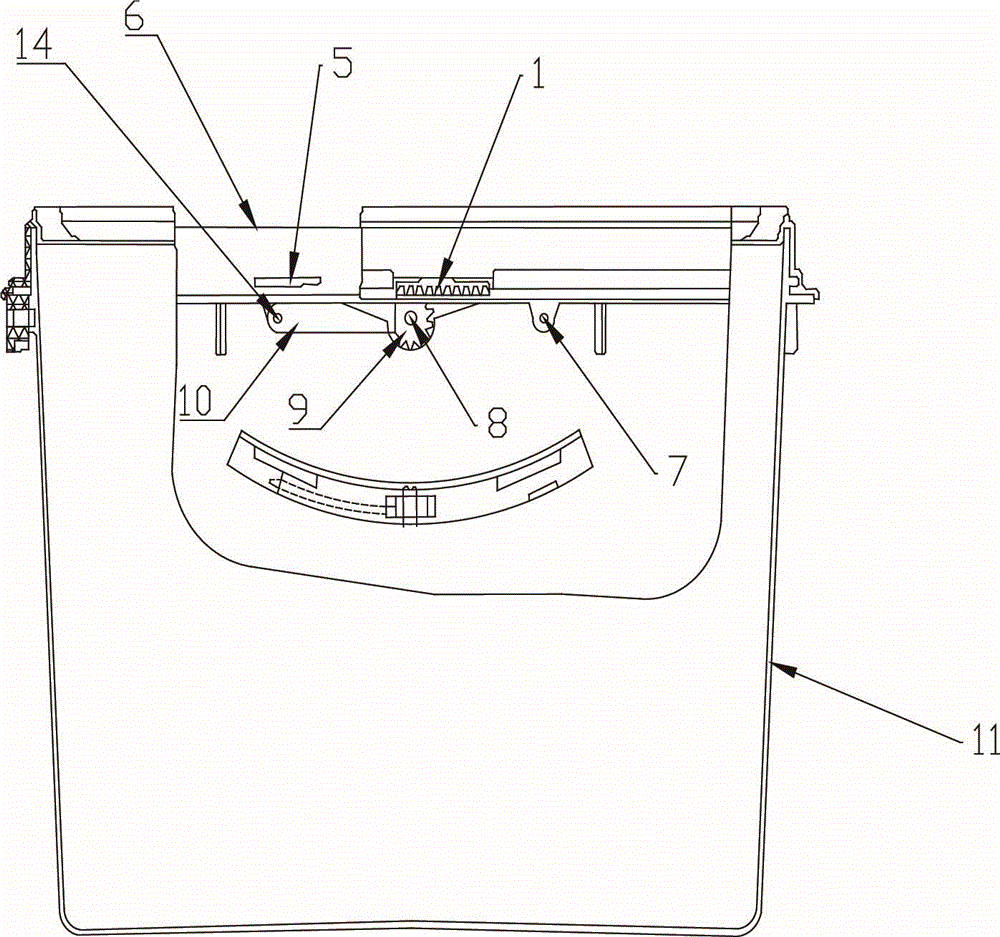

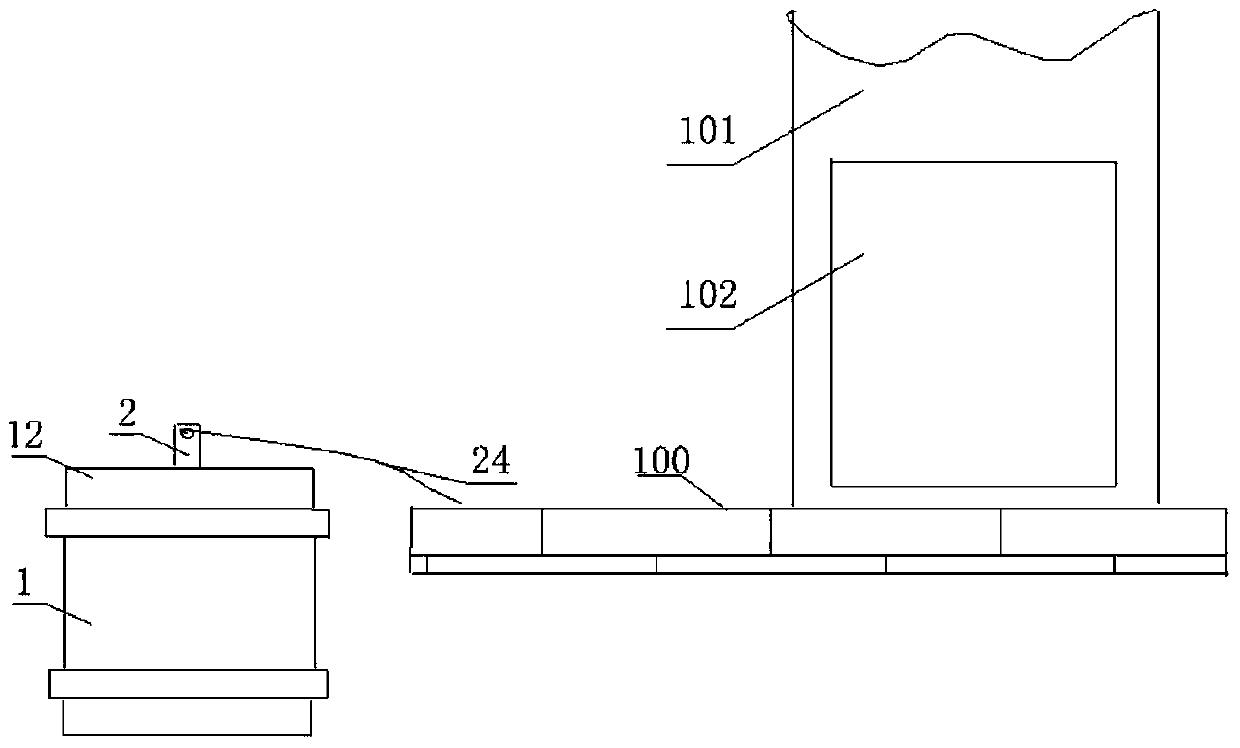

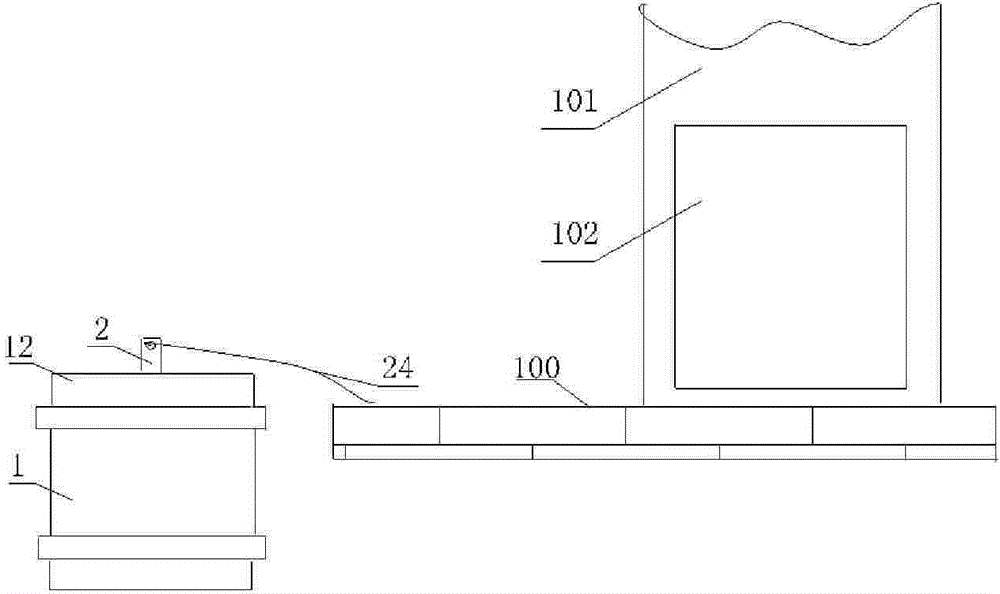

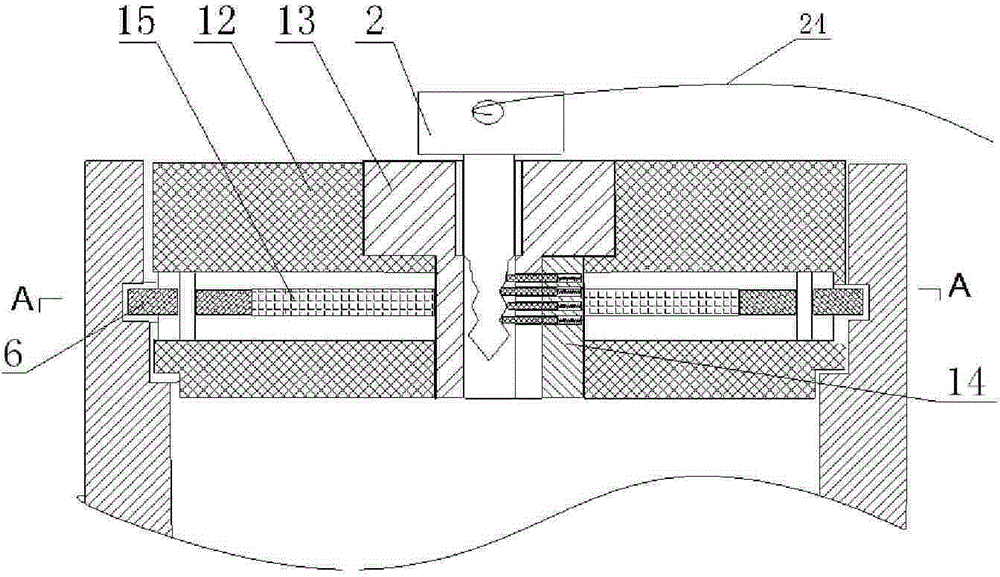

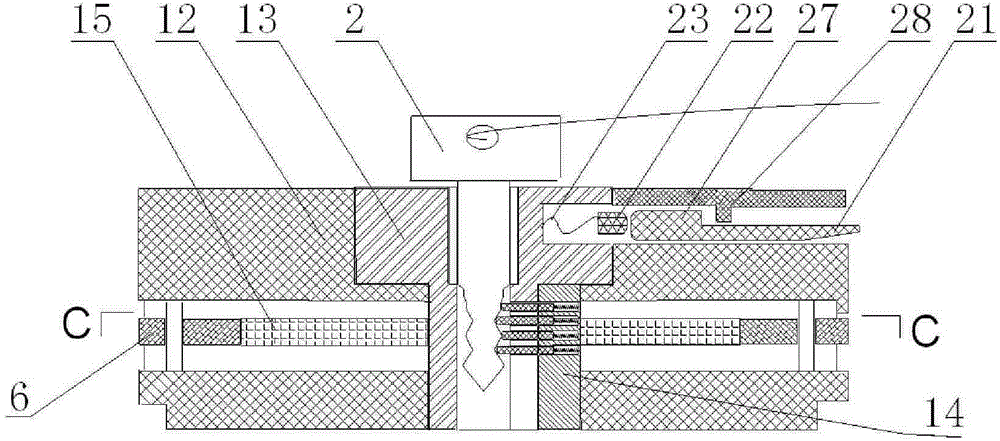

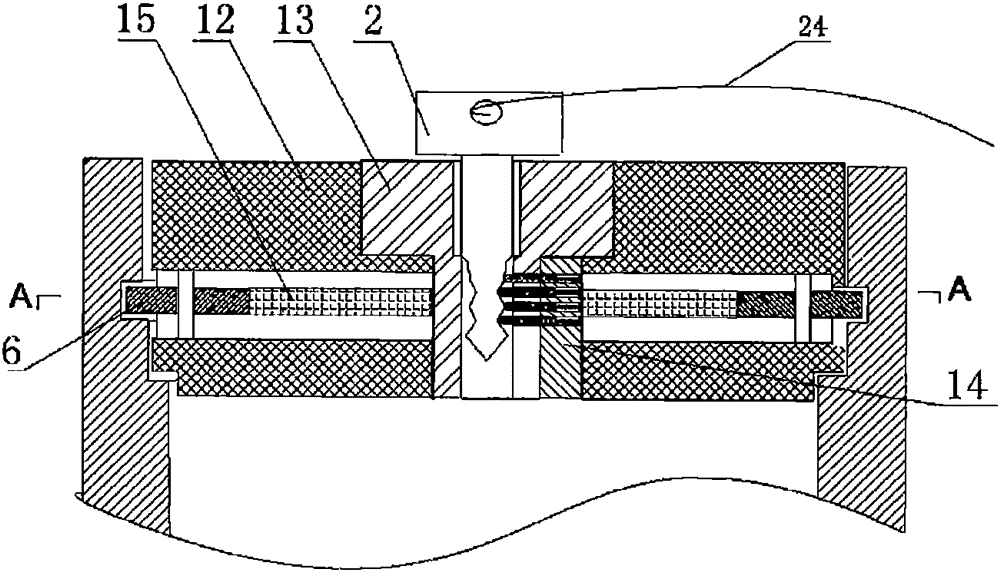

Transmitter and method for transmitter

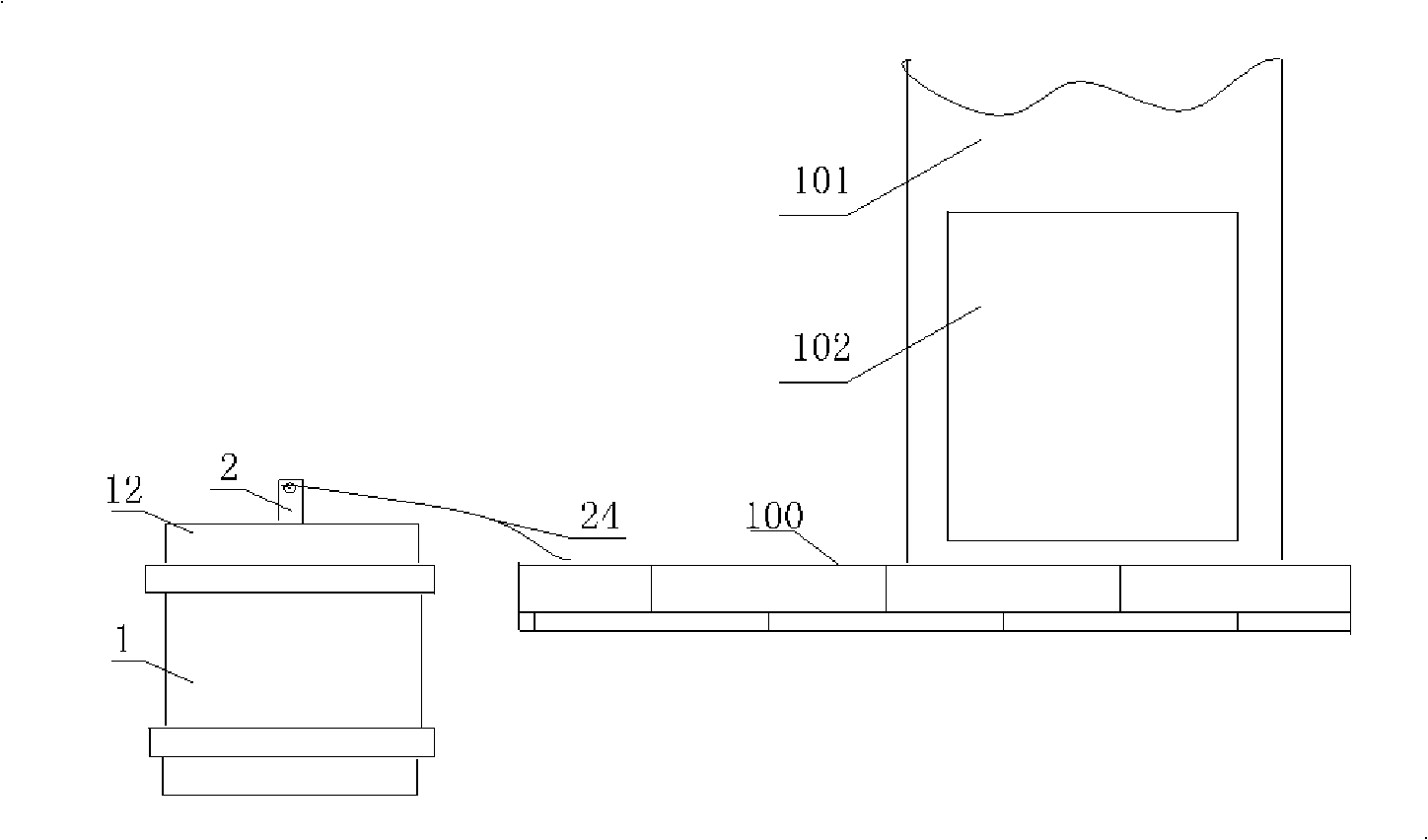

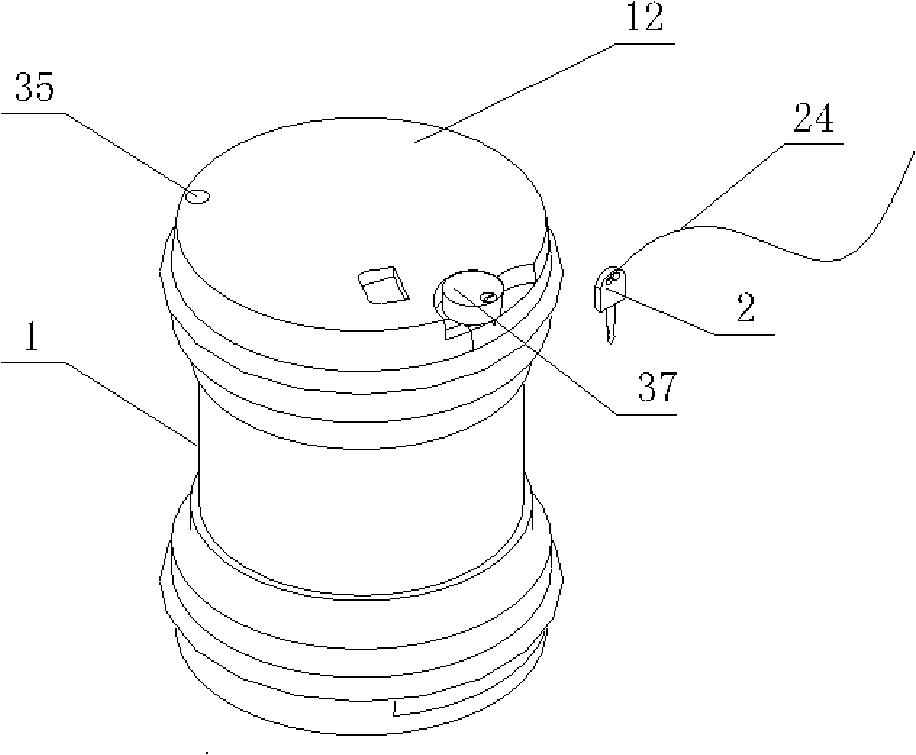

ActiveCN101314436AEnsure locking functionImprove safety and reliabilityConveyorsKeysEngineeringTransmitter

The invention relates to the pneumatic pipeline transmission field. A transmission device of the invention comprises a bucket body and a cover body, wherein a locking mechanism and a locking detection mechanism for detecting whether the locking mechanism locks are arranged on the bucket body or the cover body. The transmission device not only ensures the locking function, but also can be interlocked, which improves the safety reliability of the locking connection of the cover body and the bucket body of the transmission device, is favorable for improving transmission efficiency, and increases privacy.

