Patents

Literature

41results about How to "Overcoming tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

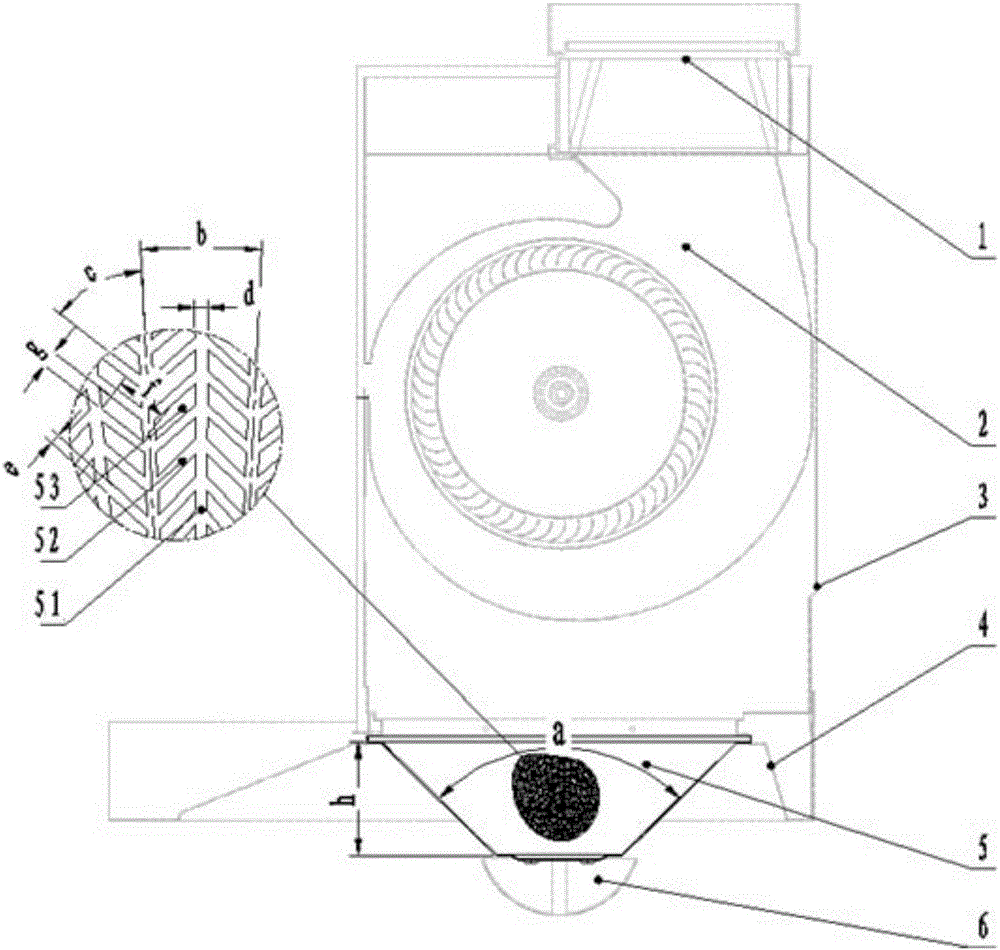

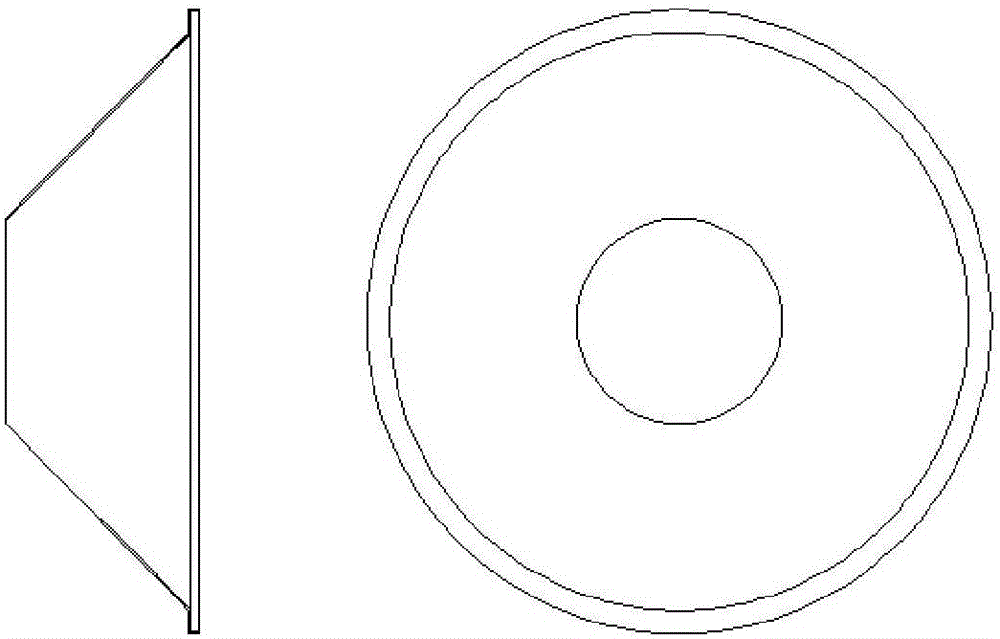

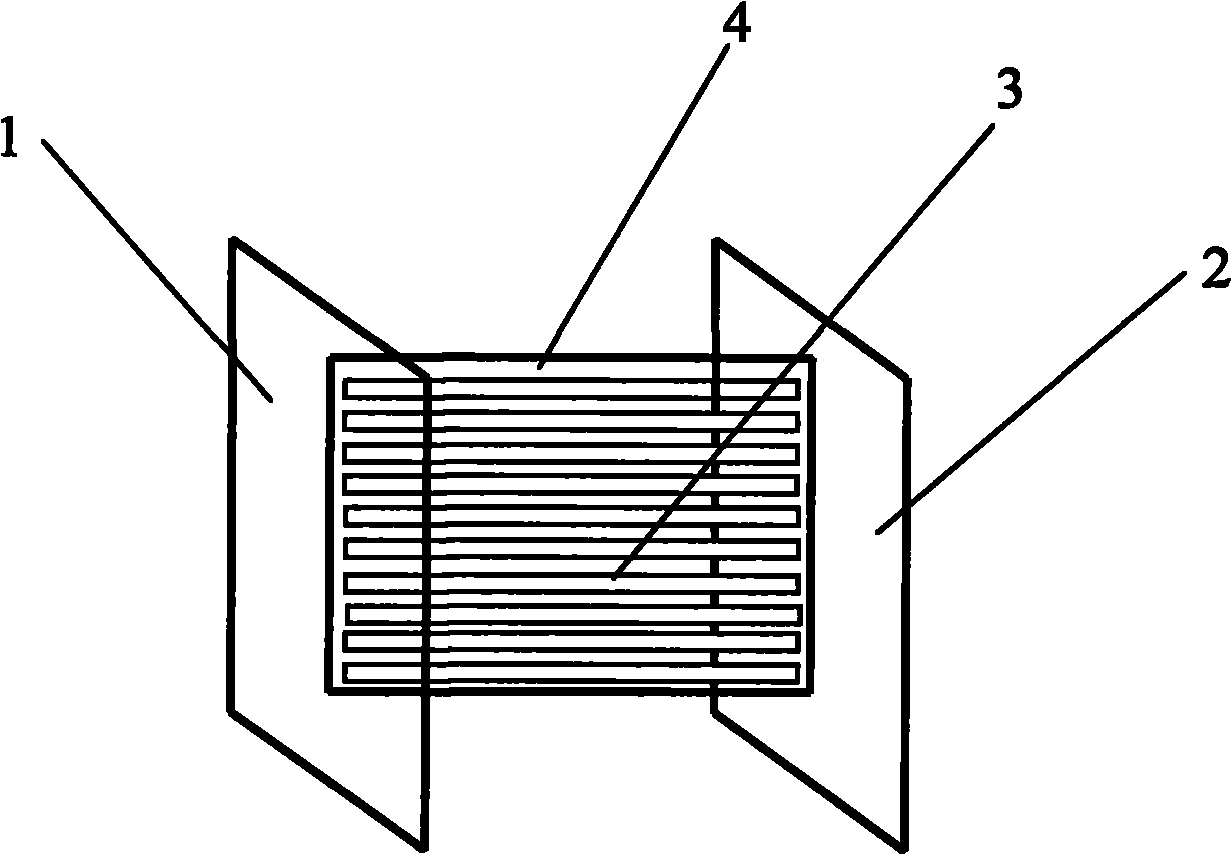

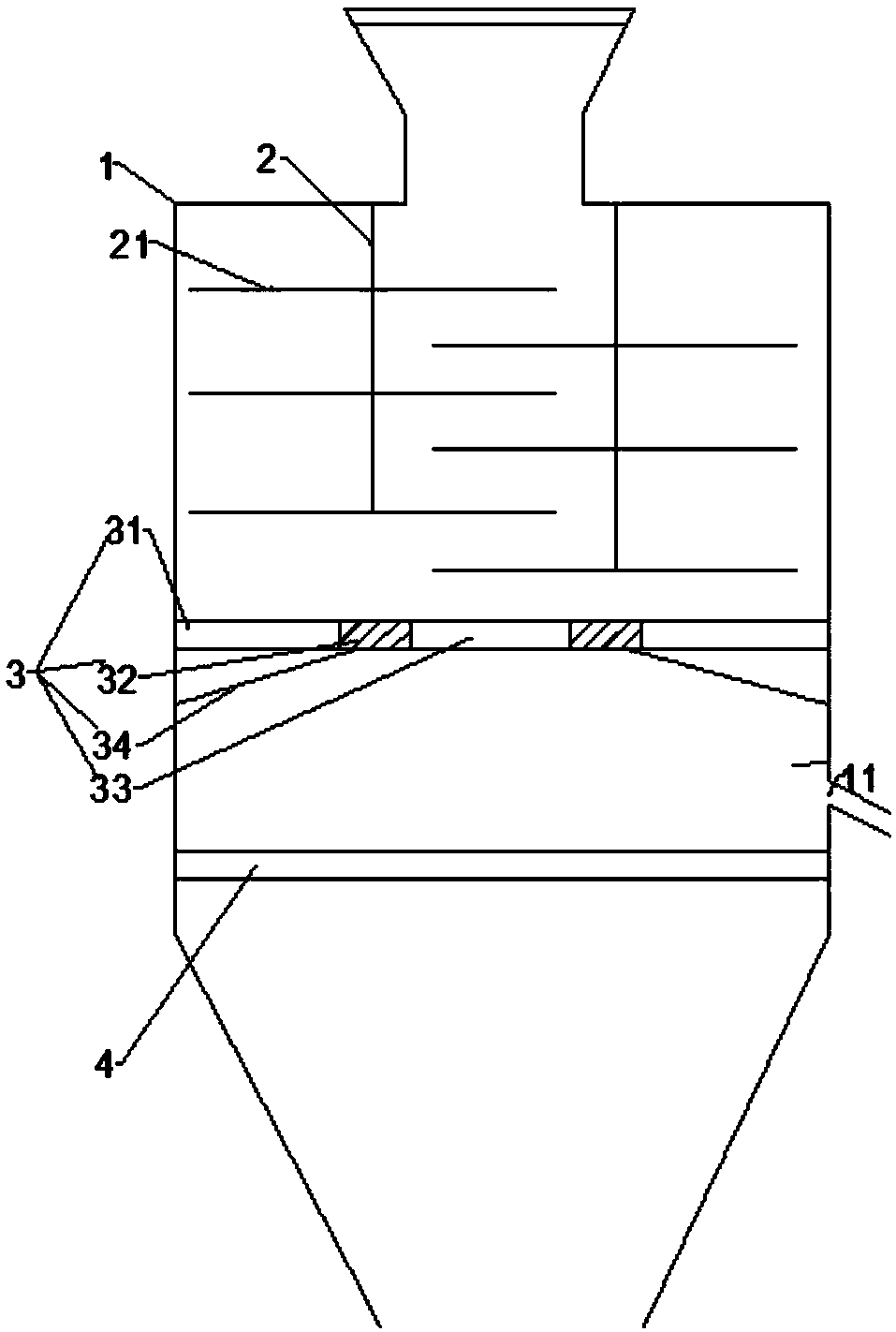

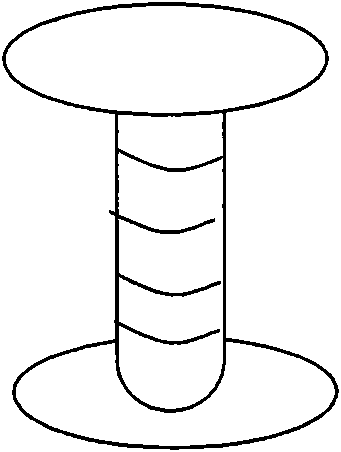

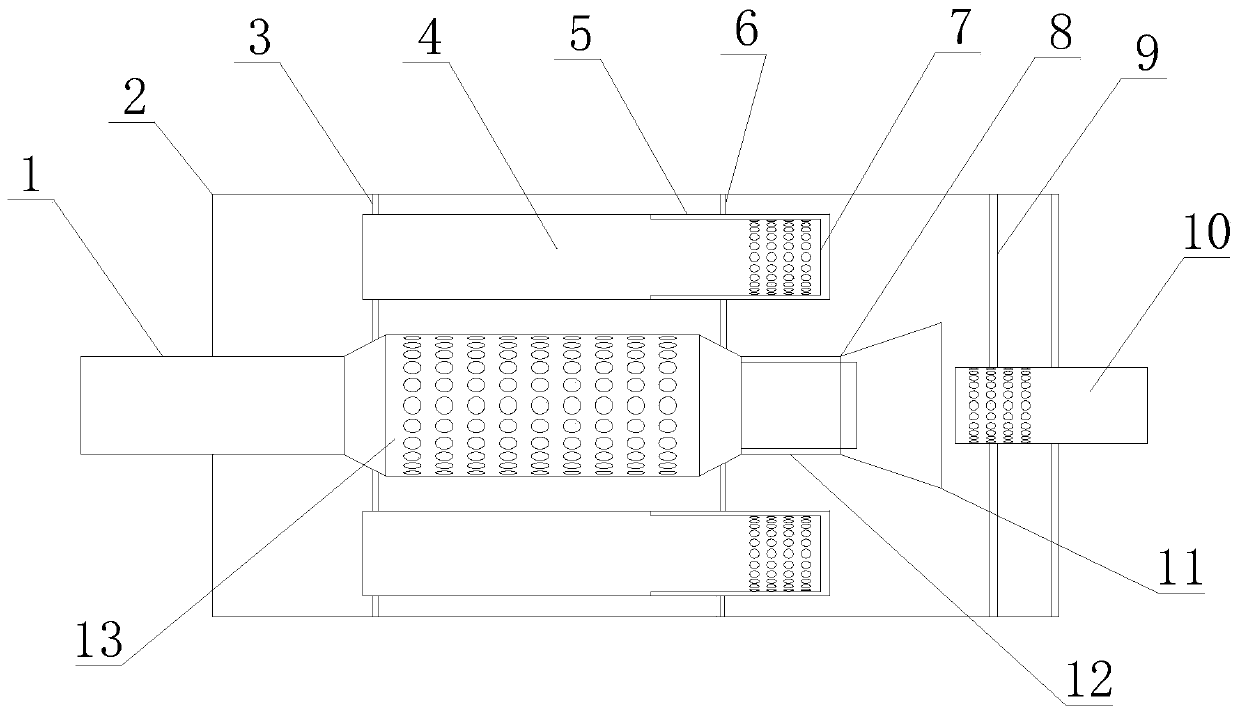

Bionic filter screen applied to range hood

ActiveCN106123068ALower draw heightLow costDomestic stoves or rangesDispersed particle filtrationThin shellsParallelogram

The invention relates to a bionic filter screen applied to a range hood. The bionic filter screen is arranged at a smoke cage hood at the lower end of a main engine of the range hood, and positioned at an air inlet at the upper end of an oil cup; a draught fan system provided with an air outlet is mounted in the main engine; the bionic filter screen is served as a big-end-up or big-end-down conical, rectangular conical or tetragonal conical metal thin shell; oil guide stems, oil trap stems and meshes are arranged on the bionic filter screen; the meshes take the shapes of parallelograms and are distributed with the oil guide stems with included angles; a plurality of the meshes are orderly and parallelly arranged at the upper and lower positions of the oil guide stems as well as symmetrically arranged at the left and right positions of the oil guide stems; the oil guide stems and the meshes are assembled as units and orderly distributed around the conical body of the bionic filter screen completely or partially; and the oil guide stems are parallel to the height h of the conical body of the bionic filter screen. The bionic filter screen provided by the invention is excellent in oil smoke trap, oil guide, resistance to oil dropping, resistance to oil hanging, and processing economy.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

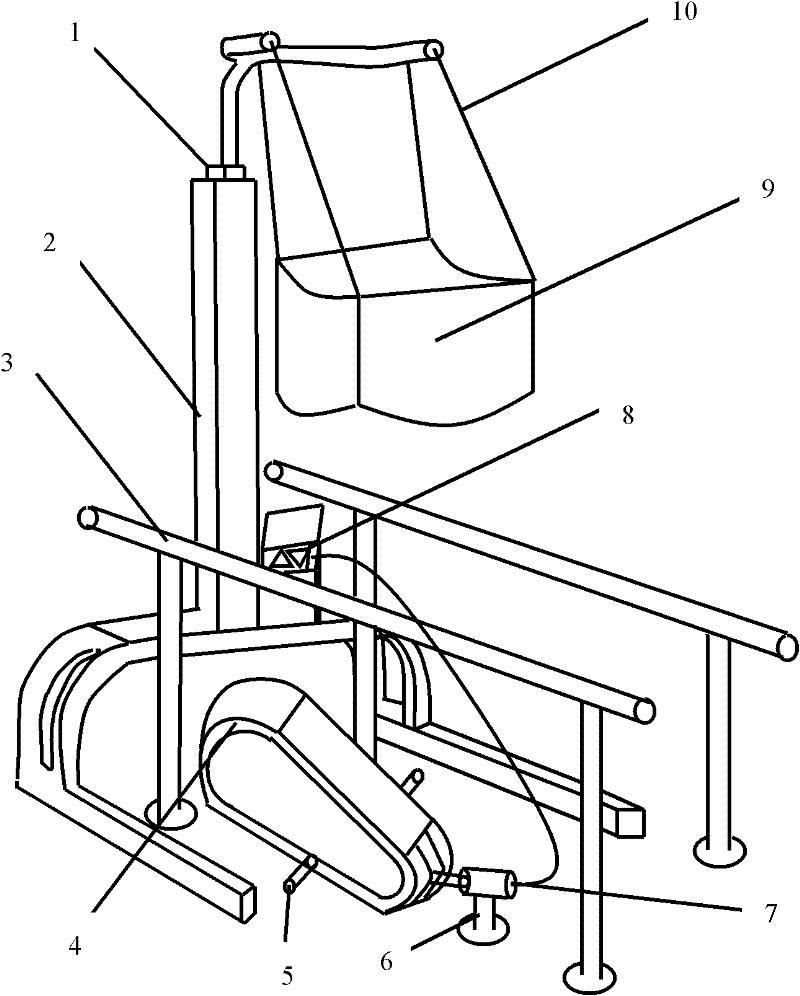

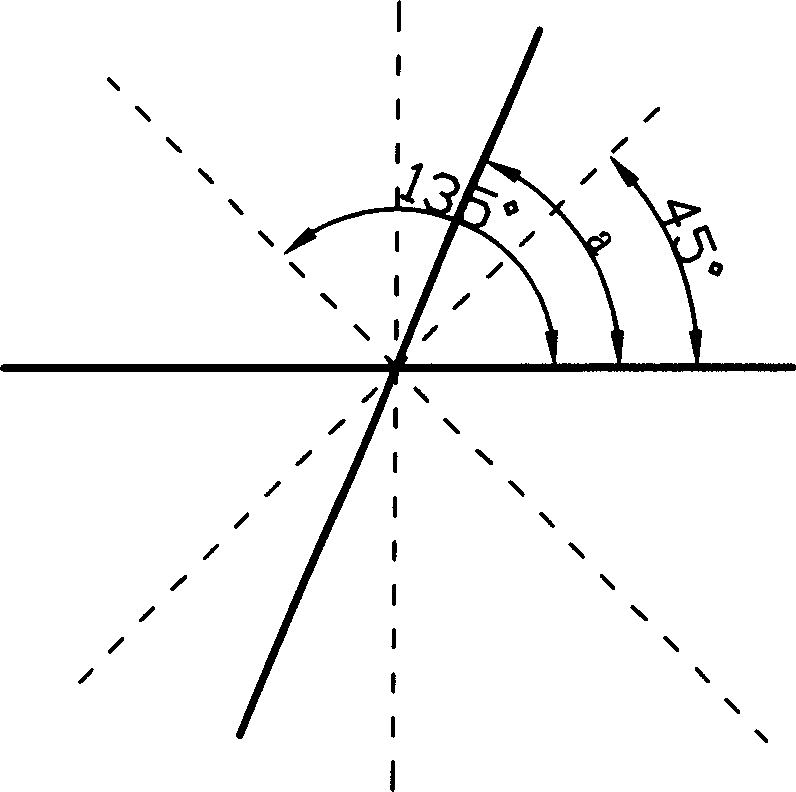

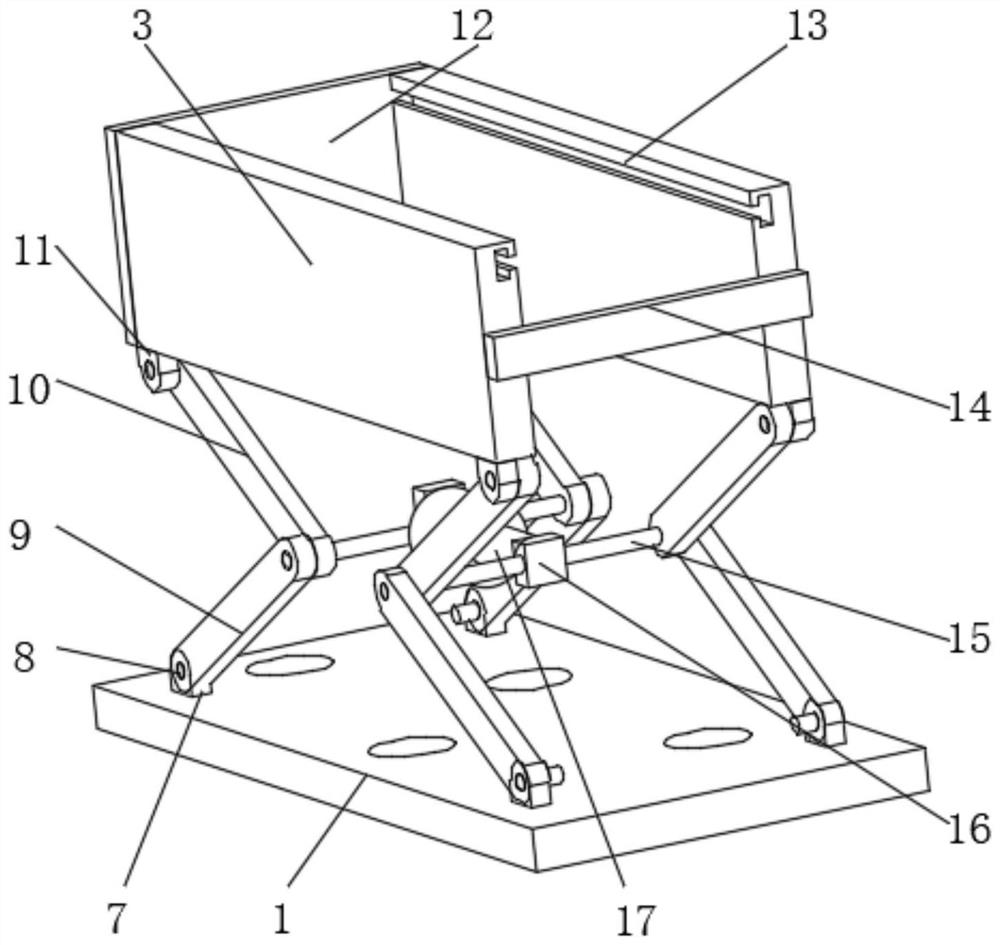

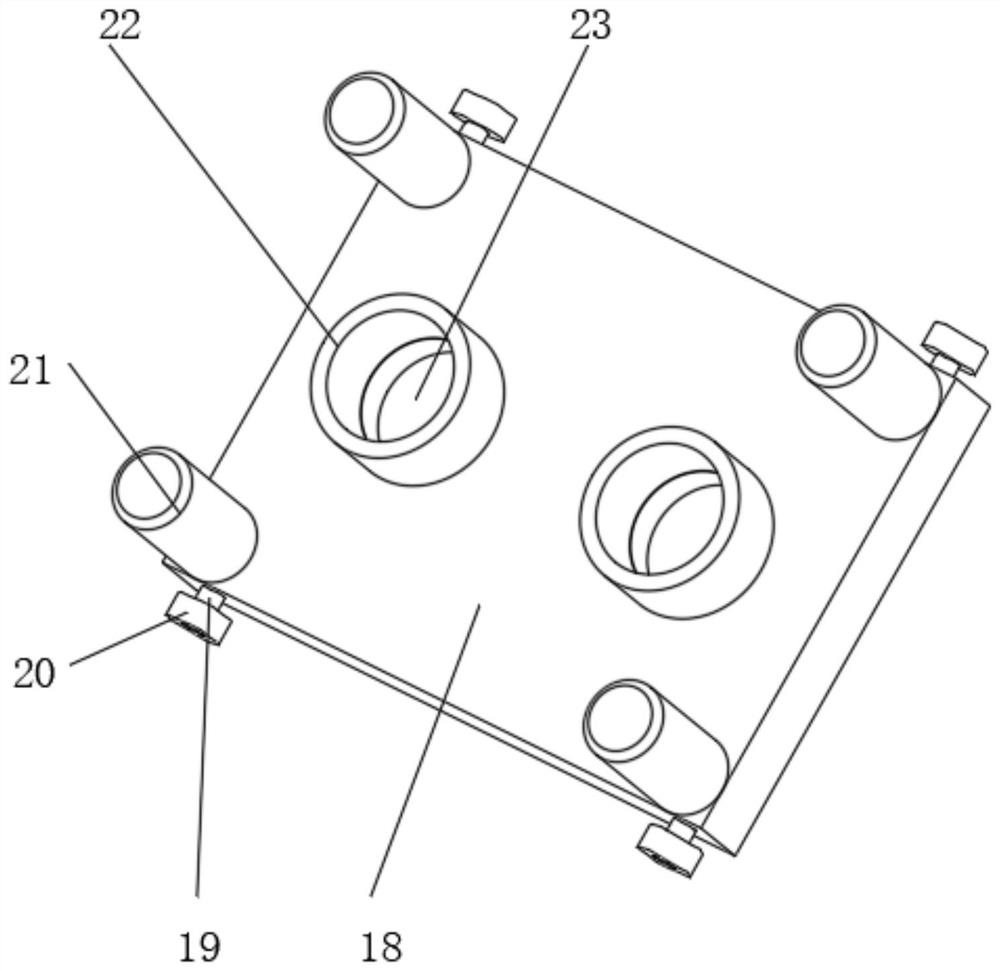

Gait rehabilitation training robot

ActiveCN102225033AAchieve compound movement trainingAchieve rehabilitationChiropractic devicesGait simulationThree-dimensional space

