Patents

Literature

37results about How to "Solving Tension Problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

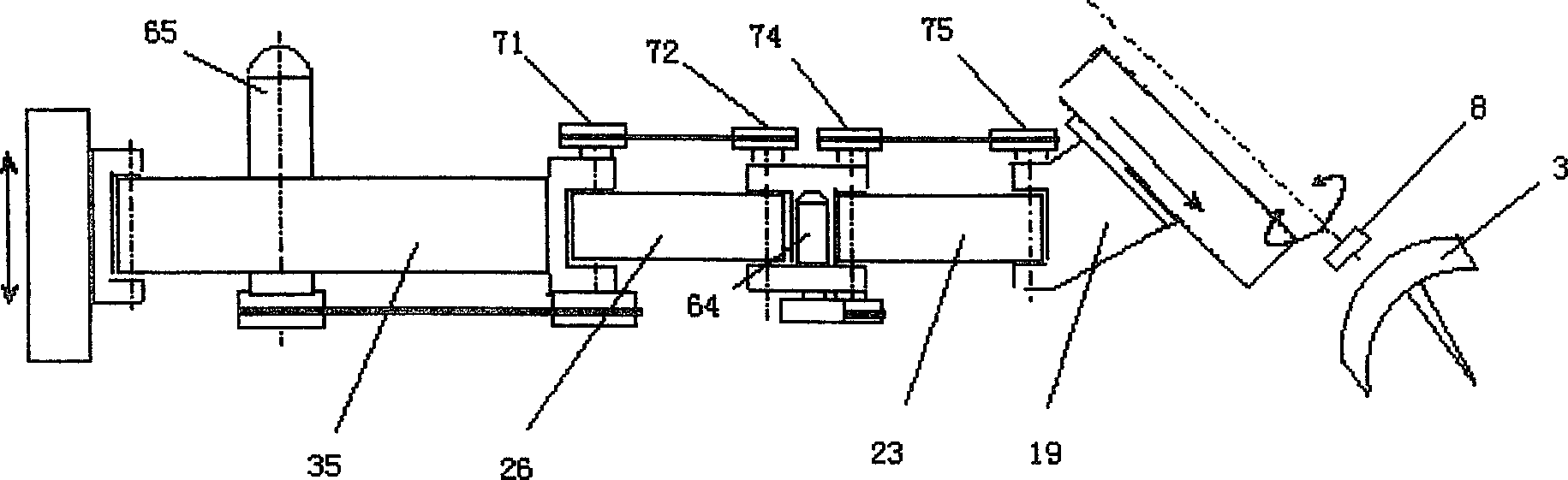

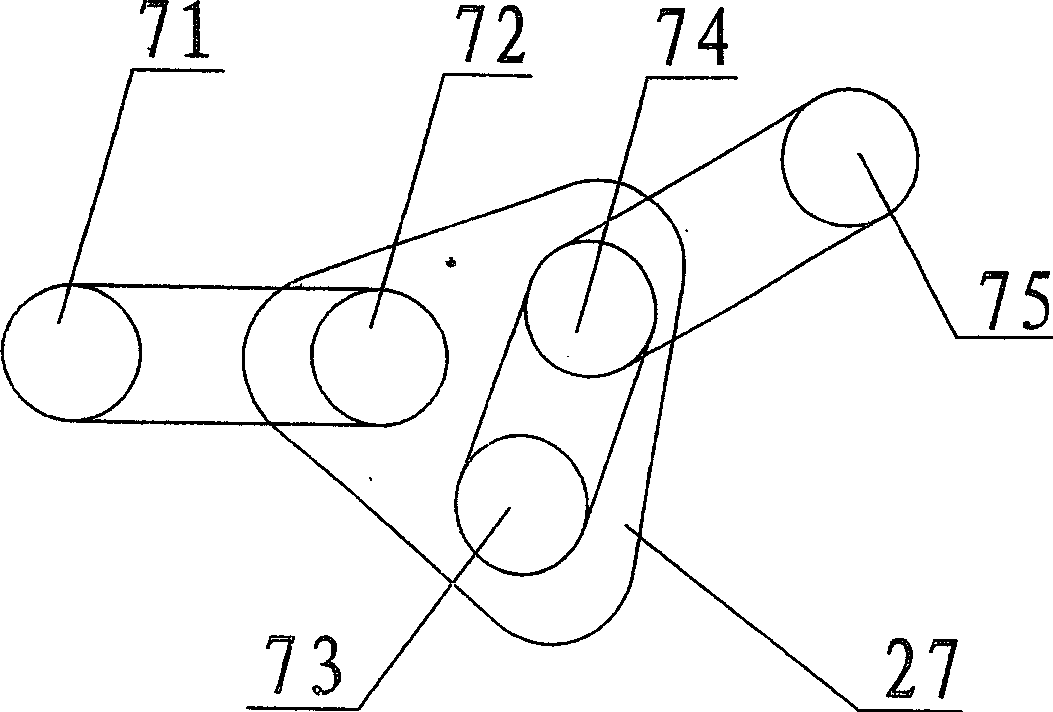

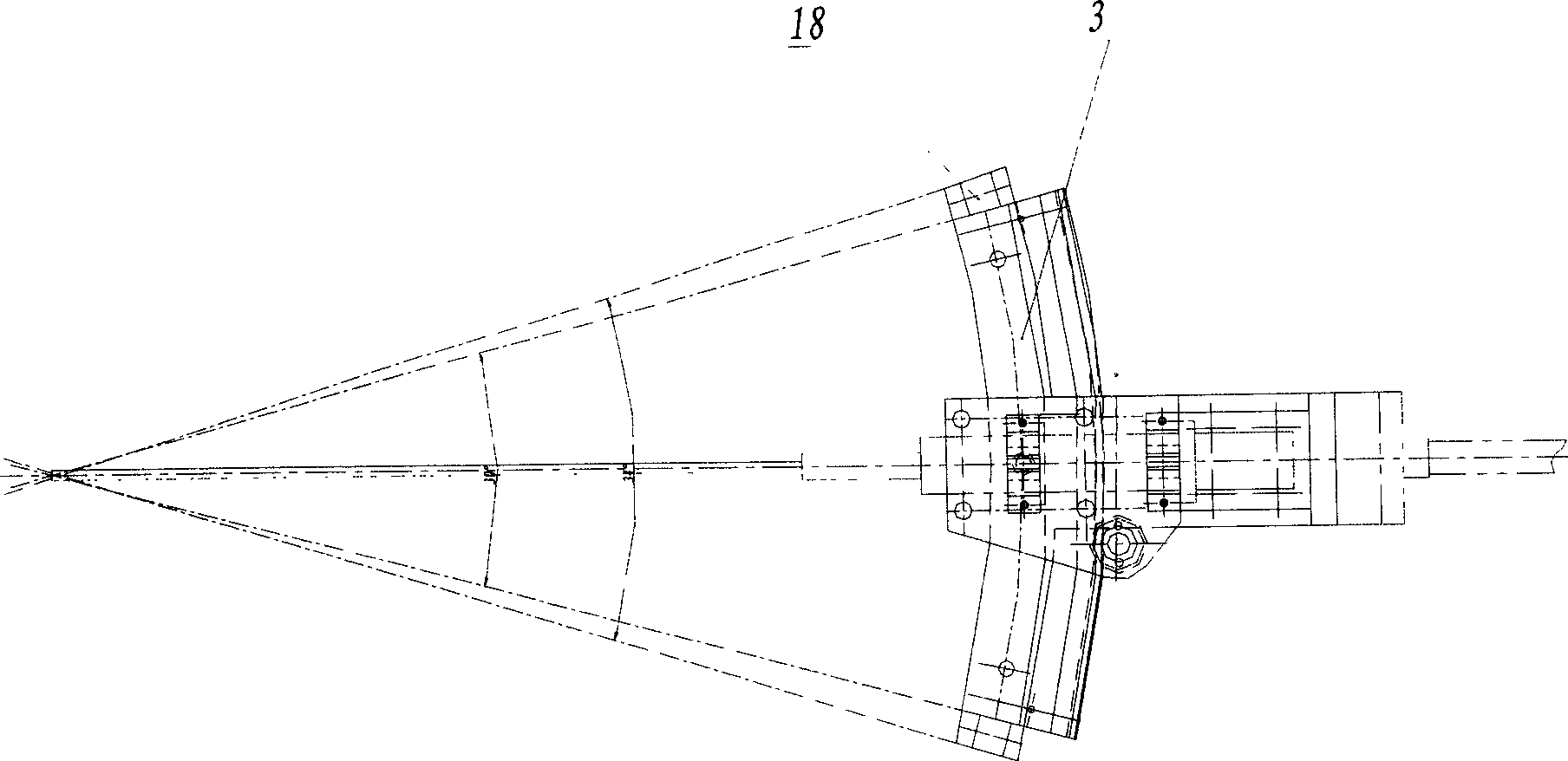

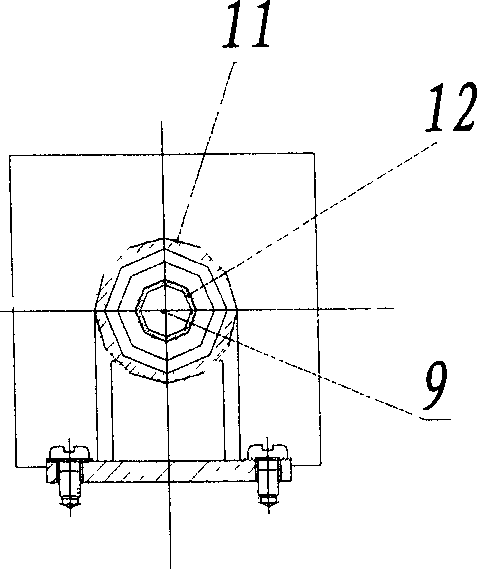

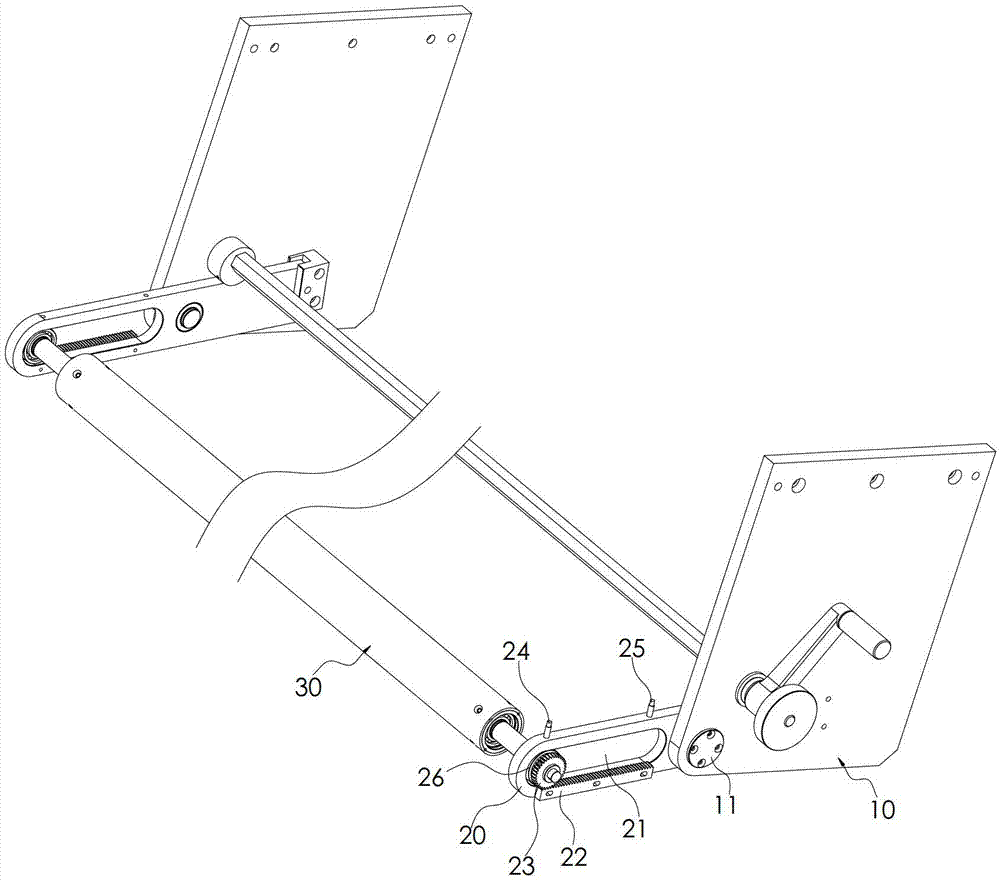

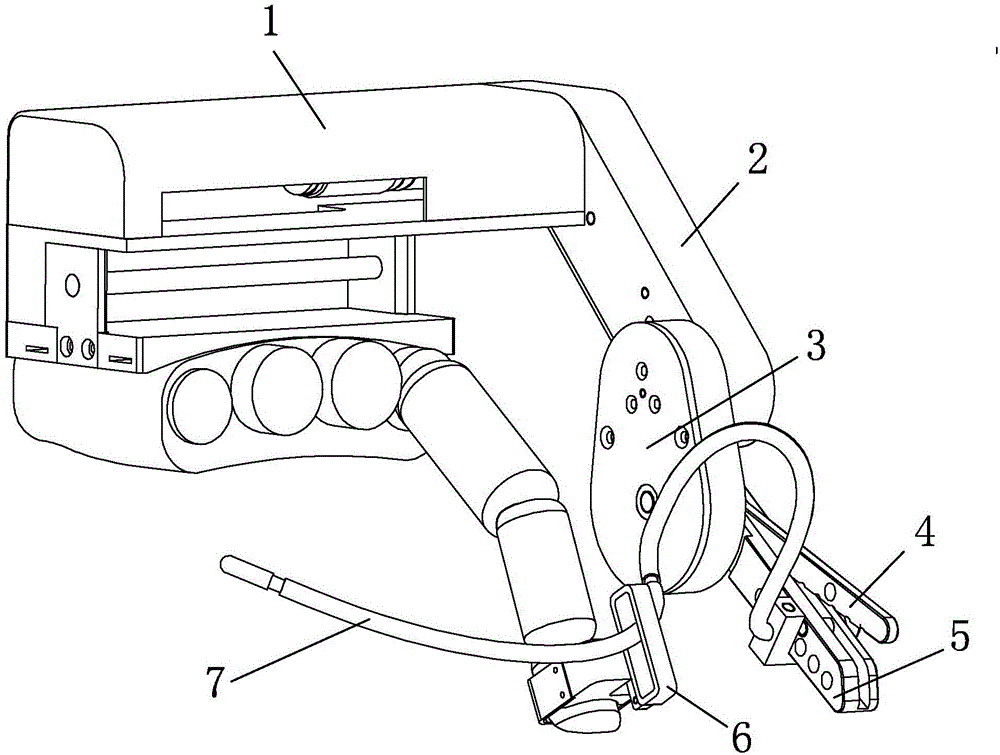

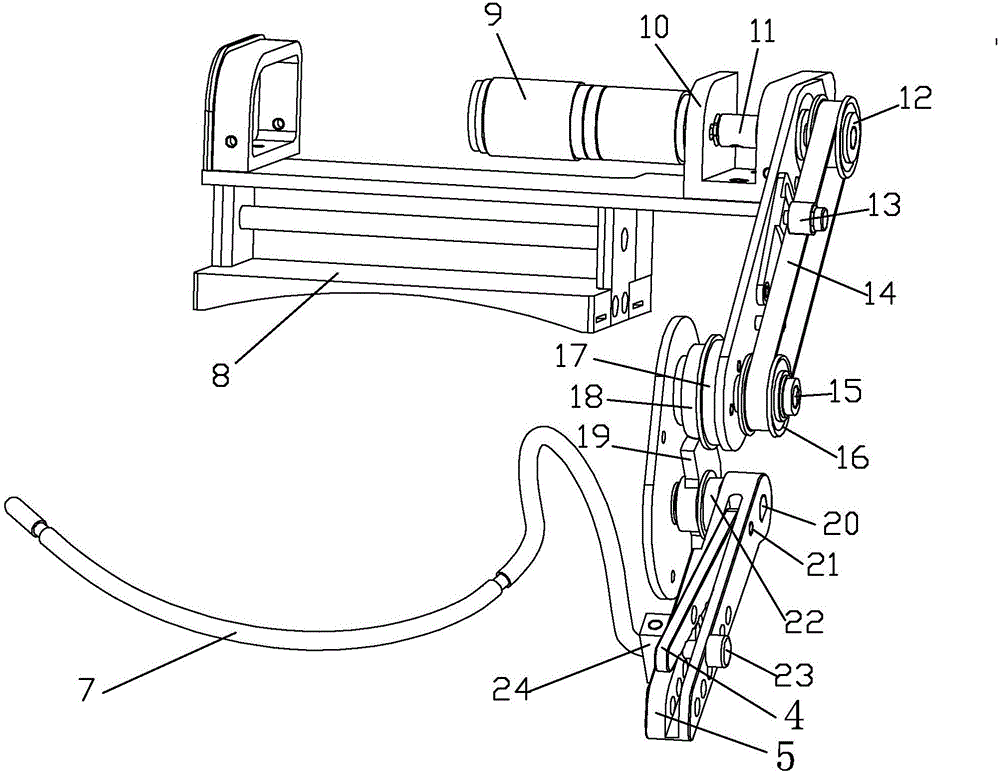

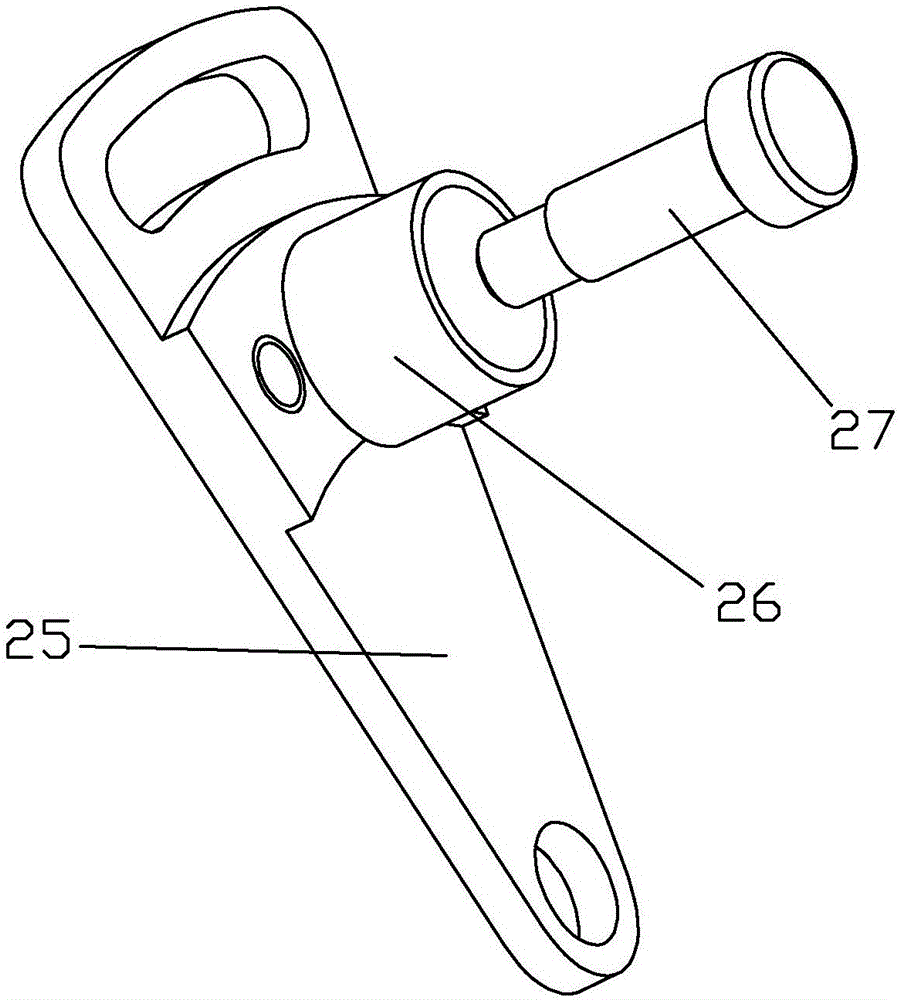

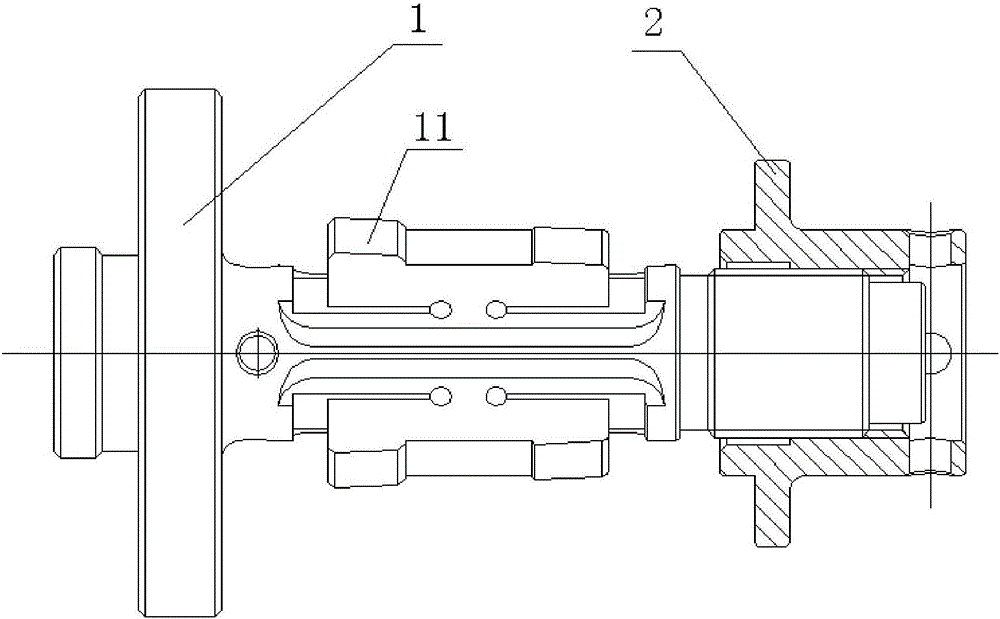

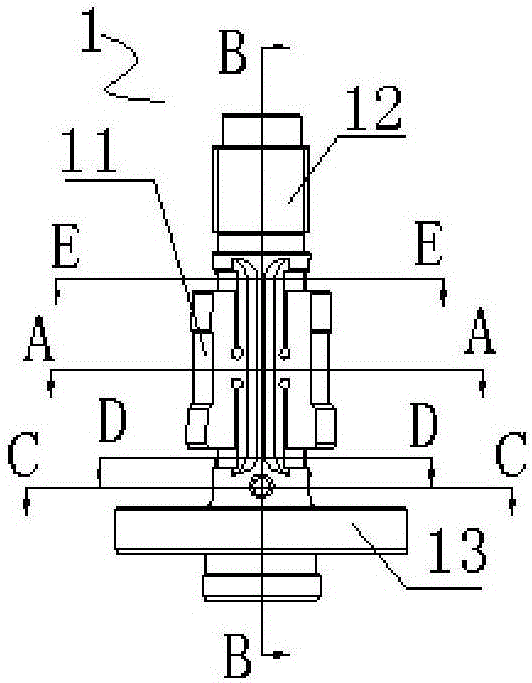

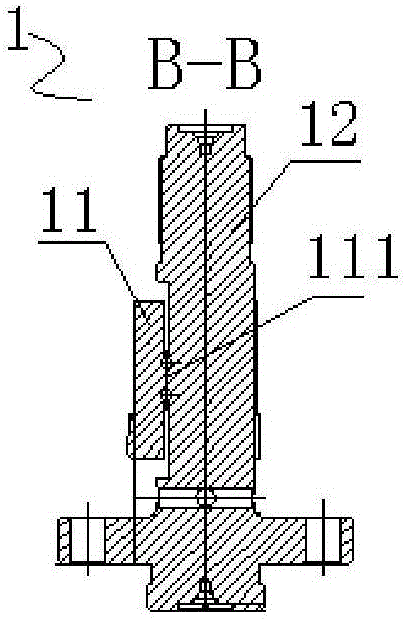

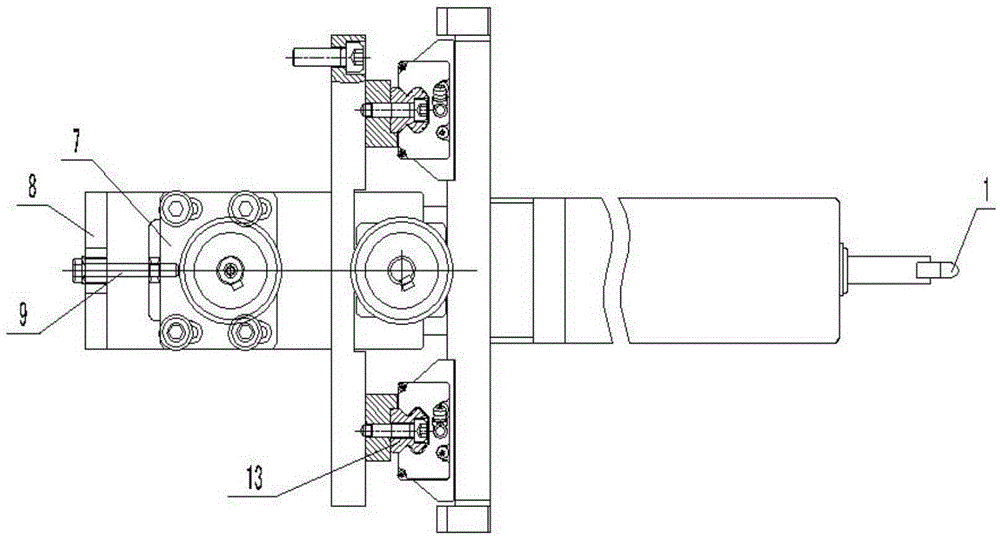

Secondary manipulator of surgery operation robot

ActiveCN1654174AEasy and flexible operationRealize mechanical structure uncouplingJointsDiagnosticsBlood vesselRobot manipulator