Owner:BEIJING RINRONG TECH

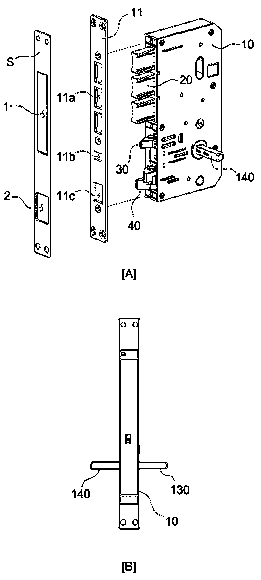

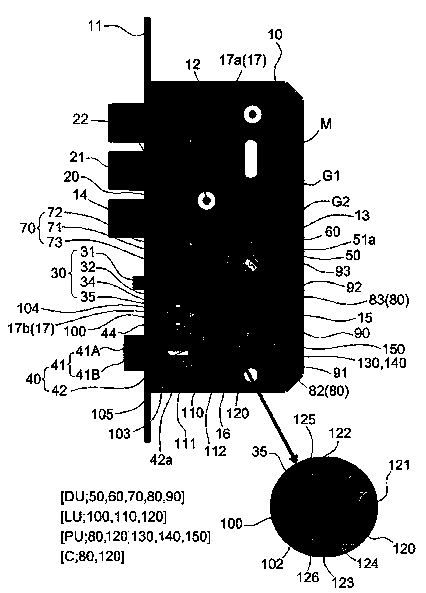

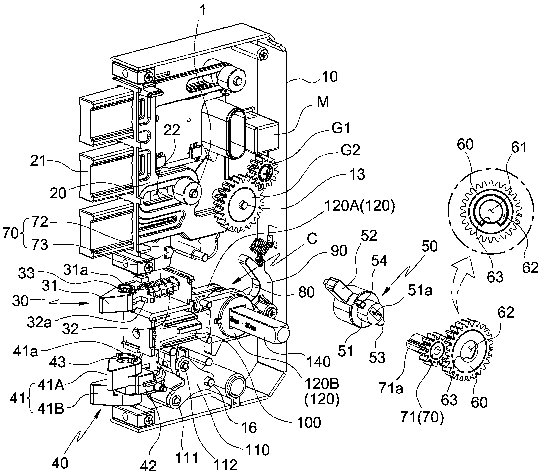

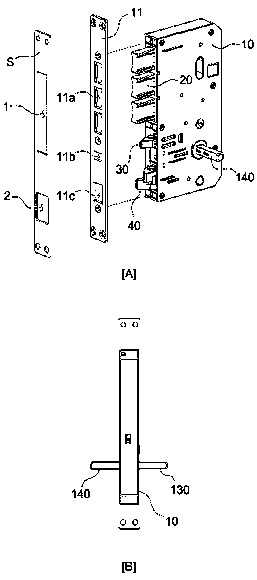

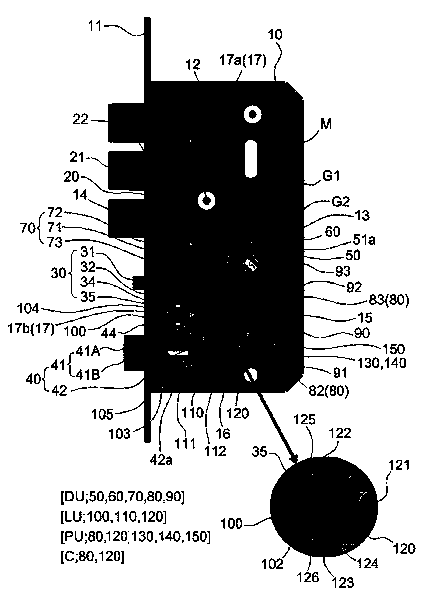

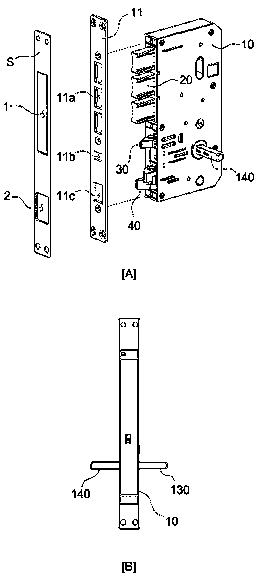

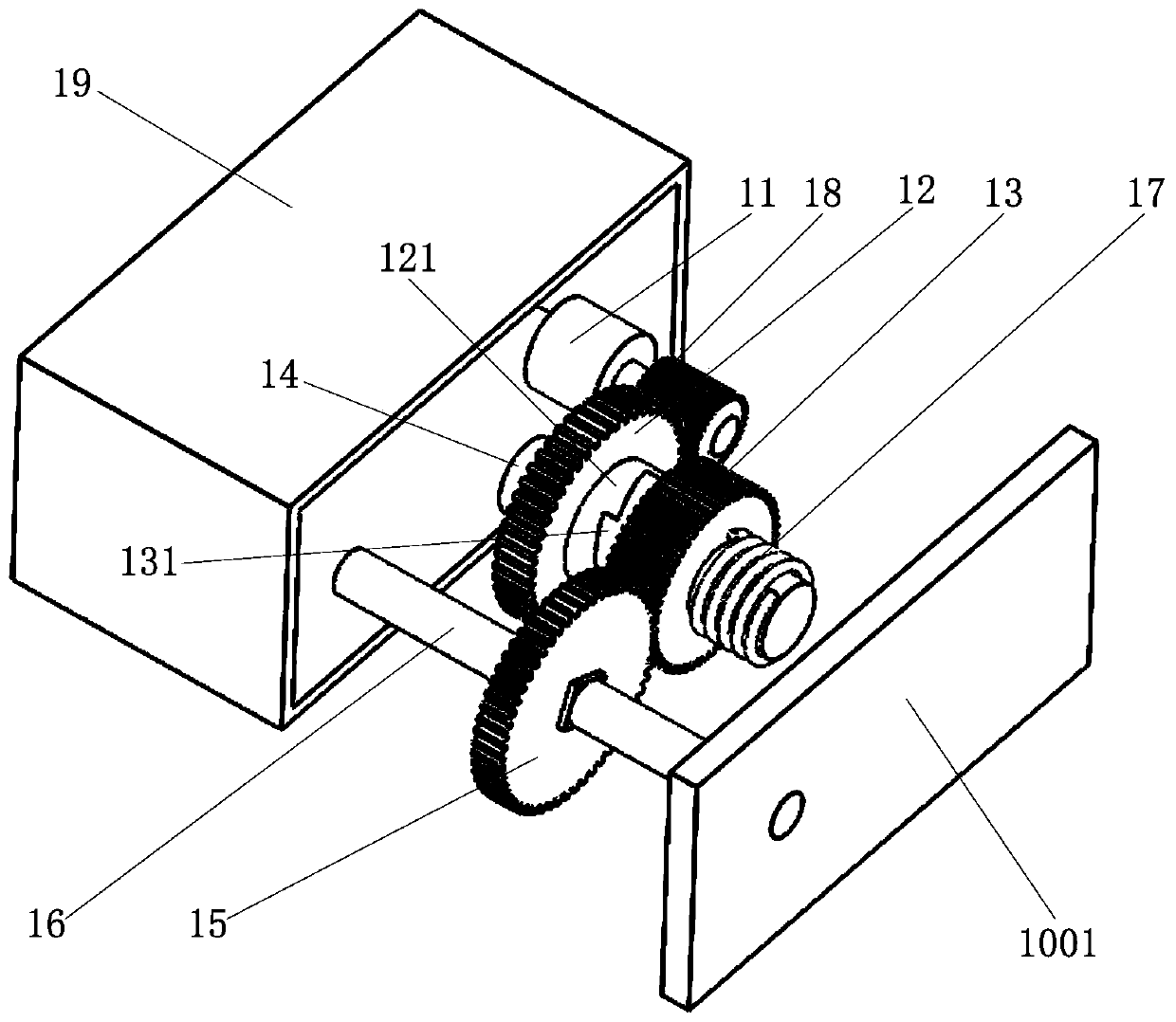

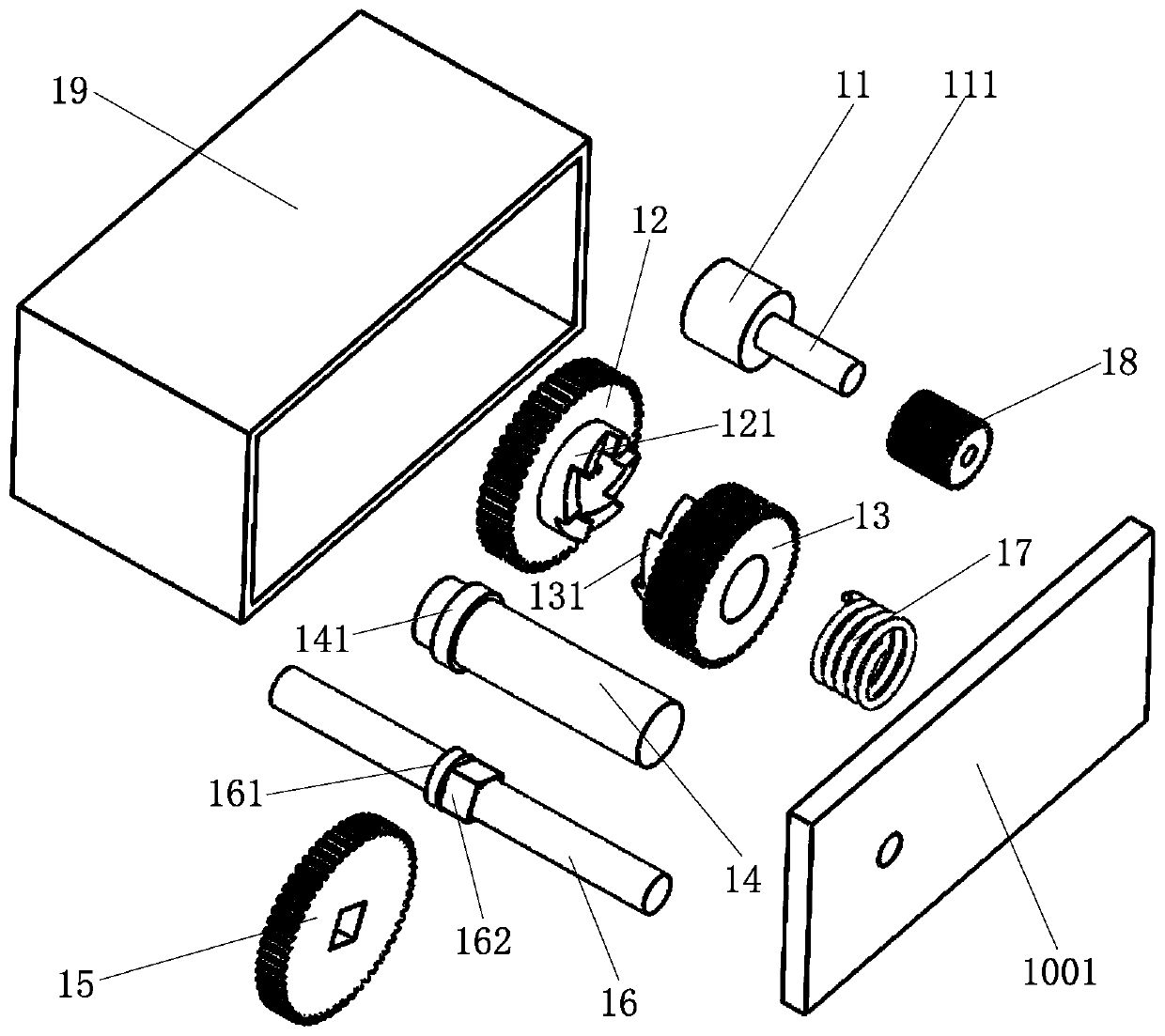

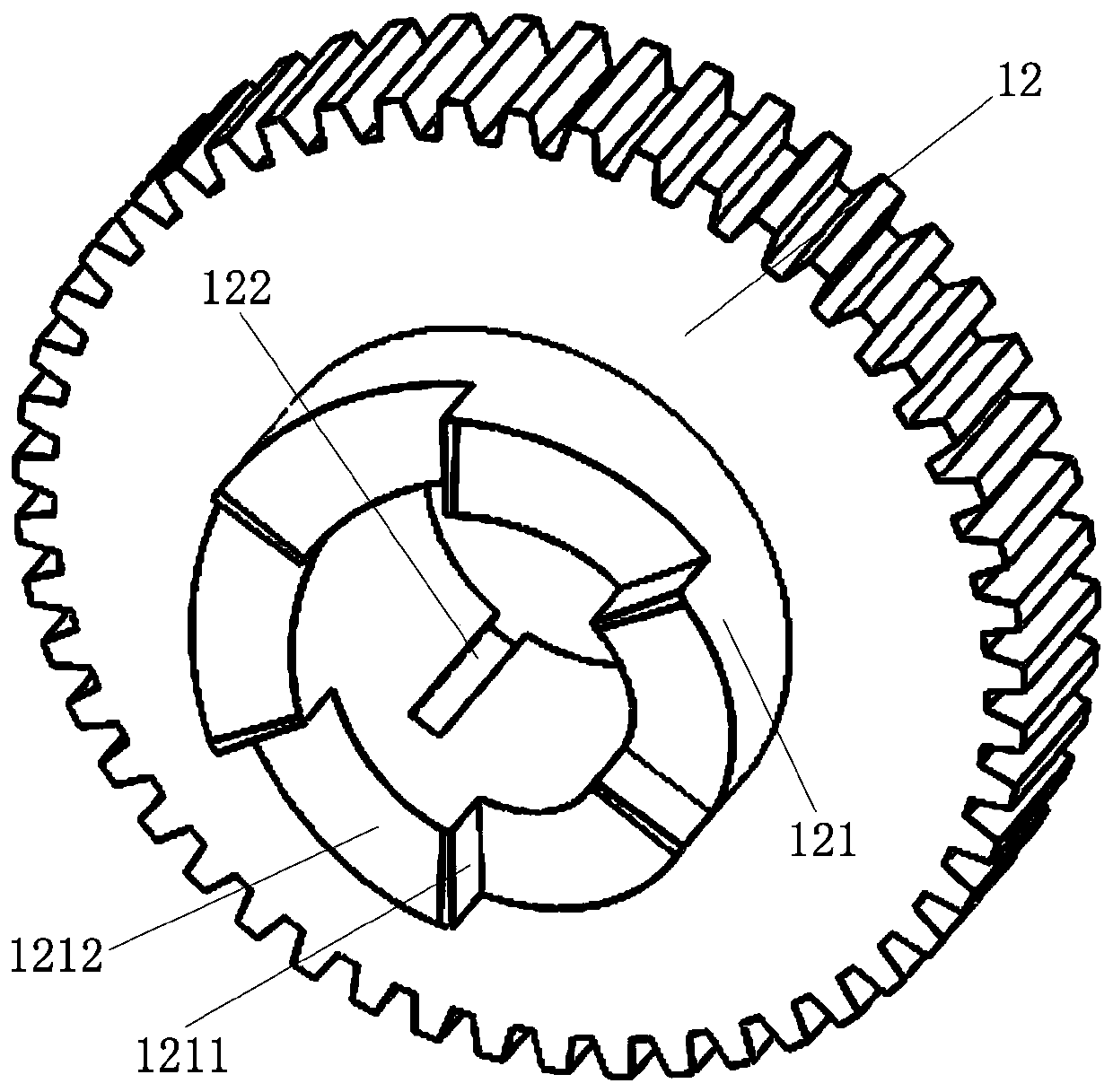

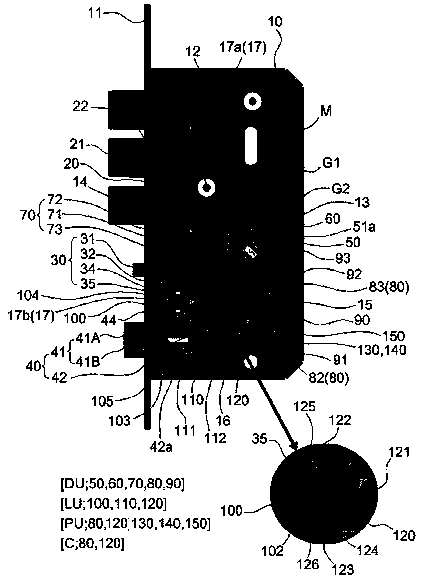

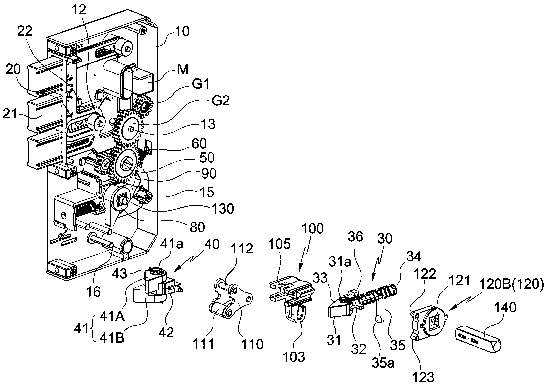

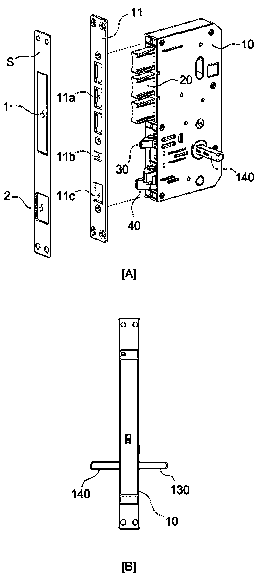

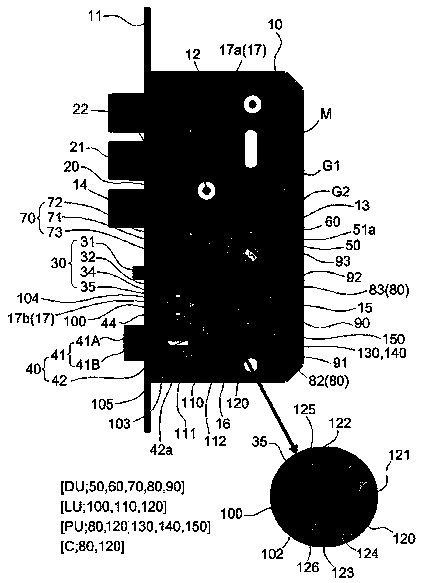

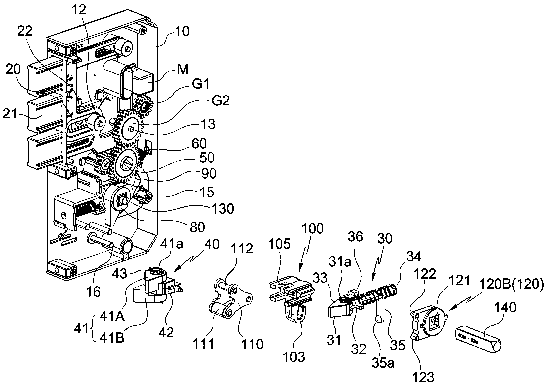

Mortise without load generation in bolt opseration

ActiveCN108729759ASmooth movementPrevent ejectionNon-mechanical controlsElectric permutation locksPasswordLoad generation

The invention provides a mortise without load generation in bolt operation. The mortise includes a deadbolt a sub latch, a main latch, and a deadbolt operation unit to lock and unlock a door. In particular, a deadbolt operation member and a driven gear are coupled to be able to rotate by using a guide groove so that a locking protrusion and a pressing protrusion part are separated from each otheron opposite sides, and the mortise includes a control means to control a motor in order to allow the driven gear to operate the deadbolt operation member and then to be returned to an original position thereof. Accordingly, when the deadbolt is locked and unlocked manually by using a key or a handle, or through operation of the motor by an input of a password, the deadbolt operation member or thedriven gear is rotated at first in a non-load state, thereby smoothly performing locking and unlocking operations of the deadbolt.