The invention discloses a gait rehabilitation training robot. The robot is characterized by comprising a weight reduction device, a gait simulative generator, a given motion trail and a personal computer. The weight reduction device and the gait simulative generator are installed on a pedal lever through a pair of protective boots worn by a trainer, and the pedal lever operates according to the given motion trail at a set speed in a set training pattern; the center line of the given motion trail is a closed curved trail fitting the walking of lower limbs of people, which is obtained by projecting the motion trail of an ankle joint in a three-dimensional space during normal walking into a two-dimensional space plane; and the personal computer is used for controlling the real-time speed of the gait simulative generator and selecting different training modes. By the adoption of the gait rehabilitation training robot disclosed by the invention, the problem of the consistency between the rehabilitation training gait trail and naturally walking gait trail of people can be solved.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Marine fair-faced concrete containing limestone powder and preparation method of concrete

The invention discloses marine fair-faced concrete containing limestone powder. The marine fair-faced concrete is prepared from components as follows: a concrete additive, a mixed cementing material, aggregate and water, wherein the mixed cementing material is prepared from cement and a concrete admixture; the concrete admixture is prepared from the limestone powder and granulated blast-furnace slag powder, the added limestone powder accounts for 5%-20% of the total mass of the concrete, and the added granulated blast-furnace slag powder accounts for 15%-40% of the total mass of the concrete; the consumption of the cementing material is 320-450 kg / m<3>, and the ratio of water to the cementing material is 0.30-0.42. According to the fair-faced concrete, fly ash is replaced with the limestone powder, the problem of raw material shortage due to adoption of fly ash is solved, defects of the fair-faced concrete adopting the fly ash are also avoided, the homogeneity and the workability of the concrete are improved simultaneously, the concrete bleeding risk is reduced, the requirement for durability is met, the appearance quality of the concrete structure is stable, and the requirement for the appearance quality of the fair-faced concrete is met.

Owner:CCCC WUHAN HARBOR ENG DESIGN & RES

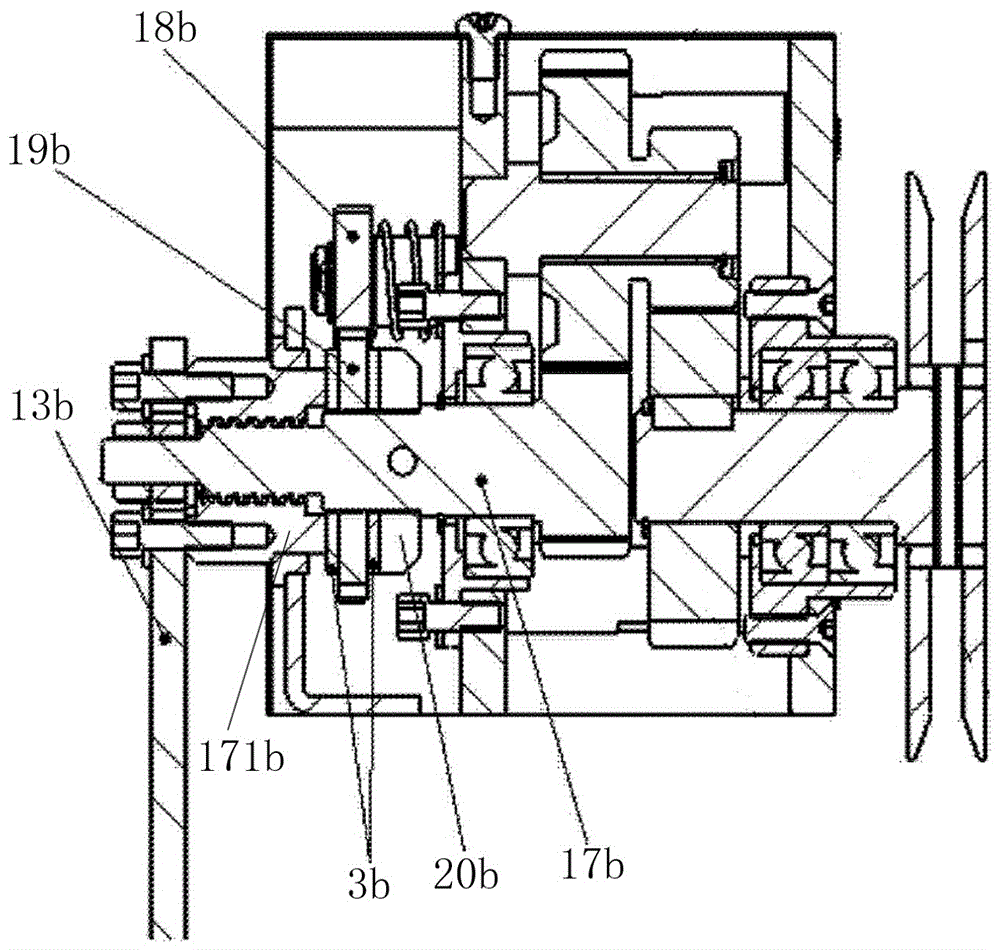

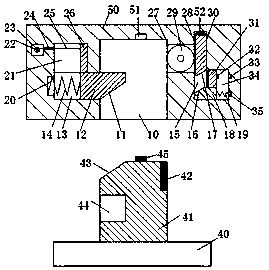

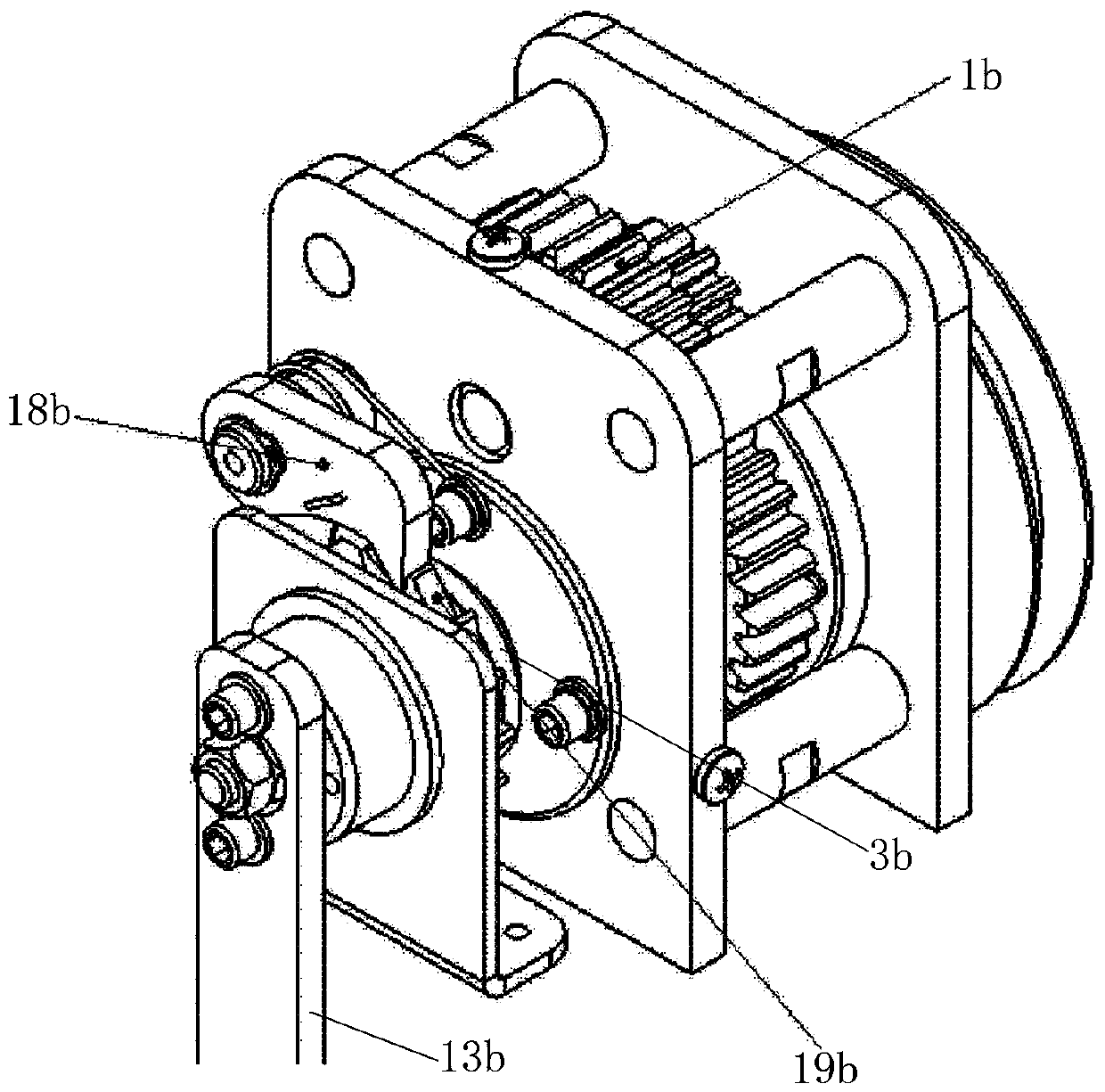

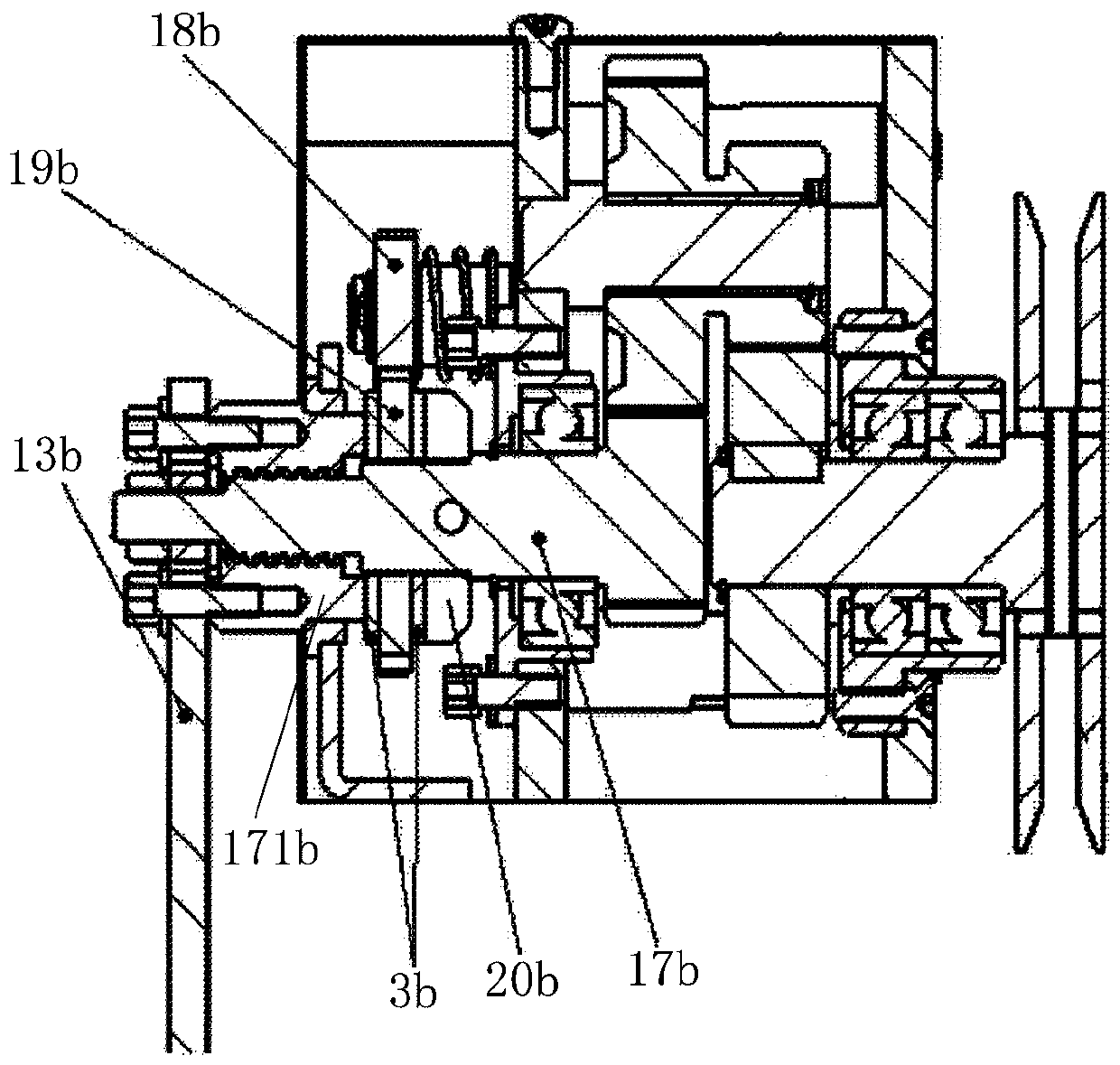

Improved locking device for main rotating shaft and application

ActiveCN105972201AAchieve brakingRealize the locking functionGearing controlHoisting equipmentsEngineeringCentrifugal force

The invention discloses an improved locking device for a main rotating shaft. The device is characterized in that a torsional spring which can overcome screwing frictional resistance between the main rotating shaft and a connecting nut is additionally arranged between the connecting nut and the main rotating shaft so as to prevent the main rotating shaft from uncontrollable high-speed rotating caused by human errors; the connecting nut can overcome the thread frictional force relative to the main rotating shaft under the effect of the inverted torsion of the torsional spring, and thus the connecting nut can be rotated relative to the main rotating shaft, and as a result, the main rotating shaft can be braked. The invention also provides another scheme for locking the main rotating shaft. The scheme is characterized in that an inner pawl which can be limited through an elastic connector is arranged on a flywheel disc; in case that the main rotating shaft is subjected to uncontrollable high-speed rotating, the outward centrifugal force of the inner pawl on the flywheel disc can be utilized to overcome the tensioning force of the elastic connector, thus the inner pawl can be locked to an inner ratchet wheel, and as a result, the function of locking the main rotating shaft can be further achieved.

Owner:施耐德电气(厦门)开关设备有限公司

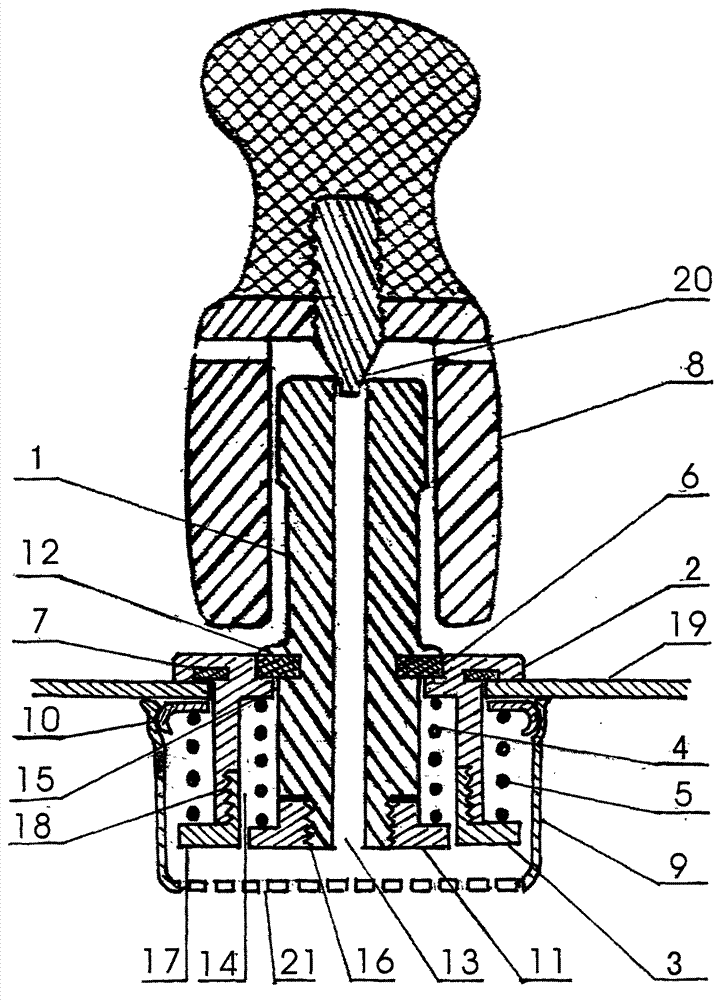

Pressure limiting, safety and pressure relief integrated valve of pressure cooker

The invention discloses a pressure limiting, safety and pressure relief integrated valve of a pressure cooker. The pressure limiting, safety and pressure relief integrated valve comprises a pressure limiting exhaust pipe, an upper threaded connector, a lower threaded connector, a safety pressure spring, a relief pressure spring, a sealing ring, a pressure limiting valve, an anti-blocking cover and a clamping structure. The pressure limiting exhaust pipe, the upper threaded connector, the lower threaded connector, the safety pressure spring, the relief pressure spring, the sealing ring, the pressure limiting valve, the anti-blocking cover and the clamping structure are combined with one another and are mounted on a lid of the pressure cooker. The working pressure of the pressure cooker is controlled by the exhaust pipe and the pressure limiting valve, the safety exhaust pressure of the pressure cooker is controlled under the matched effect of the exhaust pipe and the safety pressure spring, and the relief pressure of the pressure cooker is controlled under the matched effect of the threaded connectors and the relief pressure spring. Compared with a conventional safety valve of a pressure cooker, the pressure limiting, safety and pressure relief integrated valve has the advantages that a narrow inner cavity can be omitted, and blocking or failure can be prevented. Besides, the basic difference between the pressure limiting, safety and pressure relief integrated valve and a conventional pressure relief structure is that the relief pressure of the pressure cooker can be precisely designed and controlled by the pressure limiting, safety and pressure relief integrated valve, injury to people due to high-temperature food which is ejected out of the pressure cooker during pressure relief can be completely eradicated, a protective cover can be omitted during detection, and safety can be completely guaranteed during operation.