The servo actuated robot manipulator for surgical operation has fingers in the most front end as well as finger circularly moving joint mechanism, arc guide rotating joint mechanism, inclined guide straight motion joint mechanism, the first small arm rotating joint mechanism, the second small arm rotating joint mechanism, large arm rotating joint mechanism, vertical position regulating mechanism and sync toothed belt wheel mechanism. The present invention is used mainly in micro wound surgical operation, eye operation, orthopaedics operation, etc., especially in blood vessel stitching and other microscopic surgical operations.

Owner:TIANJIN UNIV

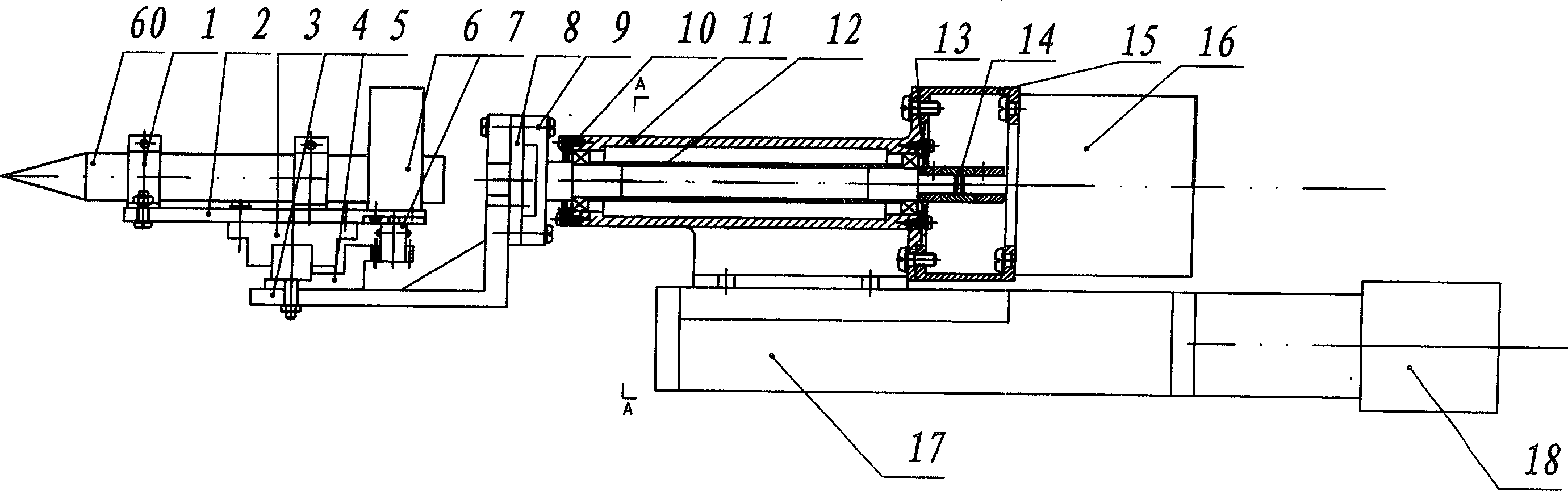

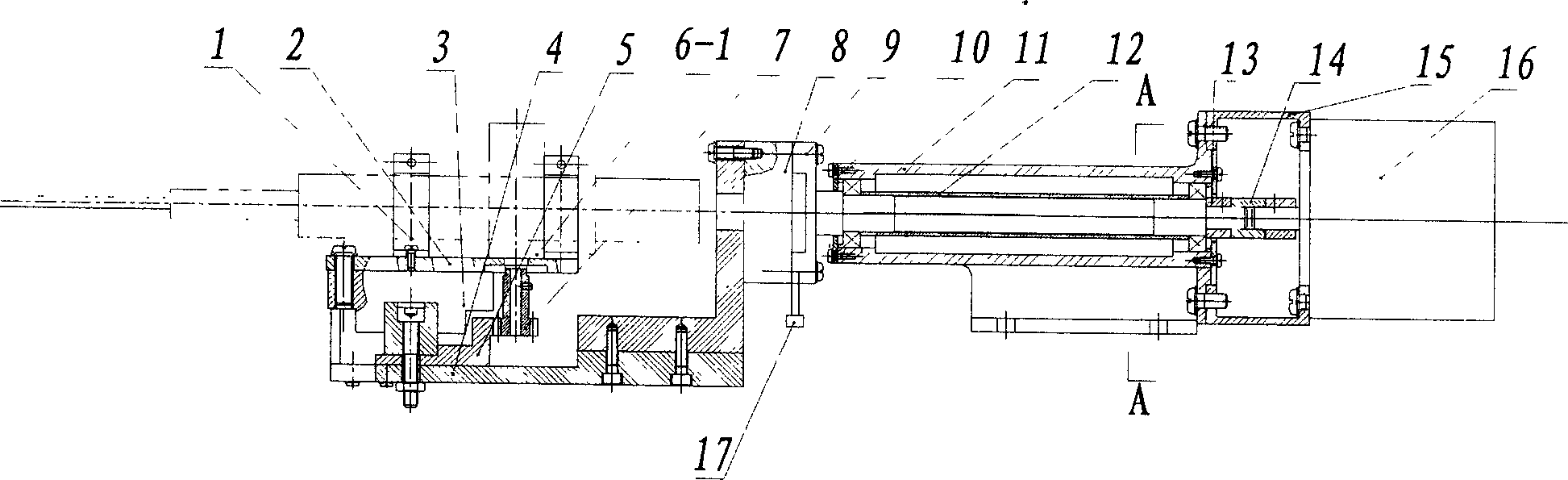

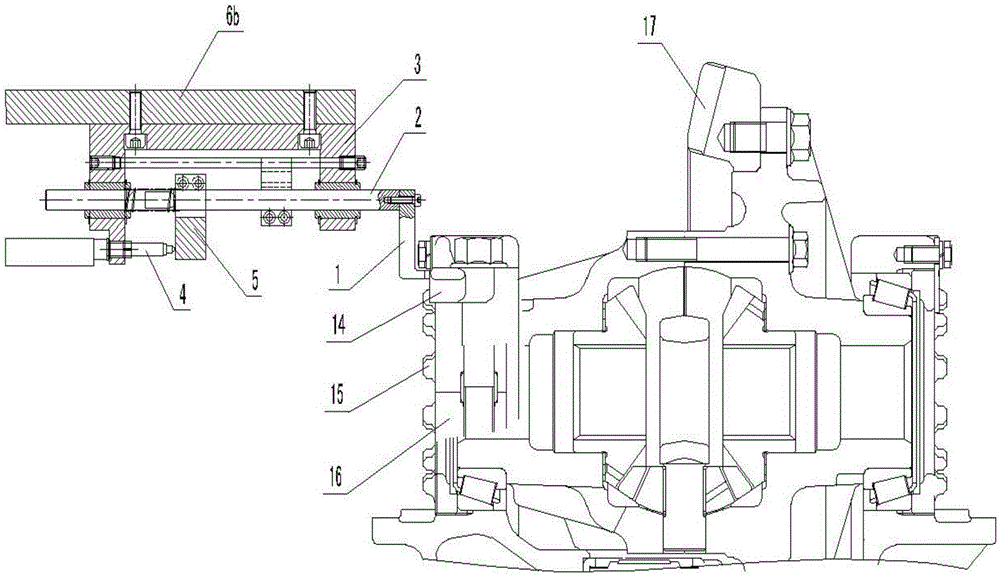

Accessory manipulation of throat surgery robot

InactiveCN1730245AEasy and flexible operationReduce the volume of institutional spaceSurgeryManipulatorThroatDouble stage

The invention discloses an accessory operation hand for throat operation robot, which comprises a finger arc motion joint mechanism, an arc guide rail rotation joint mechanism, a first and second front arm rotation joint mechanism, a back arm rotation joint mechanism, a vertical position regulation mechanism, a synchronous tooth-type belt wheel mechanism, and a steel wheel mechanism. Compared with existing technique, this invention has advantage that, the mechanism is joint-type coordination structure with eight degrees of freedom to complete all motions flexibly; the double swing lever mechanism lets the robot gesture constant when the work point varies to realize the decouple of position and gesture; the double-stage thread-gear structure decreases the volume and weight; the hand coarse adjustment can position quickly, and the fine tuning mechanism makes system has the precision fit for micro-surgery.

