Multilayer composite bamboo adhesive floor and its manufacturing process

A multi-layer composite, bamboo glue technology, applied in the direction of manufacturing tools, wood layered products, layered products, etc., can solve the problem that plywood cannot meet the standard of wooden house floor, the anti-corrosion and physical and mechanical properties of house floor, etc. problems, to achieve the effect of saving wood and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

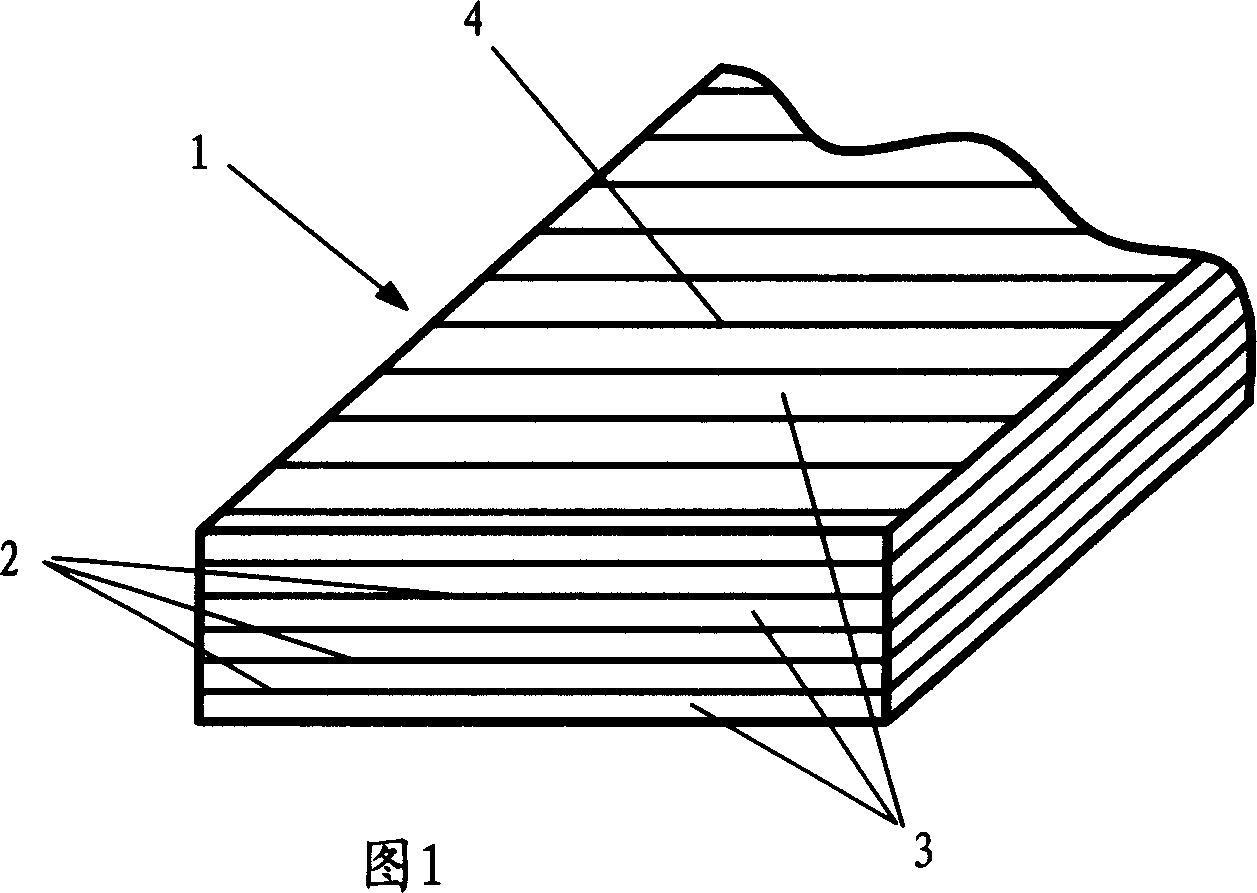

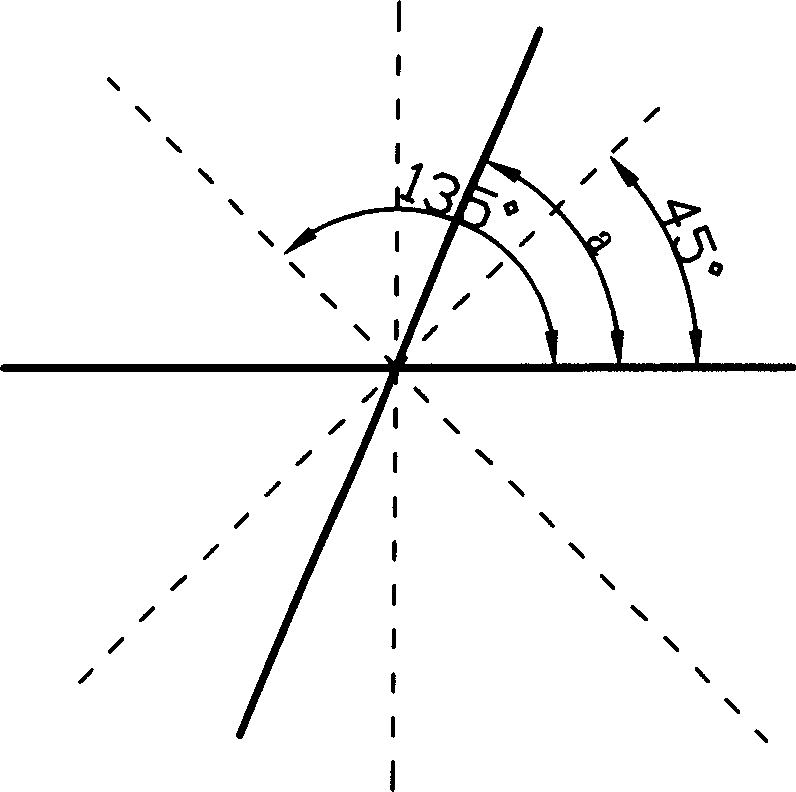

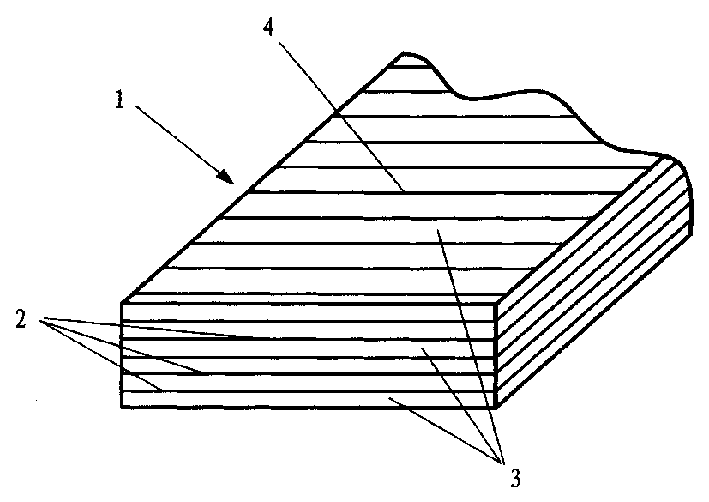

[0008] As shown in Figure 1, the house floor 1 is made of broken bamboo strips 4 arranged into strip mat laminates 2 and distributed in each strip mat laminate 2 and between each layer 2 and the phenolic resin that glues each strip mat layer 2 together And Basileum SI-84EC preservative 3 composition. The strip sheet 4 is preferably equal in width and thickness, and the strip sheet has more than 5 layers. Adjacent laminates between the laminated mats intersect at an angle a along the fiber direction, such as figure 2 shown. The angle a is preferably: 45°2 , and at the same time, from an initial temperature of 20-70 ° C, the temperature is raised to 120-160 ° C, and the pressure is kept for not less than 30 minutes. . The formula of preservative and phenolic resin mixed liquid is: phenolic resin and water are diluted by volume ratio of 1:0.5-20; preservative and water are adjusted into emulsion by weight ratio of 1:0.5-10; water-diluted phenolic resin and preservative Stir t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com