Owner:欧明华

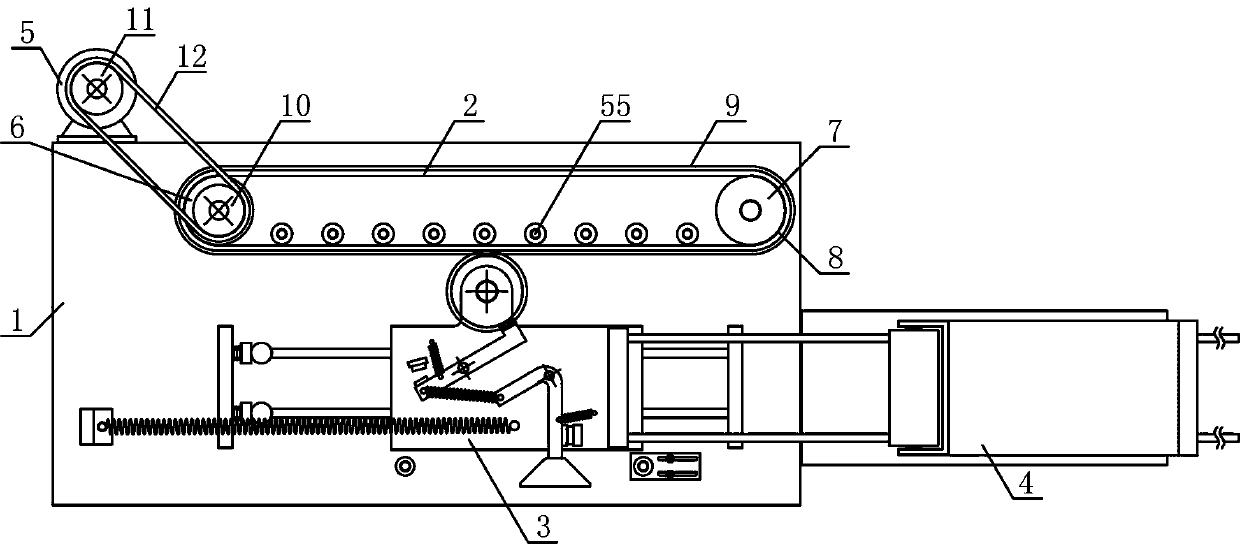

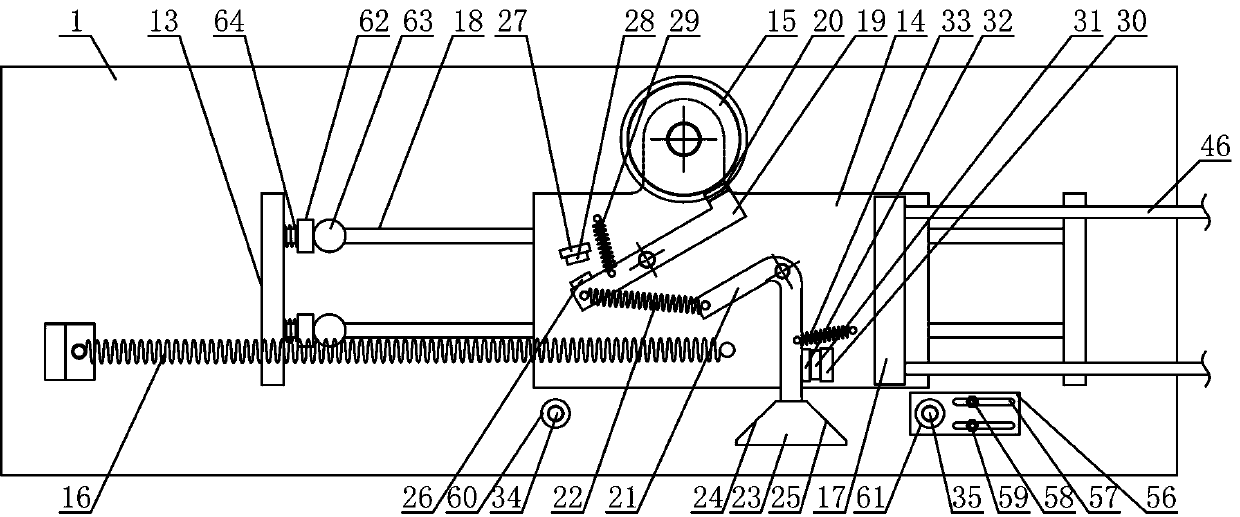

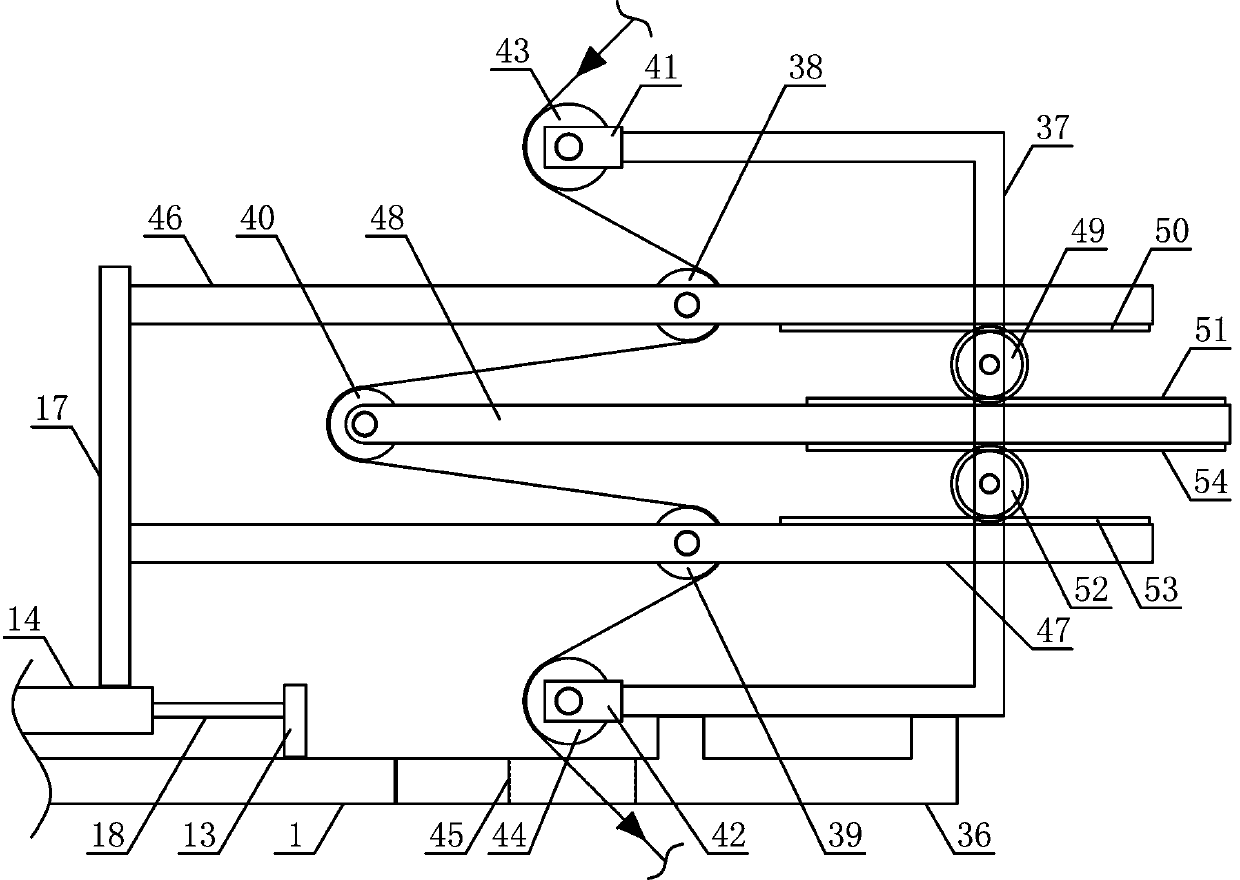

Fixed-range pulling device for textile yarns

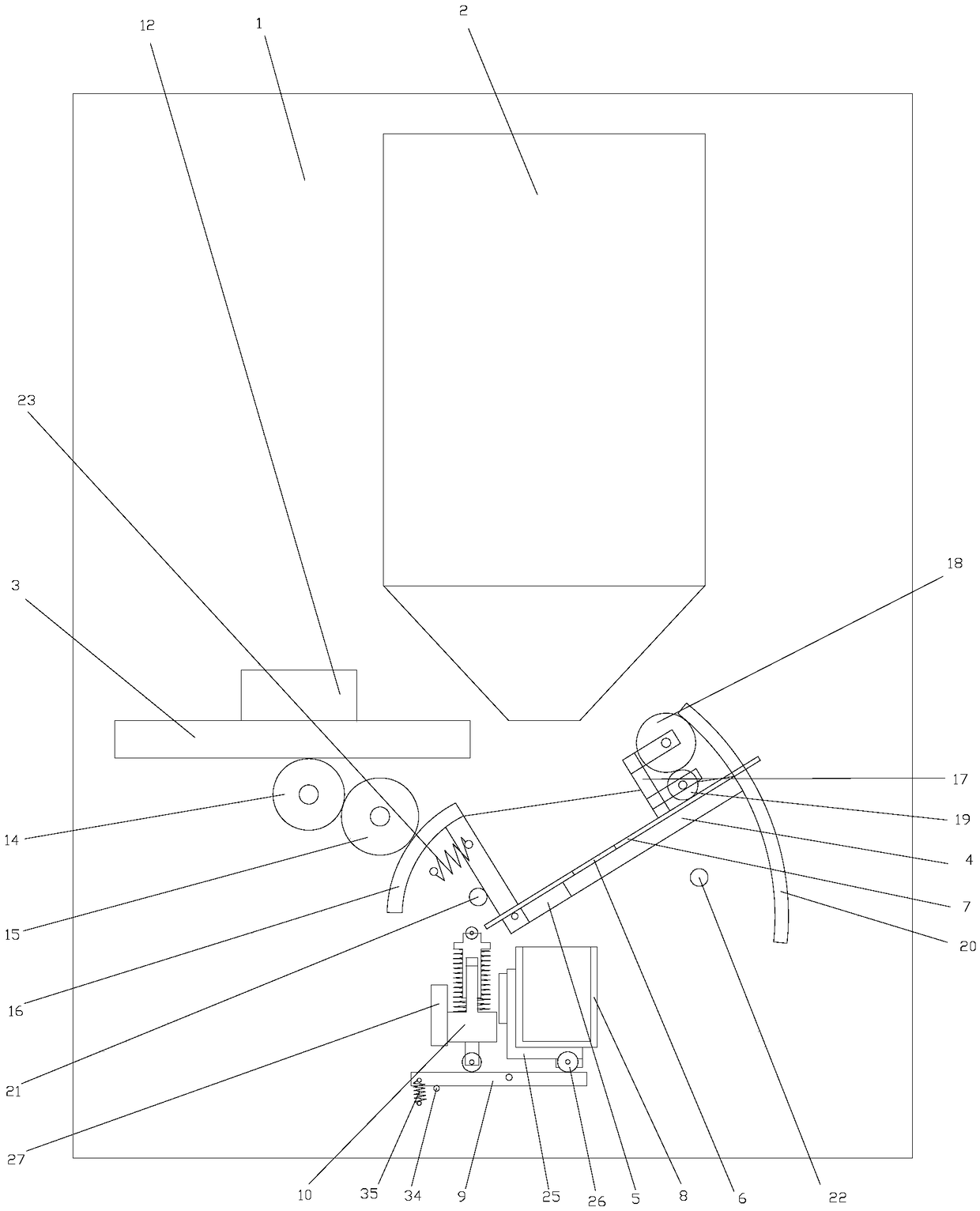

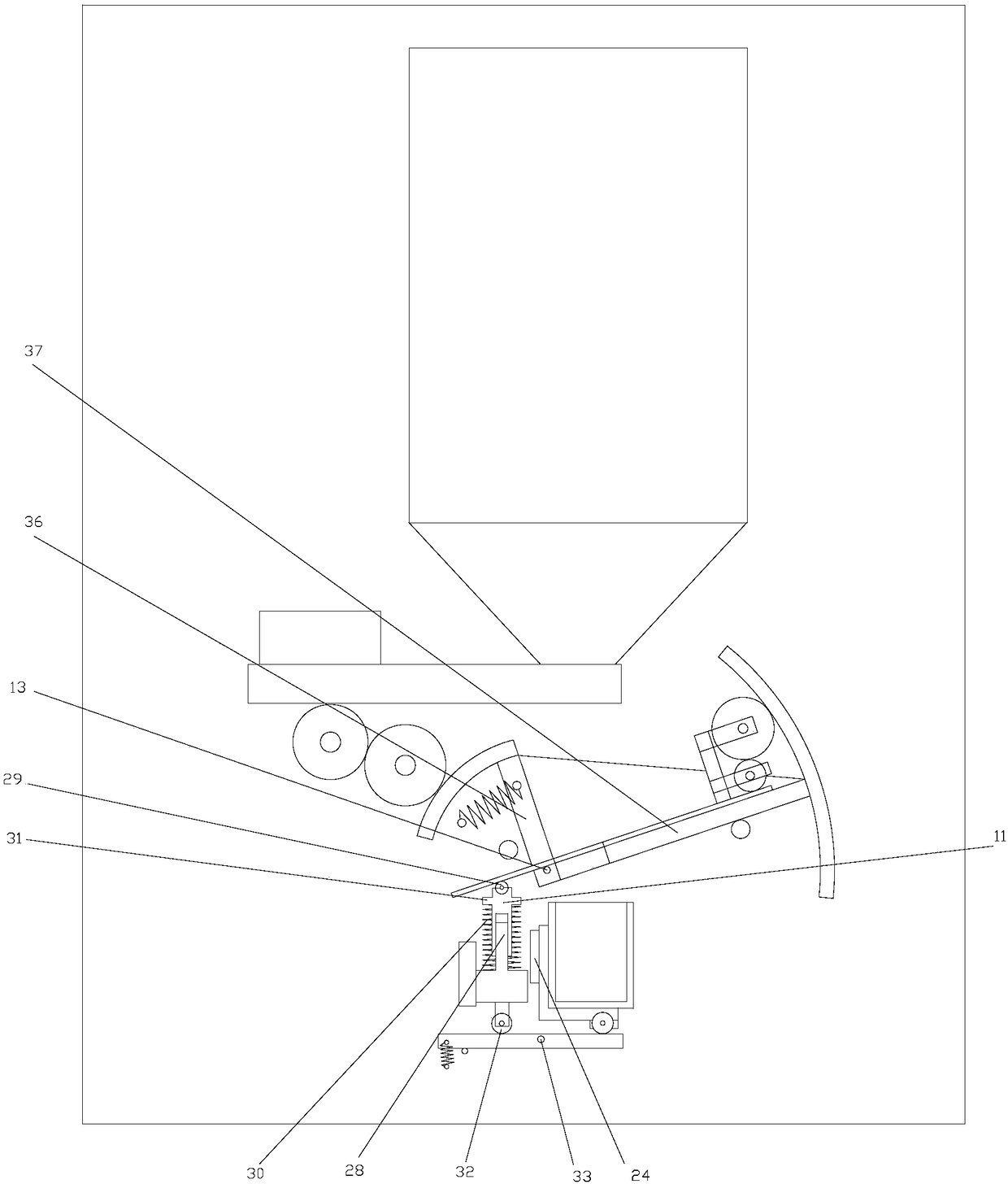

ActiveCN110485020AFast and smooth pulling processHigh degree of automationTextiles and paperYarnEngineering

The invention discloses a fixed-range pulling device for textile yarns, and belongs to the field of textile processing machinery and equipment. The outer side of a pulling belt is provided with a pulling rack, a pulling motor is in transmission connection with the pulling belt by adopting a transmission belt, a reciprocating guide plate is slidably arranged in a reciprocating guide rod, a pullingplate gear is in engaged connection with the pulling rack, a backward tension spring is horizontally connected between the reciprocating guide plate and a reciprocating base, the side, along a forwardstop lever, above the reciprocating guide plate is fixedly provided with a yarn supporting connecting plate, the ends of the upper and lower sides of a pulling bracket are horizontally and rotationally connected with a yarn inlet rotating roller and a yarn outlet rotating roller respectively, and a drafting assistance rotating roller is horizontally arranged between an upper drafting rotating roller and a lower drafting rotating roller. The fixed-range pulling device for the textile yarns has the advantages that the structural design is reasonable, pulling processing can be conducted on the textile yarns rapidly and stably, the horizontal pulling amplitude can be adjusted according to the types and specifications of the textile yarns, the automation degree of yarn pulling processing is improved, and the processing and use needs are met.

Owner:SUZHOU JUHUIBANG NEW MATERIAL TECH CO LTD

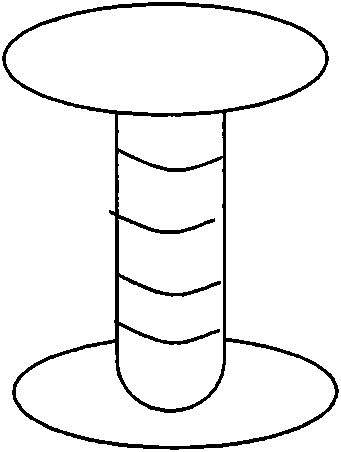

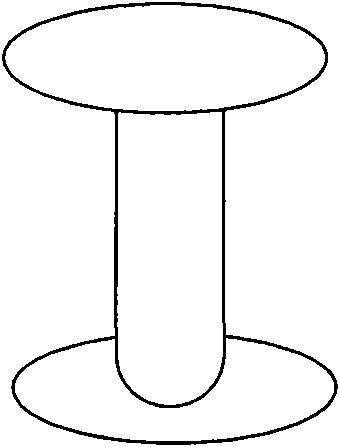

Aluminium alloy, core support prepared by same for forming of aluminum alloy casting and preparation of core support

InactiveCN102115838ASolve technical problems of poor fusionSolve the defect that non-dense gaps are easy to form cold shutFoundry mouldsFoundry cores5005 aluminium alloy5052 aluminium alloy

The invention relates to an aluminium alloy which comprises the following components by mass: 11-13% of Si, 0.15-0.30% of Mg, 86.7-88.85% of Al. Because the aluminium alloy provided by the invention has a melting temperature range lower than the pouring temperature of a casting aluminum alloy, the treated surface is easy to be melted by high-temperature casting aluminium alloy liquid and fused with a casting aluminum alloy matrix, and the technical problem of the poor fusion of a core support and an aluminium alloy casting body in the forming of a confined aluminum alloy casting in the prior art is effectively solved; and simultaneously, with the core support manufactured by the aluminium alloy, liquid flow stratifiedly flows as laminar flow when passing through the comb holes of the core support, and the flow process is subject to both the gravity action of the upper layer and the uplift action of the lower layer, which can effectively overcome the surface tension effect of liquid flow between layers and avoid the generation of stratified cold shut. The defect that existing core support always has incompact gaps which are easy to form cold shuts is effectively solved, and the internal quality requirements for confined castings are satisfied.

Owner:XIAN AERONAUSTIC POWER CONTROL ENG

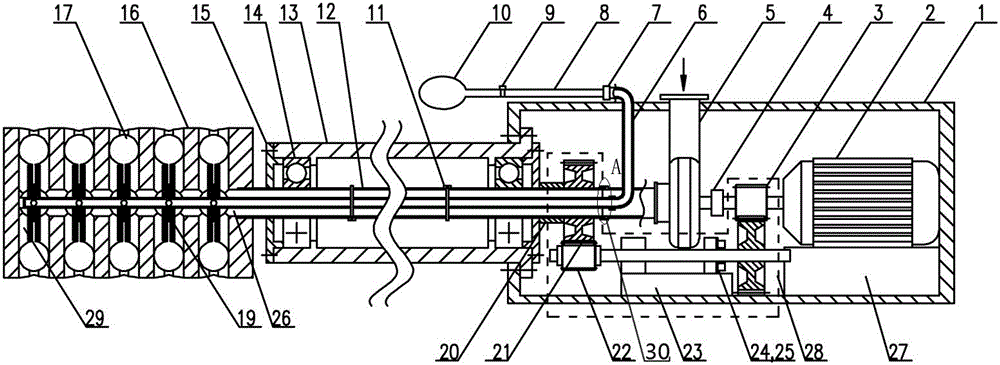

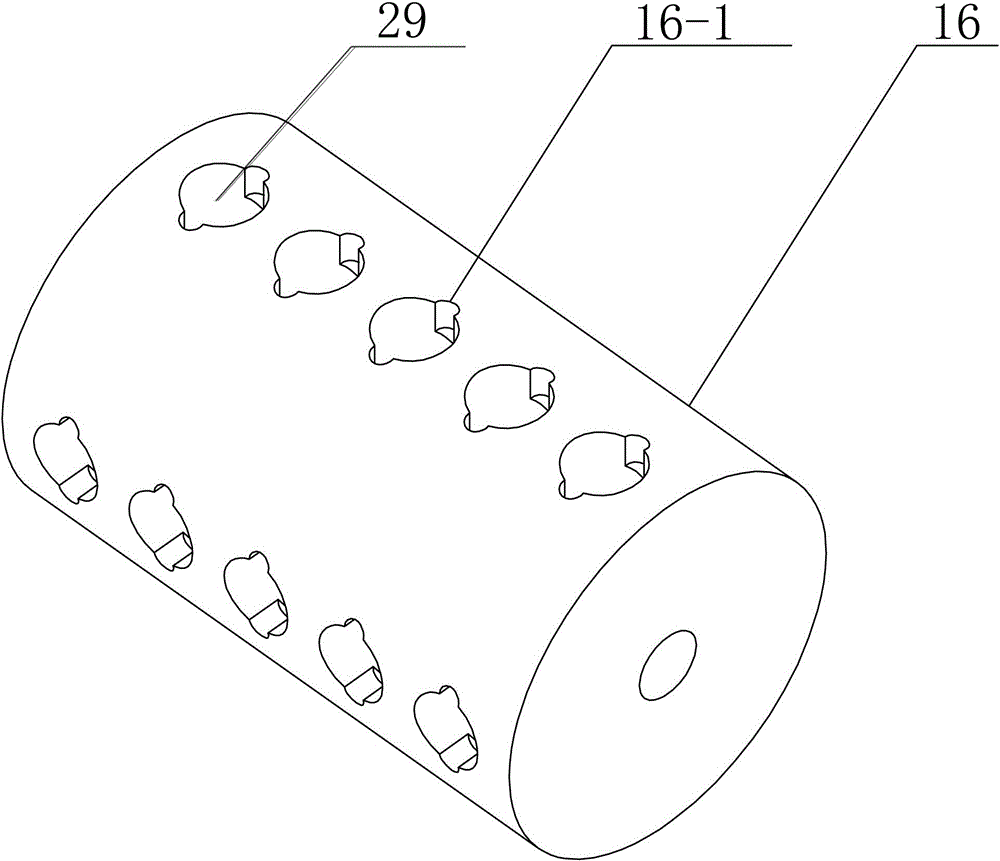

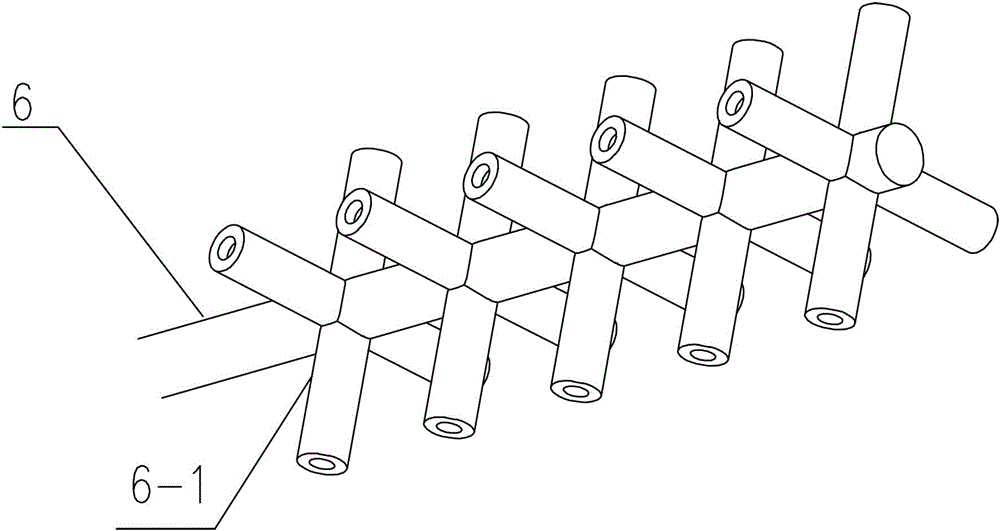

Automatic feed subpackage equipment

The invention discloses automatic feed subpackage equipment. Feed in a stock bin falls into a separating cylinder after flowing through a hopper, the accommodated feed content of each separating cylinder is equal, when the hopper rotates to abut against a second cylindrical pin, the stock bin is closed by a valve plate, and the feed in the stock bin is not scattered on the periphery the equipment;and after the hopper rotates, the feed in the hopper can automatically flow through a first discharge hole and a second discharge hole and fall into the separating cylinder, while the arrangement ofa transmission plate, a sliding sleeve and a sliding block can ensure that each time the feed in the hopper is completely discharged into the separating cylinder, and the automation level of the wholeworking process is improved. According to the automatic feed subpackage equipment, the feed does not scatter, and the subpackage structure is more automated in the process of subpackage.