Owner:INNO ELECTRIC INC

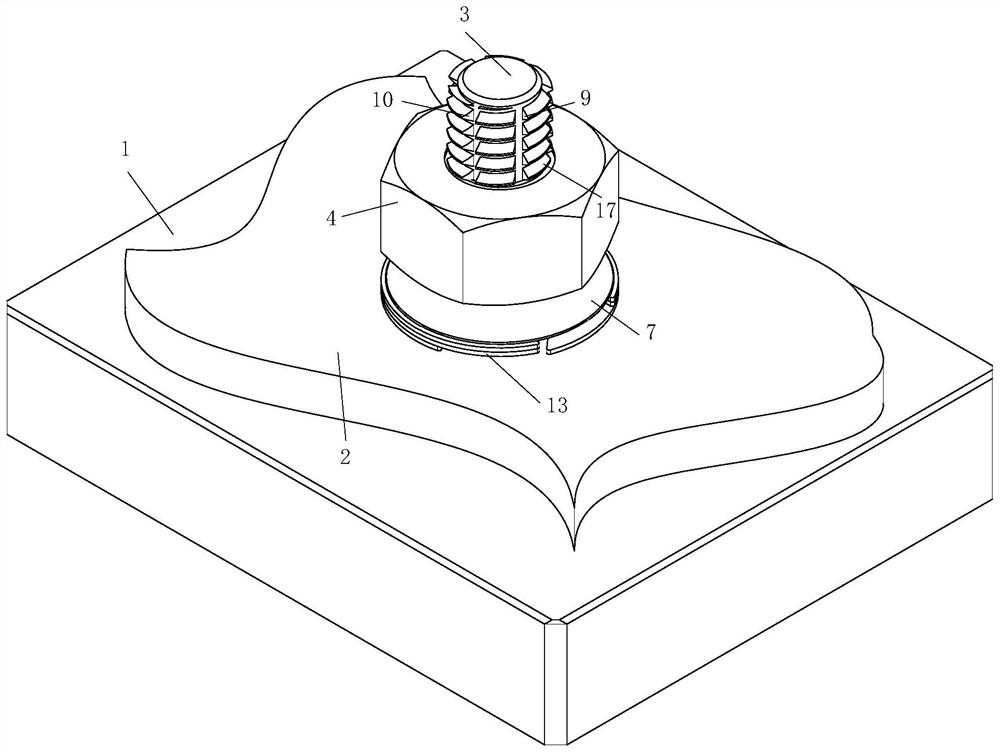

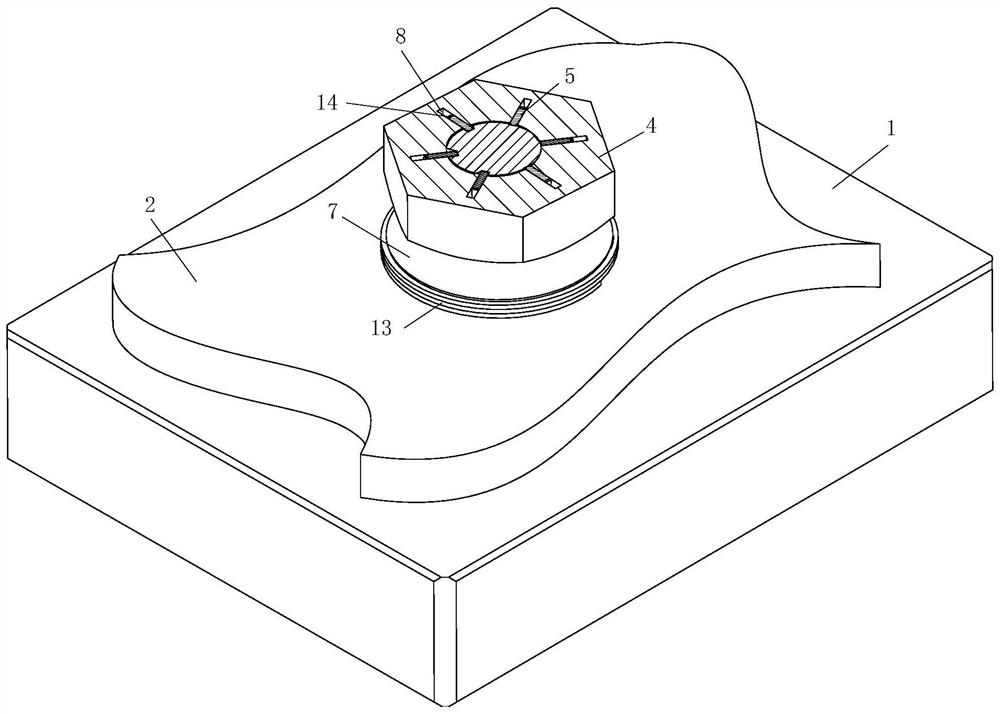

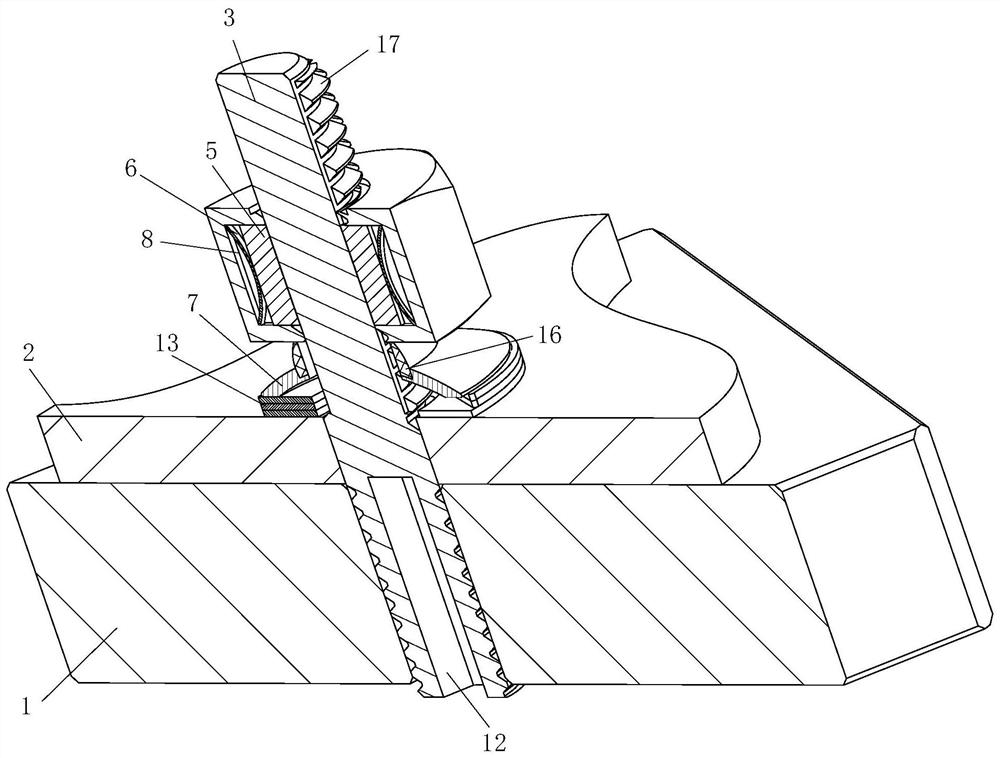

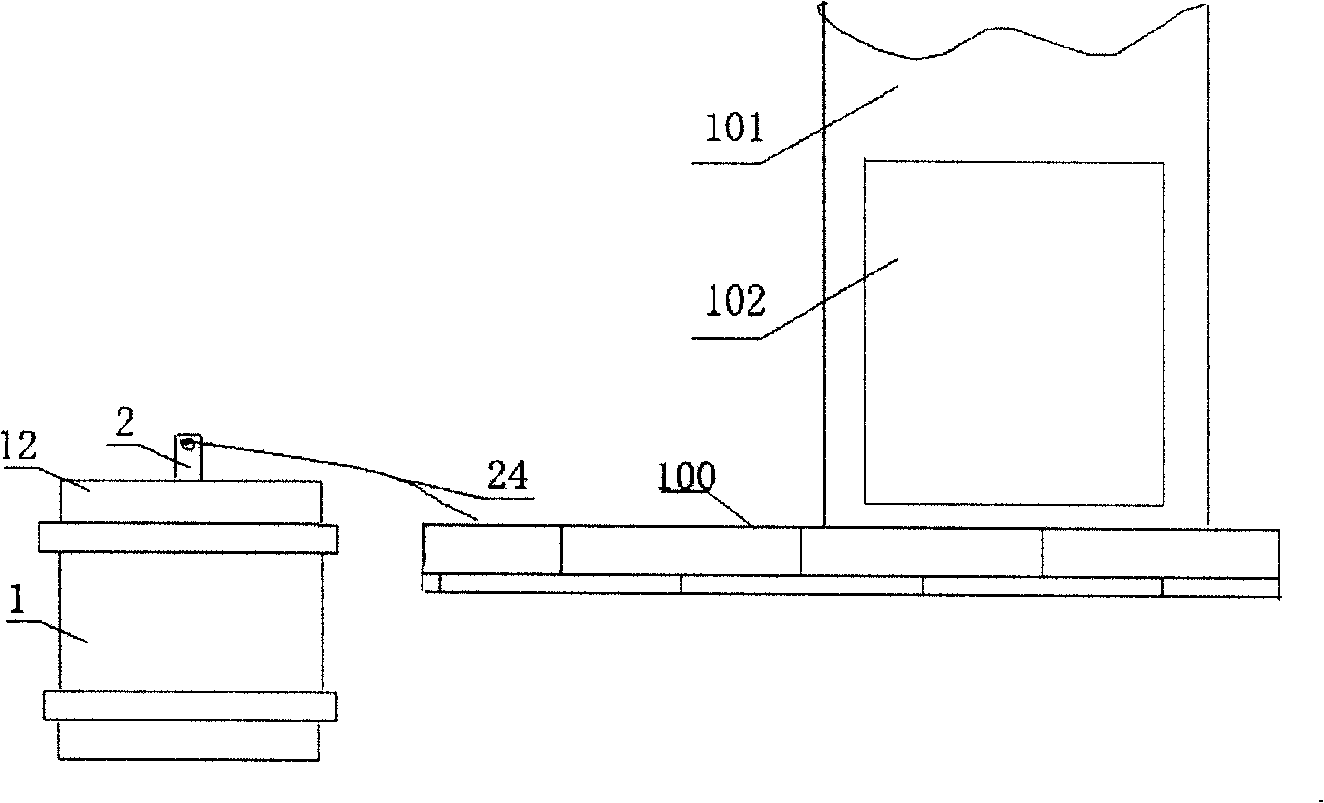

Anti-theft fastening bolt and nut thereof

The invention belongs to the technical field of fasteners, and particularly relates to an anti-theft fastening bolt and a nut thereof. The anti-theft fastening bolt comprises a base, a fastened piece, a stud, the nut, stop blocks, elastic elements and an elastic pad. According to the anti-theft fastening bolt and a nut thereof, through arranged special-shaped threads, when the nut is rotated in the clockwise direction, the stop blocks make contact with the advancing ends of the special-shaped threads, then the ends, making contact with the advancing ends, of the stop blocks slide on the advancing ends, due to the fact that the advancing ends are inclined curved surfaces, the stop blocks move in the direction away from the stud while rotating along the stud, and thus the stop blocks completely enter sliding grooves, so that the clockwise rotation of the nut is not restrained, and the nut is tightened; and one ends of the stop blocks enter grooves, when the nut is rotated in the counterclockwise direction so as to relieve the fastening of a part, one sides of the stop blocks abut against the retaining ends of the special-shaped threads, the rotation of the nut in the counterclockwise direction is limited, and the dismounting of the nut is limited, so that the anti-theft effect is achieved.

Owner:郭澳

Method and apparatus for securing cap of transfer carrier from being opened

InactiveCN101314434AGuaranteed safety and reliabilityAchieve interlockConveyorsKeysLocking mechanismEngineering

The invention relates to the pneumatic pipeline transmission field. A method for ensuring that transmission carriers cannot be uncovered comprises the following steps that: 1) a locking mechanism for locking a cover body and a bucket body of a transmission carrier is arranged on the transmission carrier; 2) a locking detection mechanism is arranged on the transmission carrier; 3) whether the locking mechanism reliably locks the cover body and the bucket body of the transmission carrier is detected by using the locking detection mechanism, and if no, the locking mechanism is operated again to lock the cover body and the bucket body; under the condition of confirming the locking, the transmission carrier is released. A method for ensuring that transmission carriers cannot be uncovered comprises the locking mechanism arranged on the bucket body or the cover body of the transmission carrier, as well as the locking detection mechanism used for detecting whether the locking mechanism locks. The method can ensure that the locking safety and reliability of the cover body and the bucket body of the transmission carrier, which improves transmission efficiency and increases privacy.

Owner:BEIJING RINRONG TECH

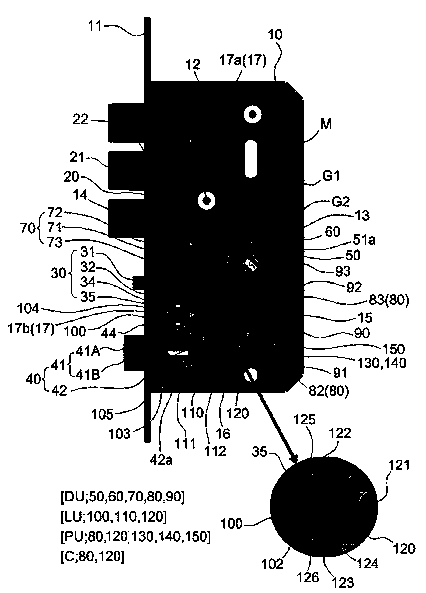

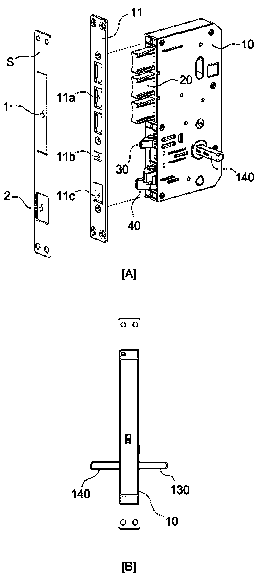

Mortise capable of limit insertion of main latch and provided with sub latch

ActiveCN108843149APop-up blockEnsure locking functionNon-mechanical controlsLatching locksEngineeringMechanical engineering

The present invention relates to a mortise capable of limit insertion of a main latch and provided with a sub latch, including a dead bolt, a sub latch, a main latch, and a dead bolt operating unit tolock and unlock a door. Specifically, the mortise permits insertion of a latch bolt when the door is open and blocks the insertion of the latch bolt when the door is locked. So, the latch bolt performs a locking function of the door with the dead bolt so that security of the mortise can be improved. To achieve the same, a pressing unit of the sub latch and a pressing protrusion of a latch cam permit a backward movement of a latch transfer while the sub latch half-protrudes due to a closure of the door. So, while the latch stopper rotates in one direction, a locking protrusion blocks the insertion of the latch bolt. When the insertion and the withdrawal of the sub latch are completed as the door is opened and closed by a handle, the pressing unit or the pressing protrusion moves the latchtransfer forward. So, the latch stopper rotates in the other direction, and the locking protrusion permits the insertion of the latch bolt, so that when a door is closed, the main latch is inhibited to be inserted by the mortise; and the main latch is inserted only if the door is opened, so that along with the dead bolt, the main latch itself has a locking function, thereby enhancing security.

