Hydraulic gravity type clocked flip-flop

A gravitational, trigger technology, applied in instruments, devices for measuring time intervals, time interval measurement with drive mechanisms, etc., can solve problems such as effects affecting timing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

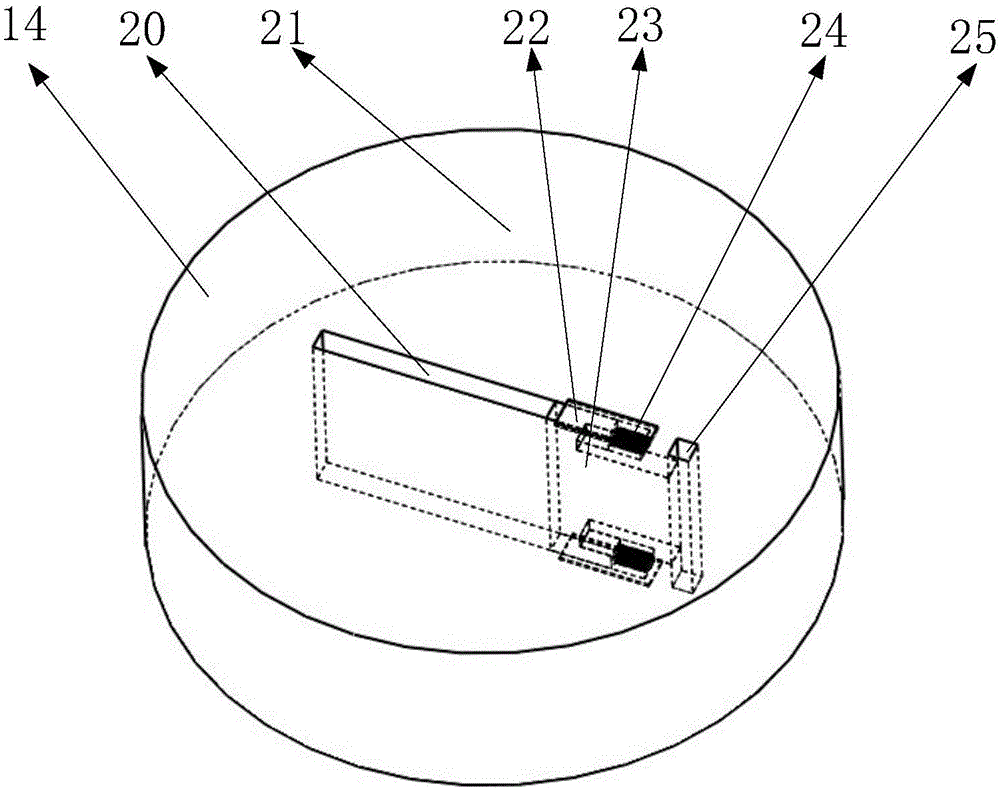

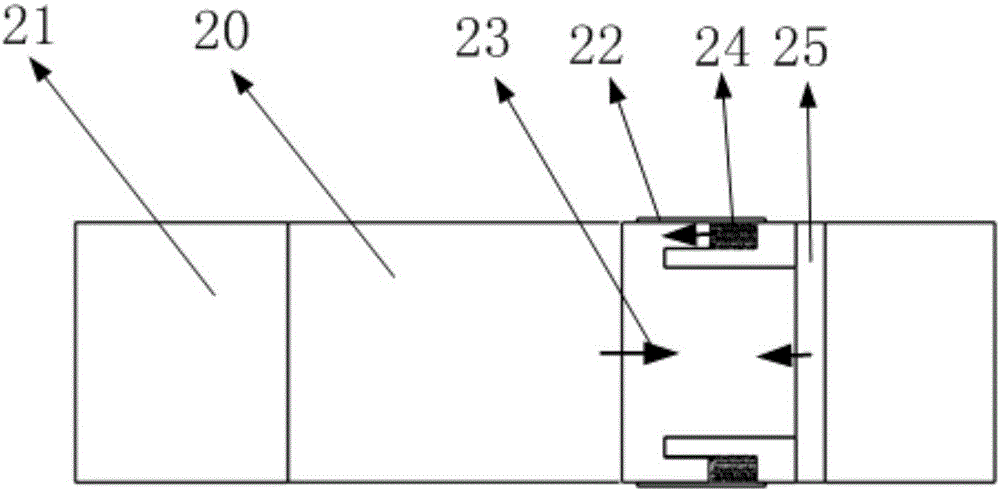

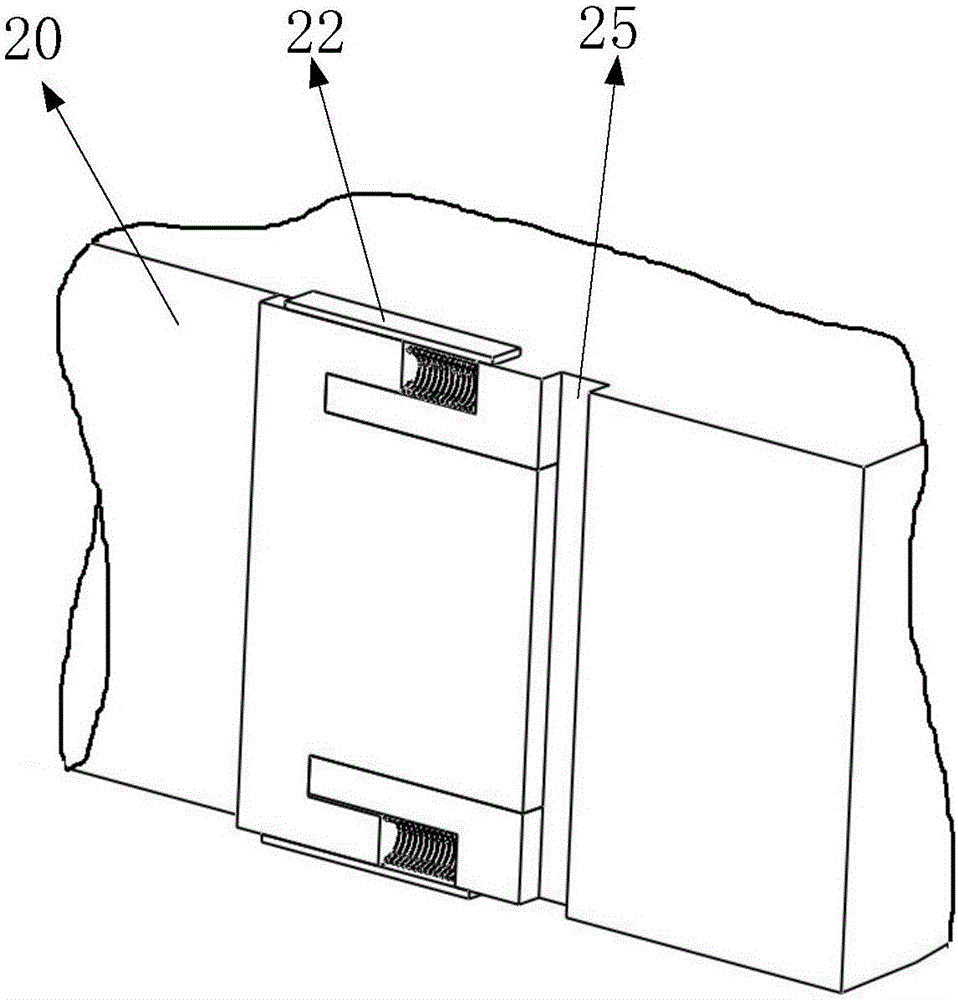

[0028] Such as Figure 6 , 7 As shown, it includes a support cover, a vibration spring, a magnetic snap ring, a vibration ring, a first magnetic ring, a housing, a support ring, a trigger spring, a trigger ring, a magnetic ring, a pillar, a top cover, a gravity plug, a bottom plate, and an impact ring , cardboard, such as Figure 8 As shown, the top cover is installed on the upper end of the housing, the support cover is installed on the top cover through the pillars, and the circular clip is installed on the upper end of the housing; the magnetic snap ring is a permanent magnet, and is nested on the outer edge of the housing and the top cover On the surface, the magnetic snap ring is located on the upper side of the card plate; the vibration ring is made of magnetically conductive material, and is nested on the outer edge surface of the upper side of the housing. One end of the vibration spring is installed on the lower side of the support cover, and the other end is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com