Owner:TIANJIN UNIV

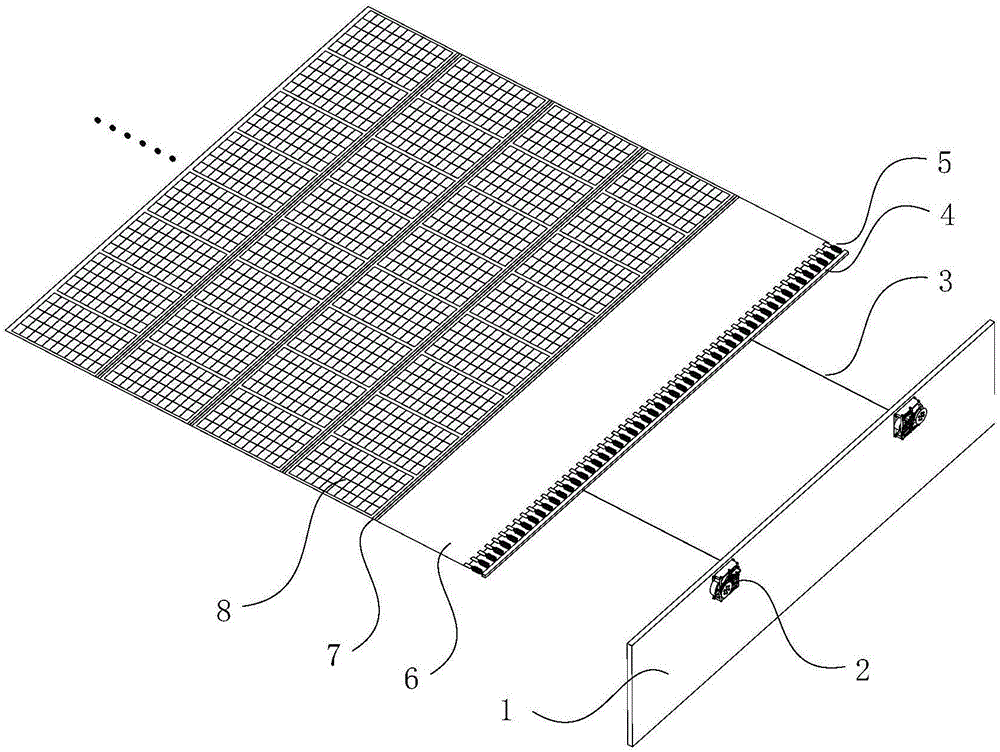

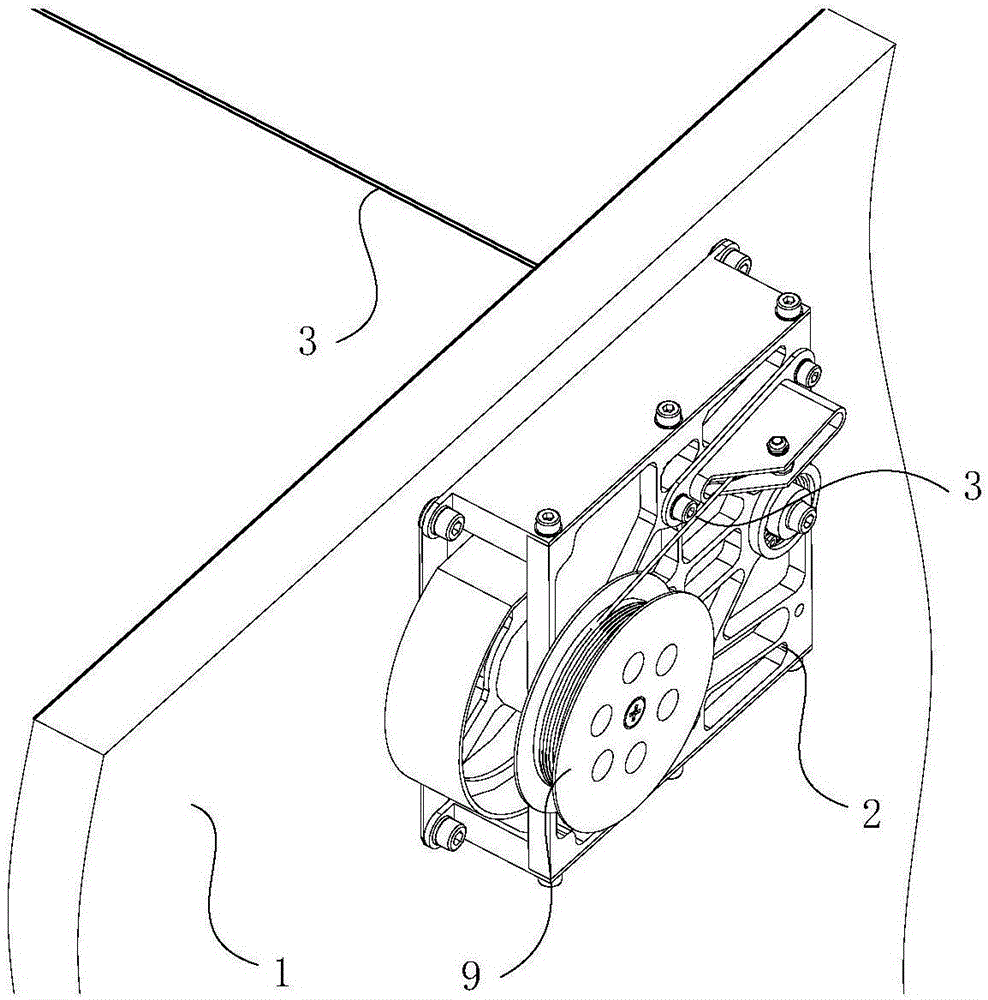

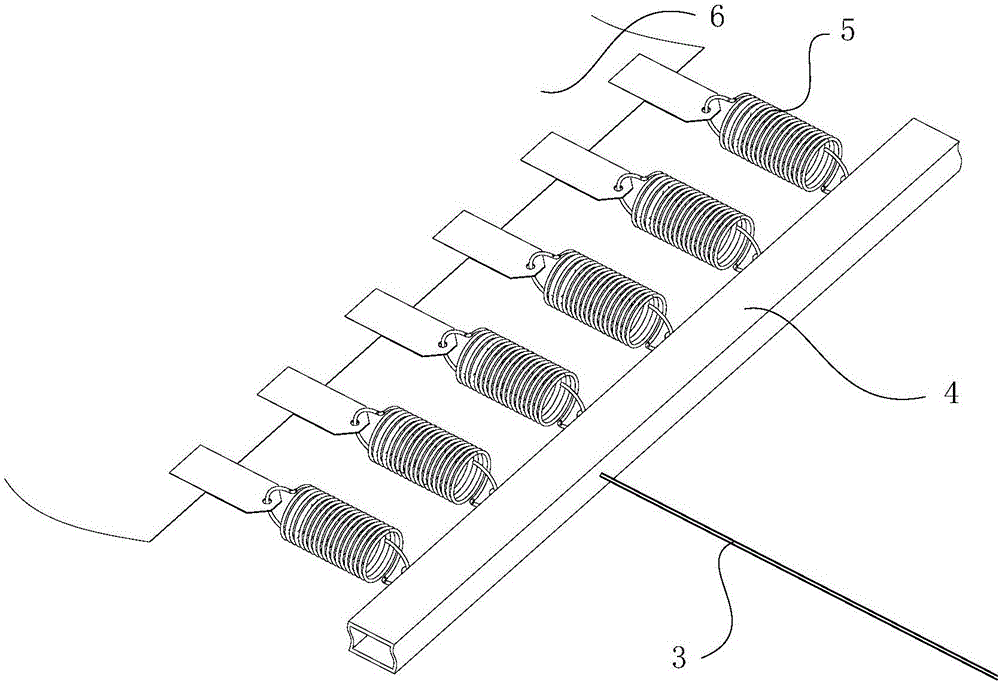

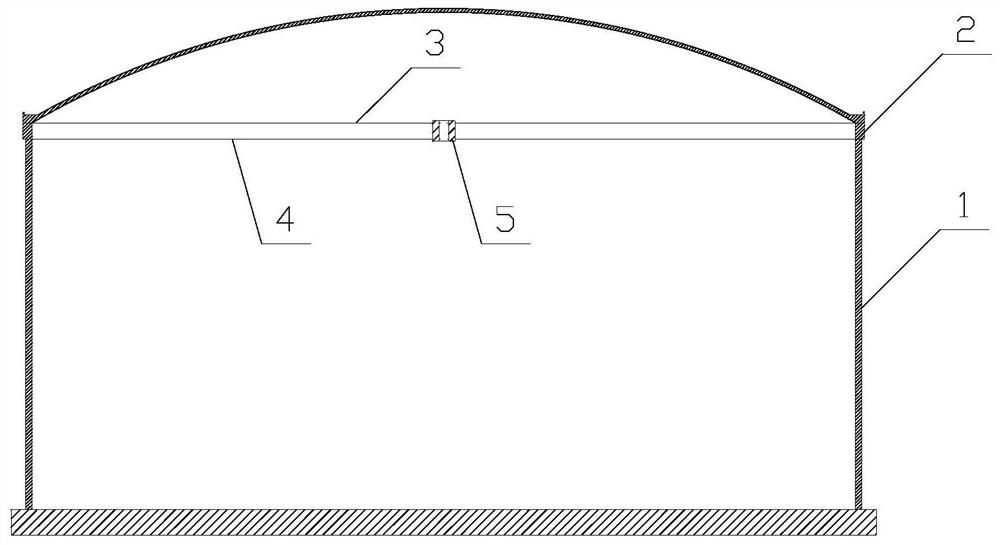

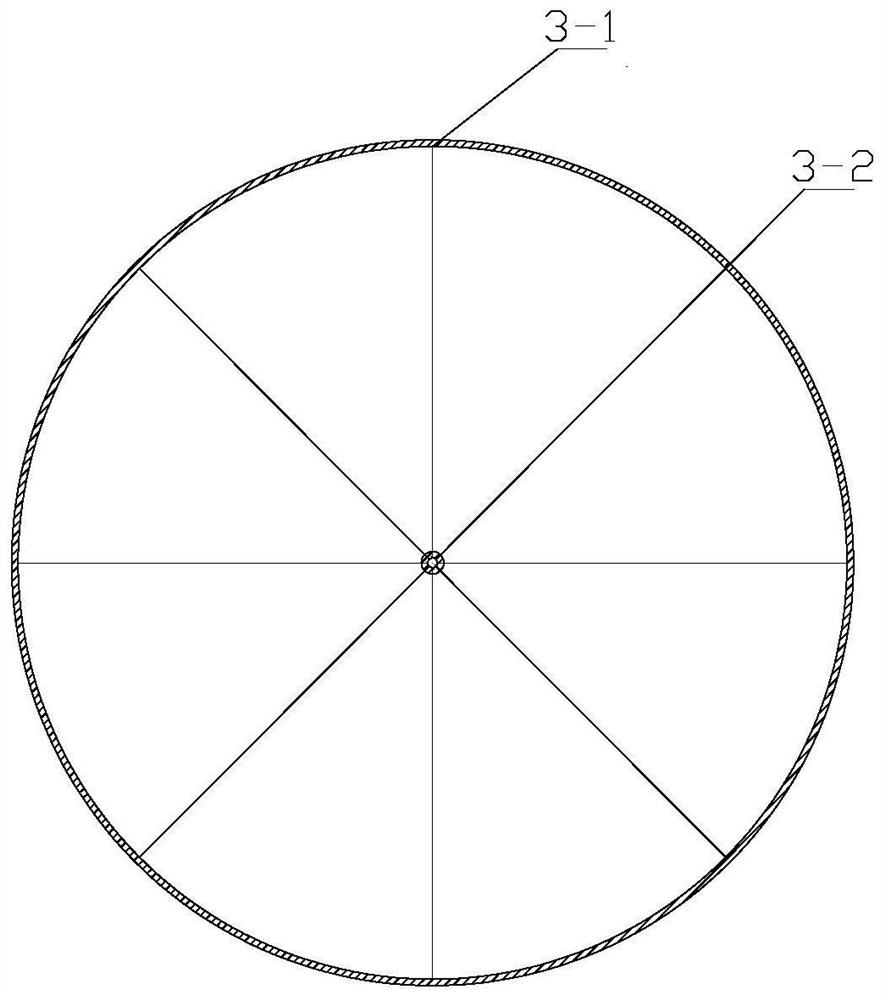

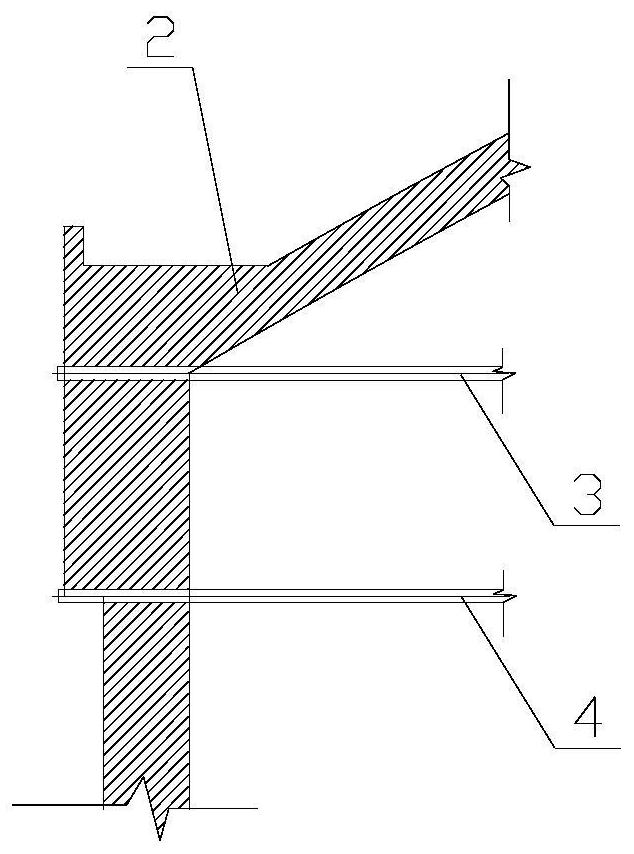

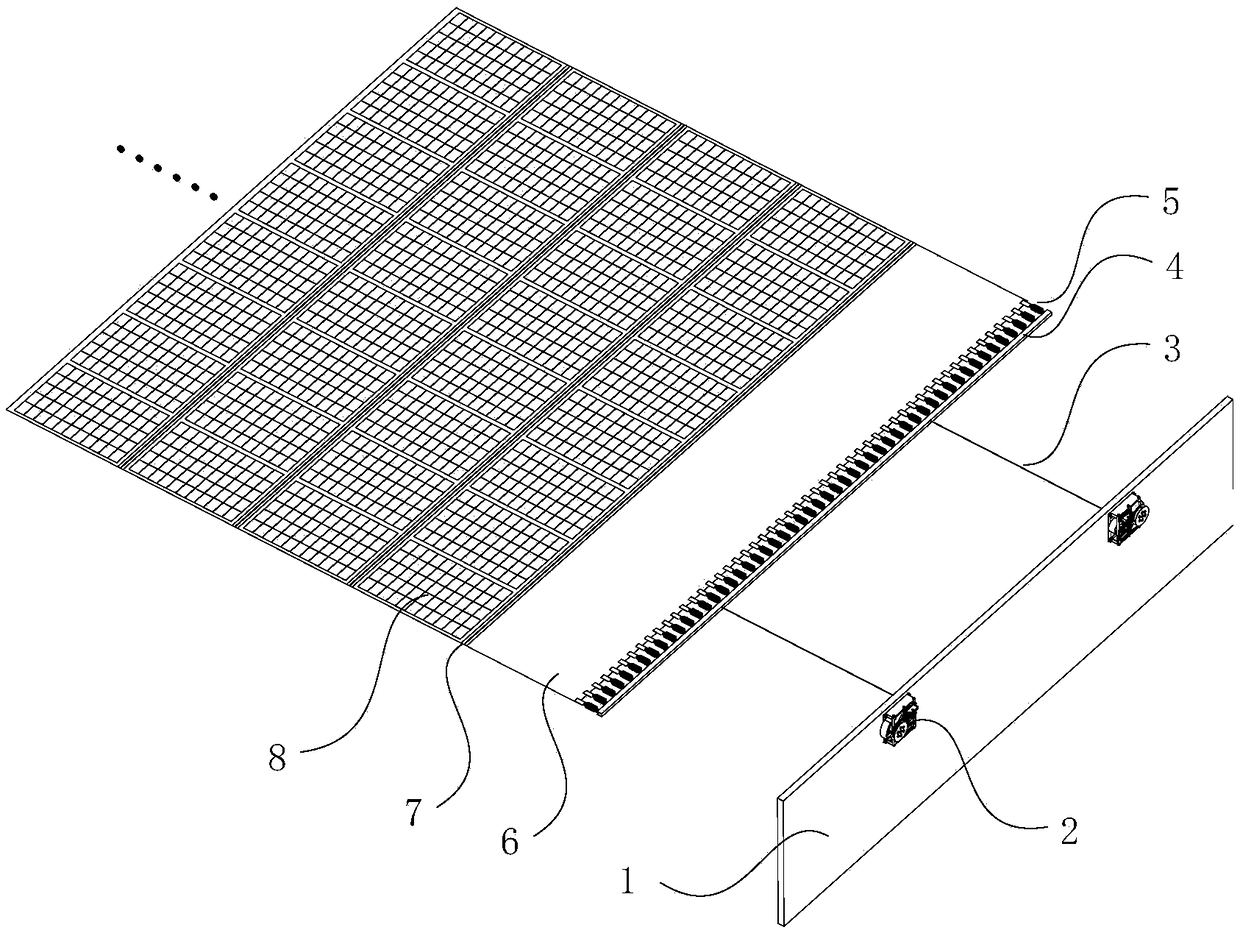

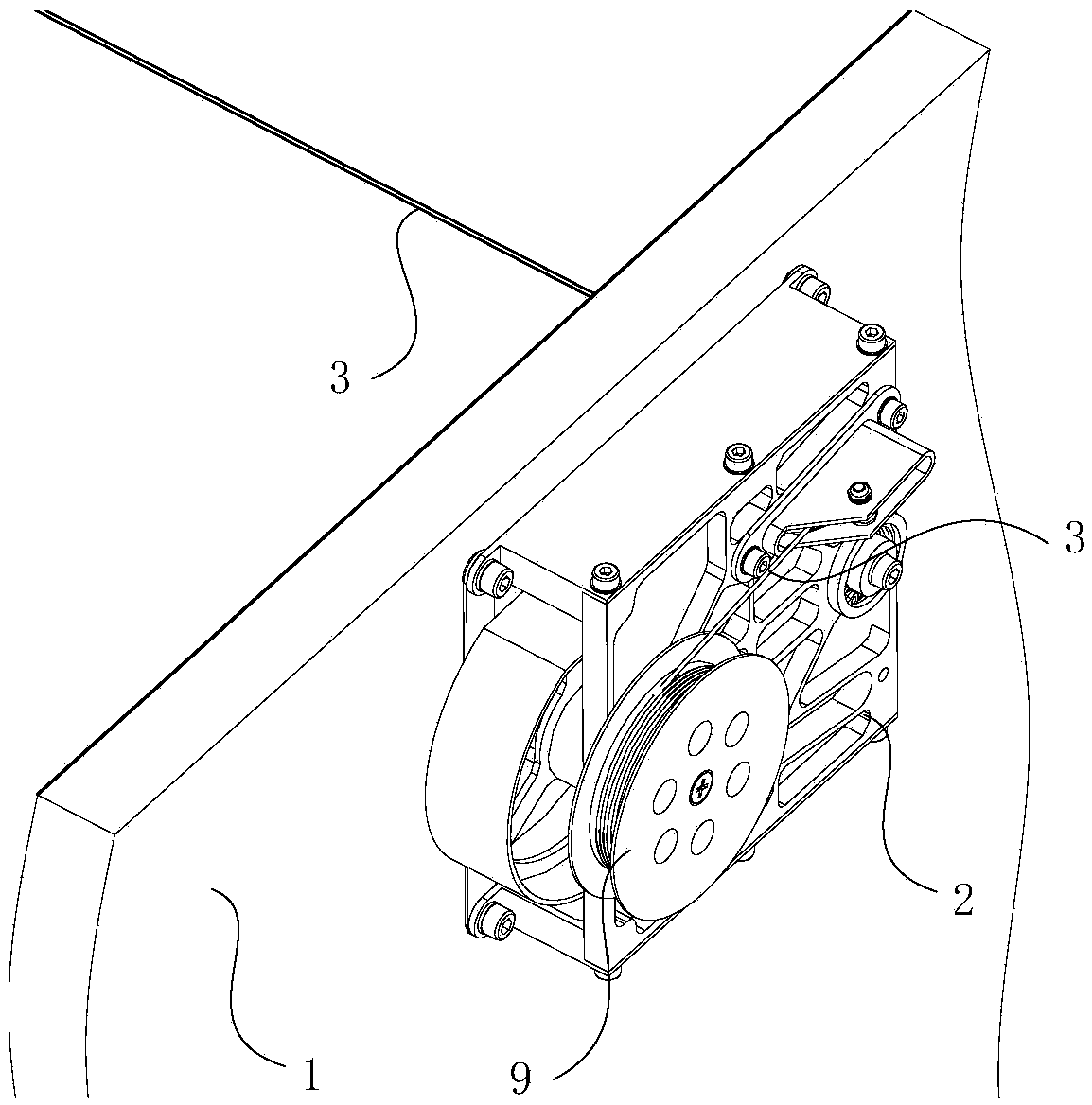

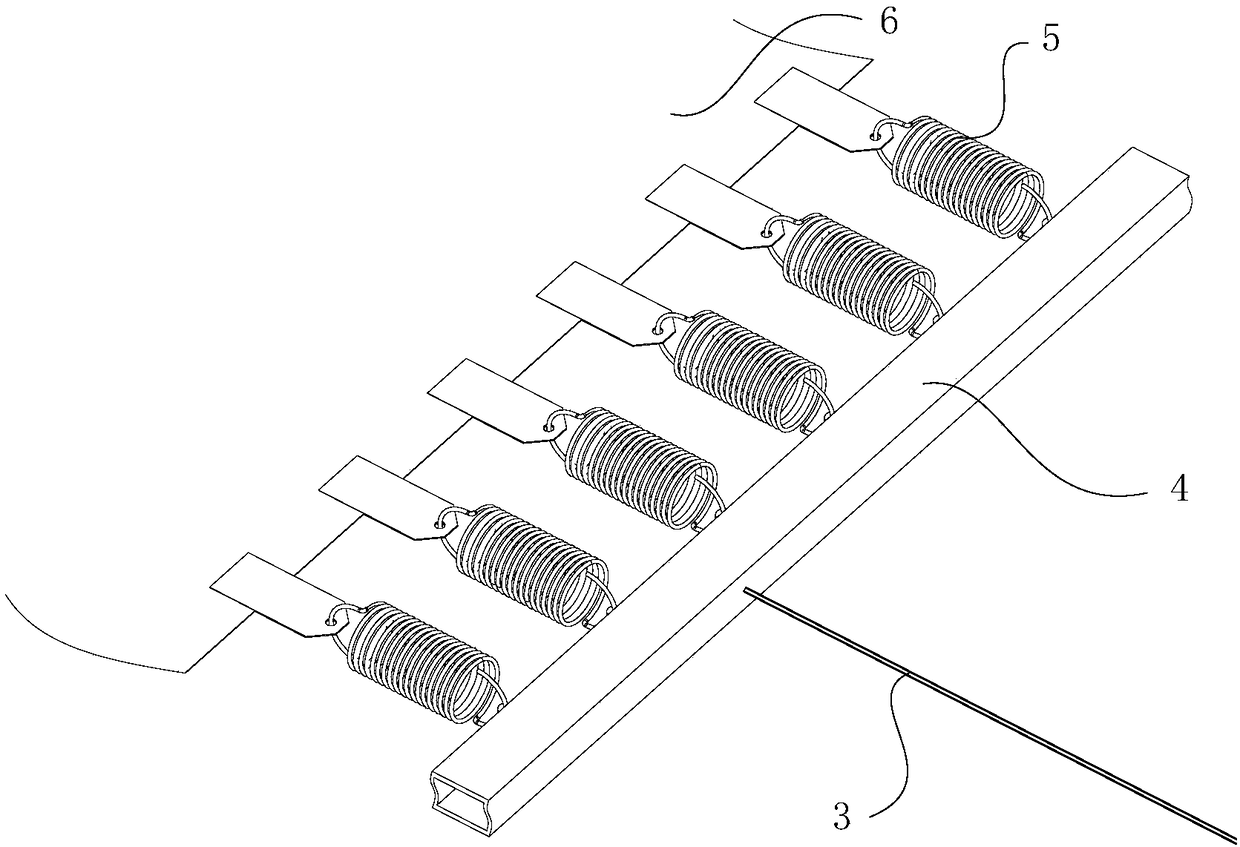

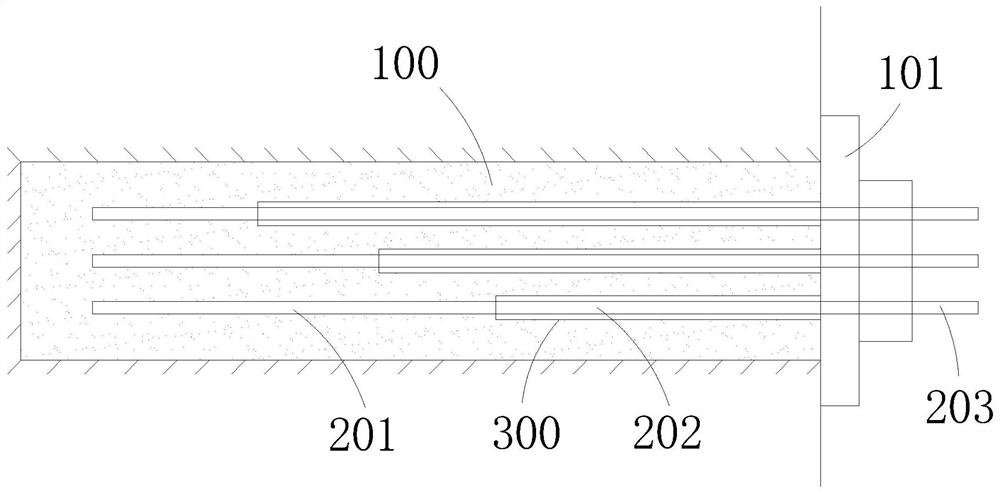

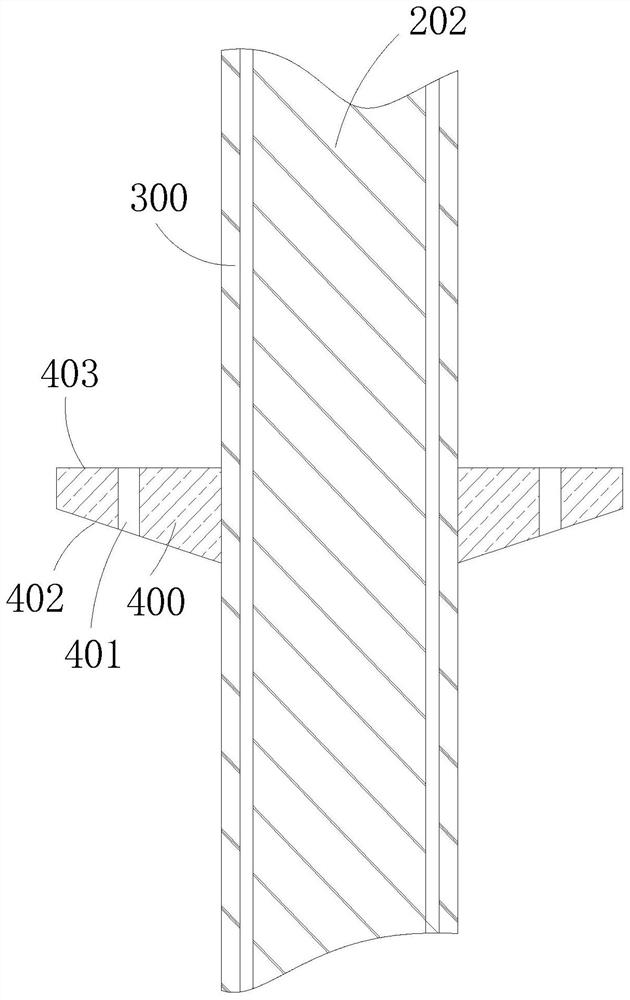

Solar carpet uniform loading, tensioning and displacement compensating mechanism

ActiveCN106240847ARealize the displacement compensation functionSolving Tension ProblemsCosmonautic vehiclesCosmonautic power supply systemsIn planeInterference resistance

The invention discloses a solar carpet uniform loading, tensioning and displacement compensation mechanism. By applying the solar carpet uniform loading, tensioning and displacement compensating mechanism, when expansion displacement of a solar wing is generated due to spatial high-low temperature alternation, uniform and constant tensioning force can be provided, the effect that the solar wing has stable rigidity property is guaranteed, the displacement compensation dimension is large, and the interference resistance is high. The solar carpet uniform loading, tensioning and displacement compensating mechanism is composed of a constant torque spring taking-up mechanism, tensioning steel wire ropes, a uniform loading beam, uniform loading springs, a flexible transitional carpet and piano wire hinges. By changing the lengths of the tensioning steel wire ropes, the displacement, generated by shrinkage and expansion, of a flexible