Improved locking device for main rotating shaft and application

A technology of locking device and main rotating shaft, applied in the field of locking devices, can solve problems such as slow lifting, damage to transported objects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

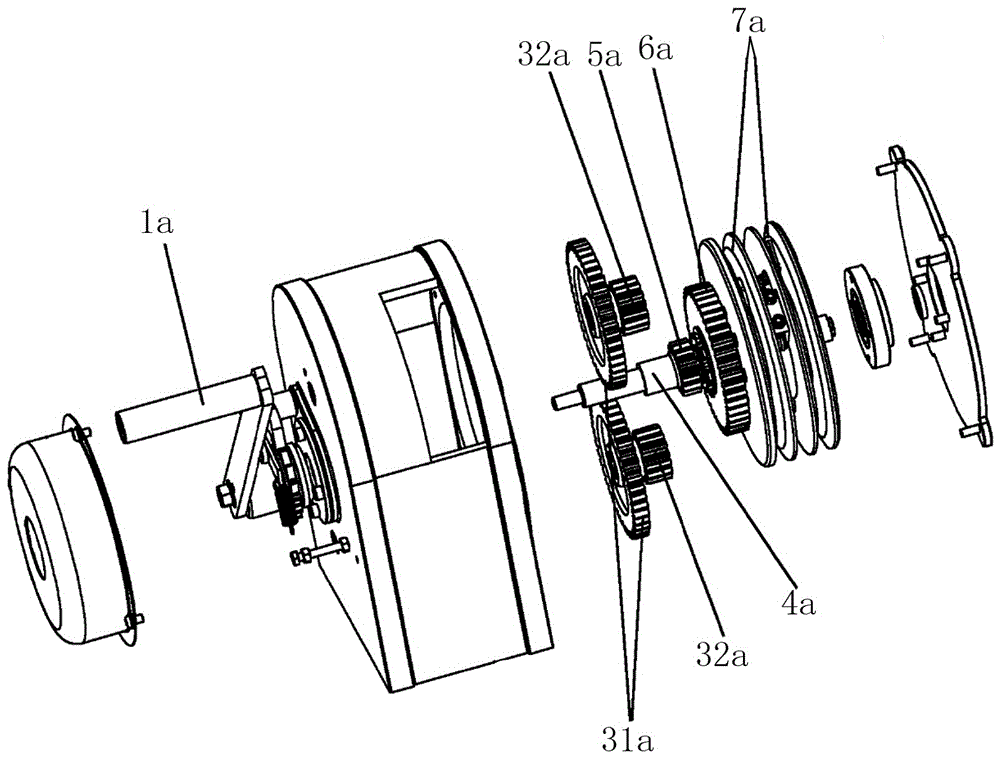

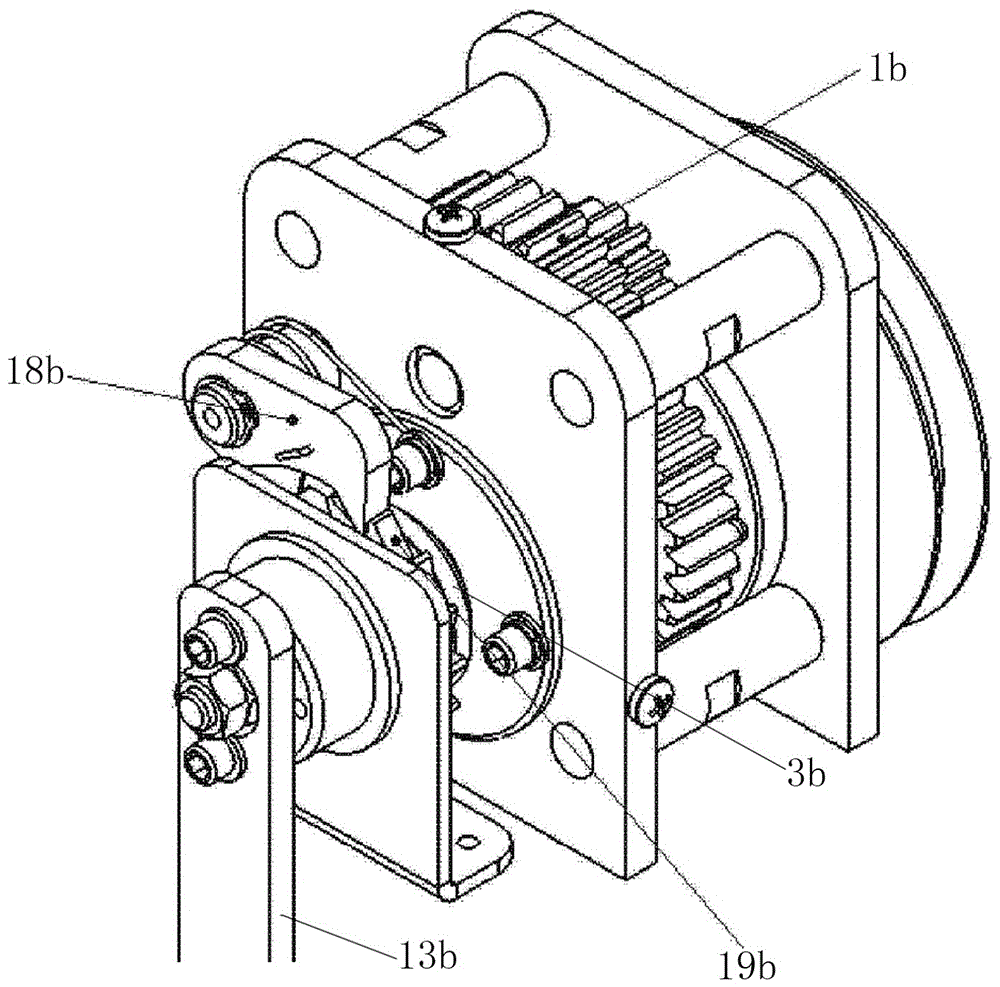

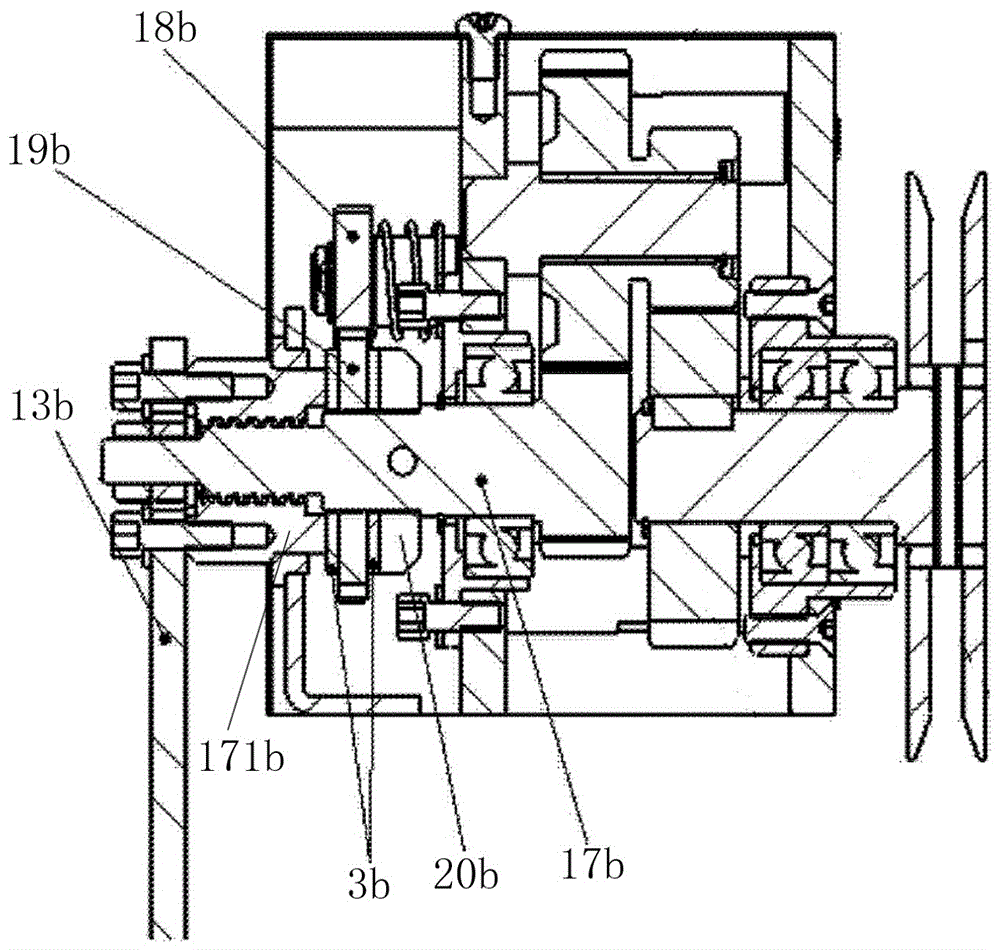

[0031] Taking the specific application of the main shaft locking device in the driving device of the lifting handcart as an example, the present invention will be described in detail in conjunction with the accompanying drawings.

[0032] like image 3 , 4 , 5-1, 5-2 shown, a kind of improved lifting handcart power driving device, it comprises reduction gear box 1 and handle 2, and described reduction gear box 1 comprises chassis 10, reduction gear set, main shaft 11. External ratchet 12, ratchet 13, anti-rotation disk 14, first brake pad 15, second brake pad 16, connecting nut 17 and wire wheel 100; The large teeth on the main rotating shaft 11 are meshed with the small teeth to form (see figure 1 ), to achieve the purpose of deceleration; or as shown in Figures 5 and 6, a gear 111 is provided on the main shaft 11, the gear 111 meshes with the secondary reduction gear 112, and the small tooth end of the secondary reduction gear 112 is then connected to the The output gears...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com