Owner:山东海伦食品股份有限公司

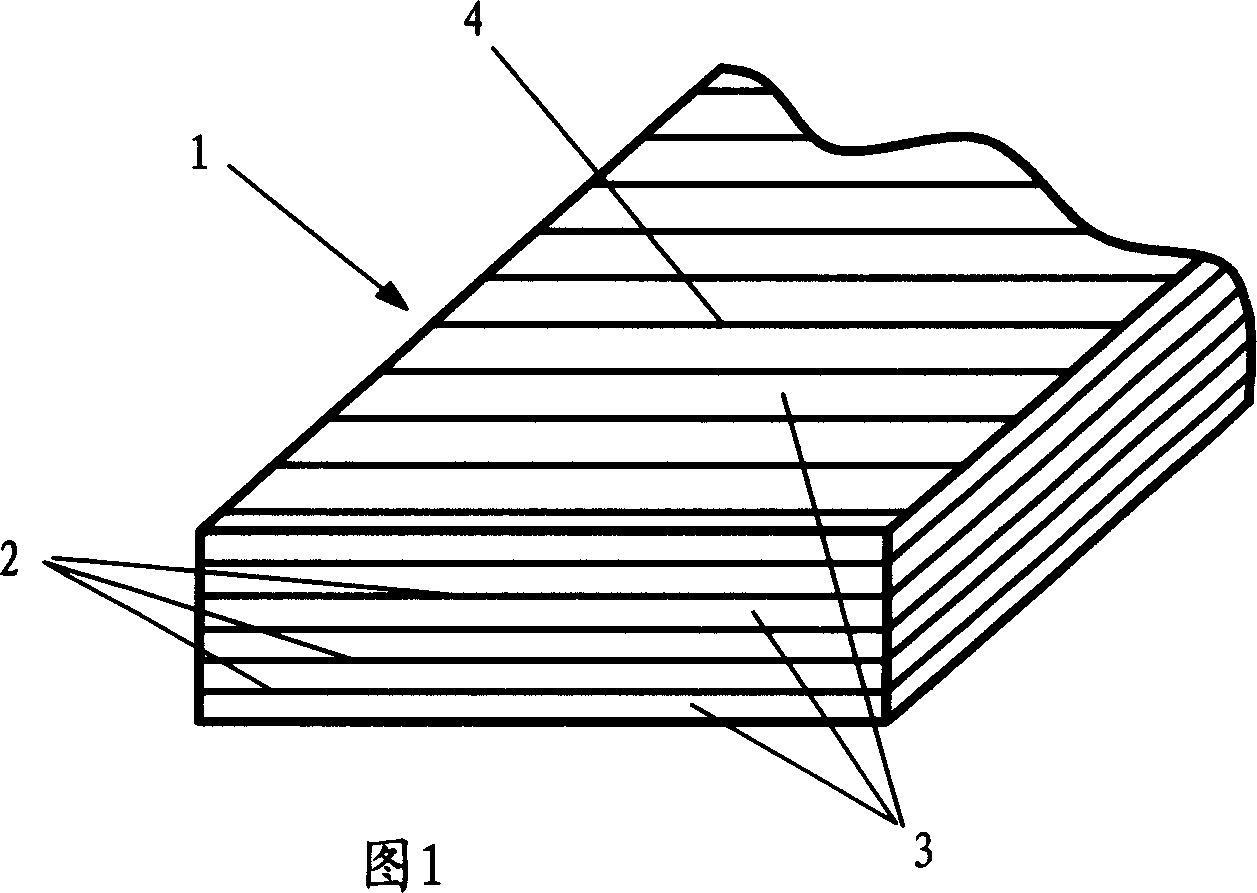

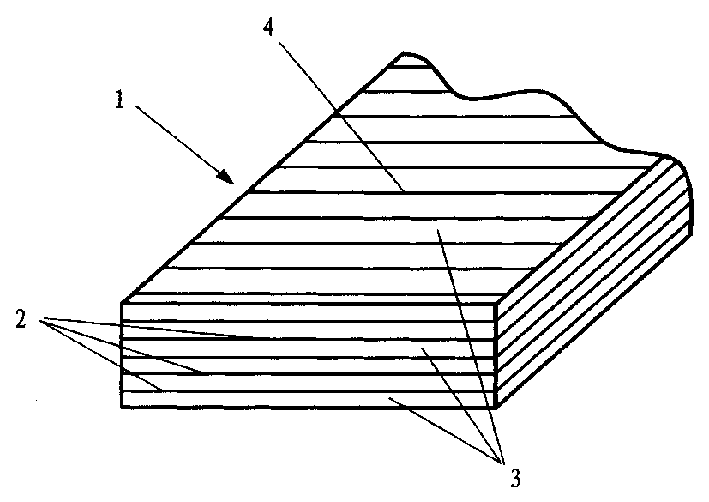

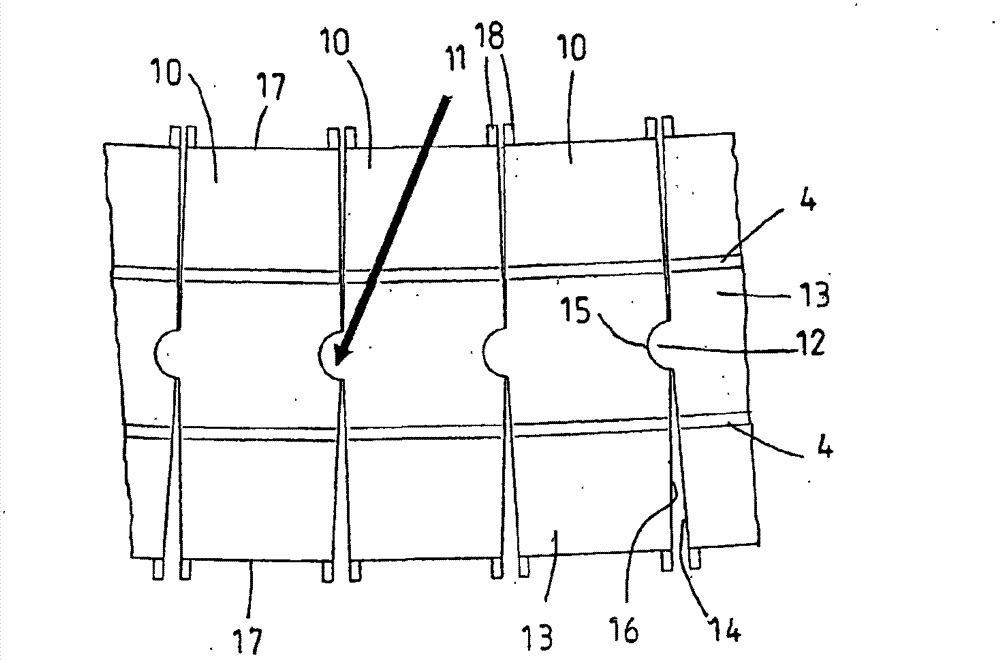

Multilayer composite bamboo adhesive floor and its manufacturing process

InactiveCN1475644AOvercoming raw material tensionOvercoming tensionWood layered productsFlooringAdhesivePreservative

A ply-bamboo adhesive floor block is composed of bamboo layers and the adhesive-antiseptic layers between adjacent bamboo layers. It is made through splitting bamboo to obtain bamboo strips, braidingmats, drying, immersing in liquid mixture of adhesive and antiseptic, dripdrying, dryina again, laminating mats, pressing while heating, and cooling.

Owner:上海锦江科技工程公司

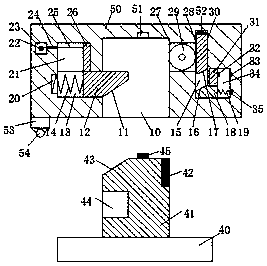

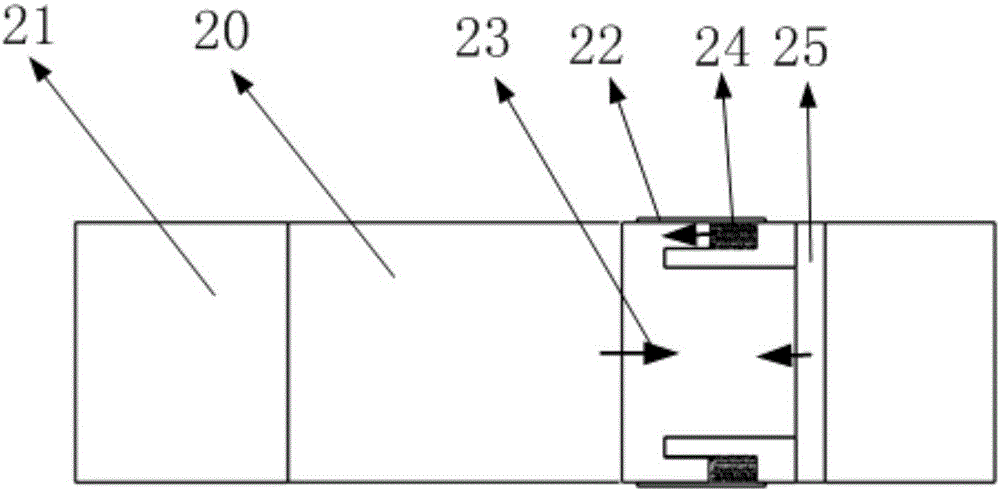

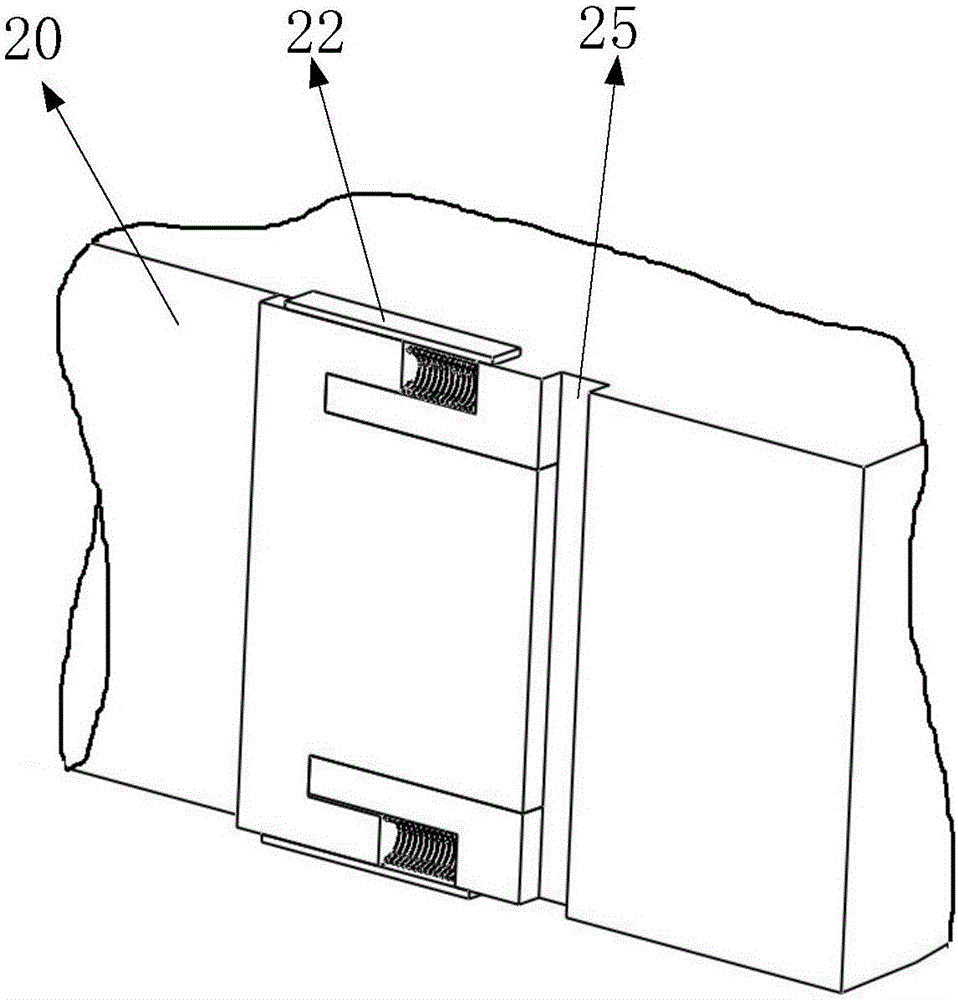

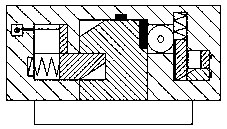

Improved vehicle-mounted navigation device

InactiveCN108955698AOvercoming tensionReliable lockingInstruments for road network navigationSoftware engineeringElectric shock

The invention discloses an improved vehicle-mounted navigation device including a mounting carrier and a navigator connected with the mounting carrier in an inserted manner. The top end face of the navigator is fixed with an inserting column; the bottom of the mounting carrier is provided with an inserting groove; the left side of the inserting groove is provided with a first sliding groove in a communication manner; the left side of the first sliding groove is provided with a first spring groove in a communication manner; the first sliding block is arranged in the first sliding groove, the first sliding block is in cooperative connection with the first sliding groove, a first spring is arranged between the left side face of the first sliding block and the left inner wall of the first spring groove in a connection manner, and the top of the first sliding groove is provided with a second sliding groove in a communication manner. The operation is convenient and fast, the installation anddisassembly efficiency of the navigator is greatly increased, and occurrence of electric shock accidents when the navigator is installed and disassembled is effectively avoided.