Owner:INNO ELECTRIC INC

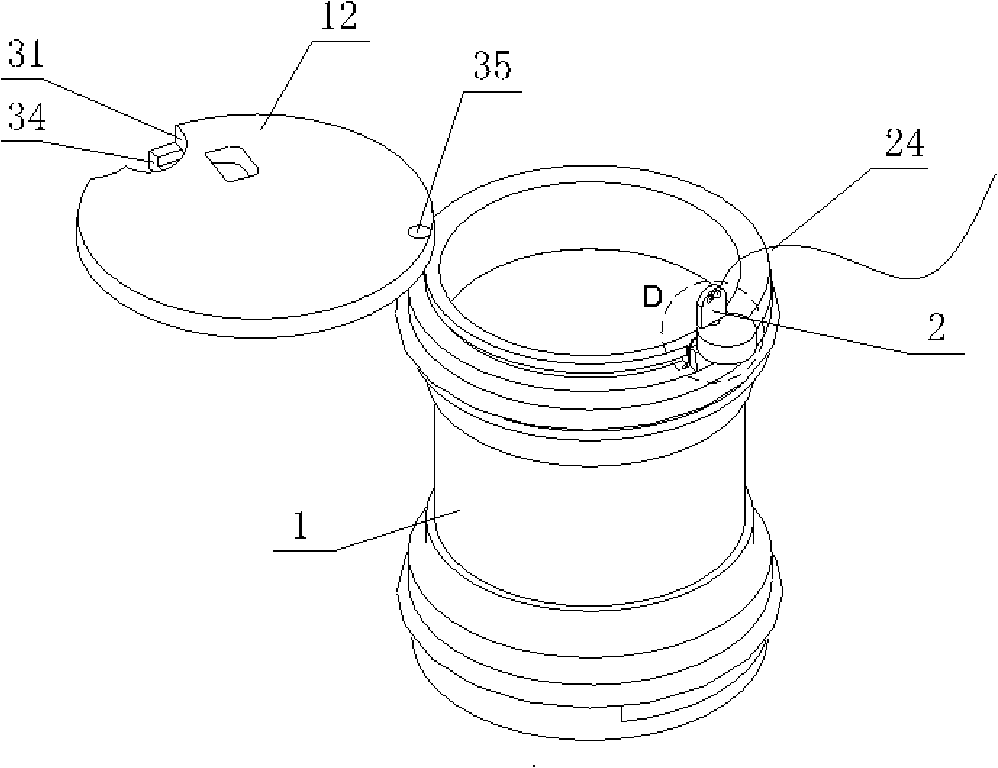

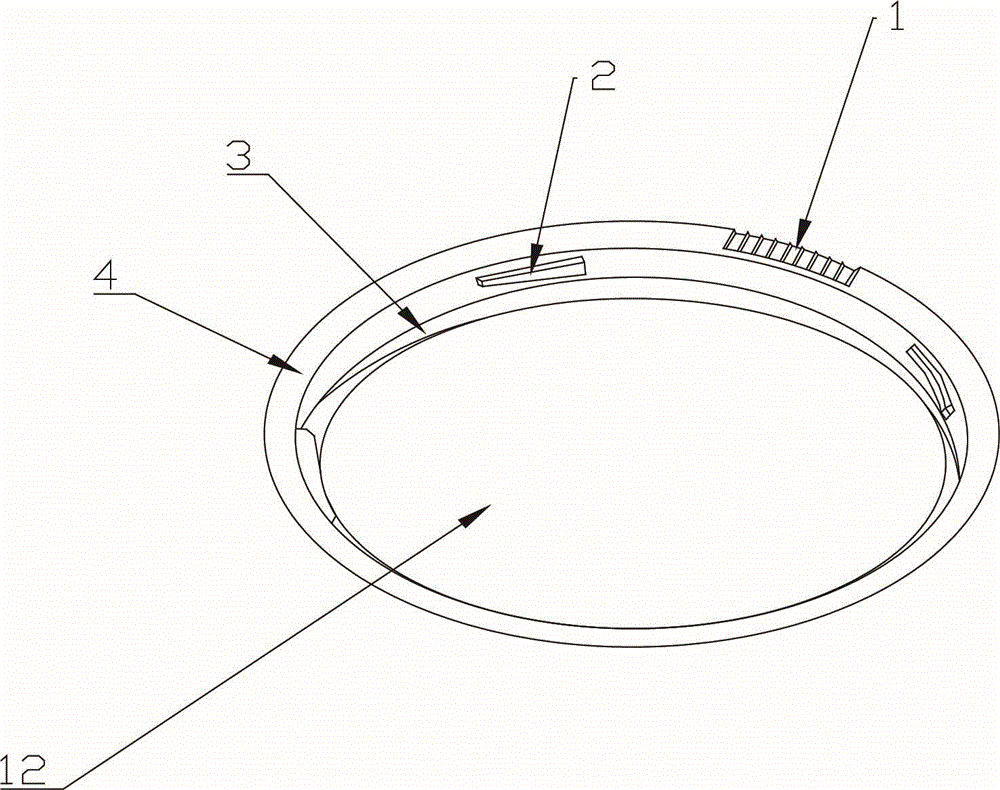

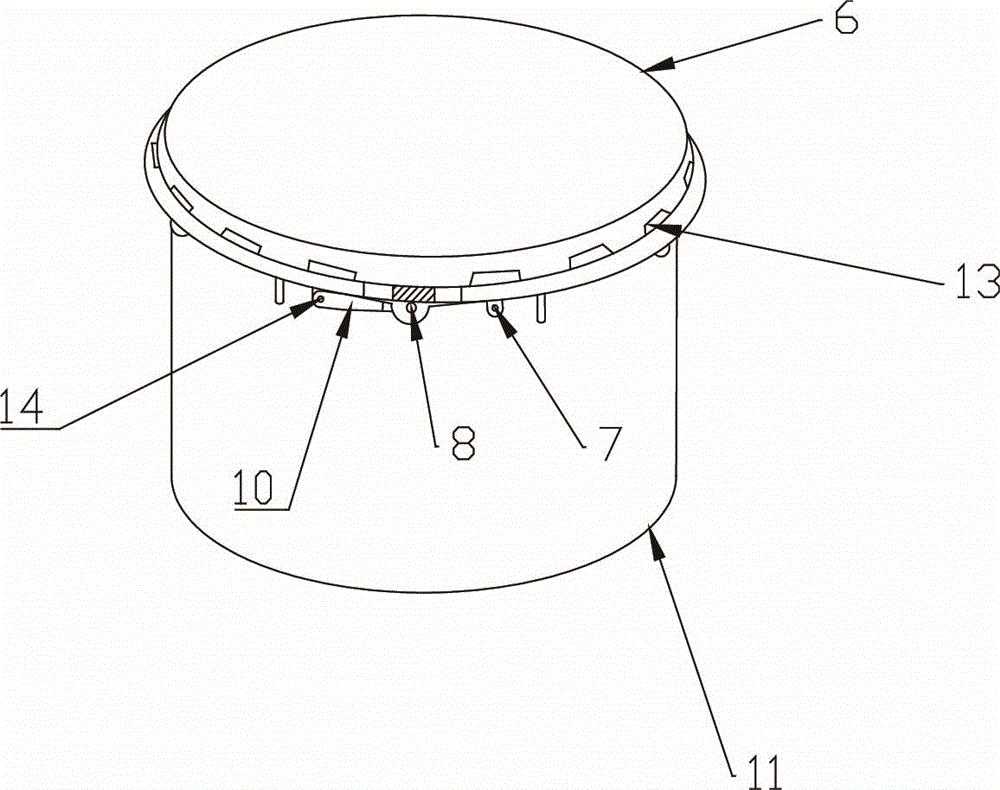

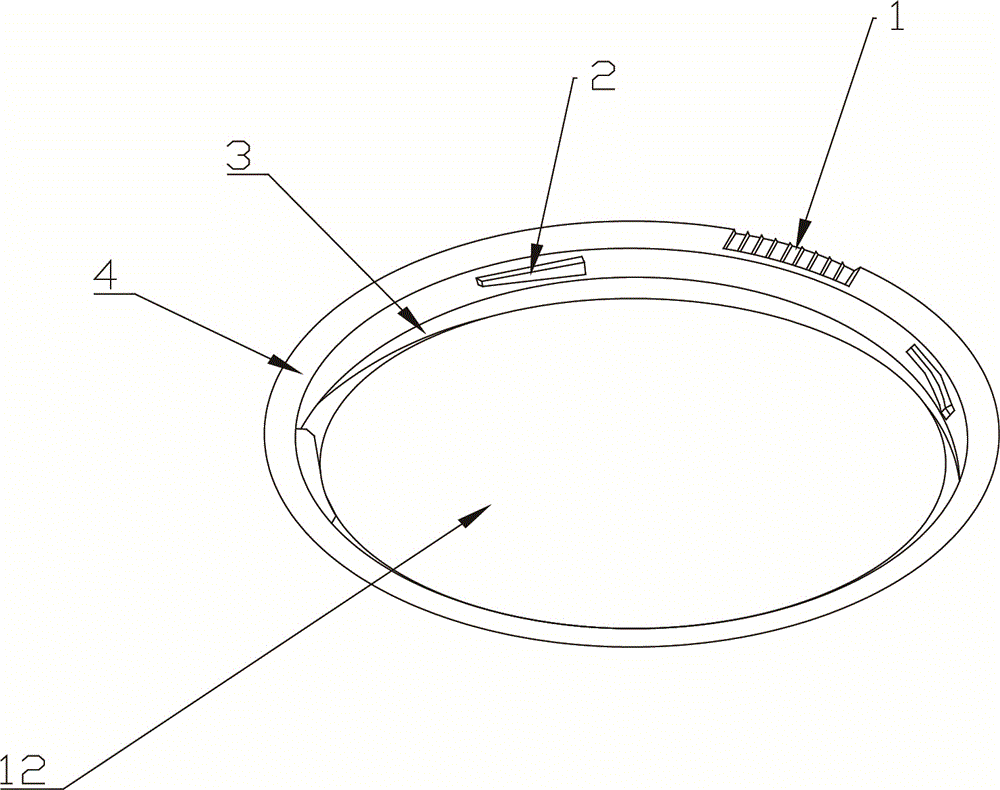

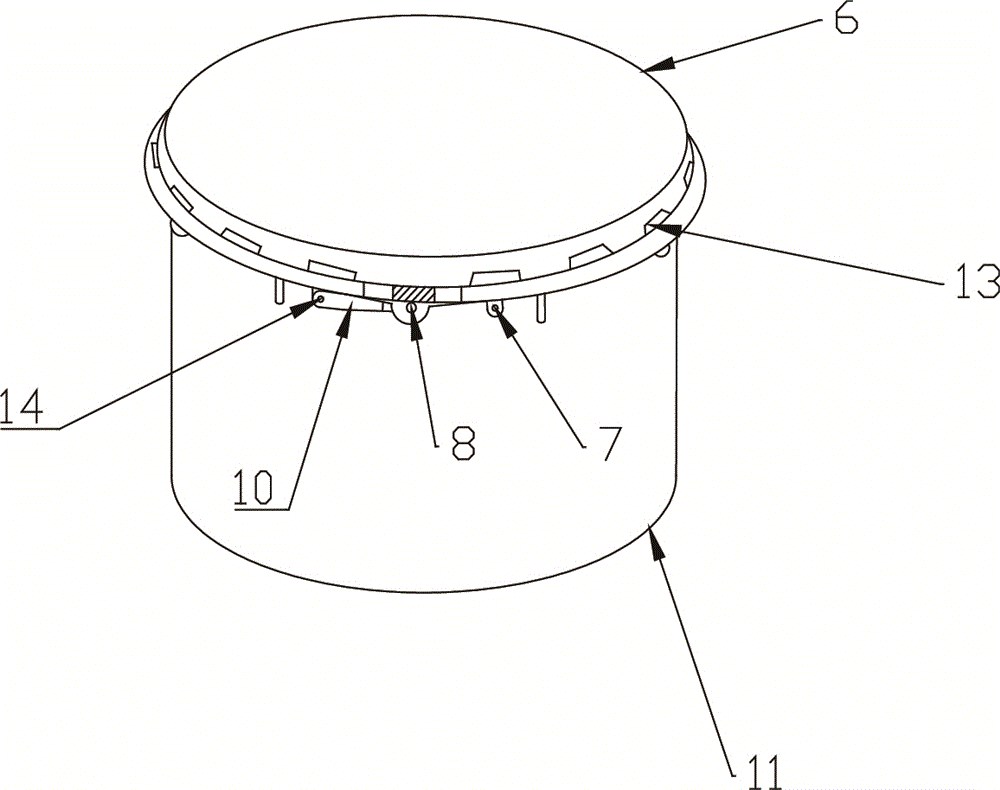

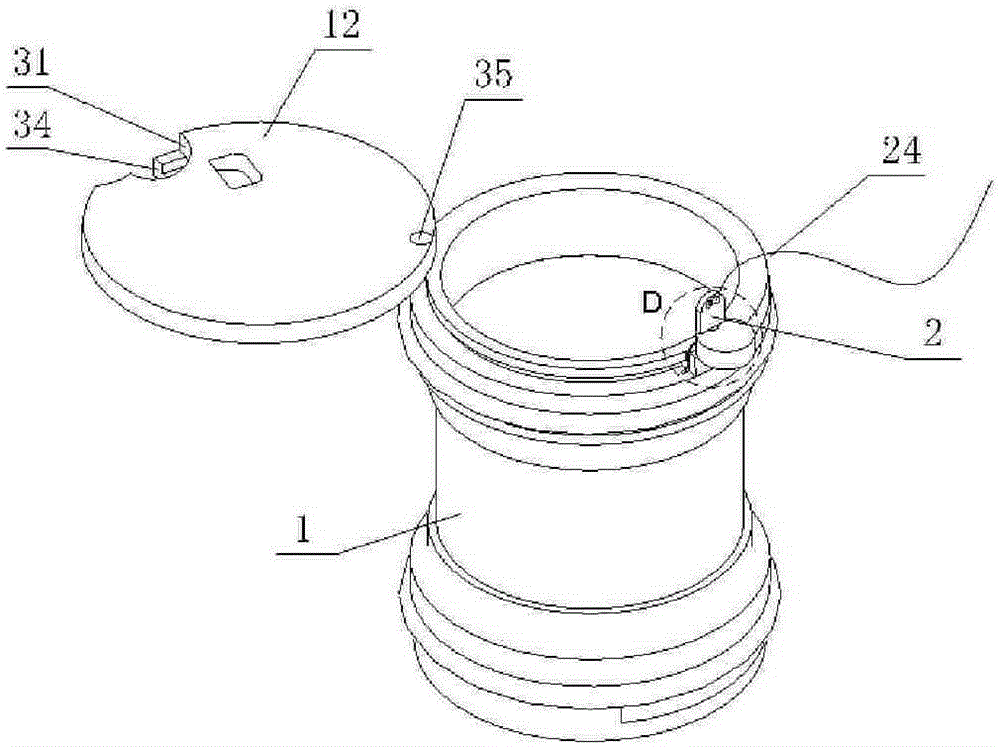

Locking structure for round plastic container

The invention discloses a locking structure for a round plastic container. The locking structure for the round plastic container comprises a barrel body and a barrel cover, wherein a plurality of barrel cover thread strips are arranged on the inner side of the barrel cover; a rack is arranged on one surface, connected with the barrel body, of the barrel cover; a plurality of barrel body thread strips are arranged on the periphery of the outer side of the opening of the barrel body; the barrel cover thread strips and the barrel body thread strips are matched with each other; a set of gears are arranged on the edge of the upper opening of the barrel body; a fixed gear central shaft is arranged in the gears, and is the gears are connected with a gear handle; when the barrel body is motionless, the gear handle drives the gears to rotate anticlockwise, and then the rack on the barrel cover and the whole barrel cover are driven by the rotating function of the gears to move clockwise; with less power, the lever effect of the gear handle on the gears and the effect of thread inclined plane moving are adopted to produce tens times of locking force of the barrel body and the barrel cover, so that the barrel cover and the barrel body are locked; when the gear handle swings clockwise, and the barrel cover moves anticlockwise, the barrel cover is then loosened; the way of locking and unlocking the barrel cover and the barrel body is very convenient.

