Pressure limiting, safety and pressure relief integrated valve of pressure cooker

A pressure cooker and safety technology, applied in pressure cooker and other directions, can solve the problems of safety valve, alarm valve not working, accumulation of rice residue and vegetable foam, and slenderness of the exhaust hole of the pressure limiting exhaust pipe, so as to achieve simple design and production process, The technical parameters are easy to guarantee and the effect of large pressure area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

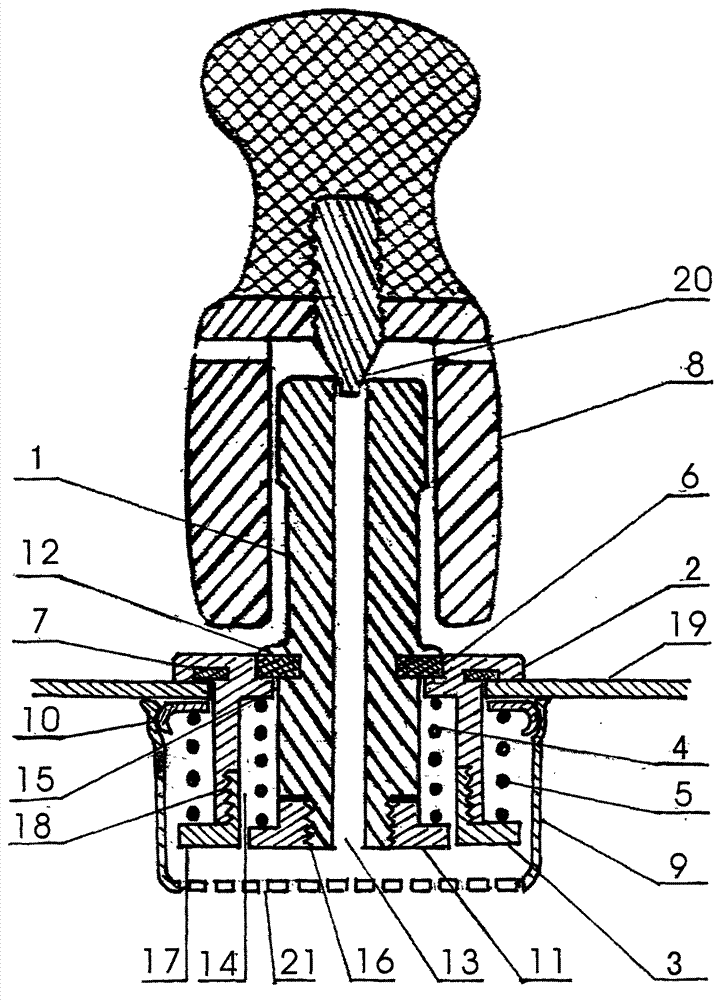

[0011] Such as figure 1 As shown, a pressure cooker pressure limiting, safety and pressure relief integrated valve of the present invention includes a pressure limiting exhaust pipe 1, an upper threaded connector 2, a lower threaded connector 3, a safety pressure spring 4, a pressure relief pressure spring 5, Sealing ring 6, sealing ring 7, pressure limiting valve body 8, anti-blocking cover 9 and clamping member 10. And the bottom end of the pressure-limiting exhaust pipe 1 is provided with a safety pressure spring clamping platform 11, the clamping platform 11 is connected by a thread 16, the middle section is provided with a sealing ring clamping groove 12, and an exhaust hole 13 is provided in the axial direction; A through hole 14 is provided in the axial direction of the lower threaded connector 3, and the top port 15 of the through hole 14 can penetrate into the pressure limiting exhaust pipe 1, and the rest of the parts can be put into the safety pressure spring 4, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com