Owner:徐盈

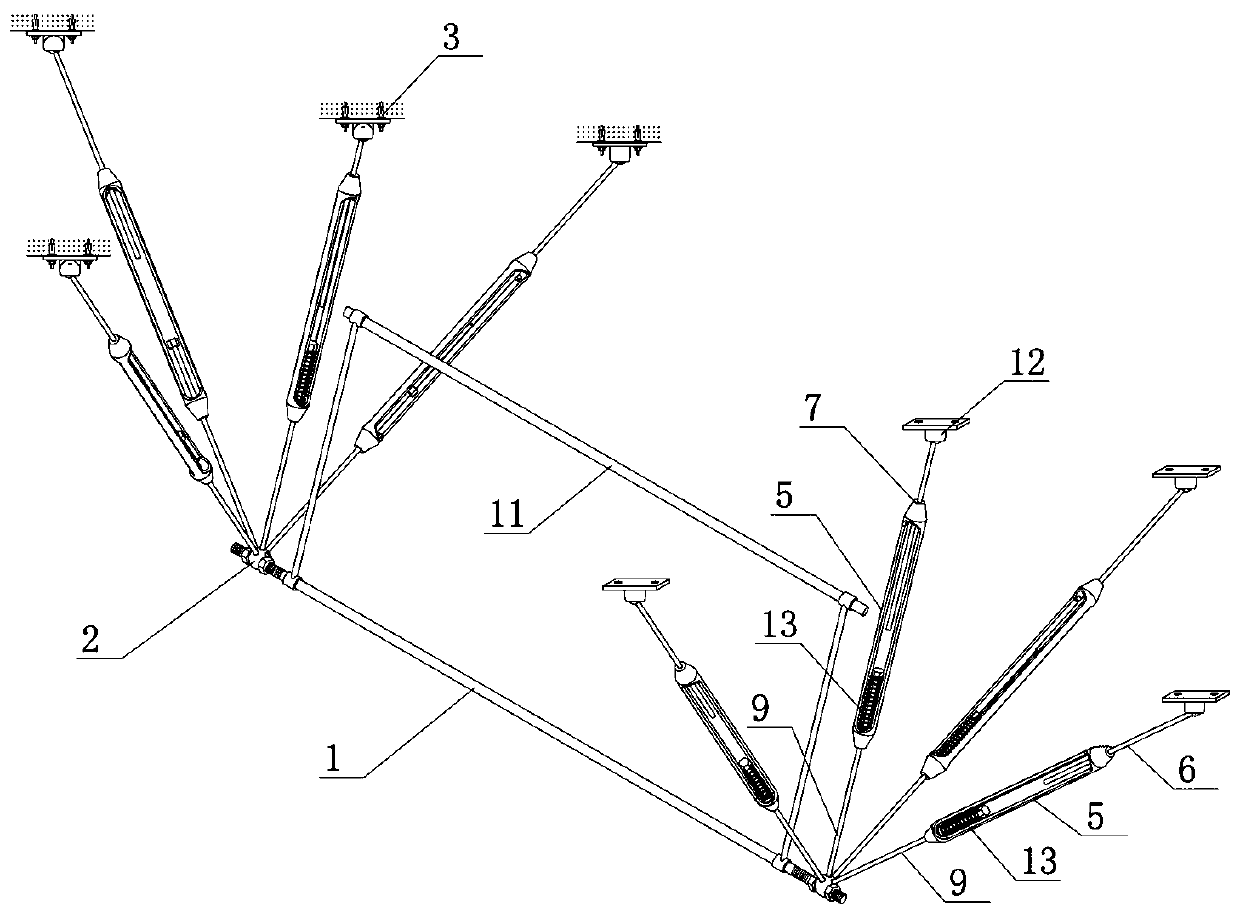

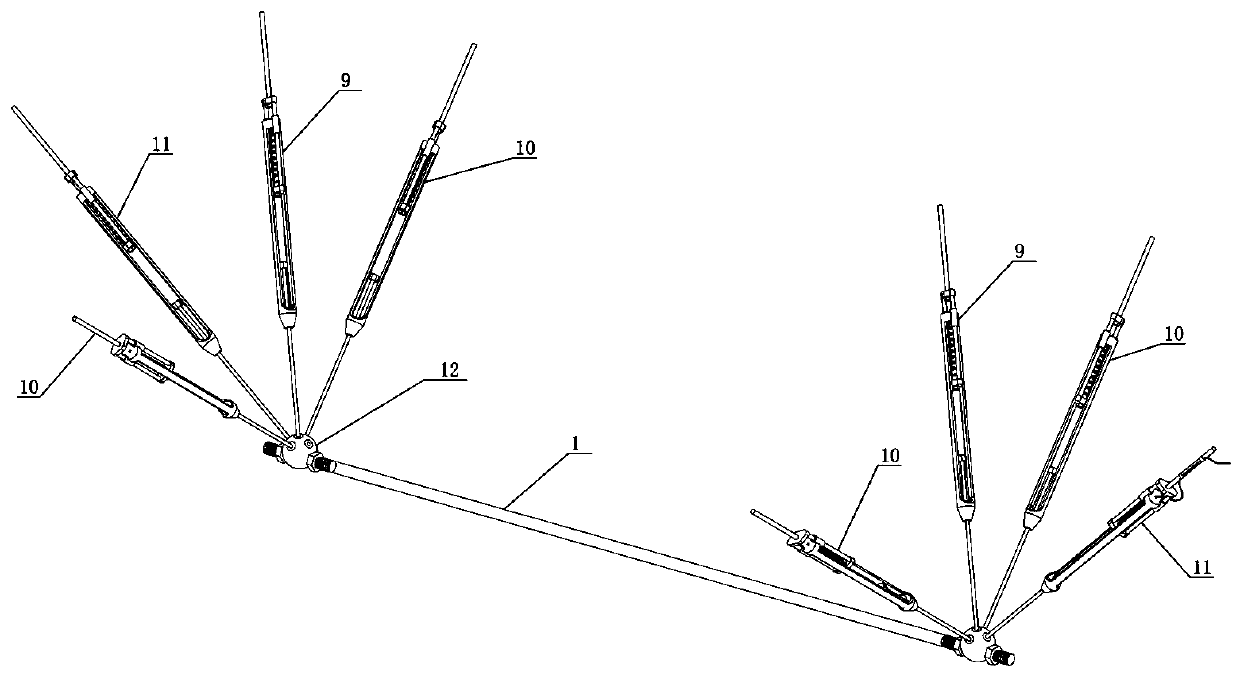

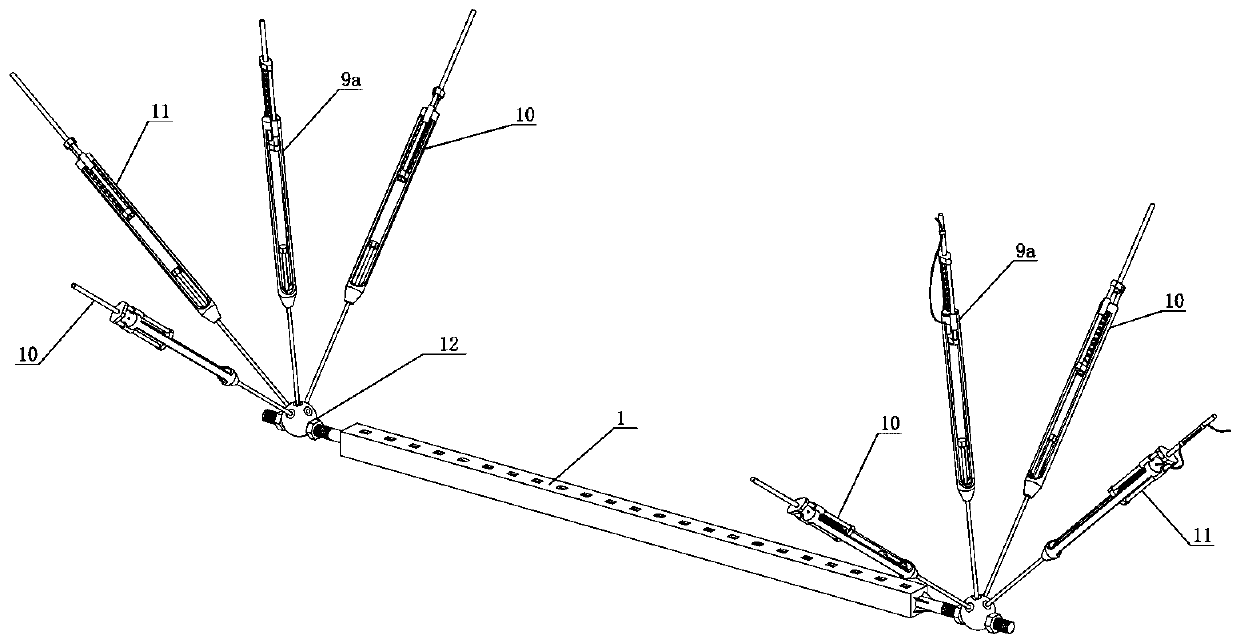

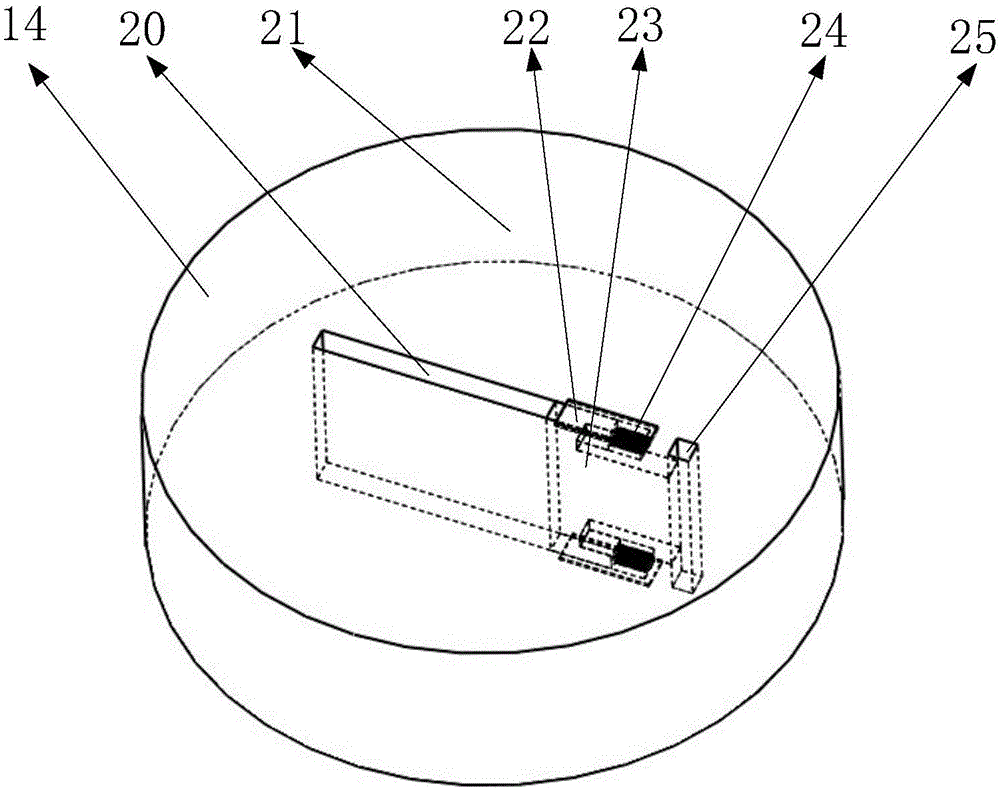

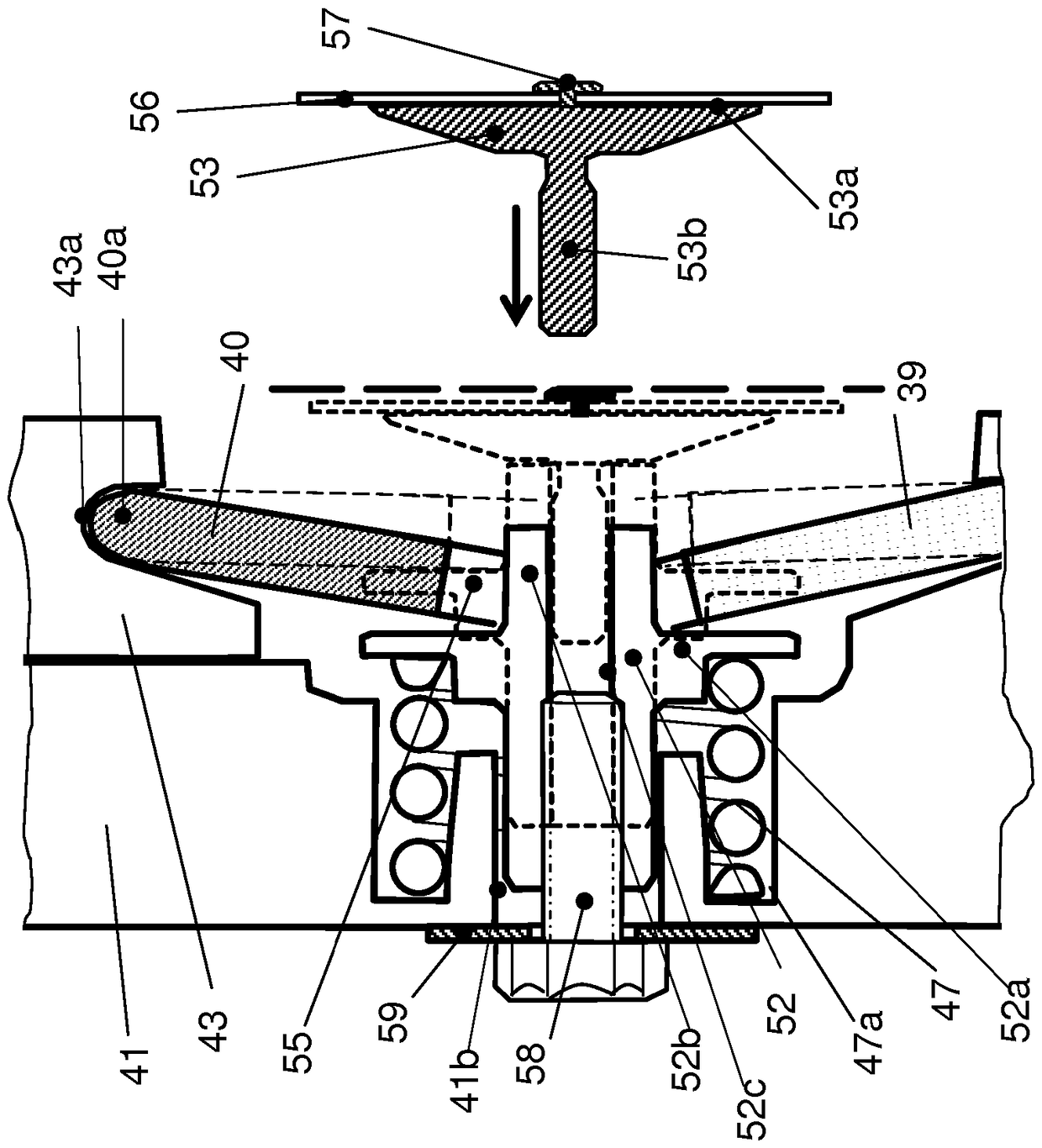

Anti-seismic bracket with bump damping adjusting function

PendingCN110425369AHas a deformation coordination effectRealization of shock absorption and damping functionPipe elementsPre stressPre stressing

The invention discloses an anti-seismic bracket with the bump damping adjusting function. The anti-seismic bracket comprises a supporting cross beam, traction end parts and traction parts; an ejectorrod assembly is upwards connected to each traction end part at the two ends of the supporting cross beam along the dead center; the upper ends of the ejector rod assemblies are connected to a ceiling;the traction end parts are supported by utilizing the ejector rod assemblies; the traction parts are hinged to the symmetric positions of the left sides and the right sides of the ejector rod assemblies and the positions right behind the ejector rod assemblies; and the upper ends of the traction parts are fixed to the ceiling through hinge bases. According to the anti-seismic bracket, the bump damping adjusting function is achieved, in addition, after thrust is applied to the centers of the traction end parts at the two ends of the supporting cross beam and balance tensile force is simultaneously applied on the periphery of the thrust, prestress thrust can be added to the ejector rod assembly providing the thrust by utilizing the interaction between the thrust and the tensile force, pre-stress tensile force is provided for the traction parts providing the tensile force, so that the traction end parts at the two ends of the supporting cross beam can be in a stress state, the stabilityof the supporting cross beam can be well improved, and therefore the stability of a pipeline component is improved.

Owner:HENAN AUSPIC TECH

Cleaning brush of automobile engine cylinder cover

InactiveCN111940364AAvoid pollutionImprove reuse efficiencyCleaning using toolsManufacturing cost reductionMetal alloy

The invention discloses a cleaning brush of an automobile engine cylinder cover, and relates to the technical field of cylinder cover production, and aims to solve the problem of collection of obliquely cut waste particles The cleaning brush specifically comprises a base, wherein a lifting mechanism is arranged on the outer wall of the top of the base, two side plates are arranged on the outer wall of the top of the lifting mechanism, a supporting mechanism is slidably connected to the inner walls of the two side plates, a brushing mechanism is arranged on the outer walls of the tops of the side plates, and a feeding and discharging mechanism is arranged on the outer walls of the opposite sides of the side plates; and the supporting mechanism comprises a supporting base, four positioning columns and supporting rings, and the four positioning columns are symmetrically fixed to the outer wall of the top of the supporting base through bolts. According to the cleaning brush, by arranging permanent magnets, cut particles are metal alloy materials, the permanent magnets can adsorb the particles, and all the removed obliquely-cut particles are collected in the supporting rings and recycled in a centralized mode, so that on one hand, the recycling efficiency of the obliquely cut particles is improved, and the manufacturing cost is reduced, and on the other hand, the obliquely cut particles are prevented from polluting the working environment.

Owner:台州霆麦网络科技有限公司

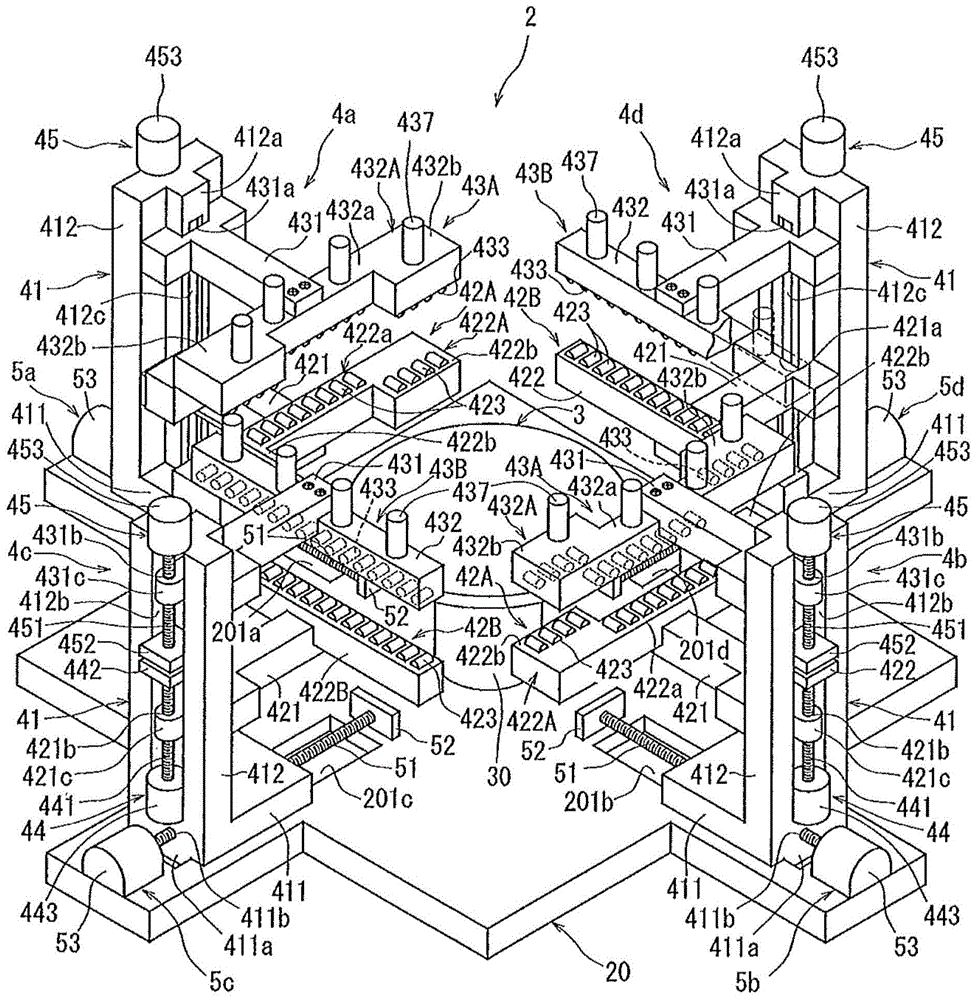

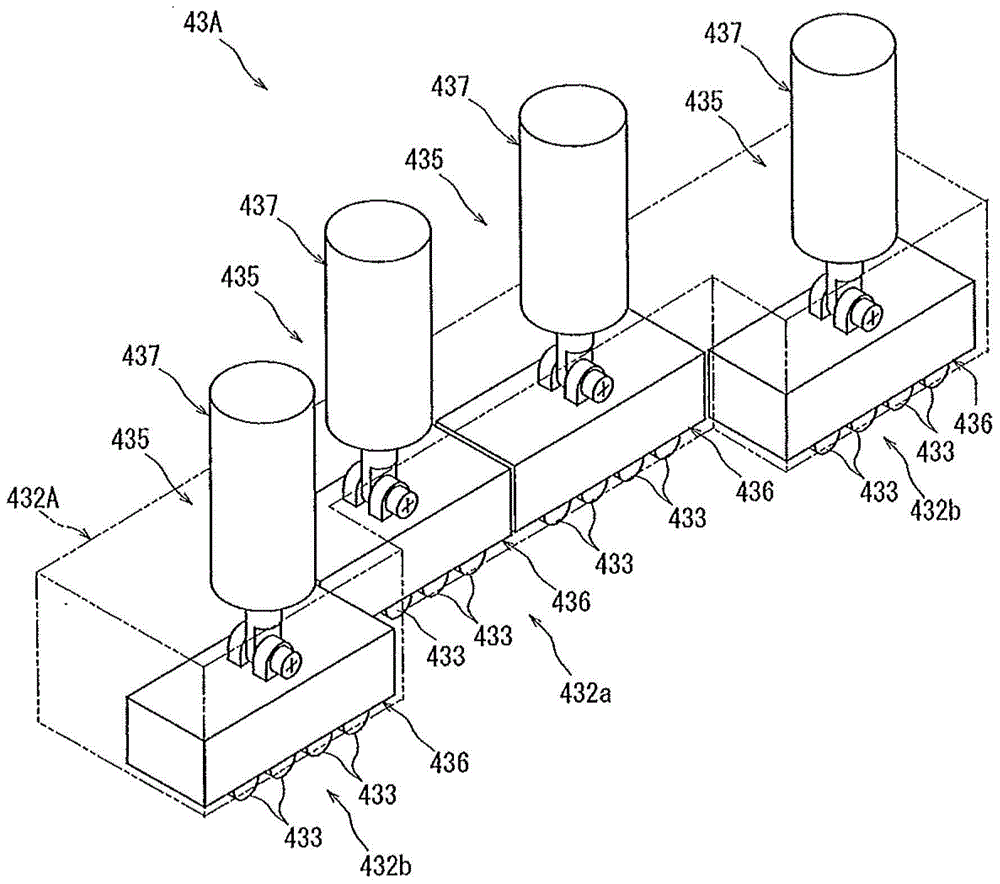

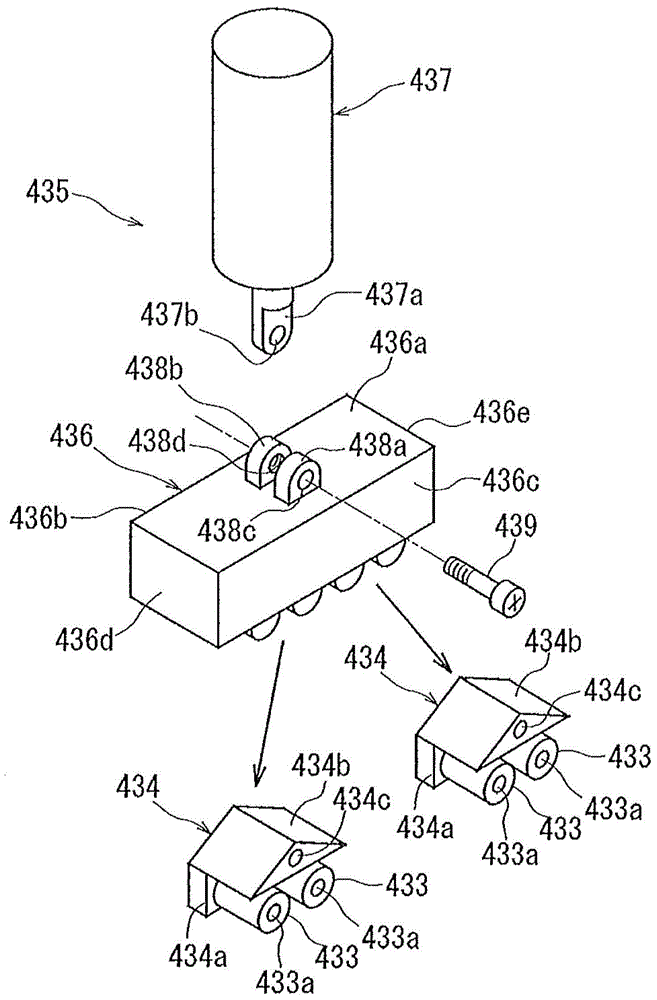

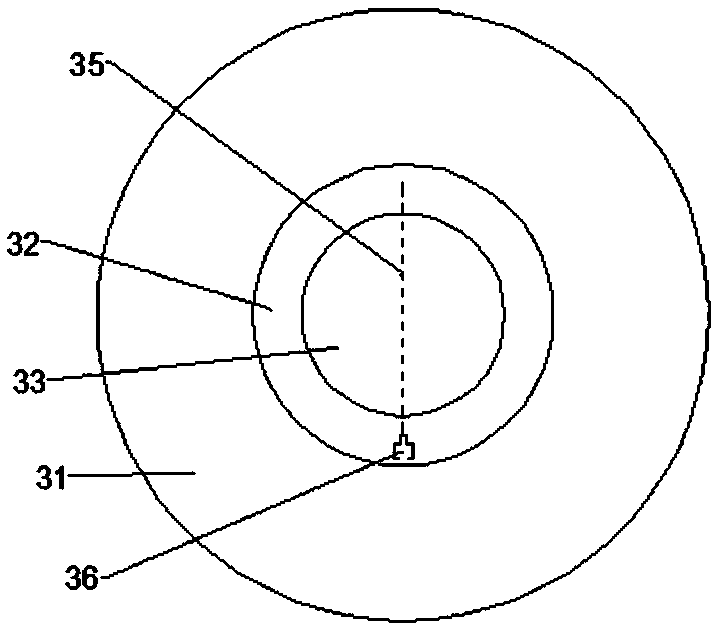

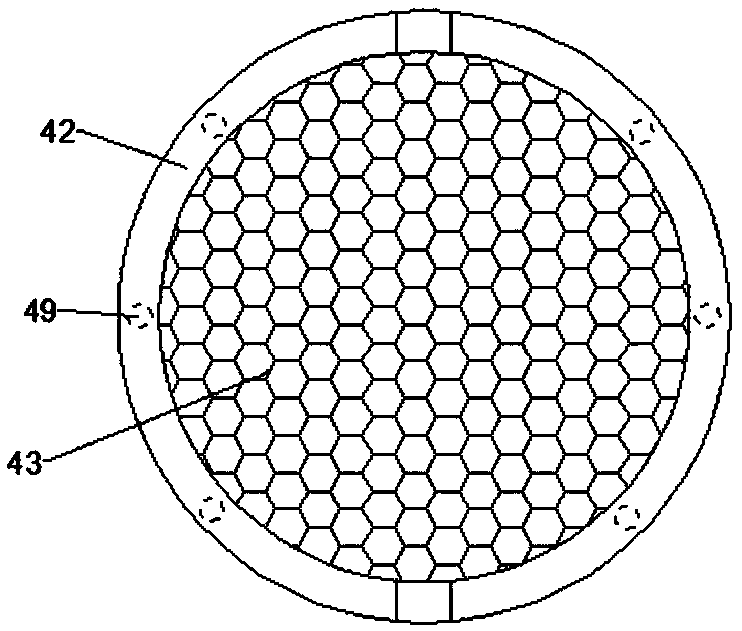

Tape expanding device

ActiveCN104103585AImprove fullyStable clampingSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