Owner:NINGBO CHANGQI FLOURINE PLASTIC PROD CO LTD

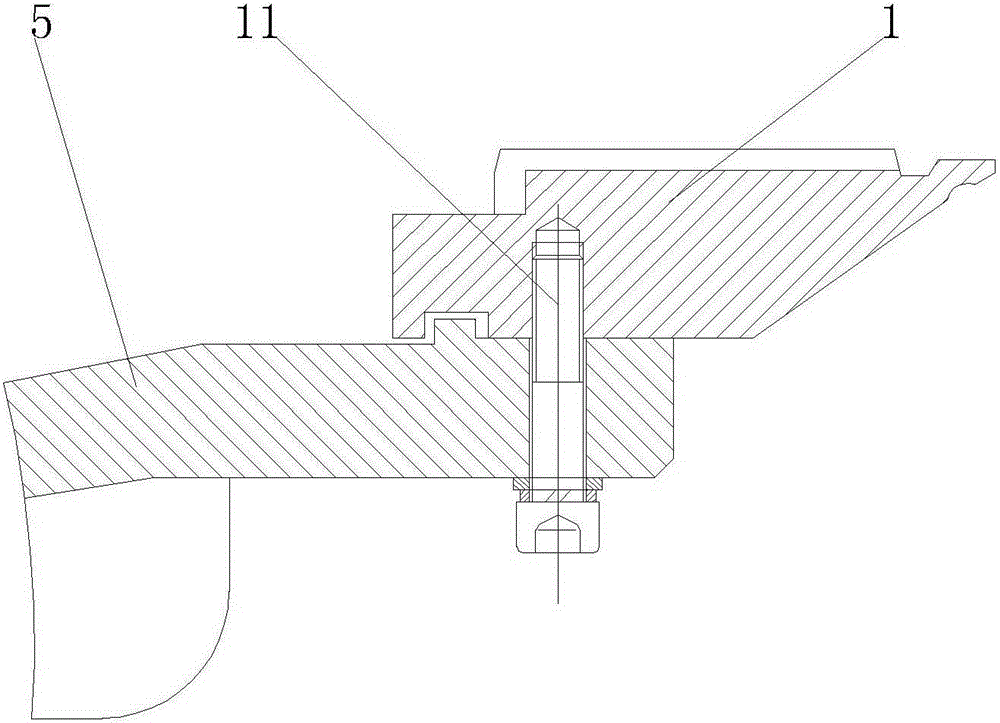

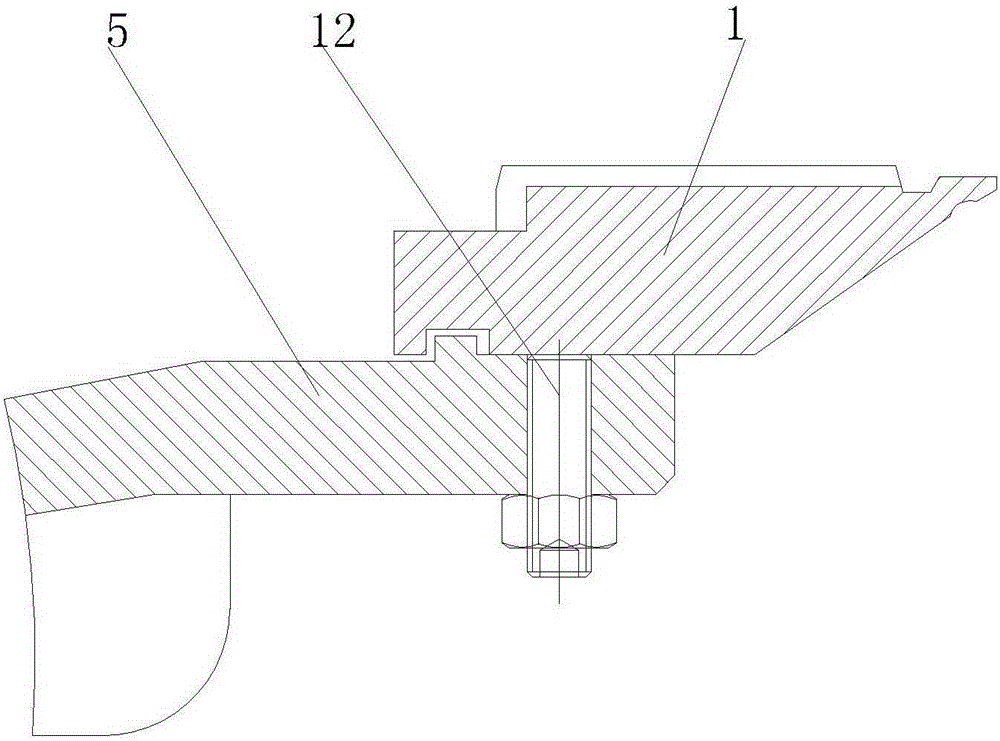

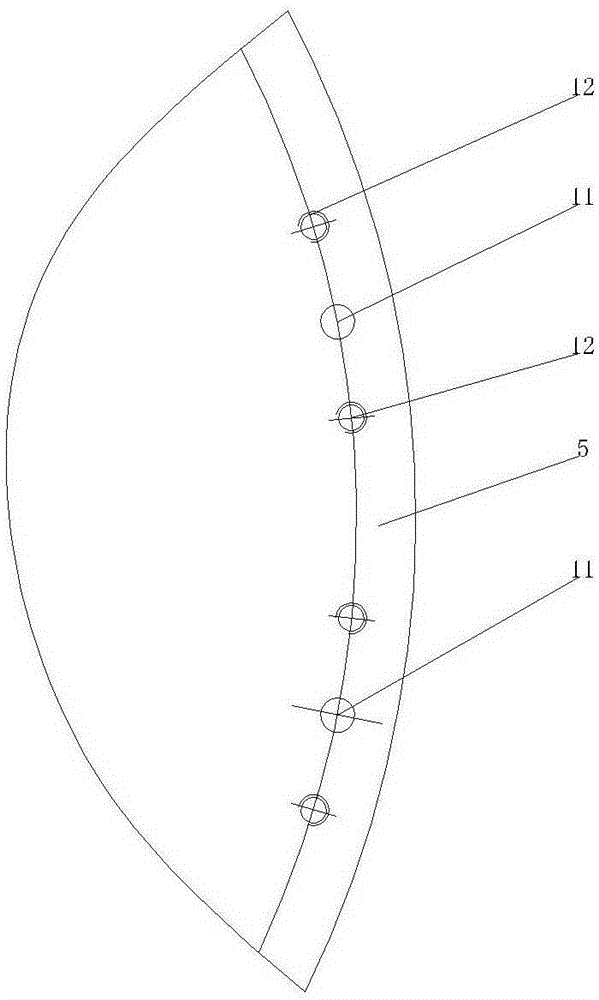

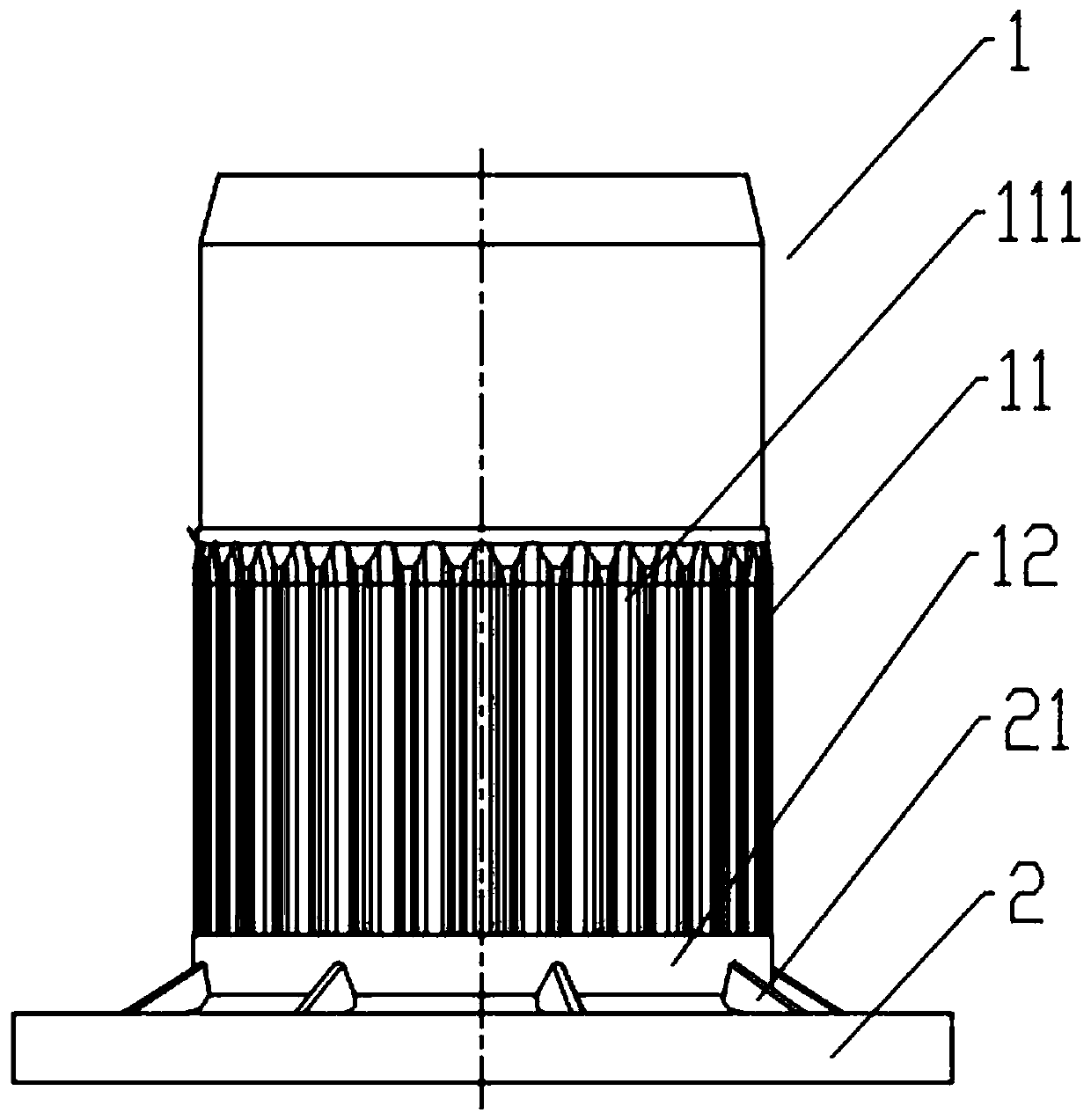

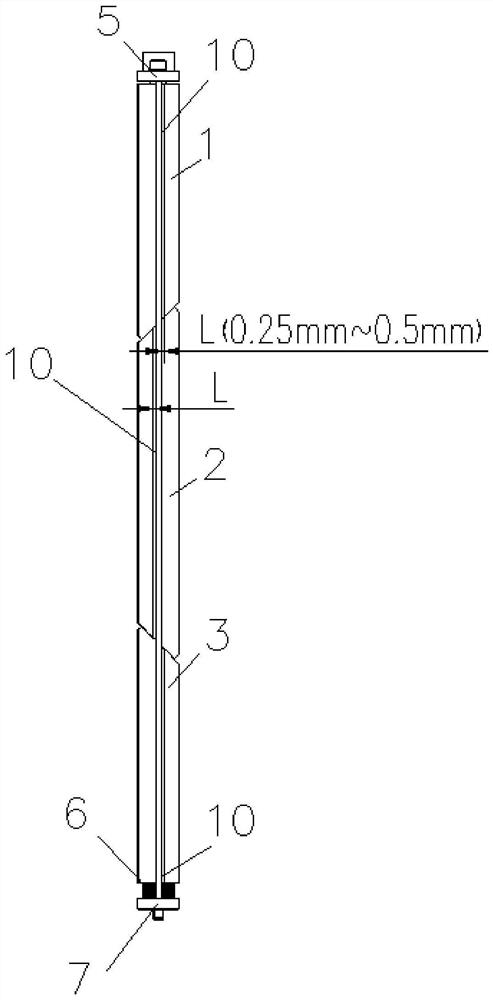

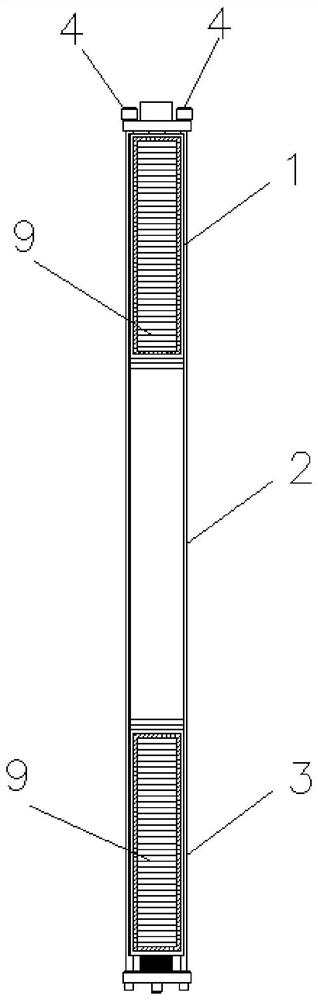

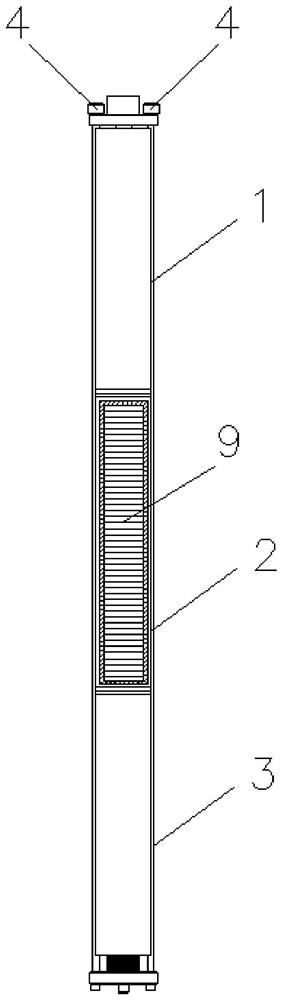

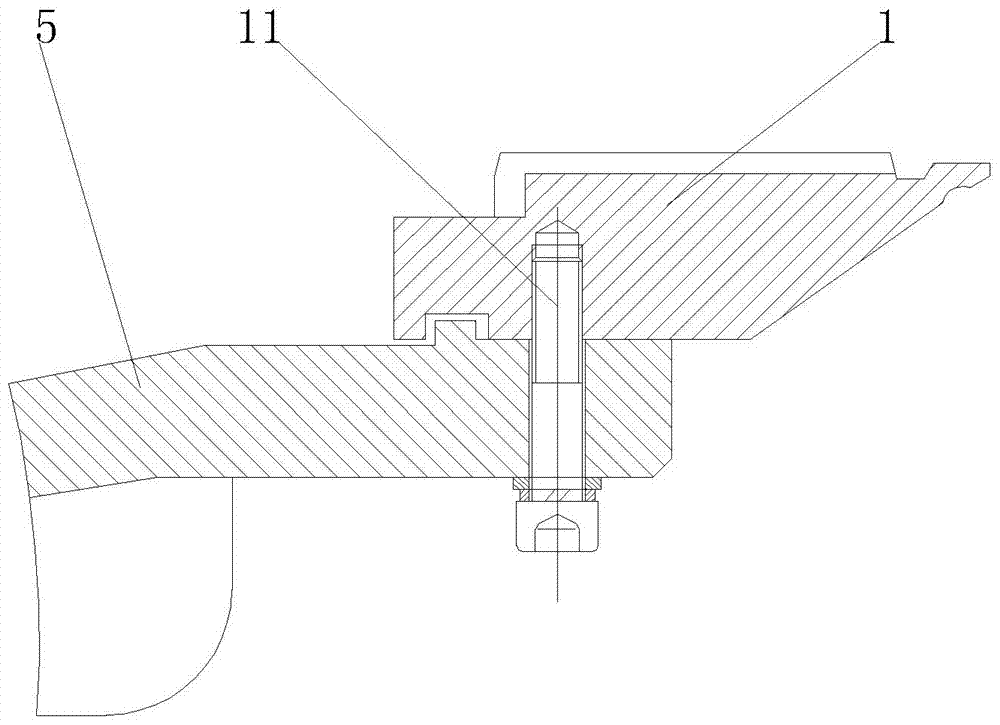

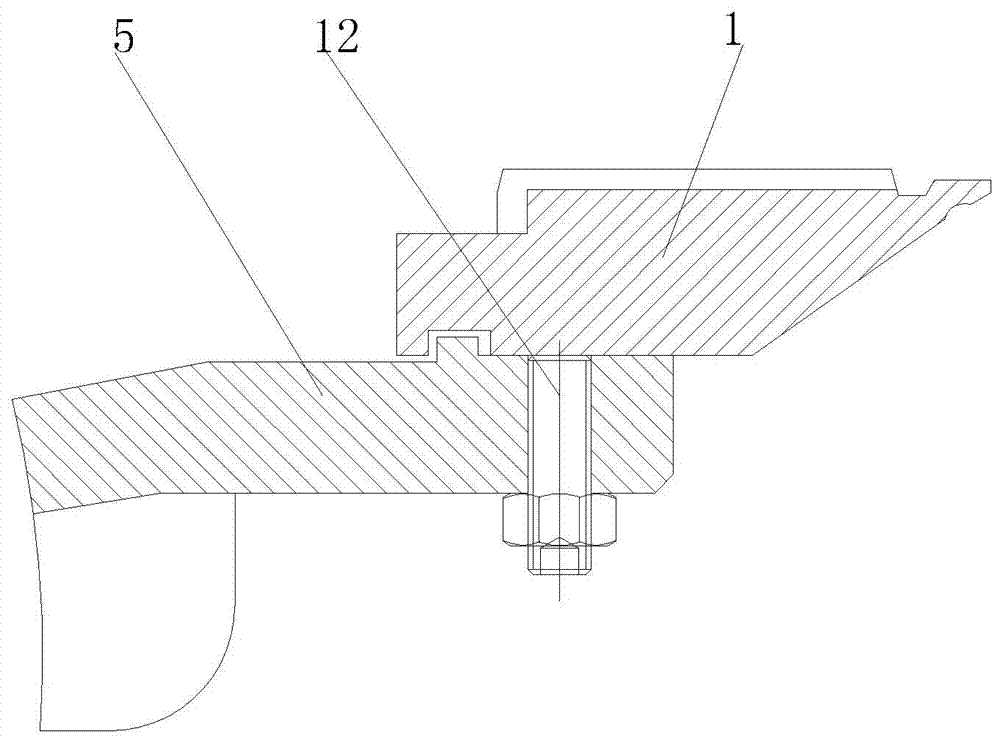

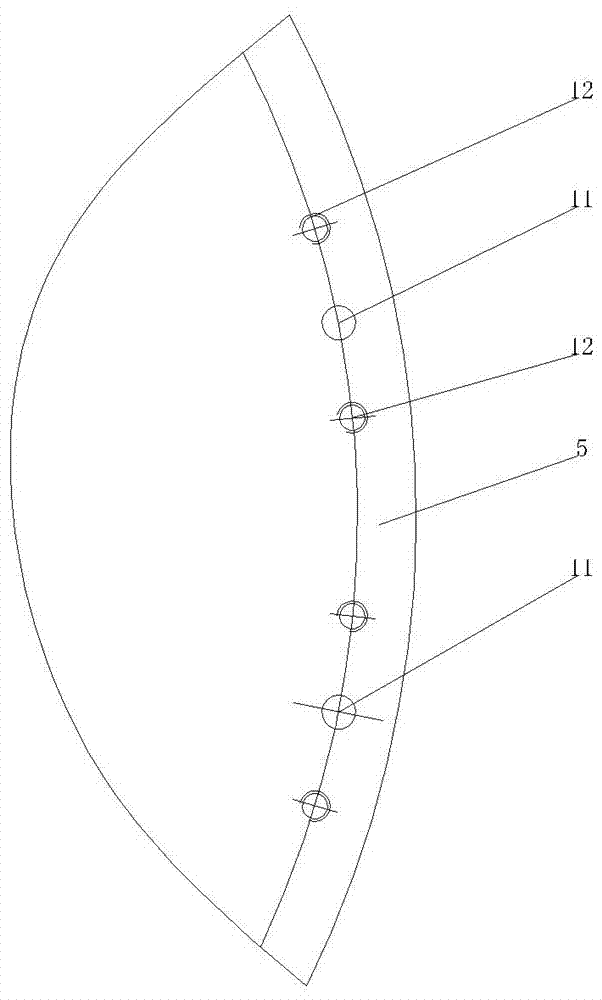

Needle dial adjusting structure of double-faced knitting machine

ActiveCN105200648AEnsure locking functionGuaranteed rigidityWeft knittingWaveform shapingEngineering

The invention relates to the field of double-faced knitting machines of circular knitting machines and particularly relates to a needle dial adjusting structure of the double-faced knitting machine. The needle dial adjusting structure comprises locking screws, hollow screw outer sleeves which sleeve the locking screws, and locking blocks which are arranged under the hollow screw outer sleeves and sleeve the locking screws, wherein the locking screws penetrate through a supporting disc to be locked on a needle dial; a through hole of the supporting disc sleeves the hollow screw outer sleeves; the hollow screw outer sleeves are in threaded connection with the through hole of the supporting disc; a cross-shaped groove is formed in the bottom of each hollow thread outer sleeve; the upper end of each locking block is provided with a cross-shaped convex key which is matched with the corresponding cross-shaped groove; the cross-shaped convex keys are inserted into the cross-shaped grooves. With the adoption of the structure, the structure guarantees a locking function of the locking screws and the flatness of the needle dial is convenient and easy to adjust; the rigidity of a whole machine is guaranteed, and all the locking screws only bear pure tension; all the locking blocks are tightly combined with the screw outer sleeves and an upper needle dial is tightly connected with the supporting disc; any waveform-shaped stress deformation is not generated and the installation intensity of the whole machine is higher.

Owner:JINJIANG HONGJI MACHINERY

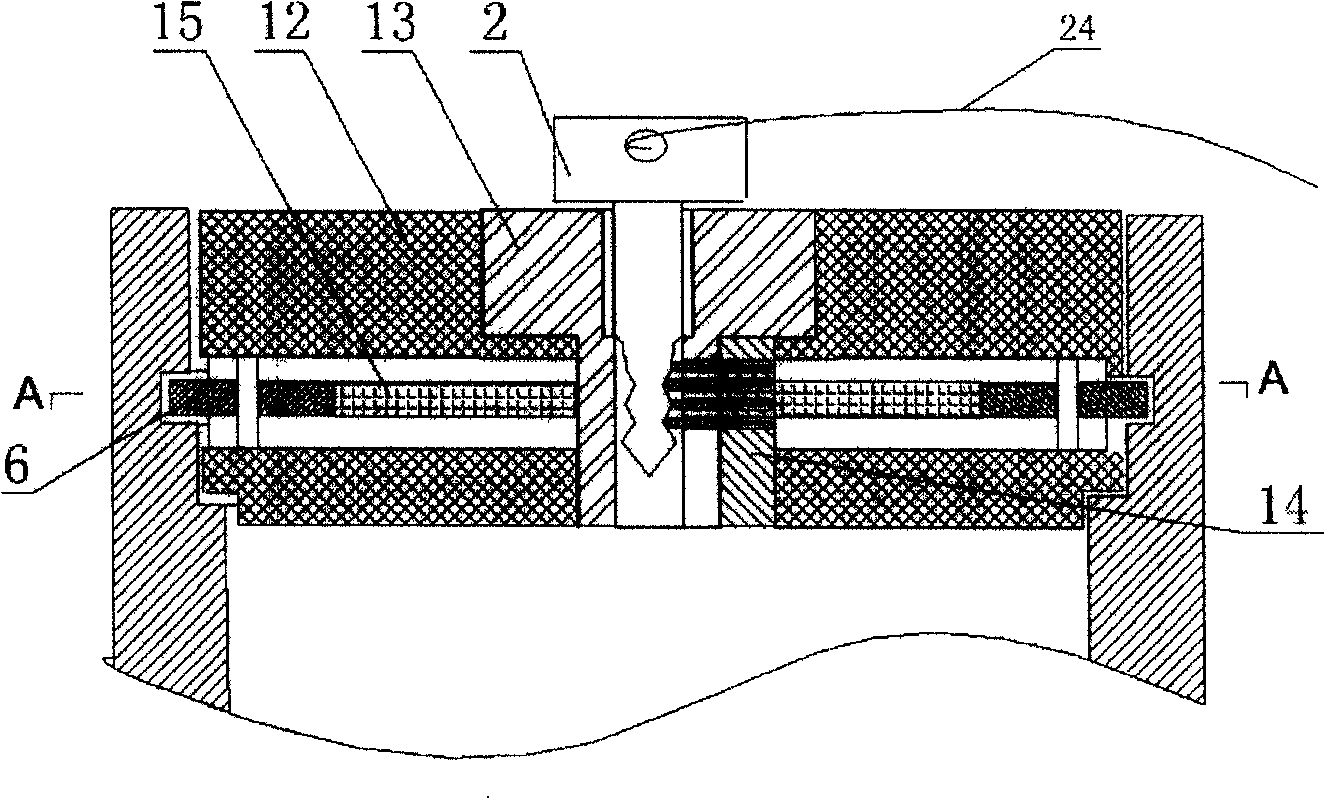

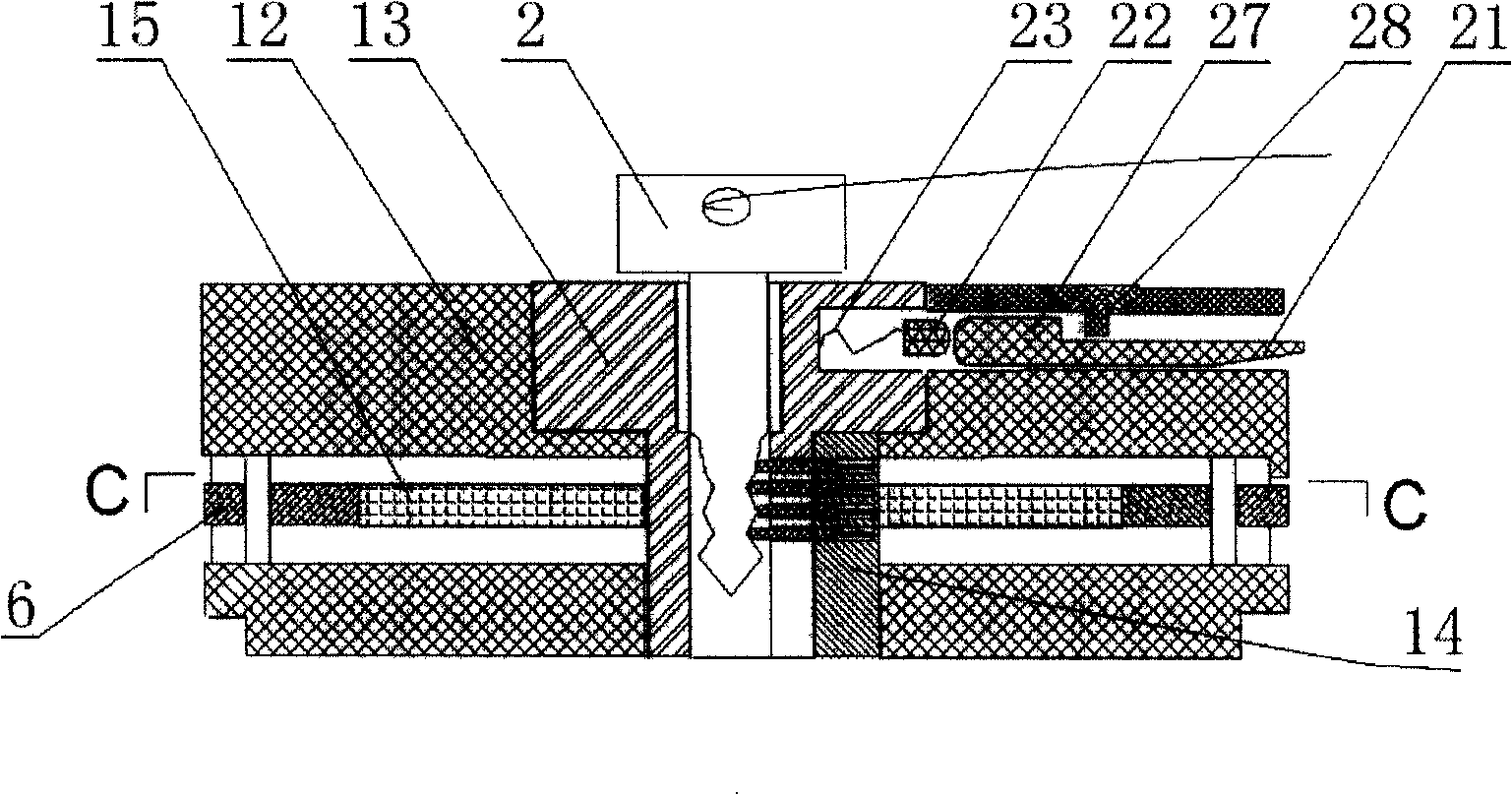

Waterproof connecting piece of riveting system and riveting system

The invention relates to a waterproof connecting piece of a riveting system and the riveting system. The waterproof connecting piece of the riveting system comprises a main body, and a base connectedto one end of the main body; a first extrusion part and a second extrusion part are arranged on the outer side surface of the main body in the axial direction of the main body; and a waterproof part is arranged on the outer side of the second extrusion part. The device is provided with the waterproof part; workpieces butt against the waterproof part; the main body is extruded by hand external force for deformation after installation; the contacted parts of the workpieces with the waterproof part are covered through the waterproof part, so that the waterproof function is effectively achieved, and meanwhile, the locking function of the main body is guaranteed; the waterproof part is arranged on the main body; and an additional waterproof piece is not needed, so that the installation precision can be guaranteed, and meanwhile, the longer service life can be achieved.

Owner:PEM CHINA

Mortise lock with no load when the bolt operates

ActiveCN108729759BSmooth movementPrevent ejectionNon-mechanical controlsElectric permutation locksPasswordLoad generation

The invention provides a mortise without load generation in bolt operation. The mortise includes a deadbolt a sub latch, a main latch, and a deadbolt operation unit to lock and unlock a door. In particular, a deadbolt operation member and a driven gear are coupled to be able to rotate by using a guide groove so that a locking protrusion and a pressing protrusion part are separated from each otheron opposite sides, and the mortise includes a control means to control a motor in order to allow the driven gear to operate the deadbolt operation member and then to be returned to an original position thereof. Accordingly, when the deadbolt is locked and unlocked manually by using a key or a handle, or through operation of the motor by an input of a password, the deadbolt operation member or thedriven gear is rotated at first in a non-load state, thereby smoothly performing locking and unlocking operations of the deadbolt.

Owner:INNO ELECTRIC INC

A method and device for ensuring that the transport carrier does not open the cover

ActiveCN104670902BGuarantee safety and reliabilityAchieve interlockConveyorsKeysLocking mechanismElectrical and Electronics engineering

The invention relates to the field of pneumatic pipeline transmission. A transmission carrier cover closure ensuring method includes 1, arranging a locking mechanism locking a transmission carrier cover and barrel on the transmission carrier; 2, arranging a locking detection mechanism on the transmission carrier; 3, utilizing the locking detection mechanism to detect whether the cover and barrel of the transmission carrier are locked through the locking mechanism or not, if not, locking the cover and barrel of the transmission carrier, and passing the transmission carrier on the condition of locking ensuring. A transmission carrier cover closure ensuring device comprises the locking mechanism arranged on the cover or barrel of the transmission carrier and the locking detection mechanism used for detecting the locking mechanism locks or not. By the aid of the method and device, the safety and reliability of the locking of the cover and barrel of the transmission carrier can be ensured, the transmitting efficiency is improved, and the privacy is optimized.

Owner:BEIJING RINRONG TECH

Conveyor with restraint rope and method thereof

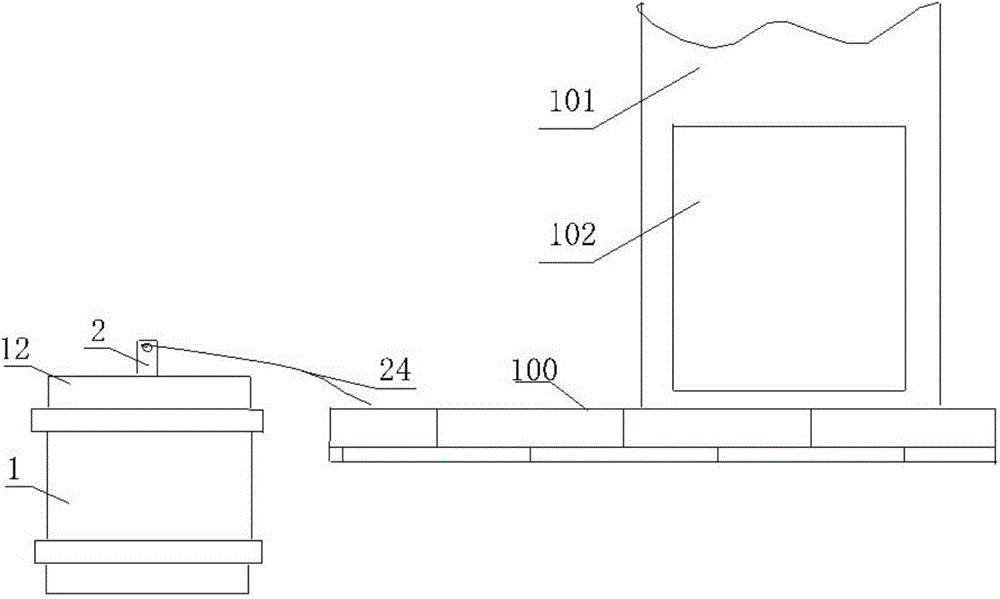

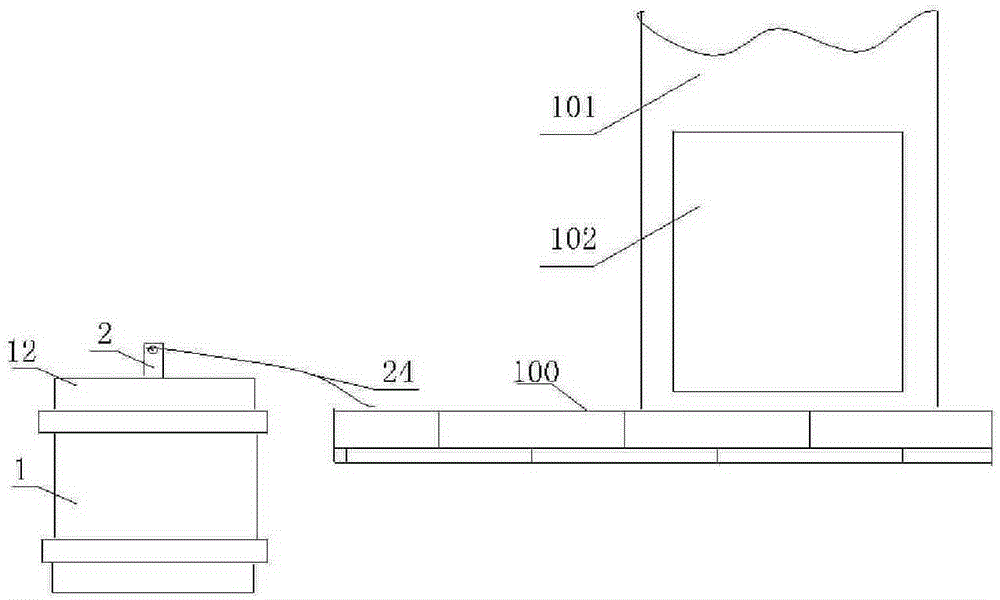

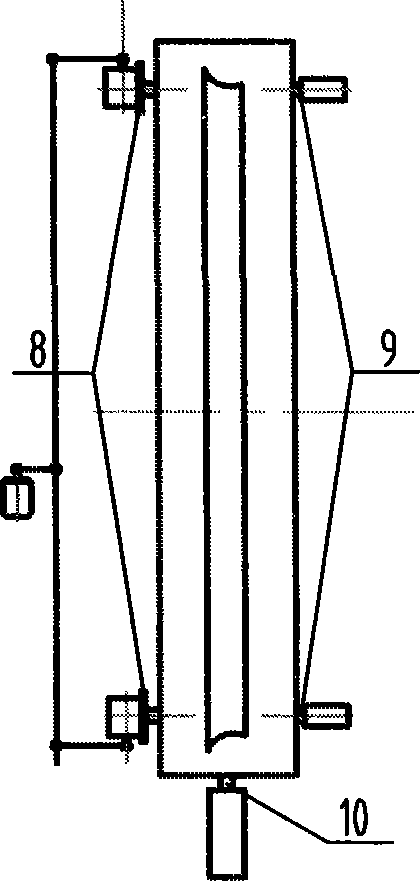

ActiveCN101314438BImprove safety and reliabilityEnsure locking functionConveyorsKeysLocking mechanismTransmission channel

The invention relates to the pneumatic pipeline transmission field. A transmission device with a constraint rope comprises a bucket body, a cover body, a locking mechanism and a locking detection mechanism. The locking mechanism comprises a lock cylinder arranged in the center of the cover body, a key inserted into the lock cylinder, a face plate fixed outside the lock cylinder, a plurality of lock tongues in rotary connection with the cover body, as well as a lock tongue limit pin fixed on the cover body; a lock groove matched with the lock tongue is arranged on the bucket body; the locking detection mechanism comprises a cylinder block between the lock cylinder and the cover body, as well as a plurality of cylinders which are arranged inside the cylinder block to control whether the key can be pulled out; the flexible constraint rope is attached to the key; the other end of the flexible constraint rope is fixed on an operation table. The transmission device not only ensures the locking function, but also can be interlocked, which improves the safety reliability of the locking connection of the cover body and the bucket body of the transmission device, is favorable for improving transmission efficiency, and increases privacy. When the transmission device is not locked, as the transmission device is pulled by the flexible constraint rope and cannot enter a transmission channel, thereby further avoiding failure occurrence.