solar carpet is compensated, and the effect that the tensile force of the tensioning steel wire ropes is constant all the time is guaranteed. Through the uniform loading beam, the uniform loading springs and the flexible transitional carpet, the concentrated tensile force transferred from the tensioning steel wire ropes is dispersed into the in-plane acting force uniformly, and the purpose of uniform loading is achieved.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

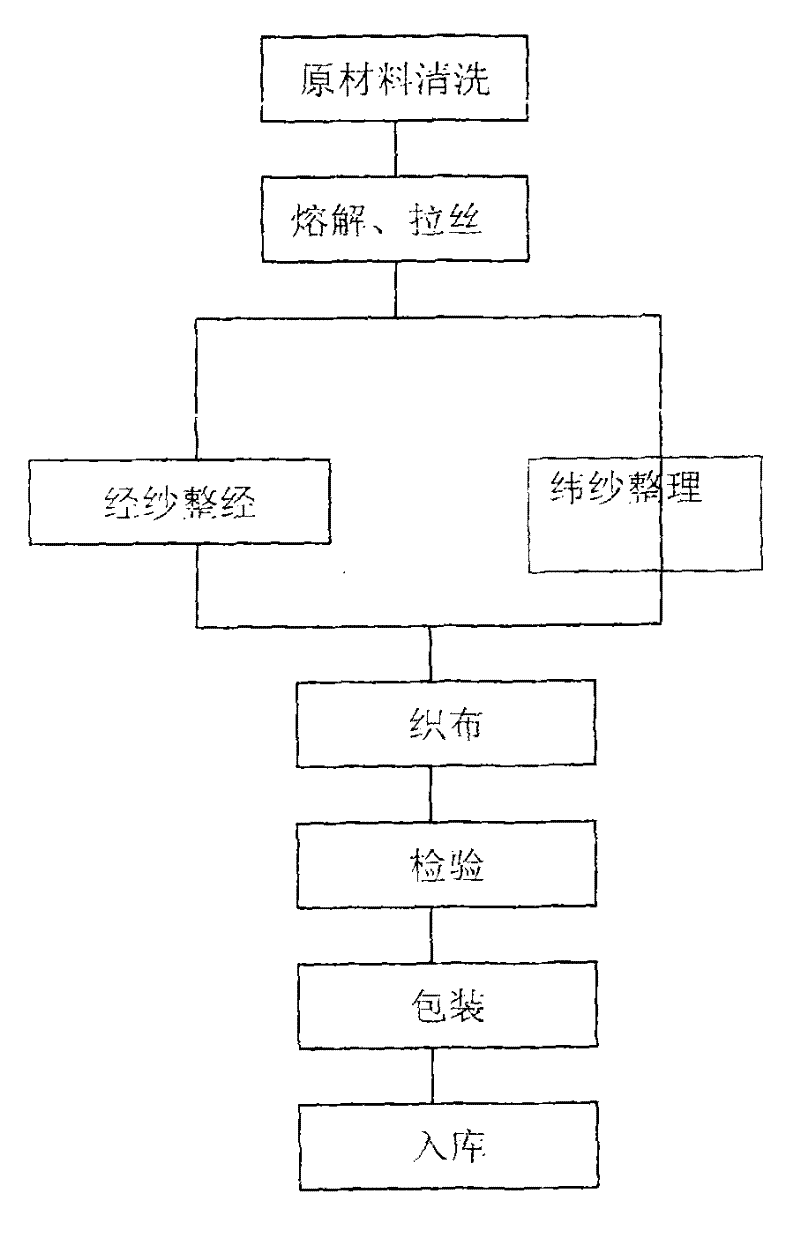

Glass fiber weaving process and special equipment thereof

InactiveCN101748546AAvoid wear and tearAvoid harmLoomsOther manufacturing equipments/toolsFiberGlass fiber

The invention discloses a glass fiber weaving process and special equipment thereof. The technological process is finished through procedures of cleaning, melting, wire drawing, warp yarn warping, weft yarn finishing, weaving, check and warehousing on raw materials. The special equipment is a warping tensioner and a weft yarn introduction device. When the process is adopted to manufacture a glass fabric, procedures of unwinding and twisting are removed from a finishing process of weft yarns, and a stranding procedure is removed from a finishing process of weft yarns so as to enable glass precursor fibers not to generate friction with equipment of unwinding, twisting and stranding, avoid abrasion and hurt to the glass precursor fibers, guarantee the tensile strength of the glass precursor fibers, enhance the product quality and the production efficiency and save the energy consumption and the product cost.

Owner:黄新春

Novel environment-friendly multifunctional satellite type washing-free gravure direct printing technology

InactiveCN111186224ASolve the emission problemTroubleshooting Tension DifficultiesOther printing apparatusTextile printerPhotogravure

The invention discloses a novel environment-friendly multifunctional satellite type washing-free gravure direct printing technology. An existing satellite type flexo printing machine and environment-friendly washing-free water-based ink are adopted. Different from the existing satellite type flexo printing machine, a large-diameter center roller serves as a base material bearing roller, and the material of the large-diameter center roller is rubber not steel; and a printing plate is gravure, the electric carving technology is adopted, and the material of the printing plate is steel not flexible material. The center large-diameter roller also serves a guide belt for printing fabric, a guide belt glue automatic feeding device and an automatic cleaning device are arranged, the rubber on the surface of the center large-diameter roller is coated with the guide belt glue, the fabric is attached to the rubber large roller for direct printing, the problem that multiple color registers do not have tension is solved, and registration is accurate. The characteristics that occupied space is smaller than the occupied space of an existing photogravure press, few printing materials are wasted, cost is saved, the machine table efficiency is high, and printing of multifunctional materials is wide; and steaming washing is not needed, and the fabric is more bright in color / higher in depth sense compared with fabric printed by the existing satellite type flexo printing machine are achieved.