Owner:DISCO CORP

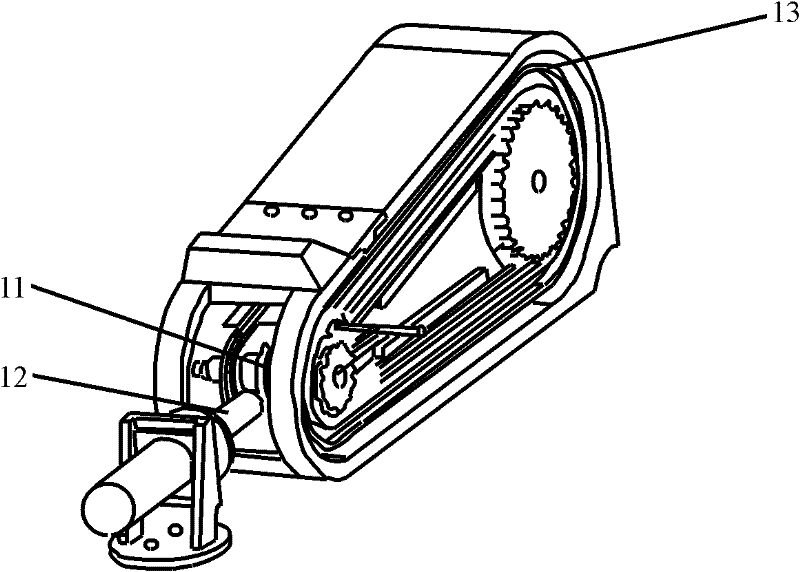

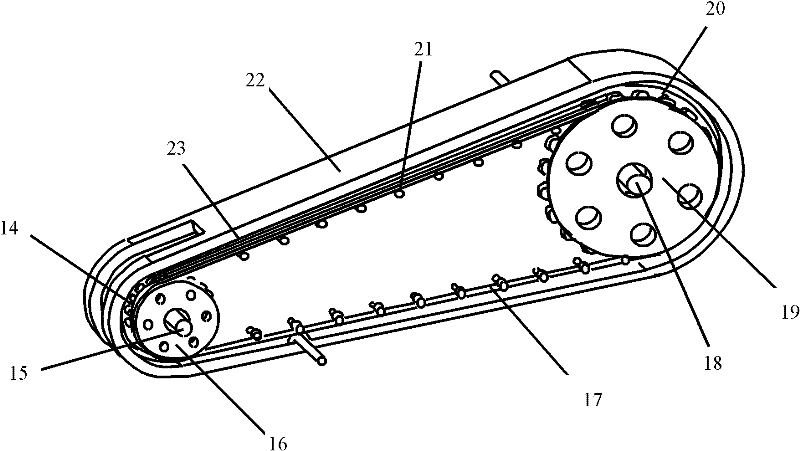

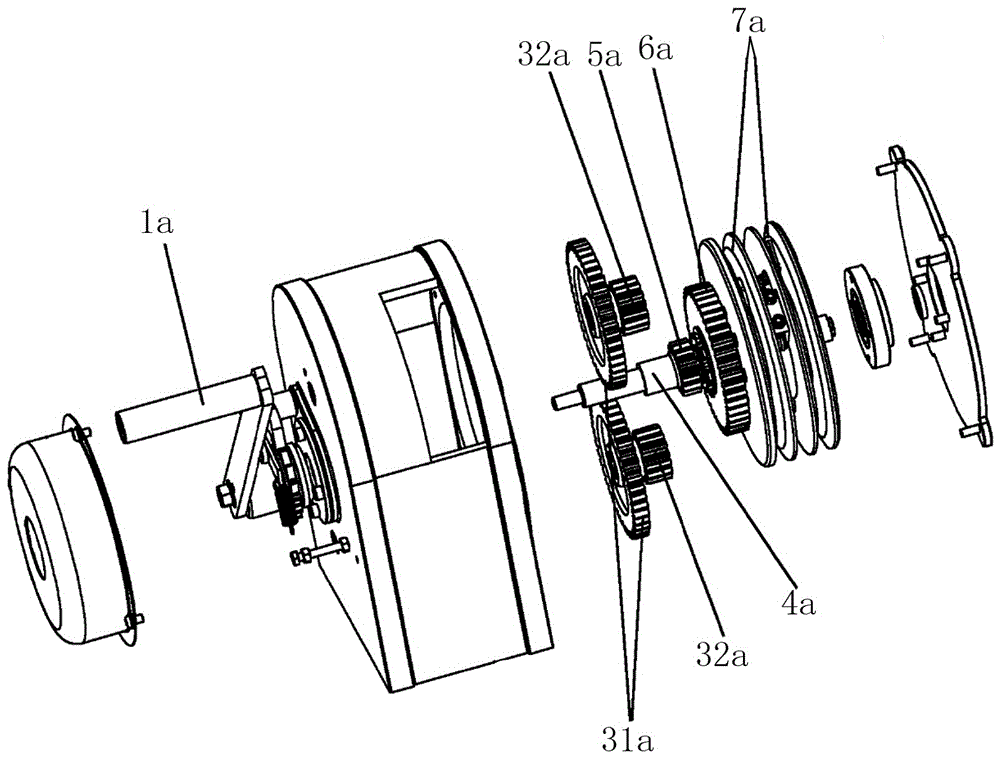

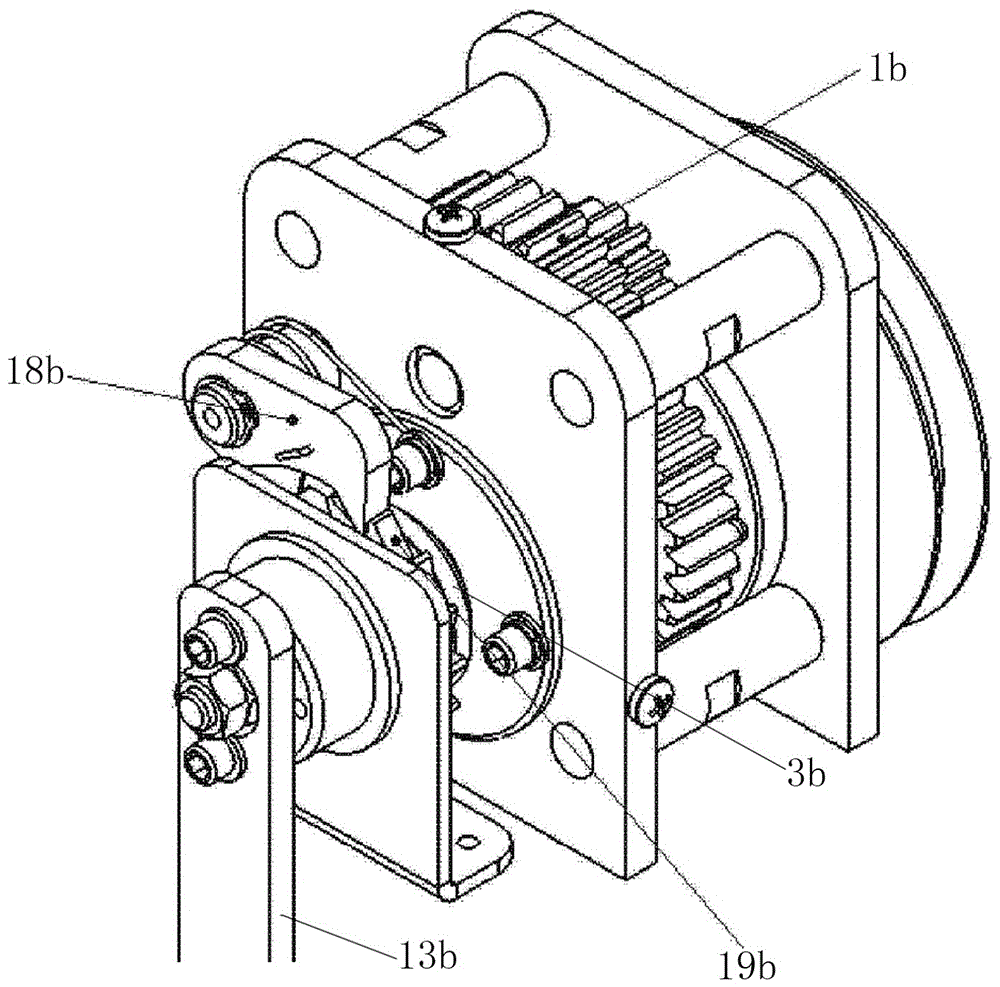

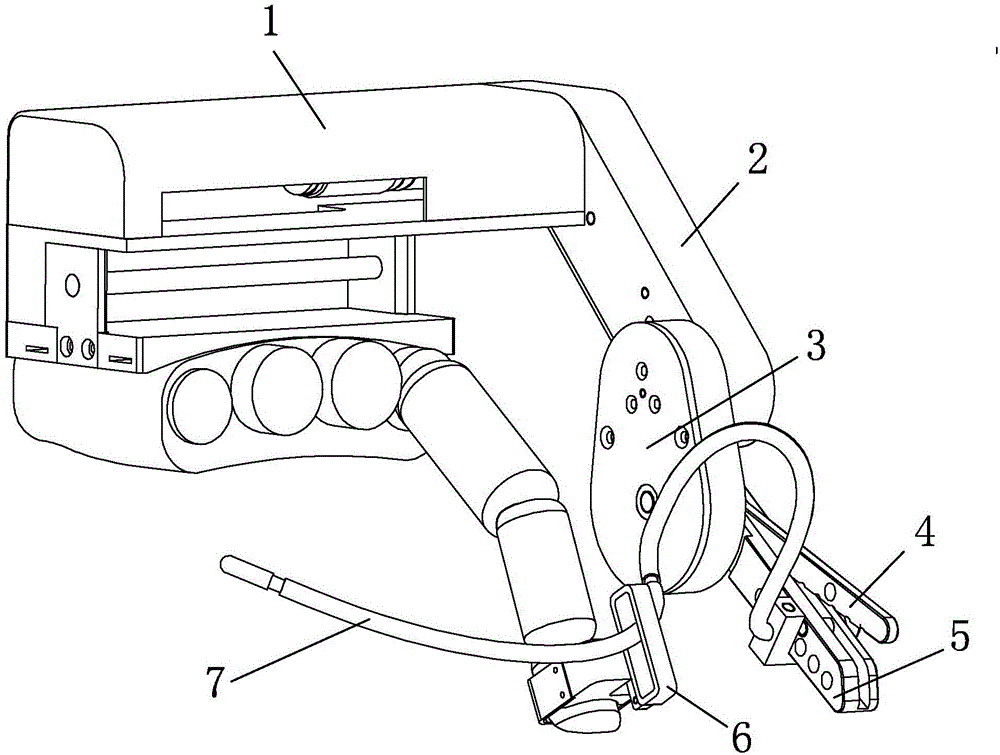

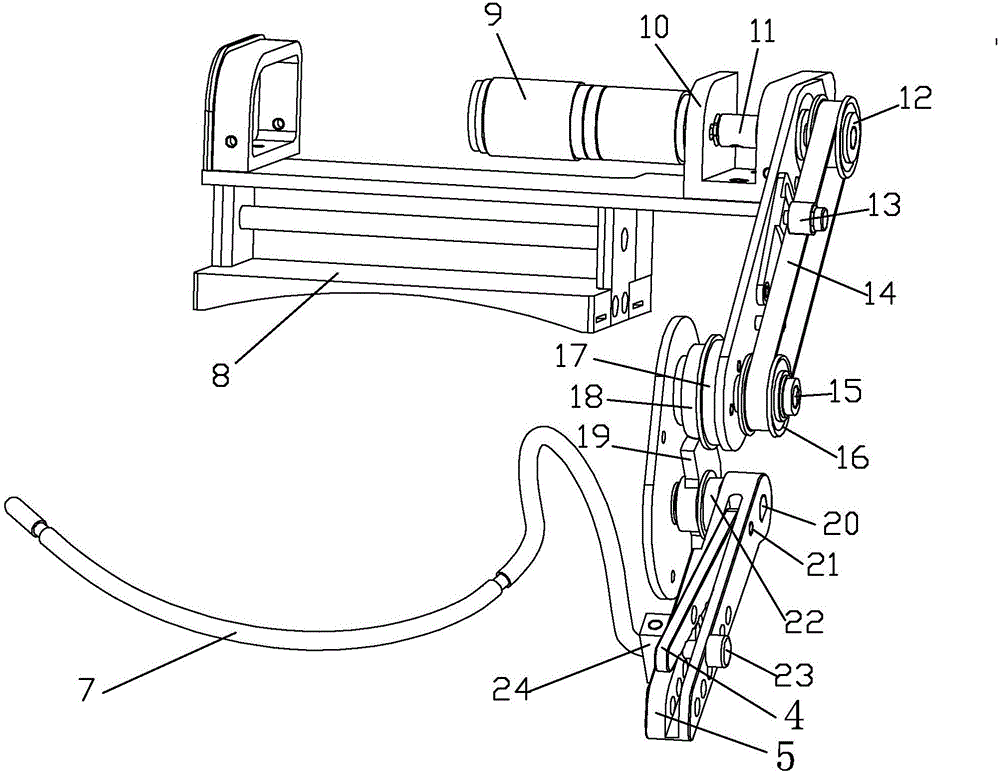

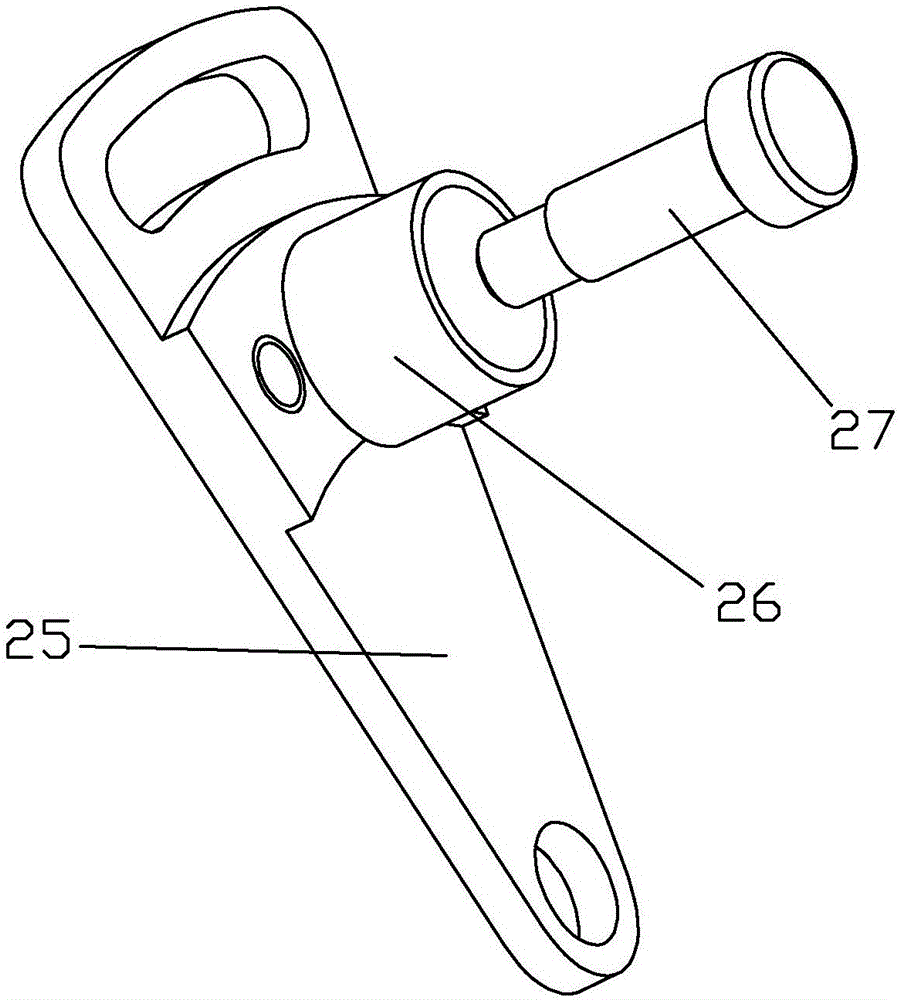

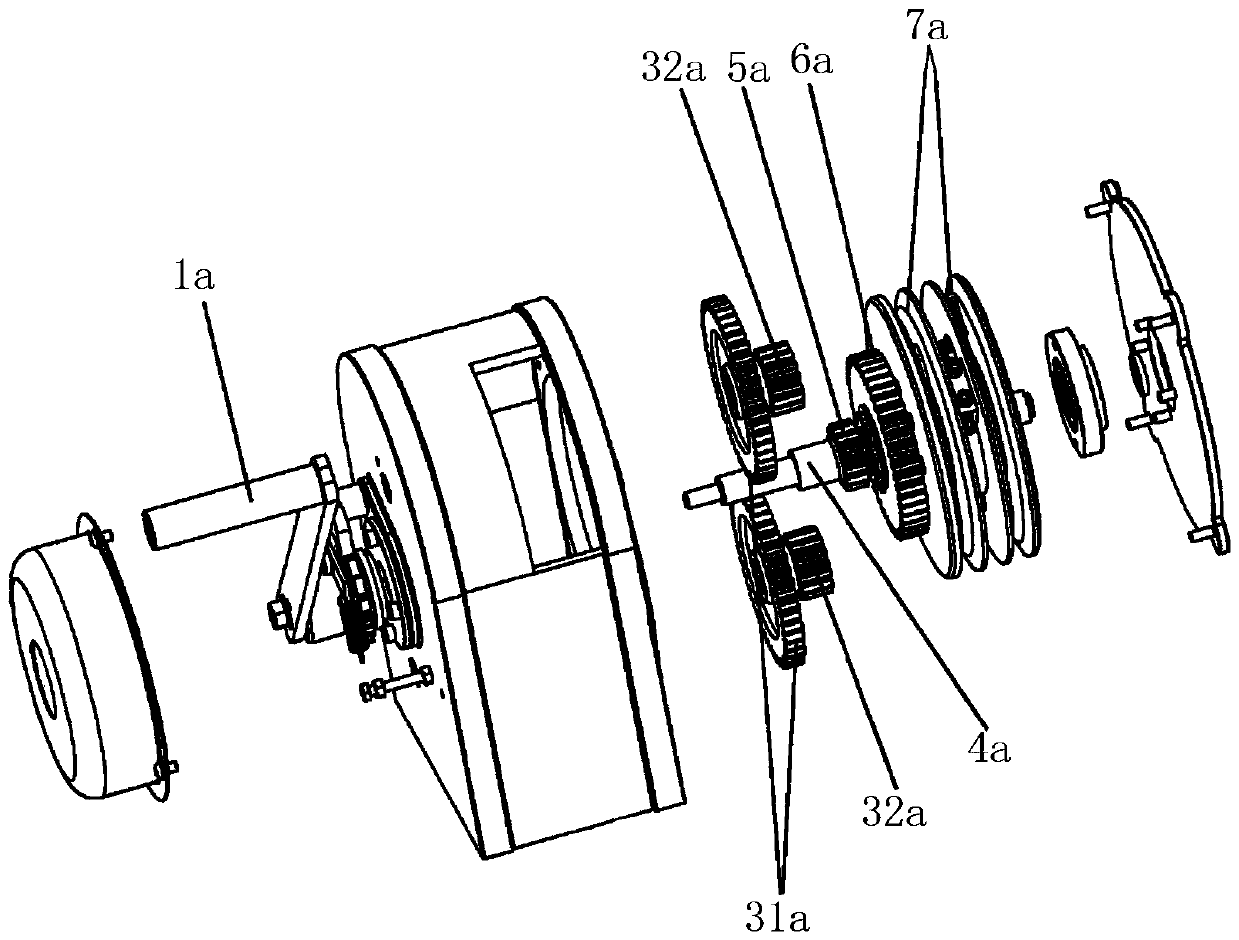

Single-freedom rehabilitation mechanical hand driving device

InactiveCN106272404ASolving Tension ProblemsAvoid harmProgramme-controlled manipulatorEngineeringDrive motor

The invention provides a single-freedom rehabilitation mechanical hand driving device, and relates to a mechanical hand driving device. The single-freedom rehabilitation mechanical hand driving device solves the problems that the existing rehabilitation finger driving device uses rope driving; the rope friction and deformation exist in the rope driving; the rope tension is caused. An output shaft of a driving motor passes through one end of the first section of connecting rod to be fixedly connected with a first joint shaft; a synchronous belt is arranged on a first synchronous belt wheel and a second synchronous belt wheel; a gear is fixedly arranged on the other end of the first section of connecting rod through a first convex sleeve; the upper part of the second section of connecting rod is rotationally connected with the other end of the first section of connecting rod through a second joint shaft; a third joint shaft is arranged at the lower part of the second section of connecting rod; a half gear is fixedly sleeved on the third joint shaft; the gear and the half gear are mutually engaged; the second convex sleeve and the upper end of the third section of connecting rod are sleeved on the third joint shaft; a locking clamp groove is positioned in a position of being rotationally connected with the third section of connecting rod through a pin shaft; one end of the driving rod passes through the fixing block to be arranged in a through hole in a penetrating way. The single-freedom rehabilitation mechanical hand driving device is used for driving a mechanical hand.

Owner:HARBIN INST OF TECH

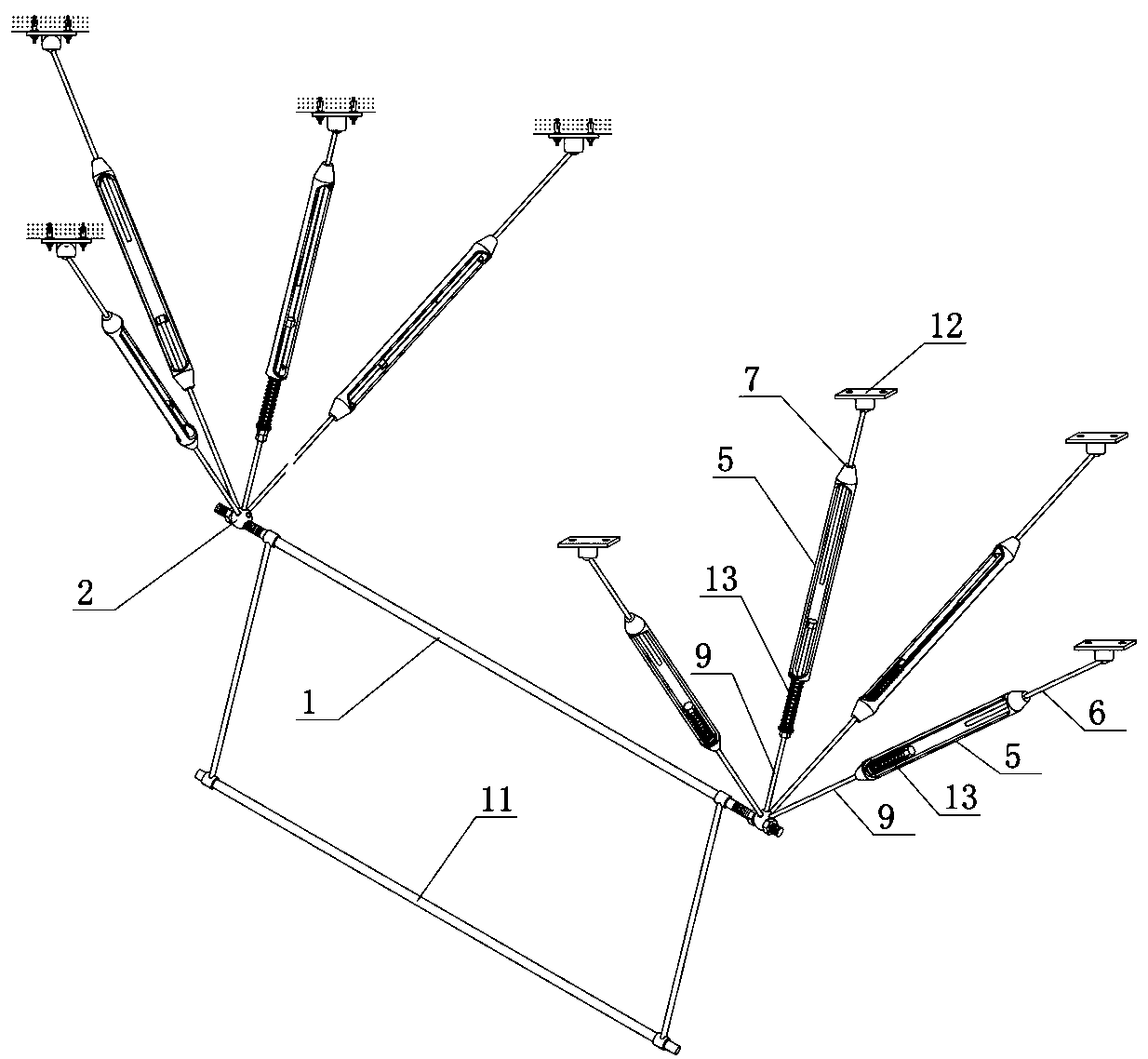

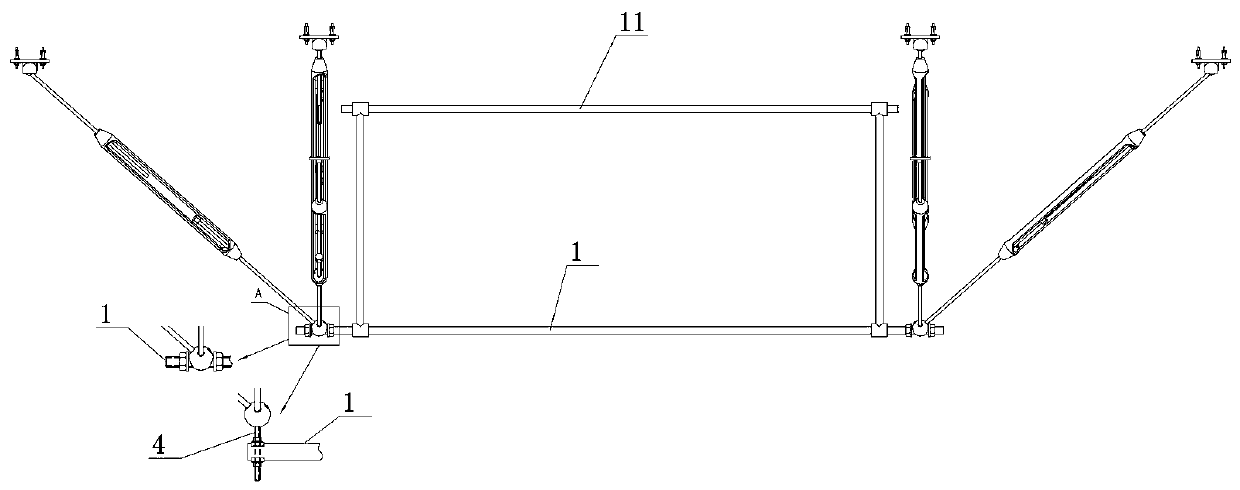

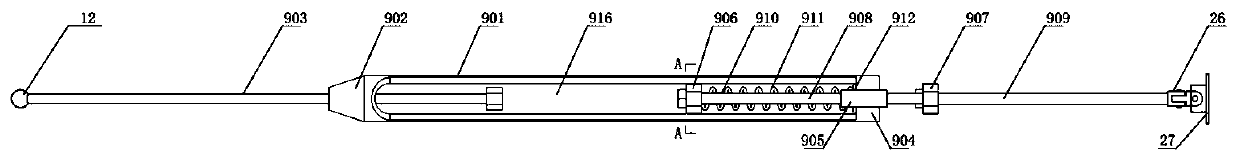

Anti-seismic bracket early warning system and early warning pull rod

PendingCN110388516AShock-absorbingHas a damping effectPipe supportsPipe elementsEarly warning systemControl system

The invention discloses an anti-seismic bracket early warning system and an early warning pull rod. Traction end parts located at the two ends of a supporting transverse beam are respectively articulated with a middle pull rod, a left pull rod, a right pull rod and a rear pull rod; one end of a jointed pipe of each pull rod is a swivel nut, and the other end of the jointed pipe is a supporting wall; side holes are symmetrically formed in the two ends of each jointed pipe, and thus, the structural body that the two ends of a jointed rod are connected to the swivel nut and the supporting wall isformed; the swivel nut is internally connected to a threaded rod; the two sides of the supporting wall are fixedly connected to sliding sleeves; sliding rods are respectively arranged in the slidingsleeves at the two sides in a sleeving manner; an inner sliding block is arranged in the jointed pipe in a sleeving pipe; the inner ends of the two side sliding rods are respectively fixed to the twosides of the inner sliding block; the outer ends of the two side sliding rods are respectively fixed to the two sides of an outer sliding block; a strong spring is connected between the inner slidingblock and the supporting wall; and a pressure sensor is arranged at the inner side of the supporting wall in a sleeving manner. The anti-seismic bracket early warning system can monitor the pressure change of each pressure part in real time through a control system, and even monitors the displacement change of each rod piece. When the variation range is greater than the set threshold value, a warning signal is sent out through a controller or a cloud monitoring system, and thus, an automatic early warning function can be provided.