Owner:BEIJING RINRONG TECH

Novel conveyor and method of conveyor

InactiveCN105712083AImprove safety and reliabilityEnsure locking functionConveyorsKeysLocking mechanismEngineering

Owner:BEIJING RINRONG TECH

A circular plastic container locking structure

The invention discloses a locking structure for a round plastic container. The locking structure for the round plastic container comprises a barrel body and a barrel cover, wherein a plurality of barrel cover thread strips are arranged on the inner side of the barrel cover; a rack is arranged on one surface, connected with the barrel body, of the barrel cover; a plurality of barrel body thread strips are arranged on the periphery of the outer side of the opening of the barrel body; the barrel cover thread strips and the barrel body thread strips are matched with each other; a set of gears are arranged on the edge of the upper opening of the barrel body; a fixed gear central shaft is arranged in the gears, and is the gears are connected with a gear handle; when the barrel body is motionless, the gear handle drives the gears to rotate anticlockwise, and then the rack on the barrel cover and the whole barrel cover are driven by the rotating function of the gears to move clockwise; with less power, the lever effect of the gear handle on the gears and the effect of thread inclined plane moving are adopted to produce tens times of locking force of the barrel body and the barrel cover, so that the barrel cover and the barrel body are locked; when the gear handle swings clockwise, and the barrel cover moves anticlockwise, the barrel cover is then loosened; the way of locking and unlocking the barrel cover and the barrel body is very convenient.

Owner:NINGBO CHANGQI FLOURINE PLASTIC PROD CO LTD

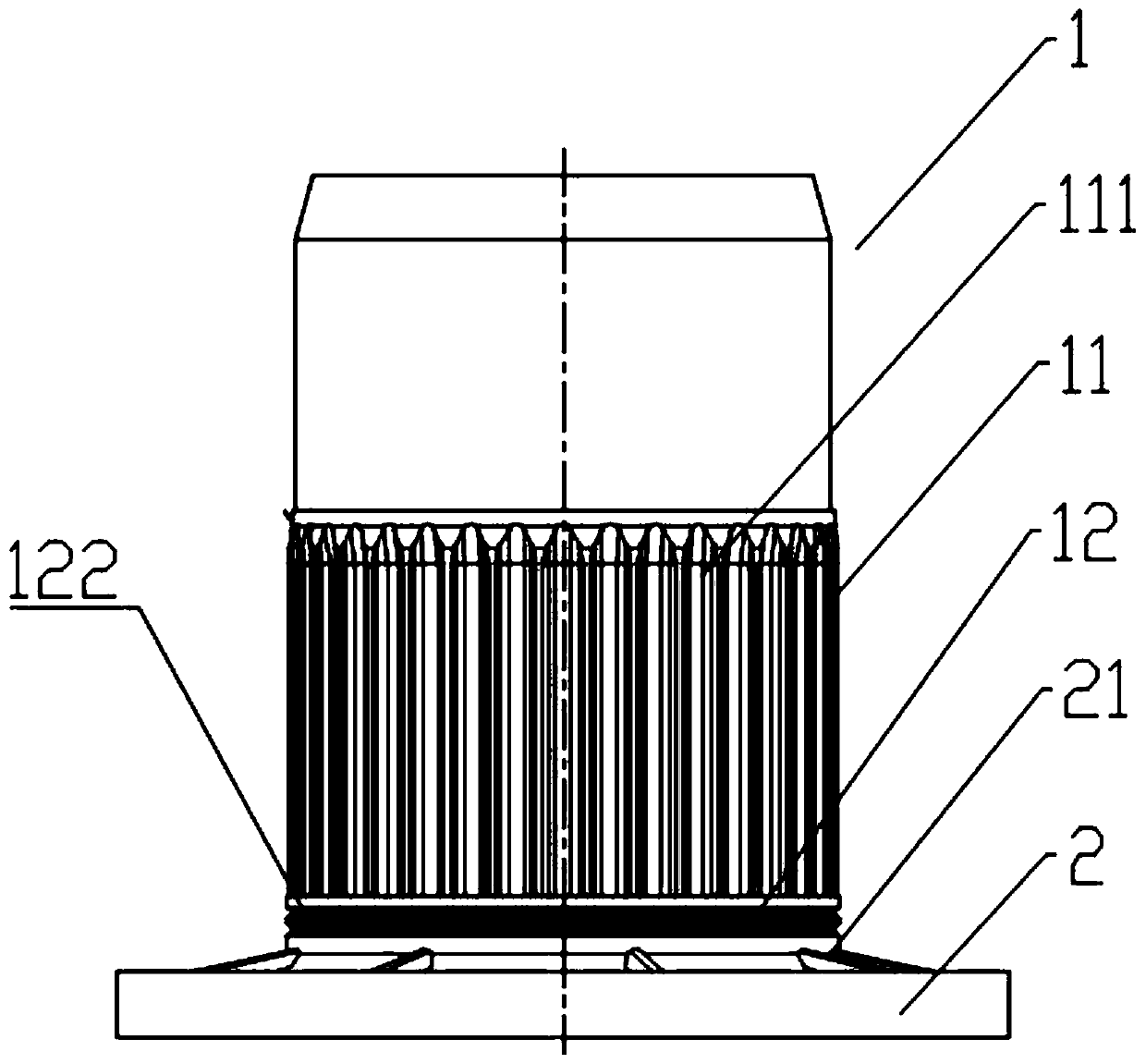

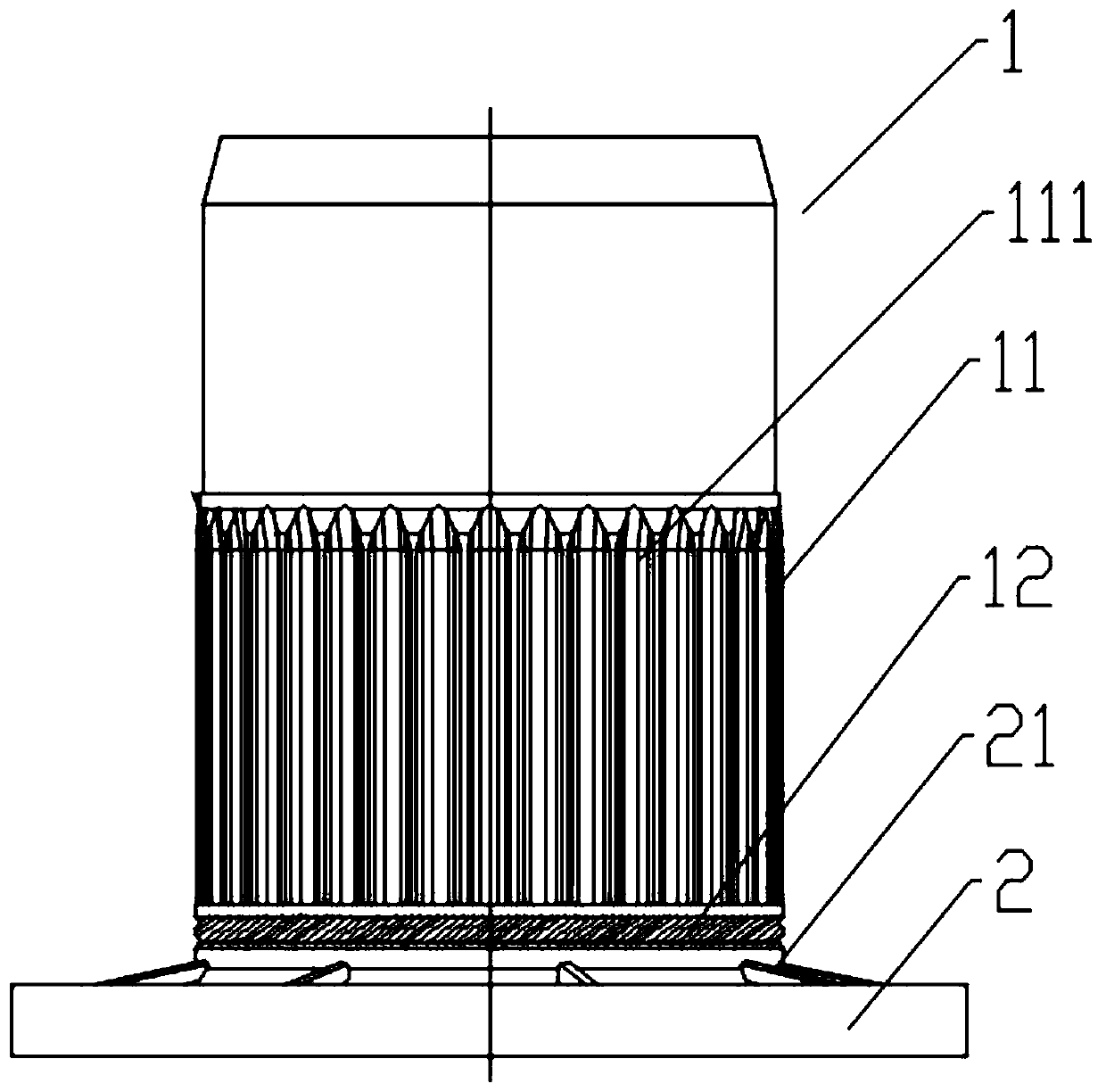

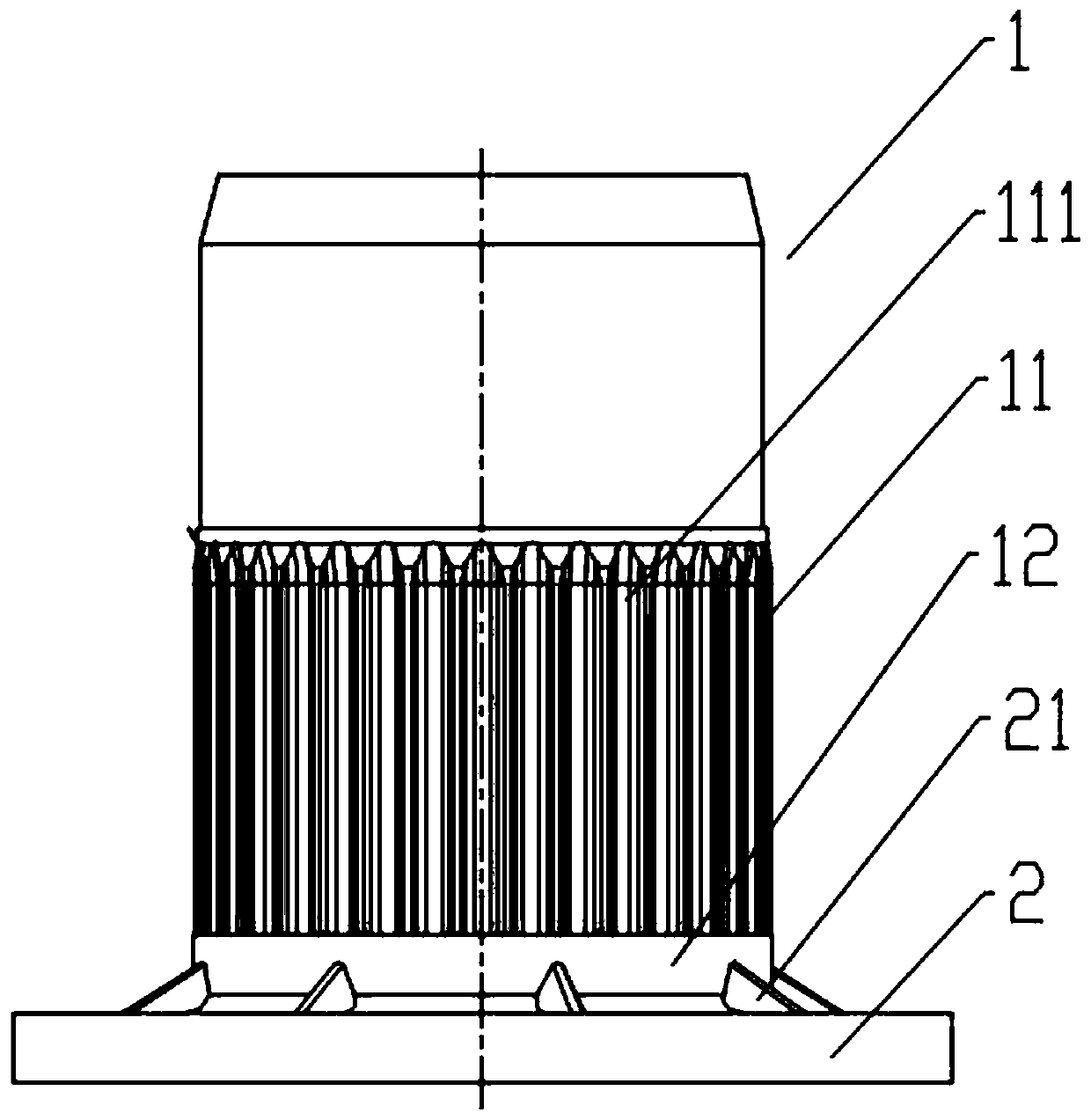

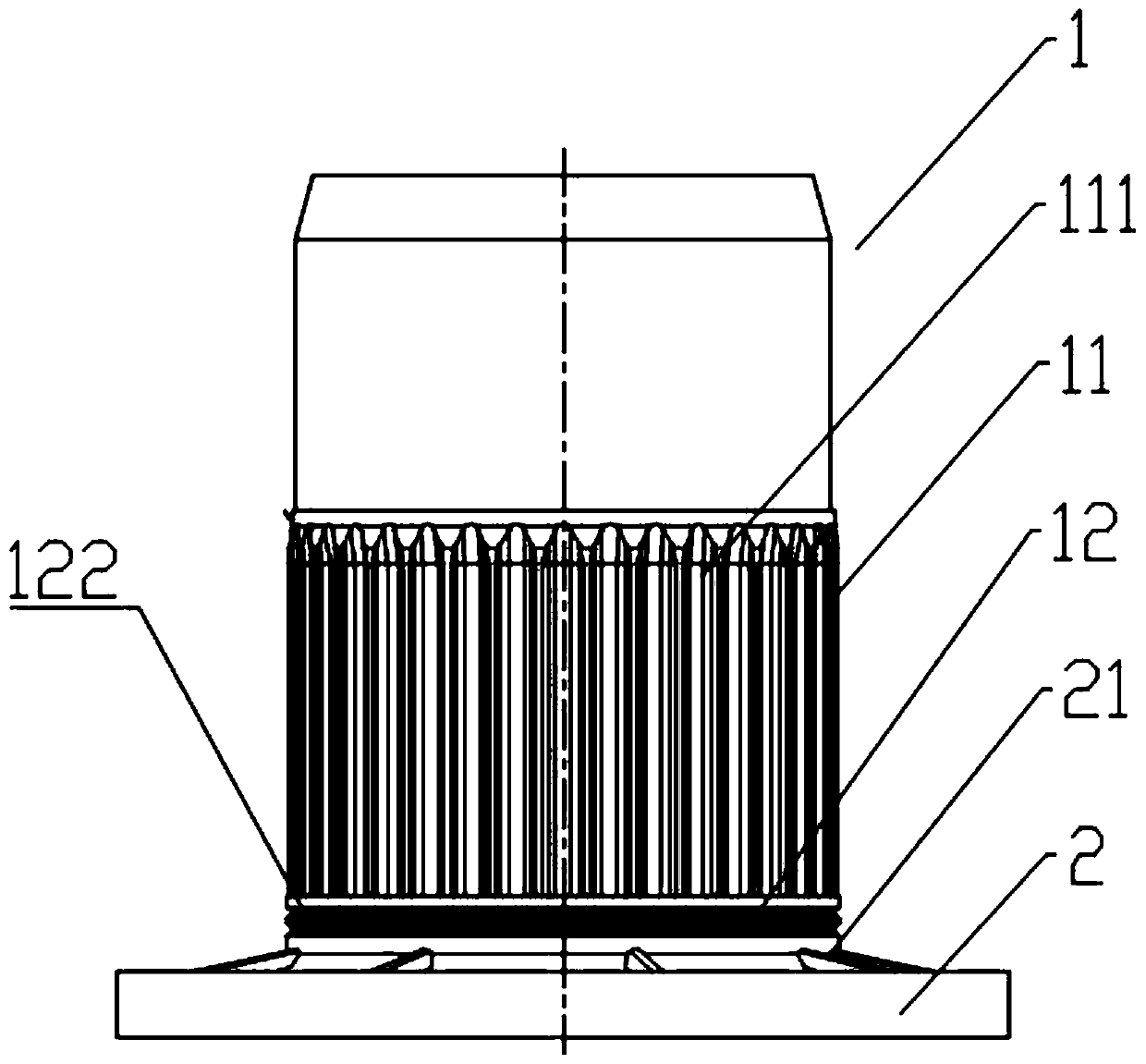

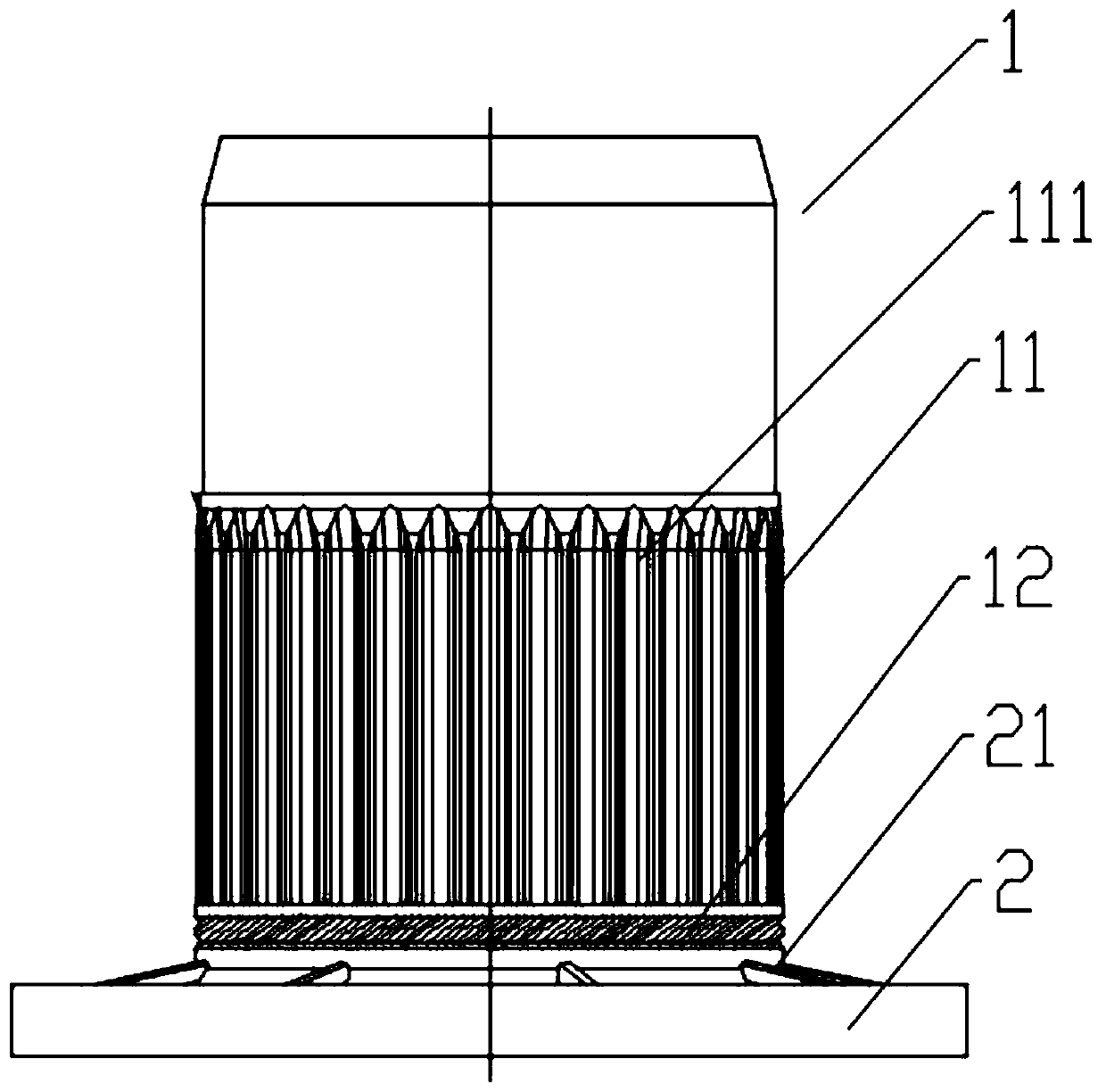

Self-adaptive heat storage high-heat-conductivity module locking device

PendingCN113873744AEnsure locking functionReasonable structural designModifications by conduction heat transferCircuit thermal arrangementsTemperature controlEngineering

The invention provides a self-adaptive heat storage high-heat-conductivity module locking device which comprises a locking strip and a pressure rod, the locking strip comprises a wedge block A, a wedge block B and a wedge block C which are connected in sequence, and the two opposite side walls of the wedge block A, the wedge block B and the wedge block C are each provided with a groove which is provided with two through ends and used for installing the pressure rod; the wedge-shaped block A, the wedge-shaped block B and the wedge-shaped block C are each internally provided with a temperature control deformation cavity, and the temperature control deformation cavities are filled with phase change materials. On the basis of meeting the mounting function of the locking module, the application requirements of short-time high heat shock and high heat-conducting property in the electronic equipment can be adaptively processed.