Owner:HENAN AUSPIC TECH

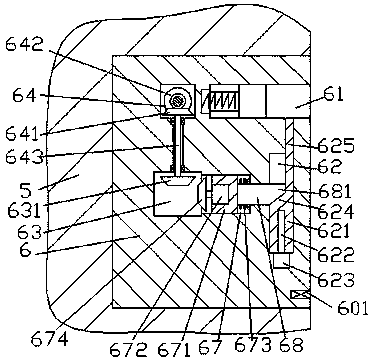

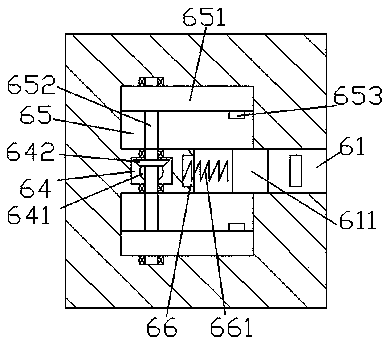

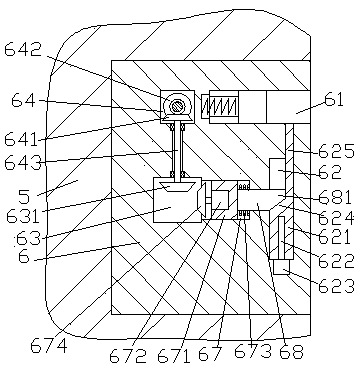

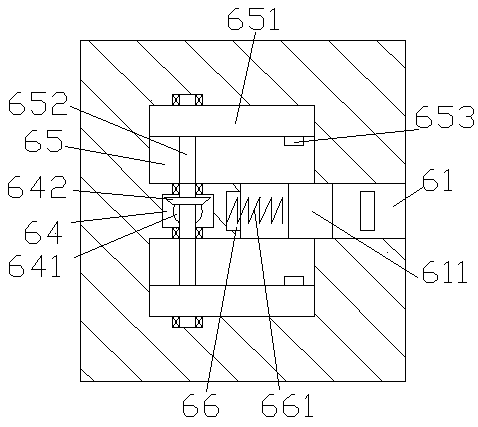

Hydraulic gravity type clocked flip-flop

ActiveCN106444342AOvercoming tensionExtended service lifeTime interval measurement with driving mechanismLiquid mediumEngineering

The invention belongs to the technical field of mechanical timing, and particularly relates to a hydraulic gravity type clocked flip-flop which comprises a magnetic clamp ring, a vibrating ring, a casing, a trigger spring, a trigger ring, a magnetic conductive ring, a gravity plug and an impact ring, wherein a liquid medium is in the casing; and the gravity plug moves from the upper end of the casing to the lower end. After a timer is subjected to vibration, during movement, magnetic force of the vibrating ring and a first magnetic ring is reduced, the vibrating ring collides with the lower side of the magnetic clamp ring through the impact ring, magnetic force which the gravity plug is subjected to is reduced, the gravity plug begins to move downwards, and timing starts. When the gravity plug moves to be near a base plate, the gravity plug drives the trigger ring to move, the trigger ring collides with the magnetic conductive ring, and the impact force can trigger an external device. The gravity plug is subjected to lubricating and air insulating effects of hydraulic oil, the contact wall between the gravity plug and the casing is not oxidized, so that the timer has the advantages of being long in service life; due to no participation of electric power, the use range is very wide; and the hydraulic gravity type clocked flip-flop has a good use effect.

Owner:GAOYOU GAONONG MACHINERY FITTINGS

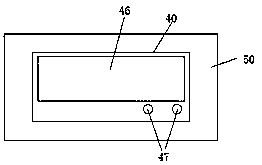

An audio and video information processing system

ActiveCN108259928BOvercoming tensionSimple structureSelective content distributionInformation processingMating connection

The invention discloses an audio and video information processing system, comprising a main body, a connector fixedly mounted in the end surface on the right side of the main body, and a connecting head member for mating connection with the connector, wherein a plugging groove is disposed in the end surface on the right side of the connector, a first sliding chamber is disposed in the connector onthe lower side of the plugging groove, a first slider is engaged in the first sliding chamber by sliding matching, a first cavity is disposed in the connector on the left side of the plugging groove,a second cavity is disposed in the connector on the lower side of the first cavity, a second sliding chamber is disposed in the inner wall on the right side of the second cavity, an interlocking conewheel member is coupled in the first cavity by rotation, and a rotating shaft extending upward and downward is coupled in the portion between the first cavity and the second cavity by rotation.

Owner:北京维卓网络科技有限公司

A digital broadcast television transmitter

ActiveCN108259927BOvercoming tensionSimple structureSelective content distributionEngineeringDigital broadcasting

Owner:NANTONG JUJIU NEW MATERIAL SCI & TECH CO LTD

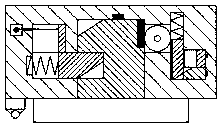

Novel vehicle-mounted navigation equipment

InactiveCN108482268AOvercoming tensionReliable lockingElectric/fluid circuitSoftware engineeringElectric shock

The invention discloses novel vehicle-mounted navigation equipment which comprises an installing carrier and a navigator in pluggable connection with the installing carrier. A pluggable column is fixedly arranged at the end face of the top of the navigator, a pluggable groove is formed in the bottom of the installing carrier, a first sliding groove is communicated with the left side of the pluggable groove, a first spring piece groove is communicated with the left side of the first sliding groove, a first sliding block is arranged in the first sliding groove, the first sliding block is in sliding-fit connection with the first sliding groove, a first spring piece is connected between the left side face of the first sliding block and the inner wall of the left side of the first spring piecegroove, and a second sliding groove is communicated with the top of the first sliding groove. The novel vehicle-mounted navigation equipment is convenient and rapid to operate, the assembling and disassembling efficiency of the navigator is greatly improved, and electric shock accidents happening when the navigator is assembled and disassembled are effectively avoided.

Owner:永春左耳贸易有限公司

Coffee bean grinding and filtering device

The invention discloses a coffee bean grinding and filtering device. The coffee bean grinding and filtering device comprises a shell, grinding rods, a base plate mechanism and a filtering mechanism, wherein the filtering mechanism is located in the shell and comprises a pair of second fixed pulleys, a second rubber ring, a pair of stay cords, an inner cylinder, a third rubber ring, a plurality ofpairs of springs, a first electric cylinder and a second electric cylinder; the outer side of the second rubber ring makes contact with the side wall of the shell in the circumferential direction, anda screen mesh is fixedly connected to the inner side of the second rubber ring in the circumferential direction; the upper ends of the pair of stay cords are separately fixed to the pair of second fixed pulleys, and the lower ends of the pair of stay cords are symmetrically fixed to the second rubber ring; an annular cavity is defined by the inner cylinder and the shell; the outer side of the third rubber ring is fixed to the side wall of the inner cylinder in the circumferential direction, a vibrating screen is fixed to the inner side of the third rubber ring in the circumferential direction, and the upper surface of the vibrating screen makes contact with the lower surface of the screen mesh; the multiple pairs of springs are fixed between the cavity and the second rubber ring; and thefirst electric cylinder and the second electric cylinder are symmetrically fixed to the bottom of the cavity, and the movable ends of the first electric cylinder and the second electric cylinder are fixed to the second rubber ring. The coffee beam grinding and filtering device has the beneficial effects that coffee beam powder meeting the granularity requirement can be rapidly separated out beforethe temperature is too high, and the uniform fineness and quality of the coffee beam powder are ensured.

Owner:保山中咖食品有限公司

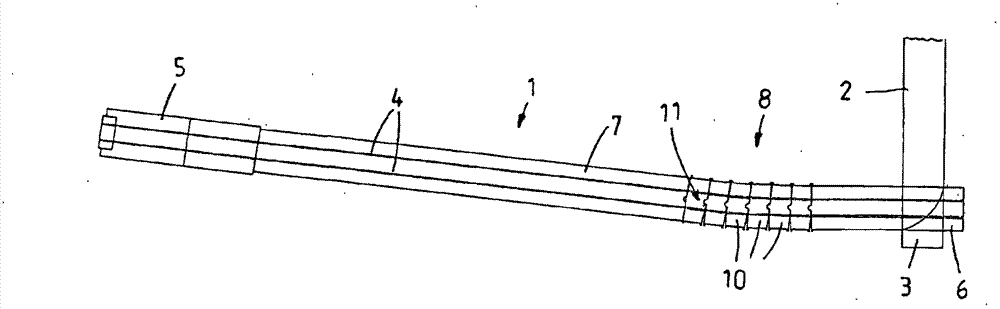

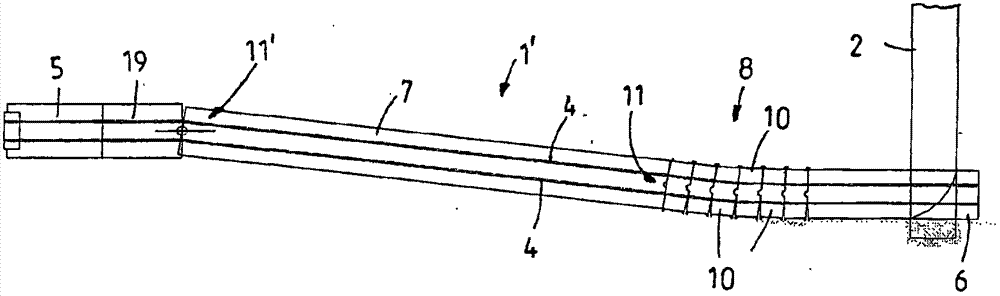

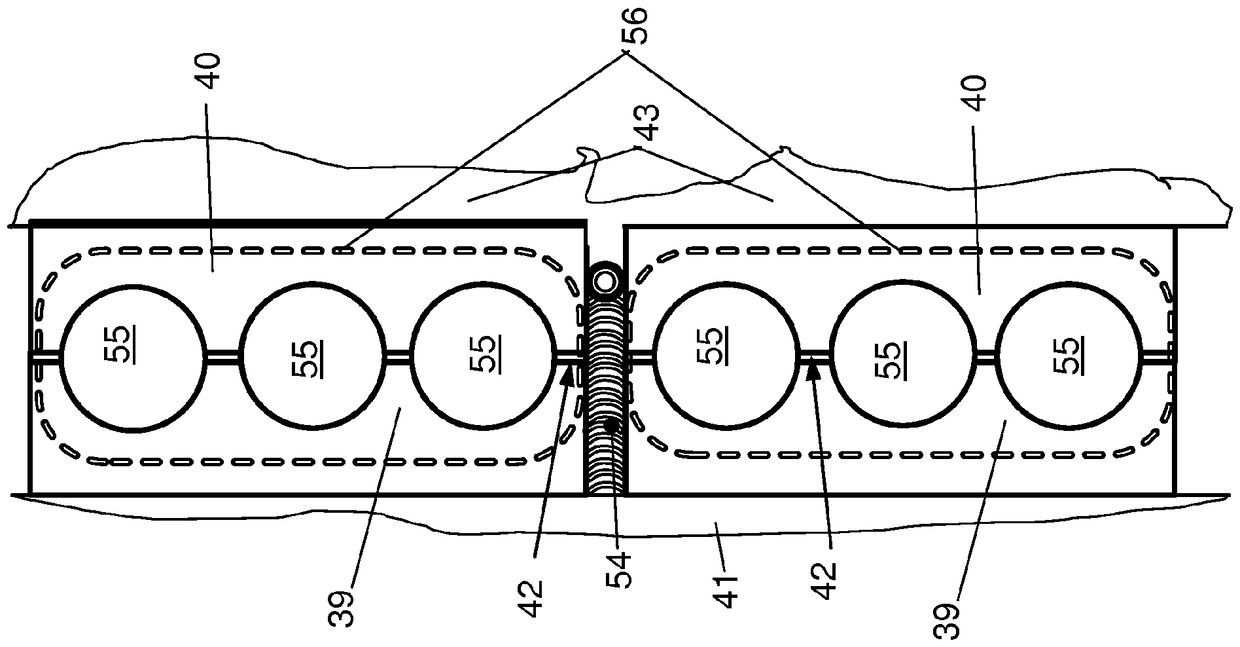

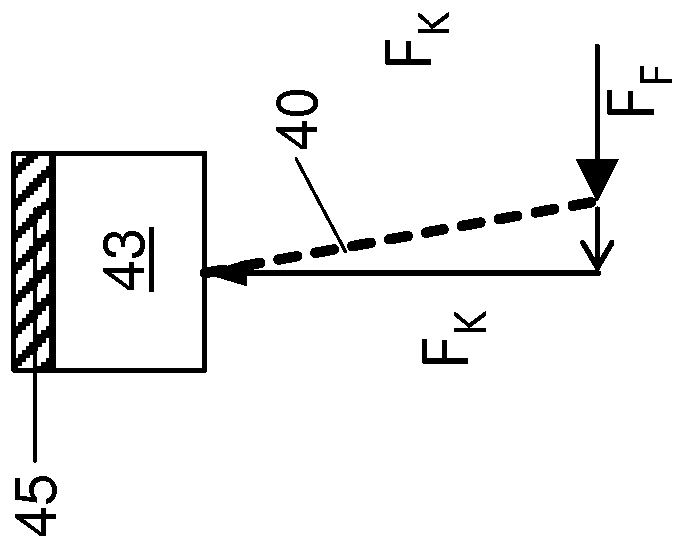

Entry conveyor and pan section for the same

ActiveCN101081660BReduced cornerabilityIncrease drive powerConveyorsSlitting machinesEngineeringChain conveyor

Owner:CATERPILLAR INC

Collagen film for auxiliary treatment of peripheral nerve injury and its preparation method and application

ActiveCN109260459BOvercoming tensionPromote repairOrganic active ingredientsNervous disorderPolyvinyl alcoholPolyethylene glycol

The invention discloses a collagen film for auxiliary treatment of peripheral nerve injury, a preparation method and application thereof. The collagen film is obtained by cross-linking collagen aqueous solution, chitosan dilute acetic acid solution, polyvinyl alcohol aqueous solution, nerve growth factor aqueous solution, B12 aqueous solution and polyethylene glycol through glutaraldehyde crosslinking. At present, the treatment of peripheral nerves is limited to the auxiliary support of neurotrophic drugs after microsurgical suture. This method will generate a certain tension on the stumps of peripheral nerves, which is not conducive to the repair of stumps. The present invention can overcome the problem of tension generated at the stumps of peripheral nerves and the degradation of the collagen membrane in the early stage of recovery can promote the recovery of peripheral nerves, and can restore their basic motor functions in a short time Membrane suture or end perineurium epineurium suture combined with nerve fusion agent is more effective.

Owner:HARBIN MEDICAL UNIVERSITY

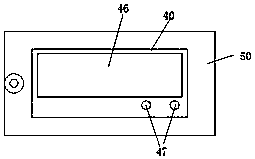

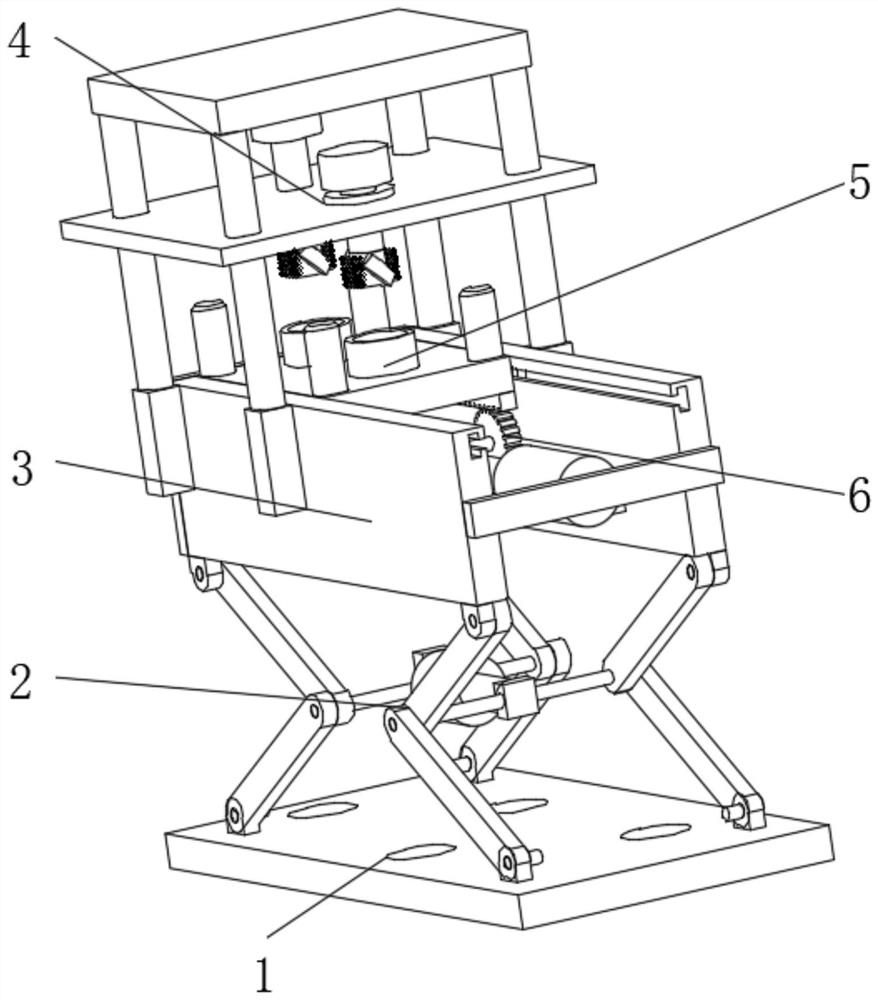

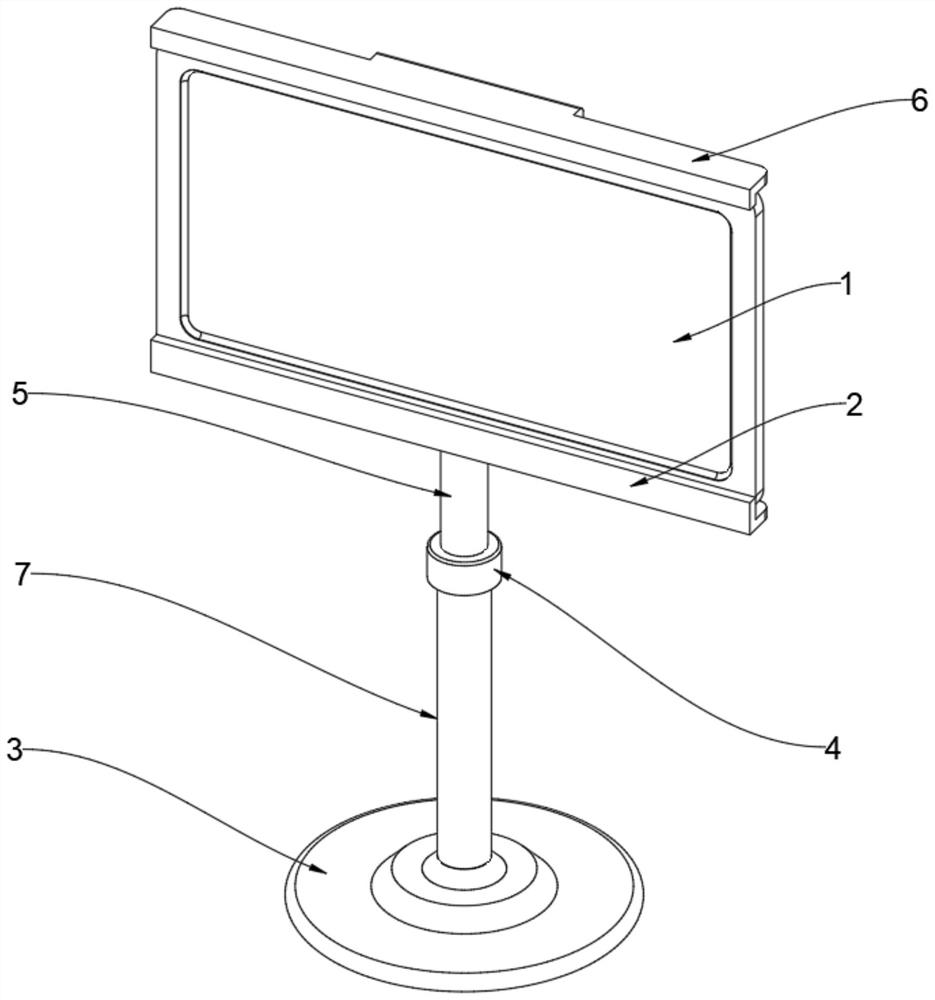

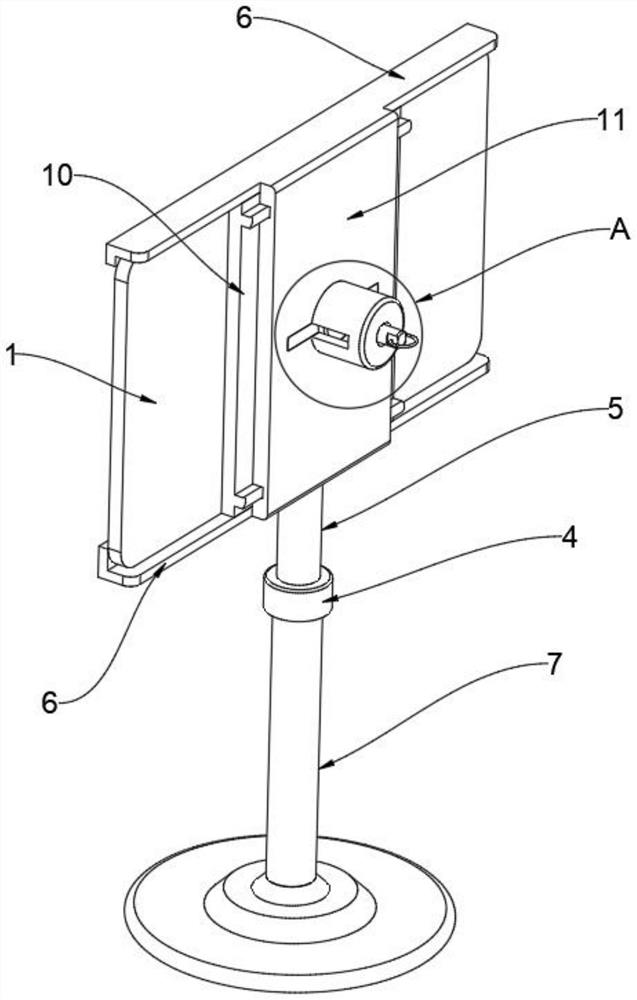

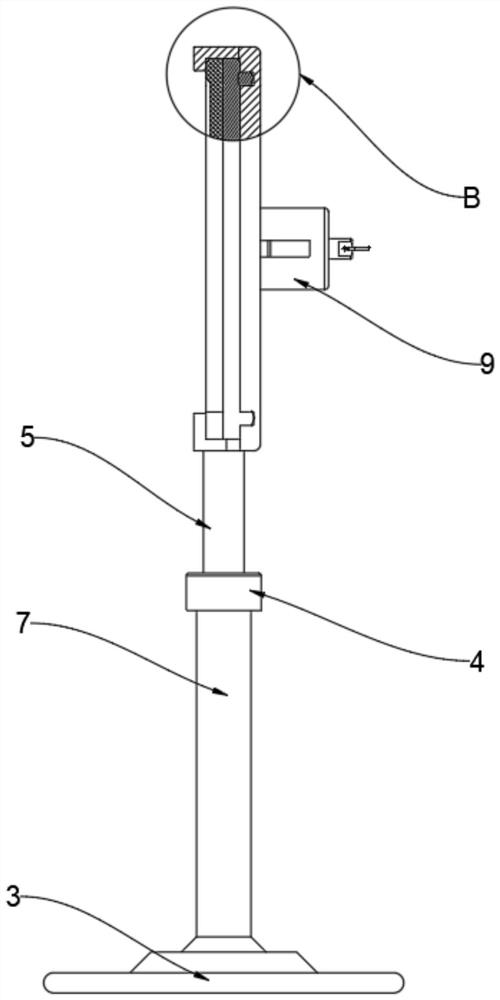

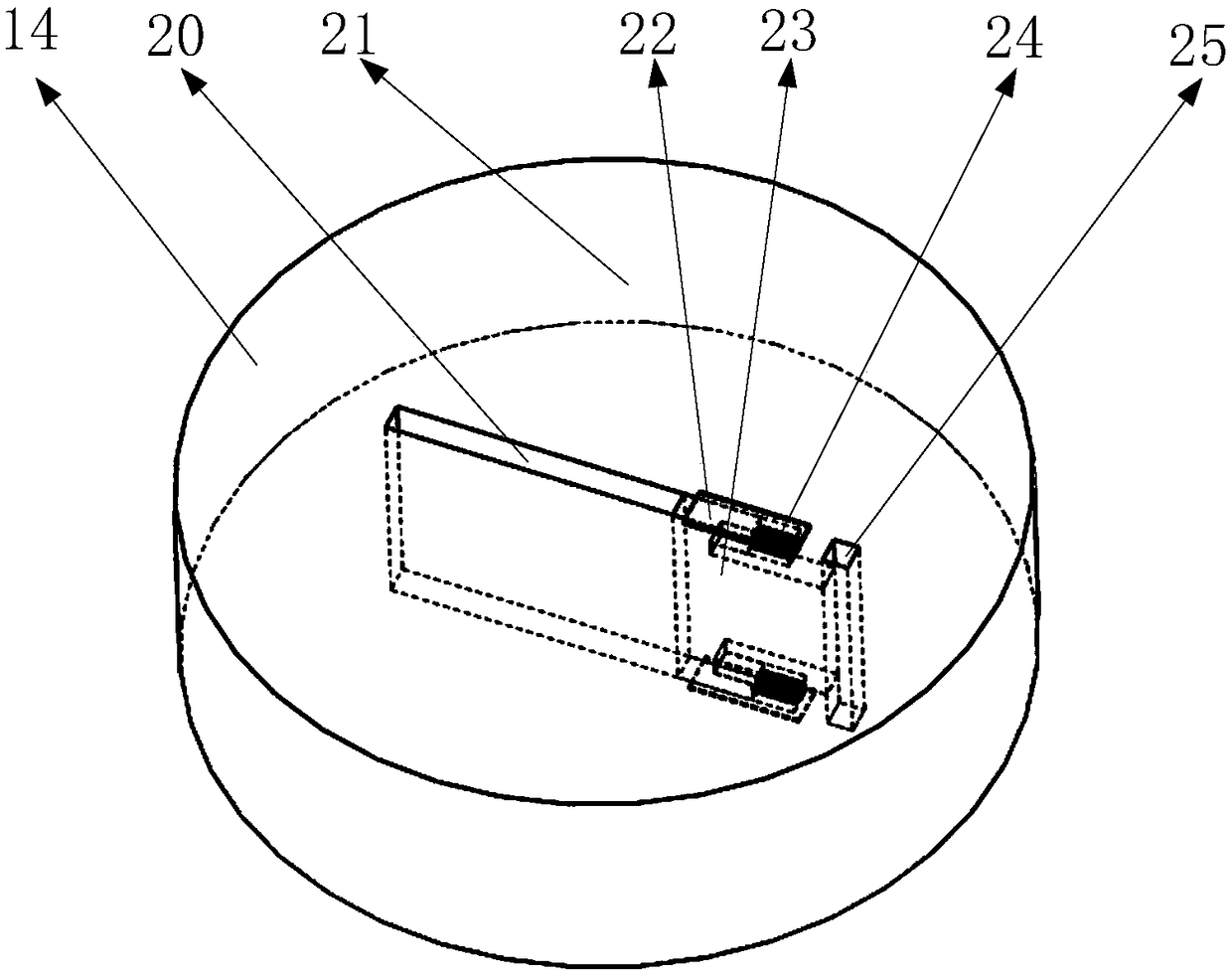

Demonstration teaching aid for computer principle teaching

PendingCN114234007AOvercoming tensionIncrease mobilityStands/trestlesElectrical appliancesTouchscreenMechanical engineering