Owner:XIAN AVIATION COMPUTING TECH RES INST OF AVIATION IND CORP OF CHINA

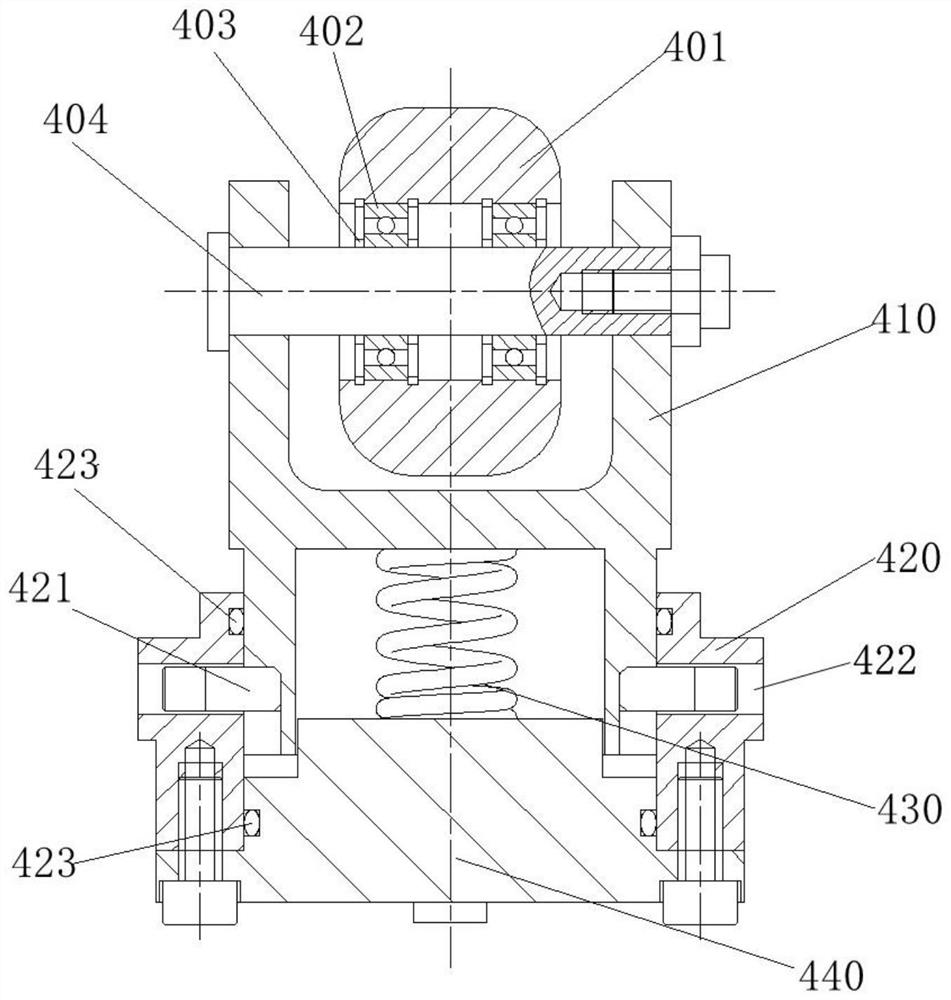

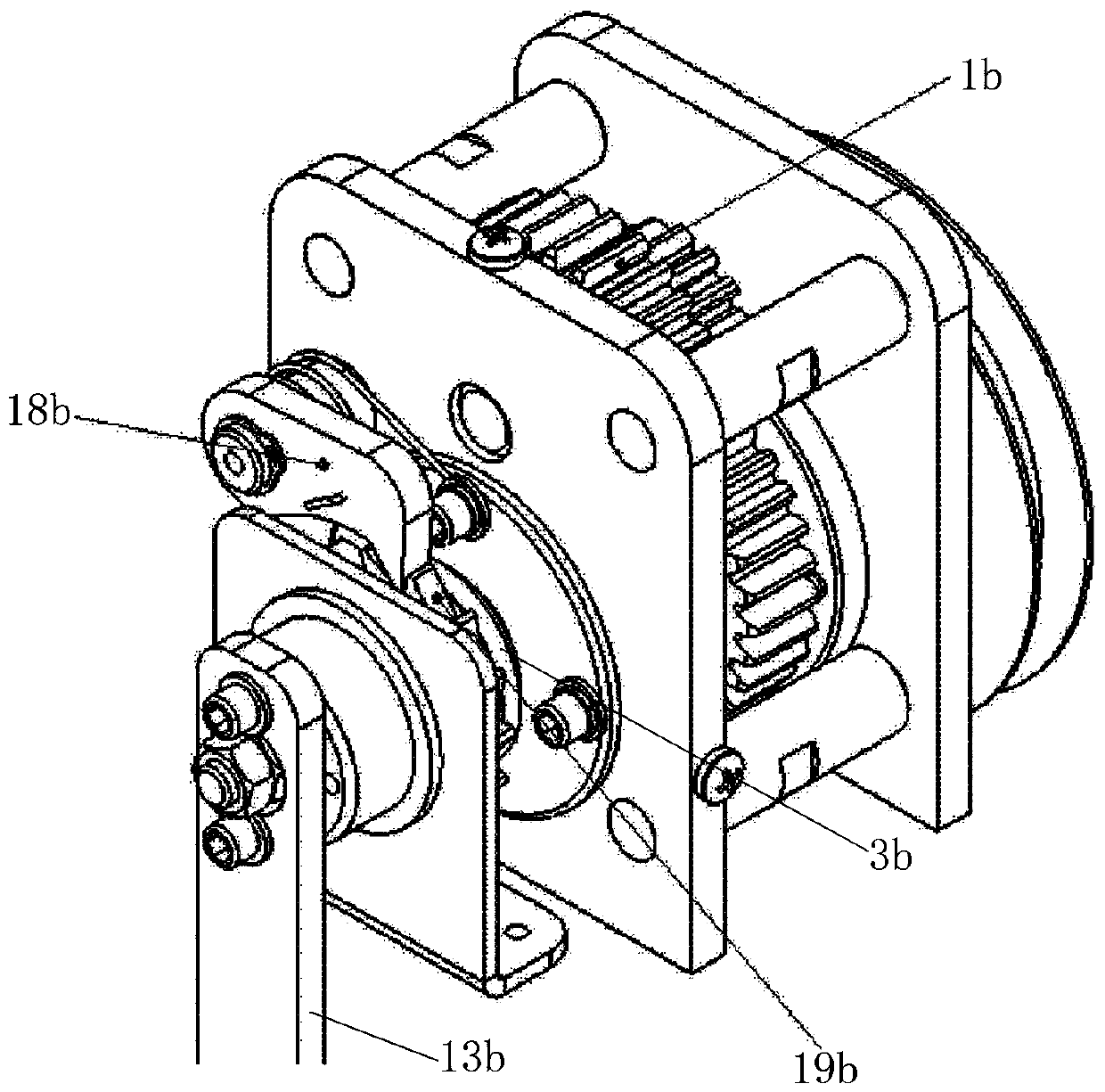

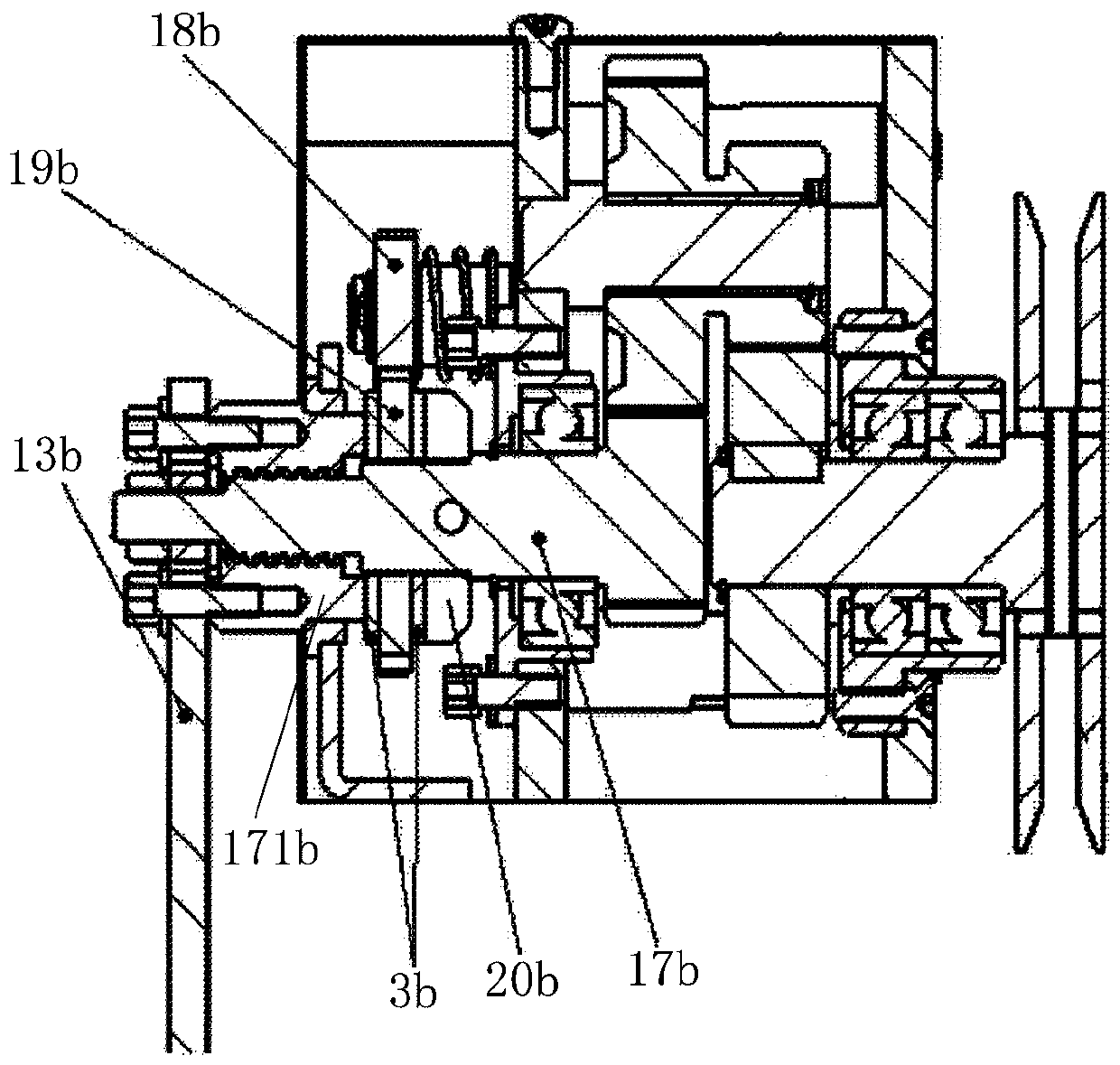

Actuator, energy filling device and vehicle

PendingCN109973604AAvoid harmEnsure locking functionGearingSuperstructure subunitsAutomatic controlElastic component

The invention belongs to the technical field of automatic control, and particularly provides an actuator, an energy filling device and a vehicle. The problem that an existing one-way self-locking actuator is high in cost and low in reliability is solved. The actuator comprises a driving component, a first gear, a second gear, a third gear, a first connecting shaft, a second connecting shaft and anelastic component. The first gear and the second gear are arranged on the first connecting shaft, and a first one-way sliding connecting structure and a second one-way sliding connecting structure are arranged between the first gear and the second gear. The third gear is arranged on the second connecting shaft, and the third gear is engaged with the second gear. Under the situation that the driving component limits rotation of the first gear, the elastic component allows the first one-way sliding connecting structure and the second one-way sliding connecting structure to move back to back, and the second gear can only rotate in the first direction. Therefore, the third gear and the second connecting shaft can only rotate in the second direction, and then a one-way self-locking function isachieved.

Owner:NIO ANHUI HLDG CO LTD

Mortise lock with sub-lock with limited bolt spring

ActiveCN108843149BPop-up blockEnsure locking functionNon-mechanical controlsLatching locksEngineeringCam

The present invention relates to a mortise capable of limit insertion of a main latch and provided with a sub latch, including a dead bolt, a sub latch, a main latch, and a dead bolt operating unit tolock and unlock a door. Specifically, the mortise permits insertion of a latch bolt when the door is open and blocks the insertion of the latch bolt when the door is locked. So, the latch bolt performs a locking function of the door with the dead bolt so that security of the mortise can be improved. To achieve the same, a pressing unit of the sub latch and a pressing protrusion of a latch cam permit a backward movement of a latch transfer while the sub latch half-protrudes due to a closure of the door. So, while the latch stopper rotates in one direction, a locking protrusion blocks the insertion of the latch bolt. When the insertion and the withdrawal of the sub latch are completed as the door is opened and closed by a handle, the pressing unit or the pressing protrusion moves the latchtransfer forward. So, the latch stopper rotates in the other direction, and the locking protrusion permits the insertion of the latch bolt, so that when a door is closed, the main latch is inhibited to be inserted by the mortise; and the main latch is inserted only if the door is opened, so that along with the dead bolt, the main latch itself has a locking function, thereby enhancing security.

Owner:INNO ELECTRIC INC

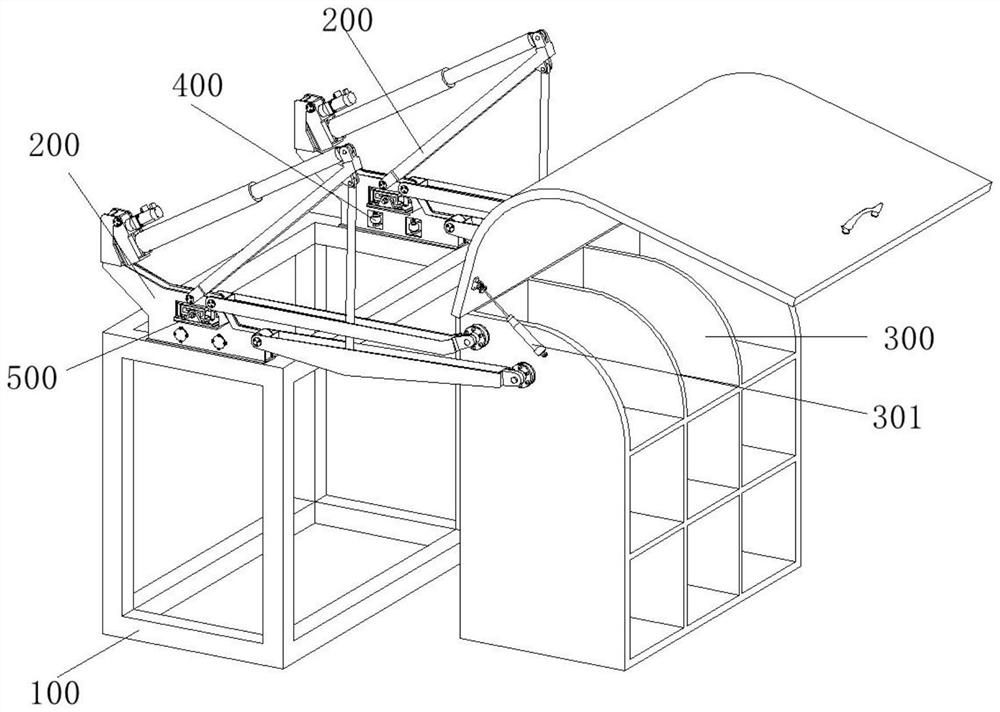

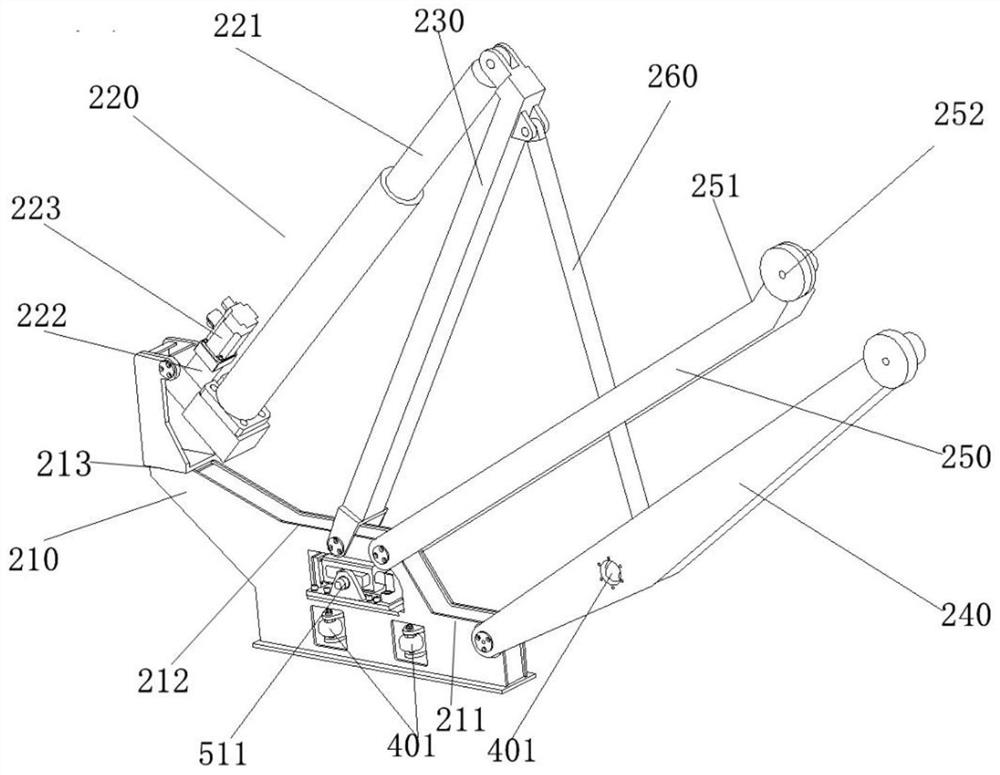

Automatic lifting device

ActiveCN114655903AQuick loading and unloadingSmall footprintLifting devicesLoading/unloadingDrive by wireEngineering

The invention relates to an automatic lifting device which comprises a base, two sets of multi-connecting-rod lifting mechanisms and a warehouse, the two sets of multi-connecting-rod lifting mechanisms are connected to the two sides of the warehouse respectively, and each multi-connecting-rod lifting mechanism comprises a fixing base fixedly connected with the base; one end of the linear driving mechanism is hinged to the fixed seat; one end of the rocker is hinged to the other end of the linear driving mechanism, and the other end of the rocker is hinged to the fixed seat; one end of the main rod is hinged to the fixing base, and the other end of the main rod is hinged to the side face of the warehouse. One end of the balance rod is hinged to the fixing base, the other end of the balance rod is hinged to the side face of the warehouse, and the balance rod and the main rod jointly form a parallelogram mechanism; one end of the pull rod is hinged to the rocker, and the other end of the pull rod is hinged to a certain position in the middle of the main rod; wherein the rocking bar, the balance bar, the main bar and the hinge point of the fixed seat are sequentially arranged from near to far.

Owner:HARBIN INST OF TECH

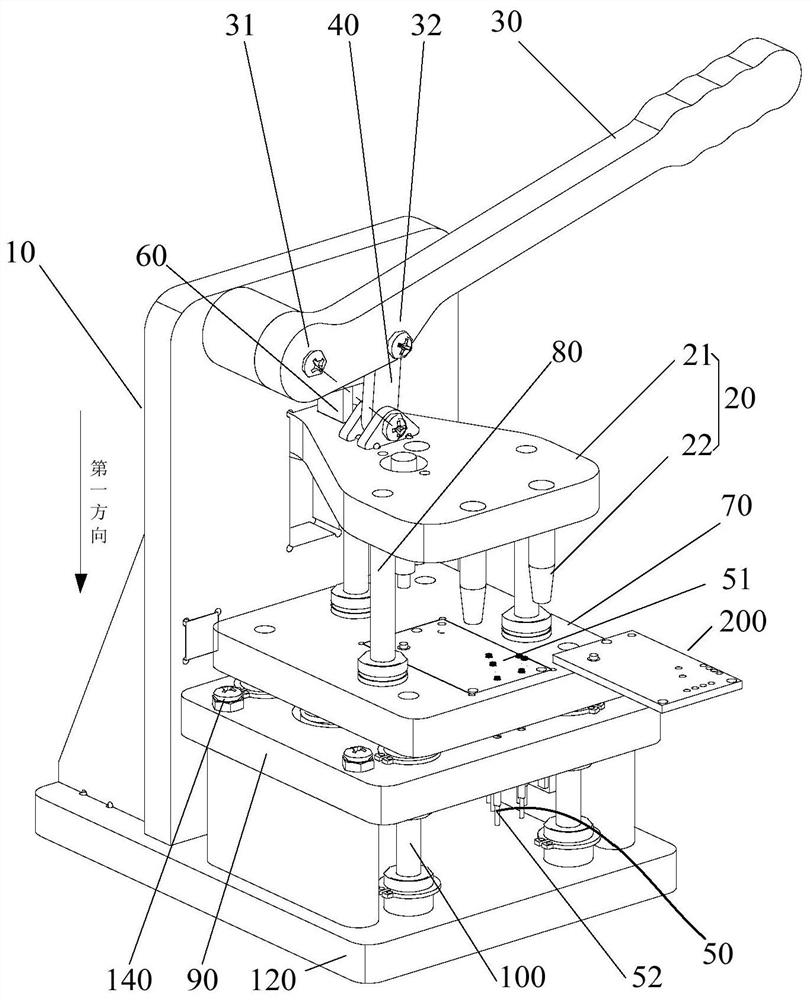

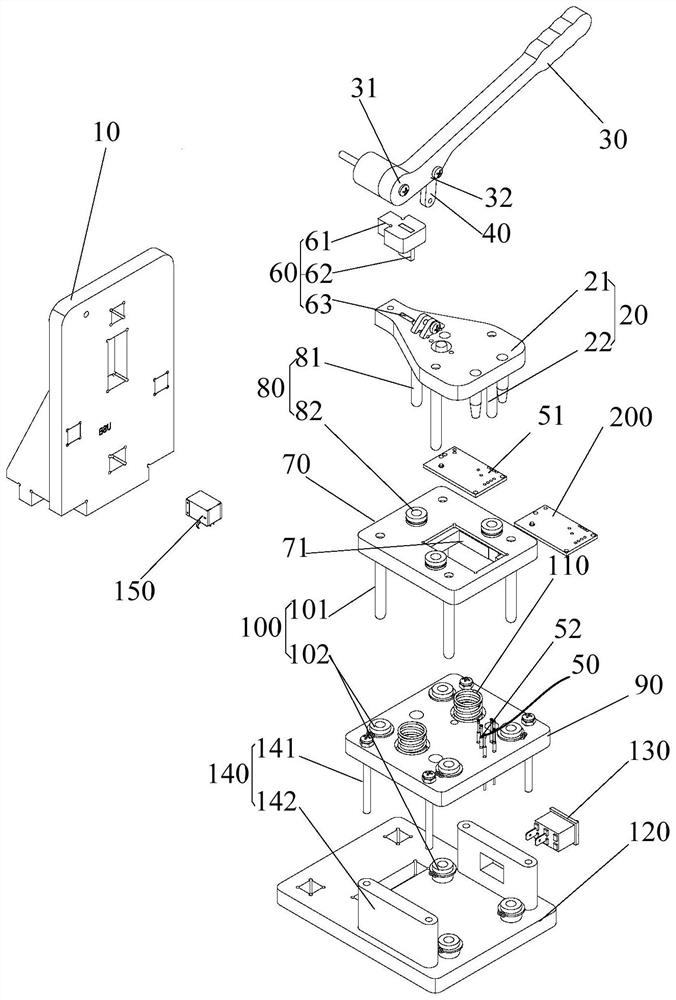

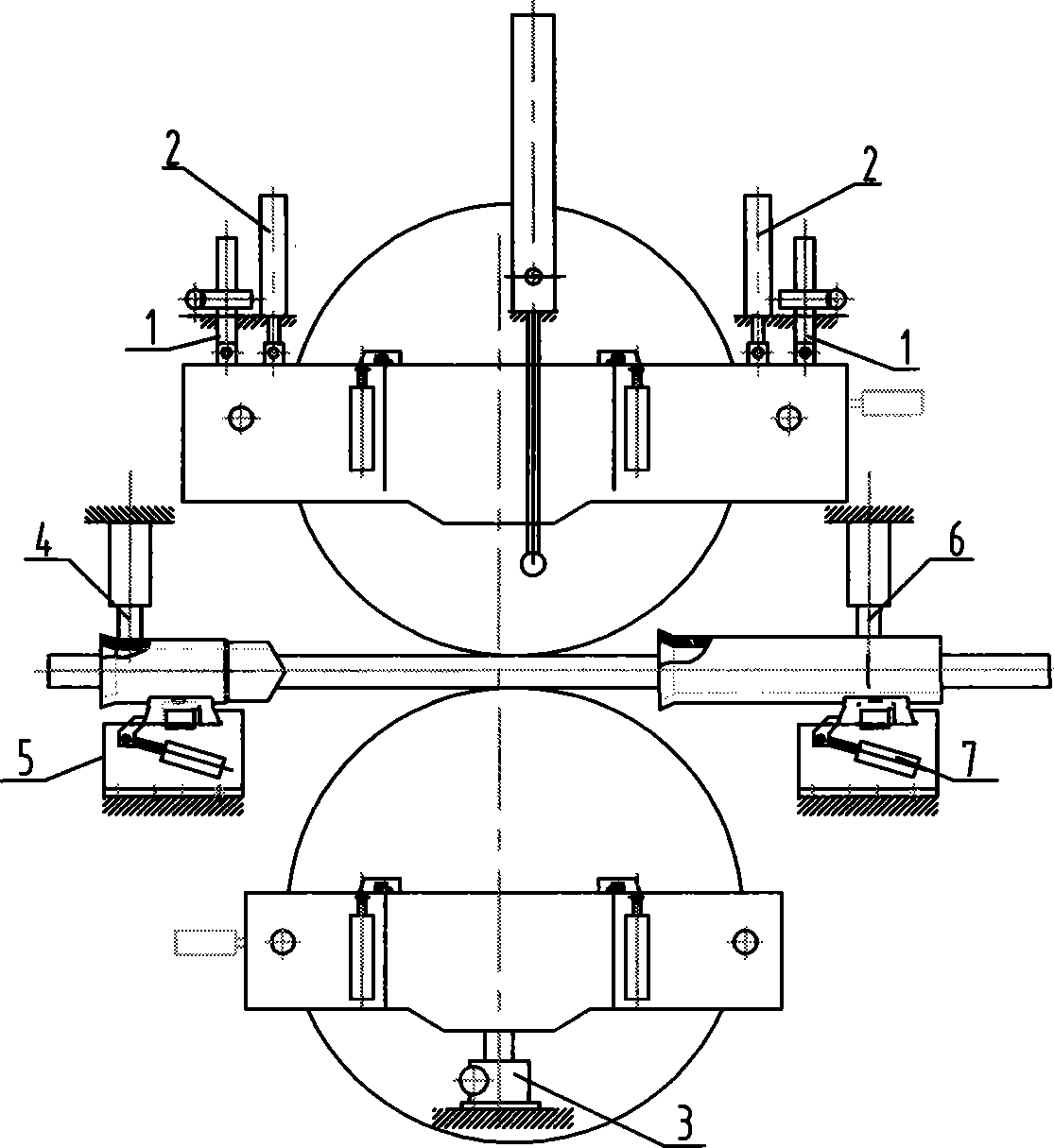

Circuit board testing device

PendingCN113281638ASimple structureRealize the locking functionPrinted circuit testingMeasurement instrument housingTester deviceElectrical connection

The present invention provides a circuit board testing device. The device comprises: a branch pressing mechanism comprising a top tray; and a bearing assembly electrically connected with an external test instrument. The pressing mechanism is provided with a dead point position, and when the pressing mechanism is located at the dead point position, the to-be-tested circuit board is pressed and contacted on the bearing assembly by the top plate, so that the to-be-tested circuit board is conducted with an external testing instrument. Based on the technical scheme, the circuit board testing device does not need to be additionally provided with a locking mechanism to achieve the locking function o fa top plate at the pressing position, so that the structure of the circuit board testing device is greatly simplified, and a rocker sliding block mechanism is simple in structure. Therefore, when the pressing mechanism adopts the rocker sliding block mechanism, the overall size of the circuit board testing device can be reduced, so that the circuit board testing device is suitable for testing circuit boards with small specifications.

Owner:GREE ELECTRIC APPLIANCES WUHAN +1

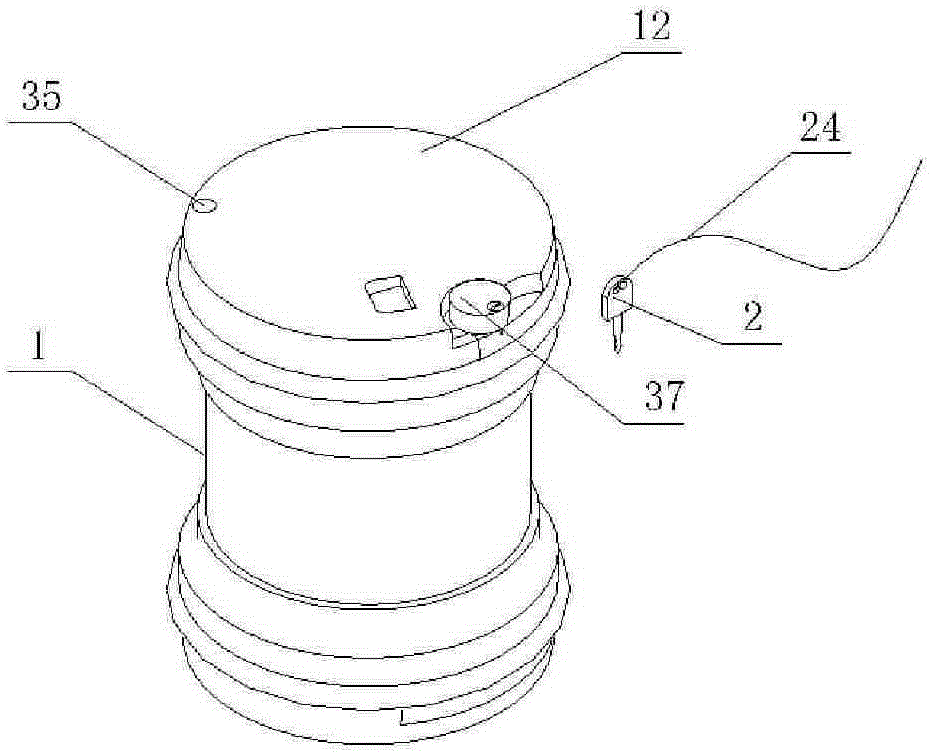

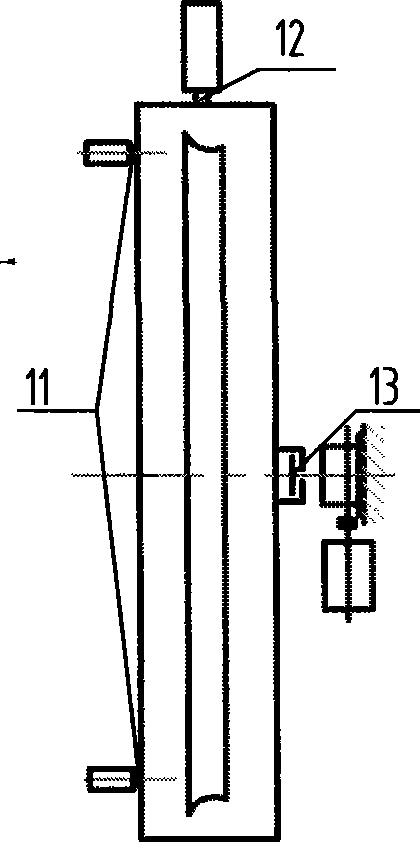

Transmitter with handle

ActiveCN101314437BAvoid accessImprove safety and reliabilityConveyorsKeysLocking mechanismTransmission channel

The invention relates to the pneumatic pipeline transmission field. A novel transmission device of the invention comprises a bucket body, a cover body, a locking mechanism and a locking detection mechanism. The locking mechanism comprises a lock cylinder arranged in the center of the cover body, a key inserted into the lock cylinder, a face plate fixed outside the lock cylinder, a plurality of lock tongues in rotary connection with the cover body, as well as a lock tongue limit pin fixed on the cover body; a lock groove matched with the lock tongue is arranged on the bucket body; the locking detection mechanism comprises a cylinder block between the lock cylinder and the cover body, as well as a plurality of cylinders which are arranged inside the cylinder block to control whether the key can be pulled out; a handle for stopping the transmission device from entering an inlet of a transmission channel is fixed on the key. The transmission device not only ensures the locking function, but also can be interlocked, which improves the safety reliability of the locking connection of the cover body and the bucket body of the transmission device, is favorable for improving transmission efficiency, and increases privacy. In addition, the handle can stop the transmission device which is not locked from entering the transmission channel, thereby further avoiding failure occurrence and improving reliability.

Owner:BEIJING RINRONG TECH

Double-sided machine dial adjustment structure

The invention relates to the field of large circular knitting double-sided knitting machines, in particular to the needle plate adjustment structure of the double-sided machine, which includes locking screws, a hollow screw cover set on the locking screw, and a hollow screw cover set under the hollow screw cover and set on the locking screw. The locking block of the screw, the locking screw passes through the support plate and is locked on the upper dial, the hollow screw sleeve is arranged in the through hole of the support plate, and the hollow screw sleeve is threadedly connected with the through hole of the support plate, so The bottom of the hollow screw jacket is provided with a "ten"-shaped groove, and the upper end of the locking block is provided with a "ten"-shaped convex key to match the "ten"-shaped groove. The "ten"-shaped convex key is inserted into the In the "ten"-shaped groove, due to the above-mentioned structure, this structure ensures the locking function of the locking screw, and makes it easy to adjust the flatness of the dial, ensuring the rigidity of the whole machine. All locking screws only Under simple tension, all locking blocks and threaded sleeves are tightly combined, while the upper dial is tightly connected to the support plate, and there will be no wave-like stress deformation, and the installation strength of the whole machine is higher.

Owner:JINJIANG HONGJI MACHINERY

An Improved Main Shaft Locking Device and Its Application

ActiveCN105972201BAchieve brakingRealize the locking functionGearing controlHoisting equipmentsFlywheelCentrifugal force

The invention discloses an improved locking device for a main rotating shaft. The device is characterized in that a torsional spring which can overcome screwing frictional resistance between the main rotating shaft and a connecting nut is additionally arranged between the connecting nut and the main rotating shaft so as to prevent the main rotating shaft from uncontrollable high-speed rotating caused by human errors; the connecting nut can overcome the thread frictional force relative to the main rotating shaft under the effect of the inverted torsion of the torsional spring, and thus the connecting nut can be rotated relative to the main rotating shaft, and as a result, the main rotating shaft can be braked. The invention also provides another scheme for locking the main rotating shaft. The scheme is characterized in that an inner pawl which can be limited through an elastic connector is arranged on a flywheel disc; in case that the main rotating shaft is subjected to uncontrollable high-speed rotating, the outward centrifugal force of the inner pawl on the flywheel disc can be utilized to overcome the tensioning force of the elastic connector, thus the inner pawl can be locked to an inner ratchet wheel, and as a result, the function of locking the main rotating shaft can be further achieved.

Owner:施耐德电气(厦门)开关设备有限公司

Transmitter with restriction rope and method thereof

ActiveCN101314438AImprove safety and reliabilityEnsure locking functionConveyorsKeysLocking mechanismTransmission channel

The invention relates to the pneumatic pipeline transmission field. A transmission device with a constraint rope comprises a bucket body, a cover body, a locking mechanism and a locking detection mechanism. The locking mechanism comprises a lock cylinder arranged in the center of the cover body, a key inserted into the lock cylinder, a face plate fixed outside the lock cylinder, a plurality of lock tongues in rotary connection with the cover body, as well as a lock tongue limit pin fixed on the cover body; a lock groove matched with the lock tongue is arranged on the bucket body; the locking detection mechanism comprises a cylinder block between the lock cylinder and the cover body, as well as a plurality of cylinders which are arranged inside the cylinder block to control whether the key can be pulled out; the flexible constraint rope is attached to the key; the other end of the flexible constraint rope is fixed on an operation table. The transmission device not only ensures the locking function, but also can be interlocked, which improves the safety reliability of the locking connection of the cover body and the bucket body of the transmission device, is favorable for improving transmission efficiency, and increases privacy. When the transmission device is not locked, as the transmission device is pulled by the flexible constraint rope and cannot enter a transmission channel, thereby further avoiding failure occurrence.

Owner:BEIJING RINRONG TECH

Transmission carrier cover closure ensuring method and device

ActiveCN104670902AGuarantee safety and reliabilityAchieve interlockConveyorsKeysLocking mechanismEngineering

The invention relates to the field of pneumatic pipeline transmission. A transmission carrier cover closure ensuring method includes 1, arranging a locking mechanism locking a transmission carrier cover and barrel on the transmission carrier; 2, arranging a locking detection mechanism on the transmission carrier; 3, utilizing the locking detection mechanism to detect whether the cover and barrel of the transmission carrier are locked through the locking mechanism or not, if not, locking the cover and barrel of the transmission carrier, and passing the transmission carrier on the condition of locking ensuring. A transmission carrier cover closure ensuring device comprises the locking mechanism arranged on the cover or barrel of the transmission carrier and the locking detection mechanism used for detecting the locking mechanism locks or not. By the aid of the method and device, the safety and reliability of the locking of the cover and barrel of the transmission carrier can be ensured, the transmitting efficiency is improved, and the privacy is optimized.

Owner:BEIJING RINRONG TECH

A transmitter and a method of the transmitter

ActiveCN101314436BImprove safety and reliabilityEnsure locking functionConveyorsKeysLocking mechanismEngineering

The invention relates to the pneumatic pipeline transmission field. A transmission device of the invention comprises a bucket body and a cover body, wherein a locking mechanism and a locking detection mechanism for detecting whether the locking mechanism locks are arranged on the bucket body or the cover body. The transmission device not only ensures the locking function, but also can be interlocked, which improves the safety reliability of the locking connection of the cover body and the bucket body of the transmission device, is favorable for improving transmission efficiency, and increases privacy.

Owner:BEIJING RINRONG TECH

Mortise lock with restricted escape function and deadbolt pop-in function

The present invention relates to a mortise including a dead bolt, a sub latch, a main latch, and a dead bolt operating unit to lock and unlock a door. Specifically, the mortise can permit insertion ofa latch bolt only when the door is open and can block the insertion of the latch bolt when the door is locked. So, the latch bolt performs a door locking function with the dead bolt so that securityof the mortise can be improved. When the sub latch half-protrudes due to a closure of the door, one among pressing protrusions of a latch cam and a pressing unit of the sub latch permit a backward movement of a latch transfer. So, when a latch stopper rotates in one direction, a locking protrusion blocks the insertion of the latch bolt. When the release of the dead bolt and the insertion and the withdrawal of the sub latch are completed as the door is opened and closed by a handle, one among the pressing protrusions or the pressing unit moves the latch transfer forward. So, the latch stopper rotates in the other direction, and the locking protrusion permits the insertion of the latch bolt. Accordingly, the mortise blocks the popping in of the spring bolt when the door is closed, and only when the door is opened, the popping in of the spring bolt can be allowed, with the bolt, the spring bolt can have the function of locking, and safety can be improved.

Owner:INNO ELECTRIC INC

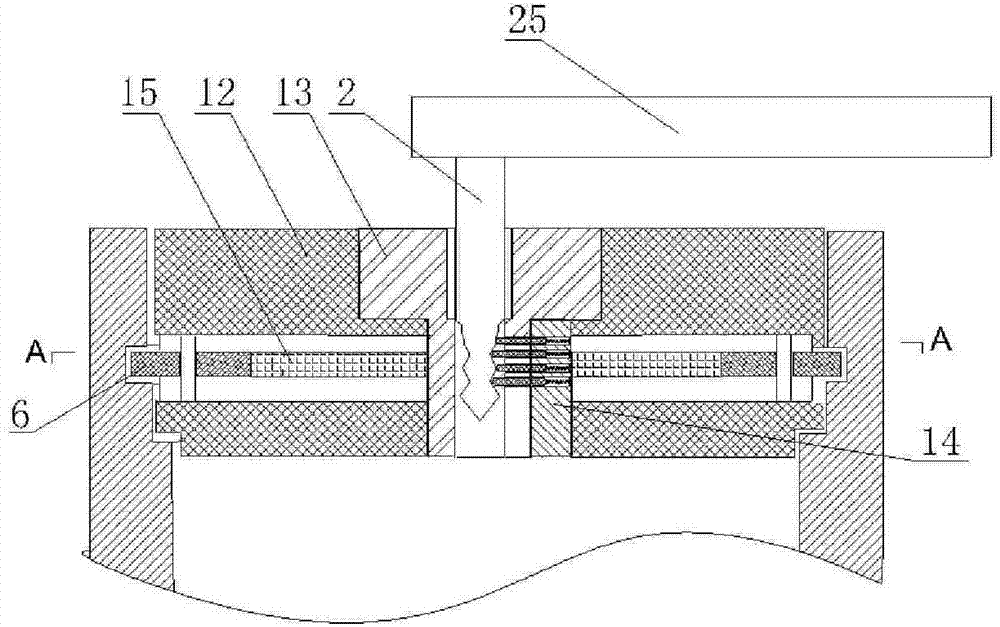

electrical connector

ActiveCN104901069BPrevent lockEnsure locking functionCoupling device detailsElectrical connectorMechanical engineering

Owner:HIROSE ELECTRIC GROUP

All direction multifunctional adjustment disc extending machine

InactiveCN101104179BIncrease the elongation factorImproved Wall Thickness AccuracyMetal rolling stand detailsGuiding/positioning/aligning arrangementsHydraulic cylinderCircular disc

The invention relates to an omnidirectional multi-functional disk type elongating mill, the diameters of an upper and a lower guide disk are increased; the lifting of the upper guide disk adopts a turbine, a worm and a leading screw device; the lifting of the lower guide disk adopts a standard spiral elevator; and the axial direction adjustment is realized by the standard spiral elevator; the positive direction location, lateral direction location and upper and lower direction location are realized by a hydraulic cylinder. The axial direction adjustment of the roller is realized by the standard spiral elevator; the radial direction is adjusted by the combination of a non-standard spiral elevator and the hydraulic cylinder; the locking device adopts the hydraulic cylinder and an adjusting wedge mechanism. Guide bushes of an outlet and an inlet port adopt the upper-pressing and lower-locking of the hydraulic cylinder. The reliability is increased by adopting the hydraulic system; the enlarged diameters of guide disks can improve the locking condition of the roller, the elongation coefficient is increased, screw threads in the steel tube are reduced after rolling, and the variety of products is enlarged; gaps of the axial direction and radial direction of the guide disks and the roller are reduced, and the stability of the rolling is strengthened; the structure of the side pressure oil cylinder of the roller is simple, and the running is reliable; the guide bushes of the outlet and inlet port adopt the upper-pressing and lower-locking device to realize the double-assurance.

Owner:ANGANG STEEL CO LTD

Waterproof connecting piece of riveting system and riveting system

The invention relates to a waterproof connecting piece of a riveting system and the riveting system. The waterproof connecting piece of the riveting system comprises a main body, and a base connectedto one end of the main body; a first extrusion part and a second extrusion part are arranged on the outer side surface of the main body in the axial direction of the main body; and a waterproof part is arranged on the outer side of the second extrusion part. The device is provided with the waterproof part; workpieces butt against the waterproof part; the main body is extruded by hand external force for deformation after installation; the contacted parts of the workpieces with the waterproof part are covered through the waterproof part, so that the waterproof function is effectively achieved, and meanwhile, the locking function of the main body is guaranteed; the waterproof part is arranged on the main body; and an additional waterproof piece is not needed, so that the installation precision can be guaranteed, and meanwhile, the longer service life can be achieved.

Owner:PEM CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com