Owner:BAICHENG NORMAL COLLEGE

A hydraulic gravity timing trigger

ActiveCN106444342BOvercoming tensionExtended service lifeTime interval measurement with driving mechanismElectricityMagnetic tension force

A hydraulic gravity-type clocked flip-flop, comprising a magnetic snap ring (3), a vibrating ring (4), a shell (6), a triggering spring (8), a triggering ring (9), a magnetically conductive ring (10), a gravity stopper (14) and an impact ring (16); the shell (6) has a liquid medium inside, the gravity stopper (14) moves from the upper end of the shell (6) to the lower end; when a timer is subjected to vibration, the magnetic force between the vibrating ring (4) and a first magnetic ring (5) decreases during movement, the vibrating ring (4) collides with the lower side of the magnetic snap ring (3) by means of the impact ring (16), the magnetic force exerted on the gravity stopper (14) decreases, the gravity stopper (14) starts moving downward, and timing is started. When the gravity stopper (14) moves close to a bottom plate (15), the triggering ring (9) is driven to move, the triggering ring (9) collides with the magnetically conductive ring (10), and the impact force produced therefrom can trigger an external device. As the gravity stopper (14) is lubricated and isolated from air by the hydraulic oil, the contact wall surface between the gravity stopper (14) and the shell (6) would not be oxidized, such that the timer has a longer service life; as no electricity is involved, the present invention has a wide application scope and has better usage effect.

Owner:GAOYOU GAONONG MACHINERY FITTINGS

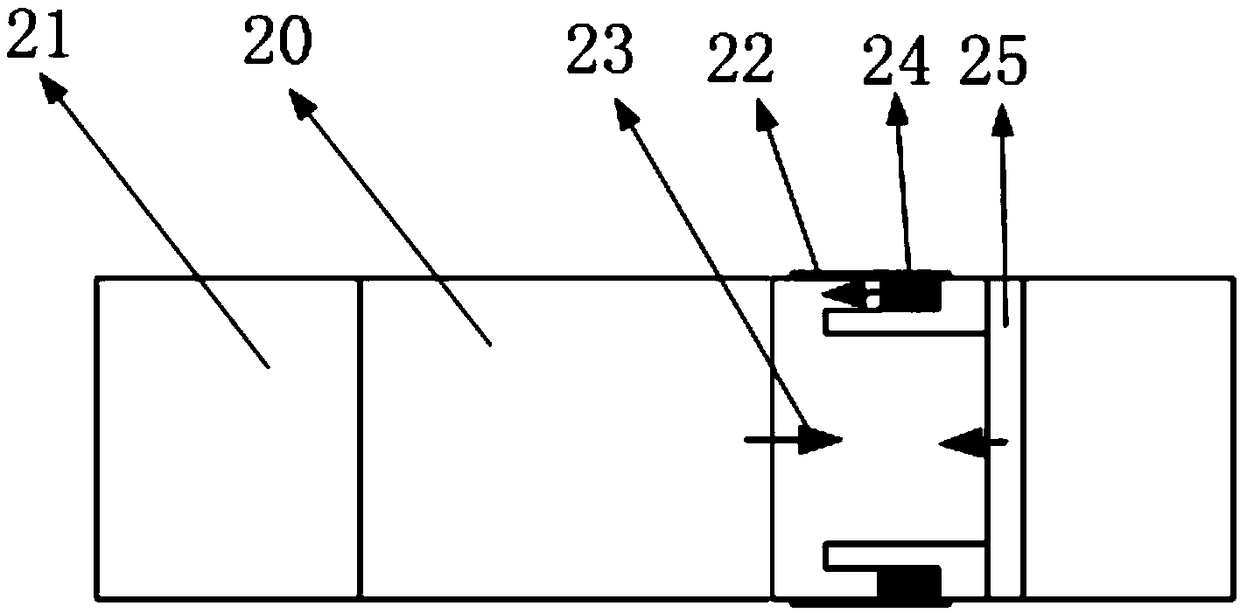

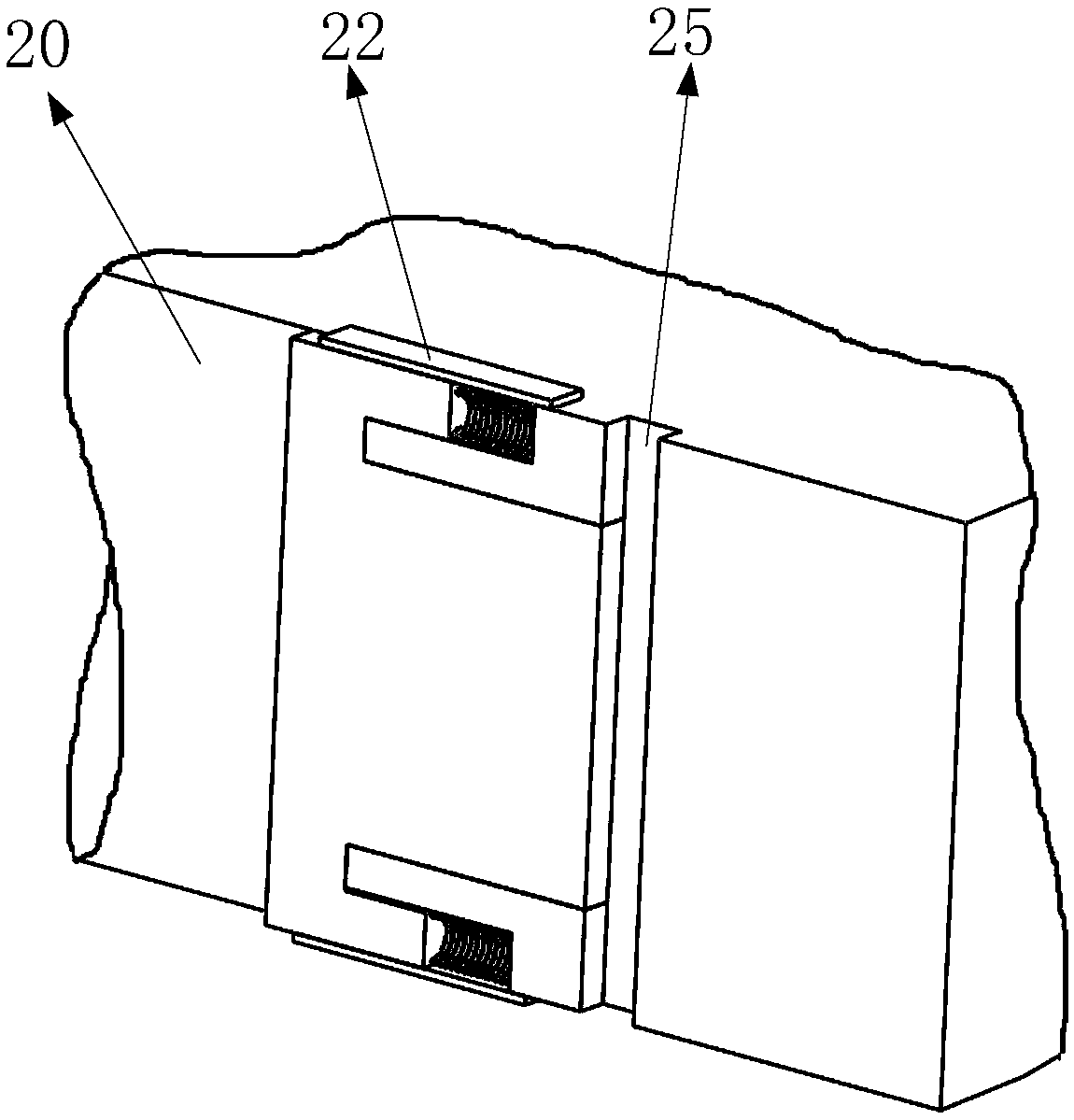

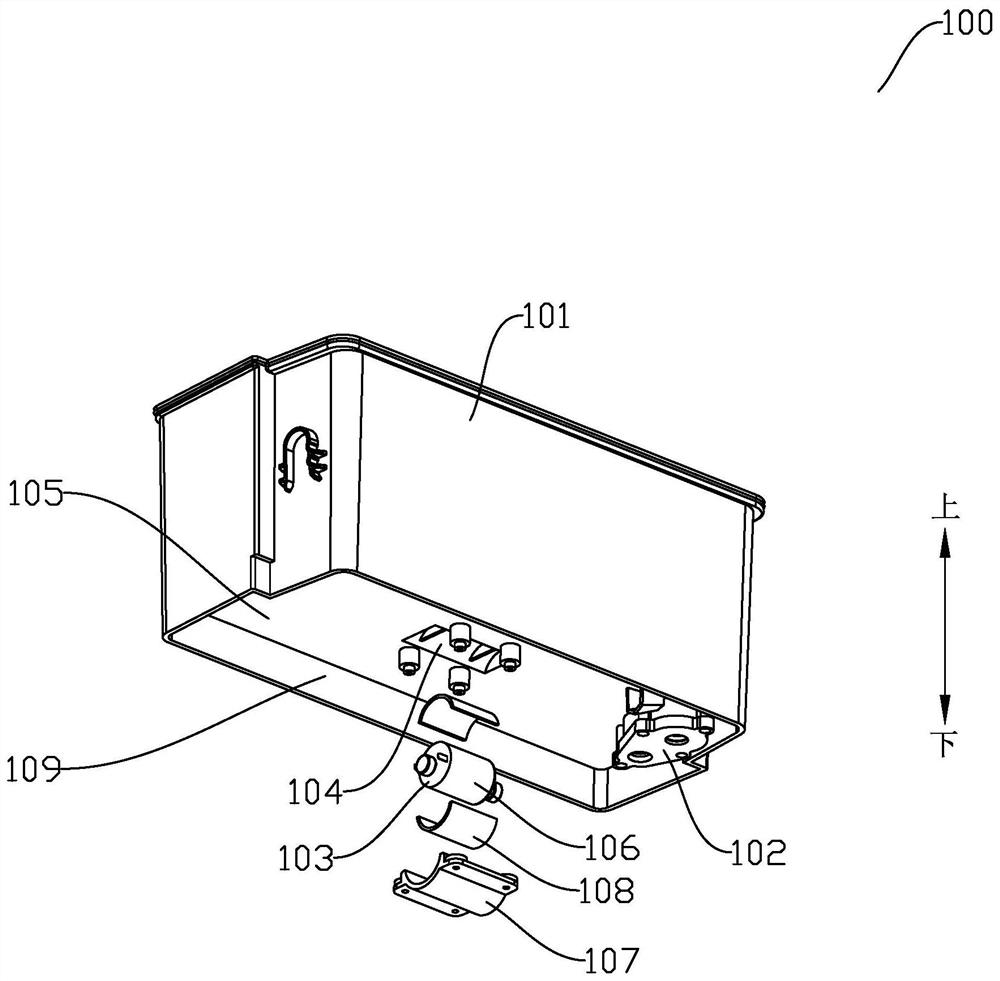

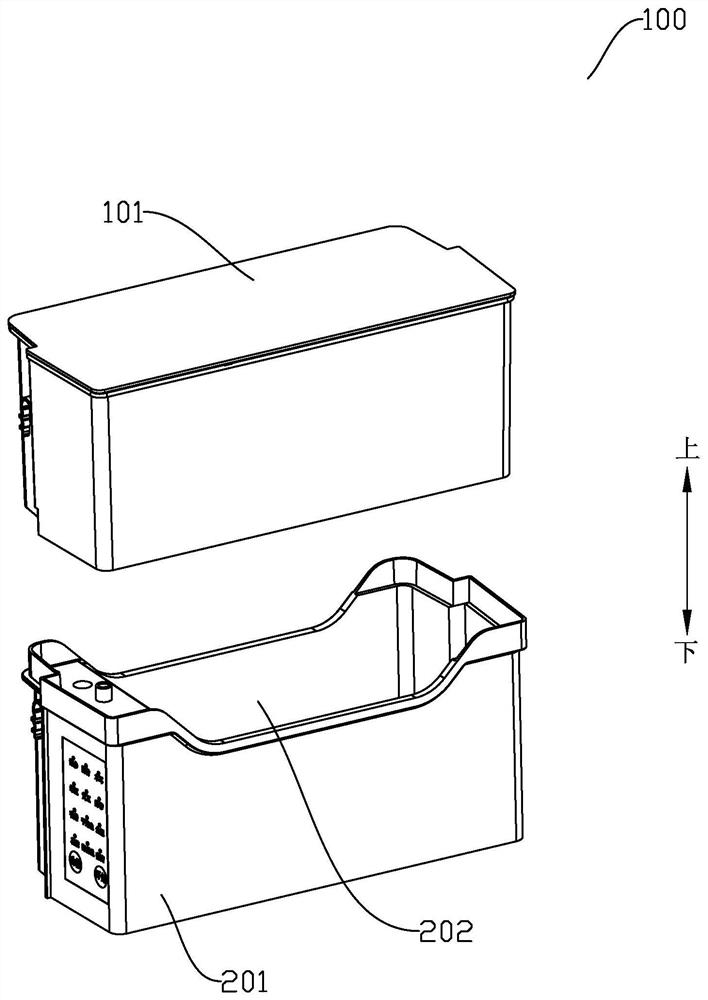

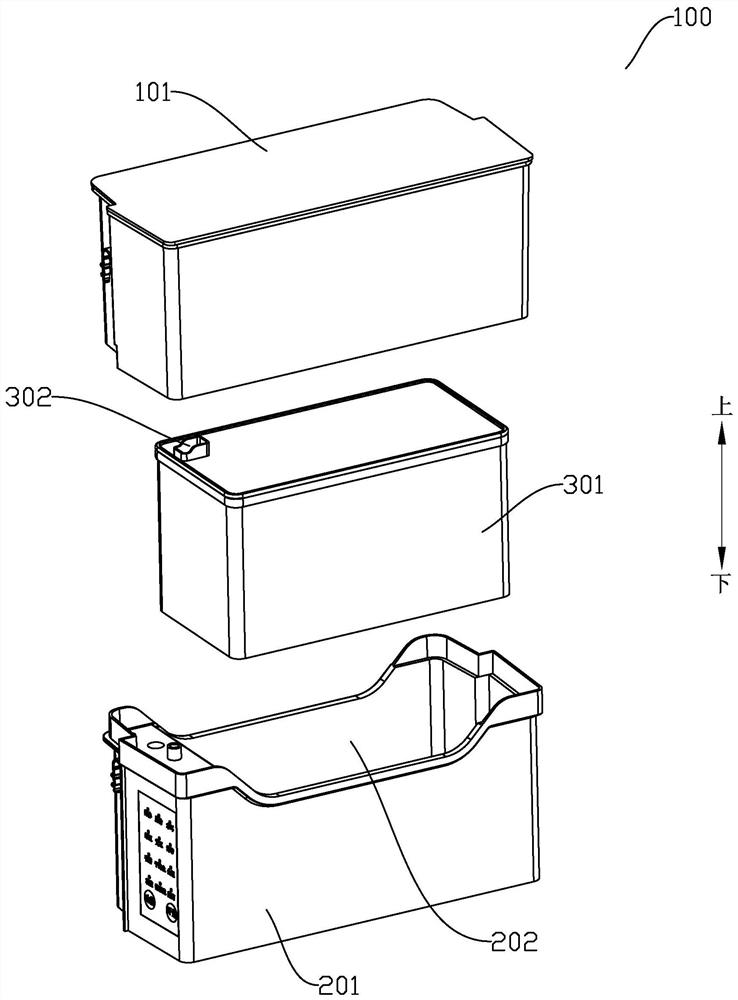

Soaking device and refrigeration device

ActiveCN113491310AOvercoming tensionEasy to storeLighting and heating apparatusFood preservationThermodynamicsProcess engineering

The present invention discloses a soaking device and a refrigeration device with the soaking device. The soaking device comprises a soaking box, a drainage mechanism and a vibrating mechanism; the soaking box is provided with a third containing cavity; the drainage mechanism is arranged at a bottom part of the soaking box and communicates with the third containing cavity; and the vibrating mechanism is arranged on the soaking box. The drainage mechanism is arranged at the soaking box, rapid and convenient drainage can be achieved, vibration waves are provided through a vibration effect of the vibrating mechanism, a tension effect between liquid and food materials is overcome, residual liquid is released from surface gaps of the food materials, between the food materials and between the food materials and vessels, and the soaked food materials are drained to the maximum extent, such that a storage effect of the soaked food materials is better.

Owner:HEFEI HUALING CO LTD +2

Aluminium alloy, core support prepared by same for forming of aluminum alloy casting and preparation of core support

InactiveCN102115838BSolve technical problems of poor fusionSolve the defect that non-dense gaps are easy to form cold shutFoundry mouldsFoundry cores5005 aluminium alloy5052 aluminium alloy

The invention relates to an aluminium alloy which comprises the following components by mass: 11-13% of Si, 0.15-0.30% of Mg, 86.7-88.85% of Al. Because the aluminium alloy provided by the invention has a melting temperature range lower than the pouring temperature of a casting aluminum alloy, the treated surface is easy to be melted by high-temperature casting aluminium alloy liquid and fused with a casting aluminum alloy matrix, and the technical problem of the poor fusion of a core support and an aluminium alloy casting body in the forming of a confined aluminum alloy casting in the prior art is effectively solved; and simultaneously, with the core support manufactured by the aluminium alloy, liquid flow stratifiedly flows as laminar flow when passing through the comb holes of the coresupport, and the flow process is subject to both the gravity action of the upper layer and the uplift action of the lower layer, which can effectively overcome the surface tension effect of liquid flow between layers and avoid the generation of stratified cold shut. The defect that existing core support always has incompact gaps which are easy to form cold shuts is effectively solved, and the internal quality requirements for confined castings are satisfied.

Owner:XIAN AERONAUSTIC POWER CONTROL ENG

Engine silencer structure with damping structures

InactiveCN110439655AImprove noise reductionReduce impactSilencing apparatusMachines/enginesBiochemical engineering

The invention discloses a silencer structure with damping structures. The silencer structure comprises a smoke inlet pipe and a sealed casing, wherein one end of the smoke inlet pipe is located in thecasing, and the other end of the smoke inlet pipe is located outside the casing; one end, located in the casing, of the smoke inlet pipe is connected and communicated with a first silencing pipe, andsilencing holes are formed in the first silencing pipe; one end of the first silencing pipe is communicated with the smoke inlet pipe, and a first damping structure is arranged at the other end of the first silencing pipe; the first damping structure comprises a first outer sleeve and a first inner sleeve, one end of the first outer sleeve is fixed on the first silencing pipe, the other end of the first outer sleeve is sealed, and the first inner sleeve is sleeved with the first outer sleeve; and an opening is formed in one end, close to the first silencing pipe, of the first inner sleeve, and the other end of the first inner sleeve is sealed. The damping structures are arranged in the silencer and the noise reducing effect of the silencer can be improved.

Owner:重庆合贵环保科技有限公司

An Improved Main Shaft Locking Device and Its Application

ActiveCN105972201BAchieve brakingRealize the locking functionGearing controlHoisting equipmentsFlywheelCentrifugal force

The invention discloses an improved locking device for a main rotating shaft. The device is characterized in that a torsional spring which can overcome screwing frictional resistance between the main rotating shaft and a connecting nut is additionally arranged between the connecting nut and the main rotating shaft so as to prevent the main rotating shaft from uncontrollable high-speed rotating caused by human errors; the connecting nut can overcome the thread frictional force relative to the main rotating shaft under the effect of the inverted torsion of the torsional spring, and thus the connecting nut can be rotated relative to the main rotating shaft, and as a result, the main rotating shaft can be braked. The invention also provides another scheme for locking the main rotating shaft. The scheme is characterized in that an inner pawl which can be limited through an elastic connector is arranged on a flywheel disc; in case that the main rotating shaft is subjected to uncontrollable high-speed rotating, the outward centrifugal force of the inner pawl on the flywheel disc can be utilized to overcome the tensioning force of the elastic connector, thus the inner pawl can be locked to an inner ratchet wheel, and as a result, the function of locking the main rotating shaft can be further achieved.

Owner:施耐德电气(厦门)开关设备有限公司

A sanitary ware cleaning device

The invention discloses a bathroom sanitary ware cleaning device. The bathroom sanitary ware cleaning device comprises a control lever, a connecting rod, a driving mechanism, a water pump, a water inlet pipe, an inflating air bag, an air pipe, a brush head and an air bag set. The driving mechanism is arranged in the control lever. The water inlet pipe is fixedly installed in the connecting rod. One end of the water inlet pipe is connected with the brush head, and the other end of the water inlet pipe is connected with a water outlet of the water pump in a sleeving mode. The middle of the water inlet pipe is connected with the air pipe by means of a pin. The air pipe is communicated with the inflating air bag. An air bag connector and springs can stretch and retract in a branch pipe of the air pipe. A motor provides power for the water pump on one hand and drives the water inlet pipe, the air pipe, the brush head and cleaning air bags to rotate together through a gear set on the other hand, and thus impurities such as incrustation and dirt adhering to the surface of bathroom sanitary ware can be removed. The bathroom sanitary ware cleaning device has the advantages that the surface of the bathroom sanitary ware can be cleaned rapidly, and labor intensity is relieved; meanwhile, damage to the bathroom sanitary ware is small.

Owner:CHINA THREE GORGES UNIV

Pressure plate clamping rail

ActiveCN108430778ALimit open strokeSynthetic clamping forcePrinting press partsEngineeringMechanical engineering

Owner:MAN ROLAND MASCHINEN AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com