Owner:苏州维宁斯化工有限公司

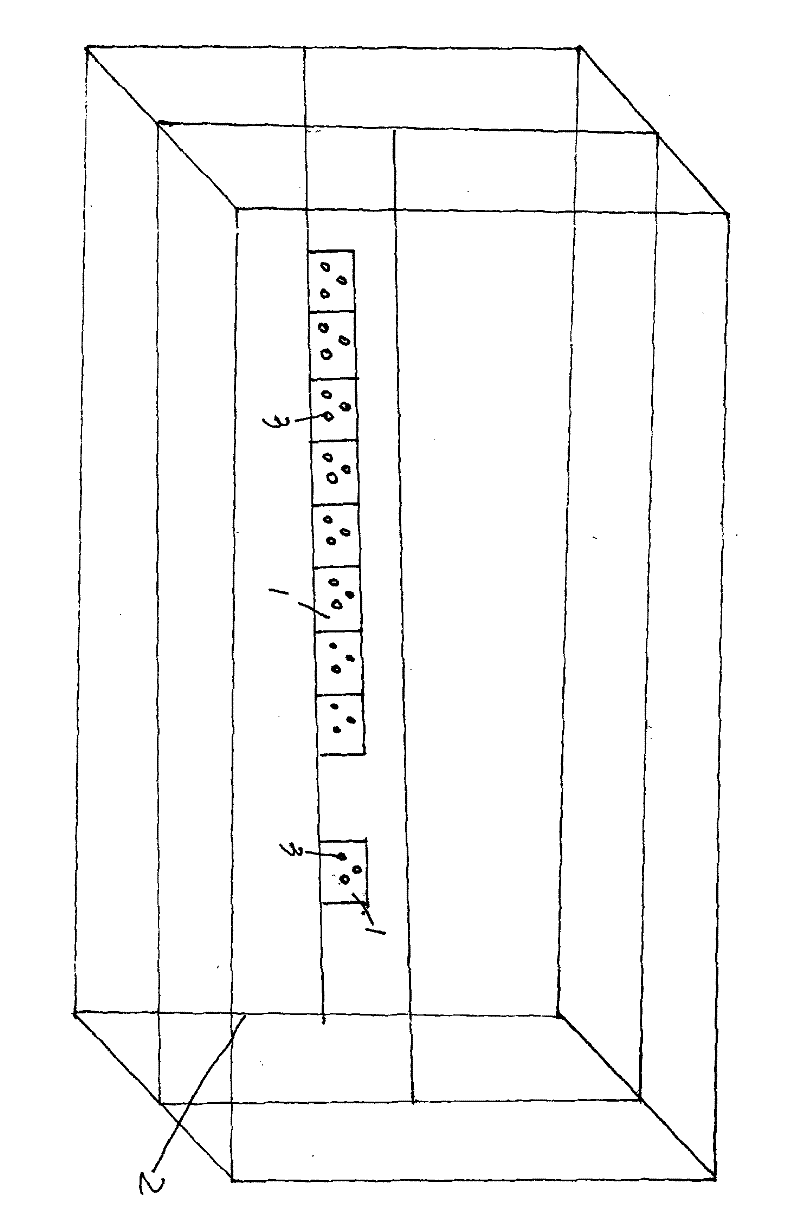

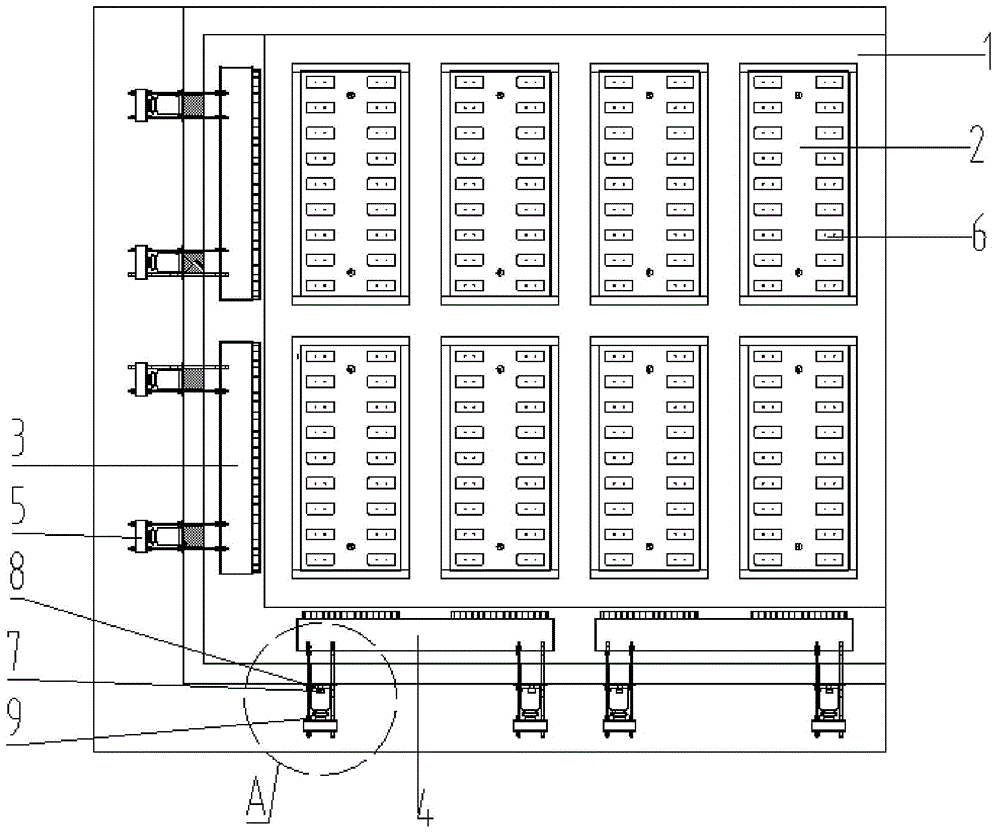

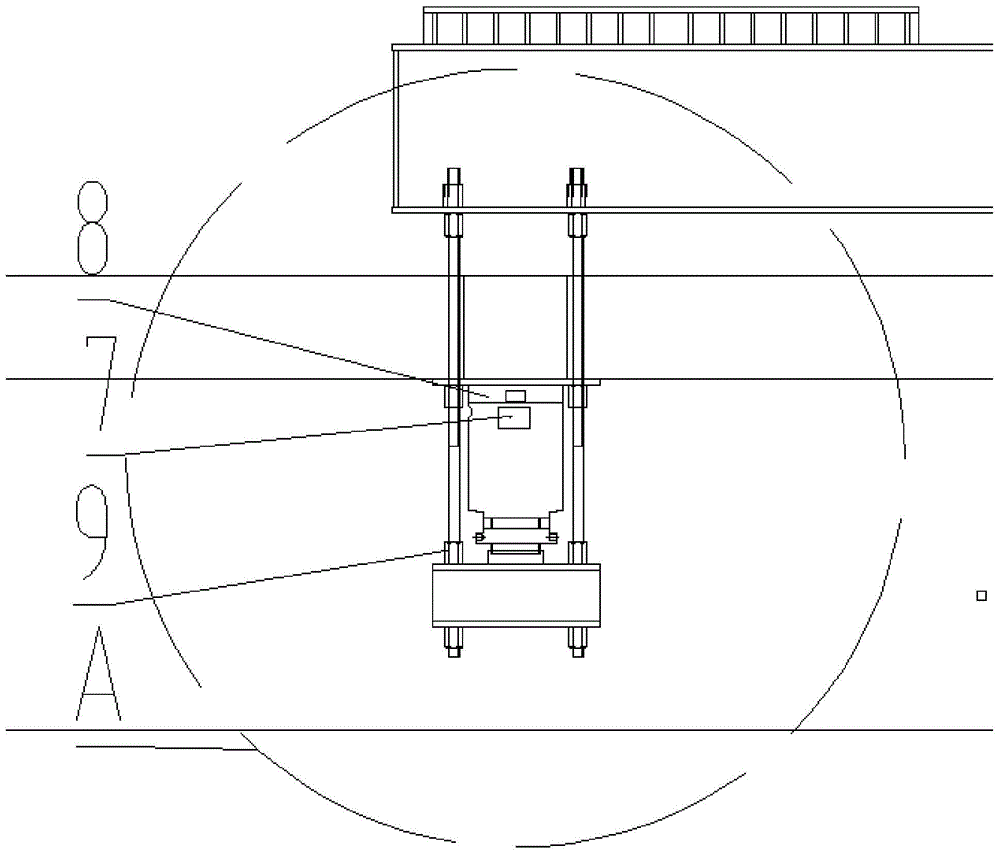

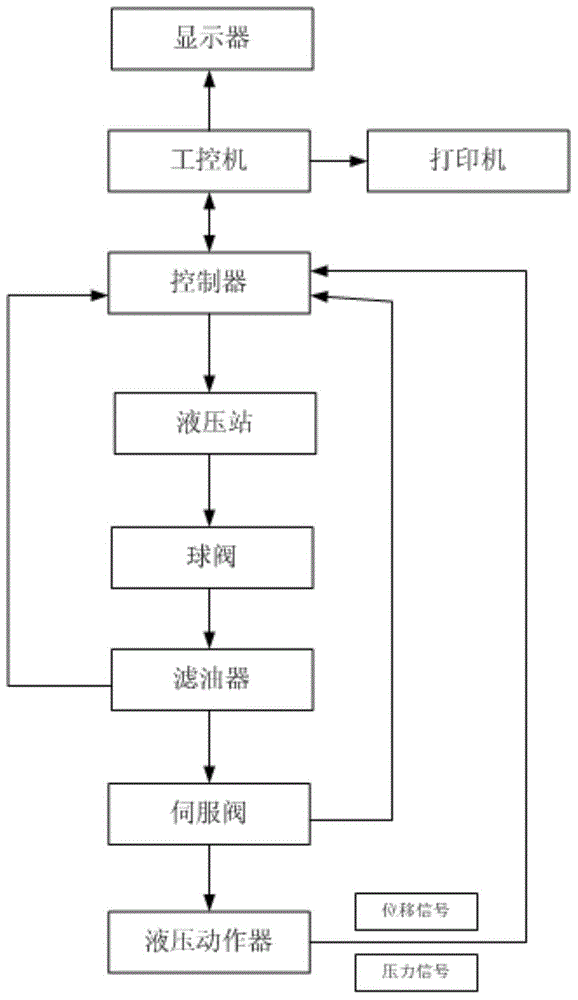

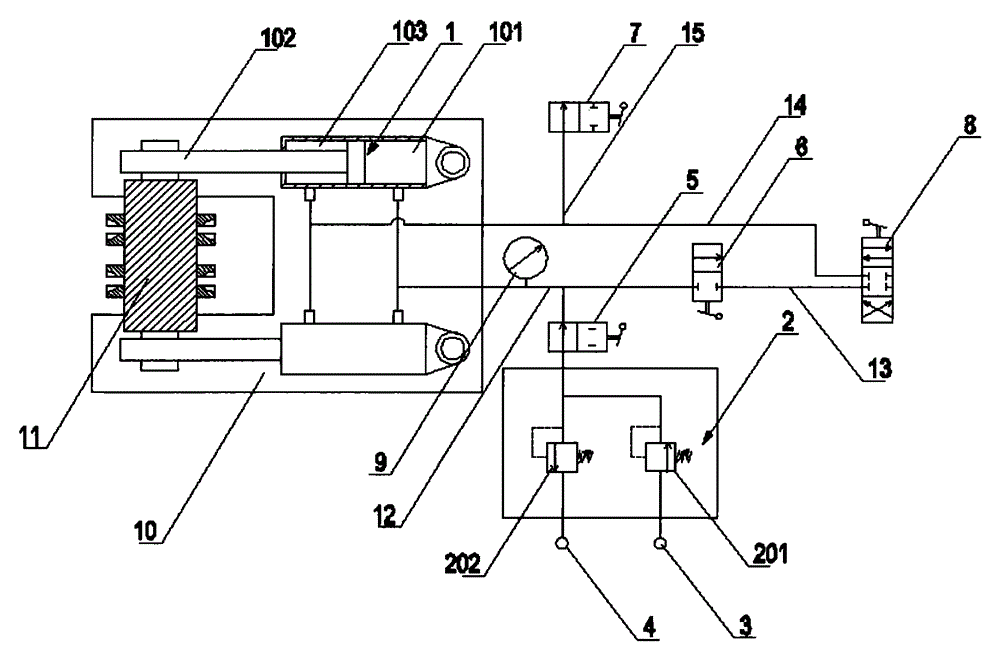

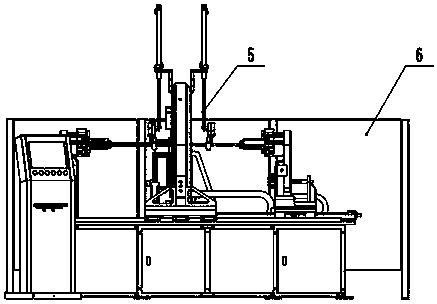

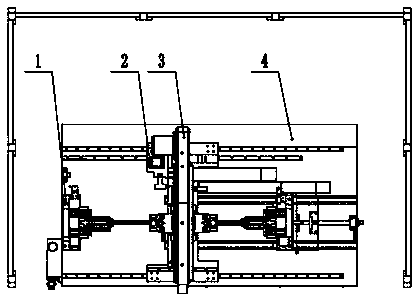

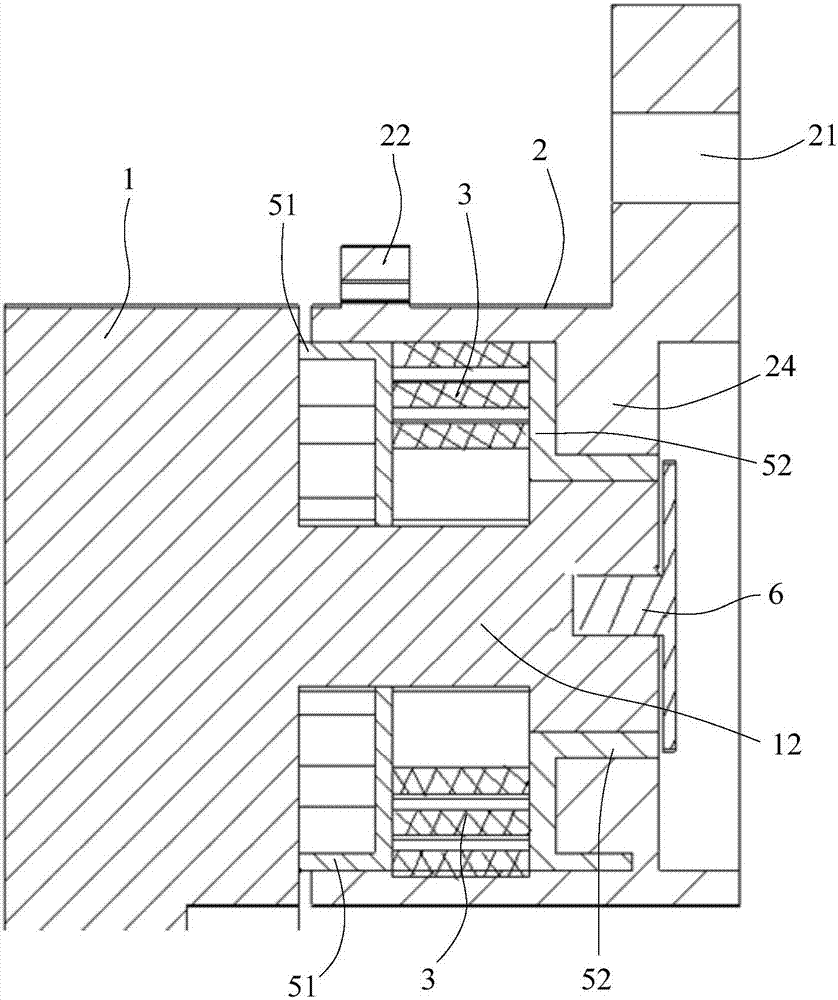

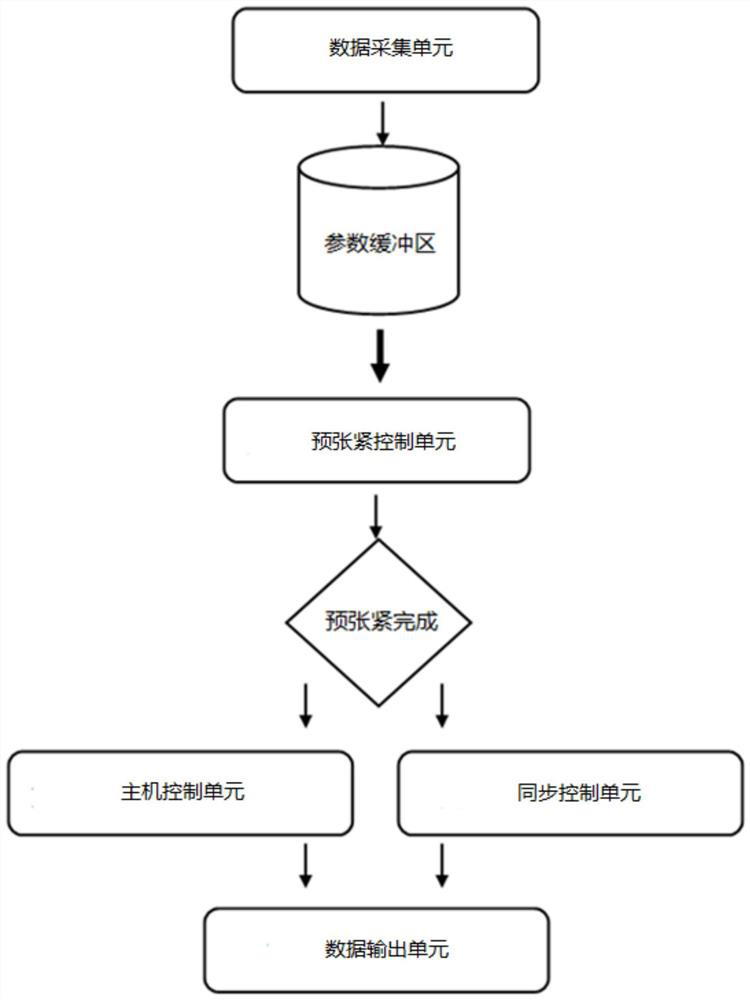

Synchronous tensioning and releasing control system for pre-tensioned track boards

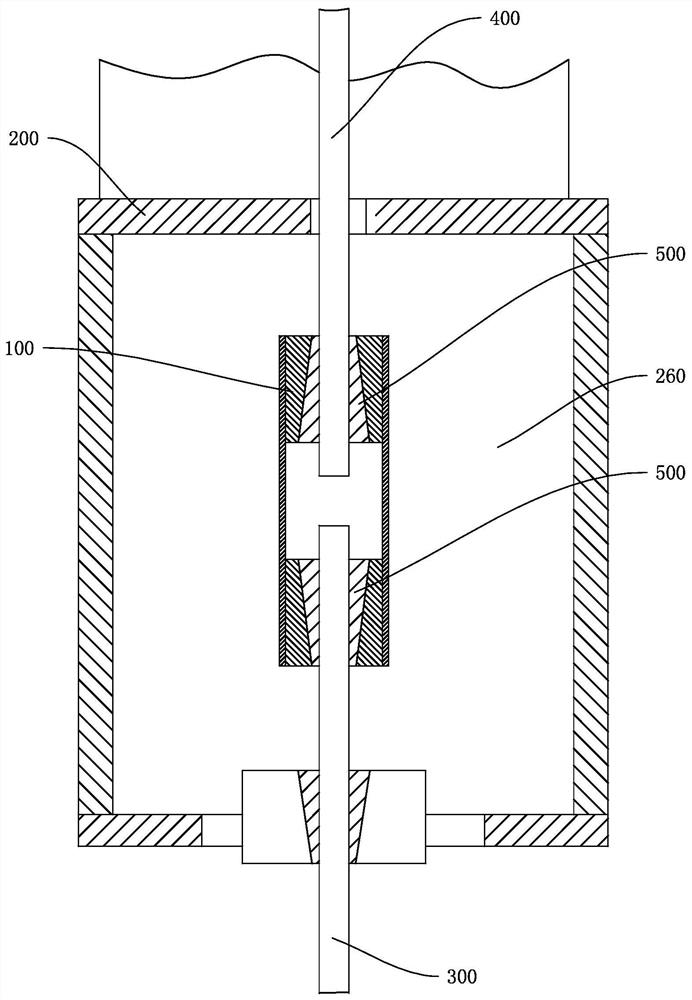

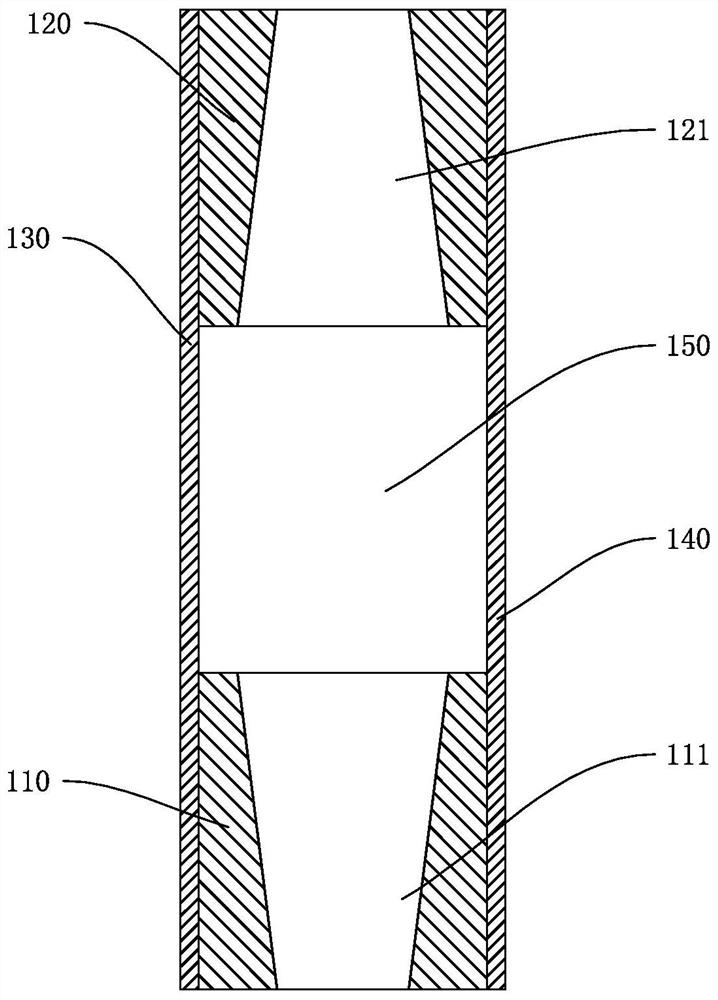

PendingCN105619600ASolve the problem of synchronous tensioningSolving Tension ProblemsCeramic shaping apparatusRebarProduction rate

The invention provides a synchronous tensioning and releasing control system for pre-tensioned track boards, which comprises a pedestal, a plurality of moulds, transverse tensioning cross beams, longitudinal tensioning cross beams and hydraulic actuators, wherein the track boards are placed on the moulds; the hydraulic actuators are located on the inner surface of a tunnel wall outside the pedestal; the transverse tensioning cross beams and the longitudinal tensioning cross beams are connected with the corresponding hydraulic actuators respectively; the moulds are transversely and longitudinally arranged on the pedestal to form a plurality of transverse mould rows and a plurality of longitudinal mould rows on the pedestal; and the transverse mould rows and the longitudinal mould rows are arranged uniformly. The synchronous tensioning and releasing control system for the pre-tensioned track boards solves the problems that conventional track boards cannot be tensioned and released synchronously and the control accuracy, the production efficiency and the yield are low. The synchronous tensioning and releasing control system for the pre-tensioned track boards can meet the production requirements for synchronous or independent tensioning and releasing of transverse and longitudinal pre-stressed reinforcements of track boards, realizes accurate control of a synchronous tensioning and releasing control process, can reach the pre-tensioning force control accuracy of + / -1%, and greatly increase the production efficiency and the yield of track boards.

Owner:SILVERY DRAGON PRESTRESSED MATERIALS CO LTD

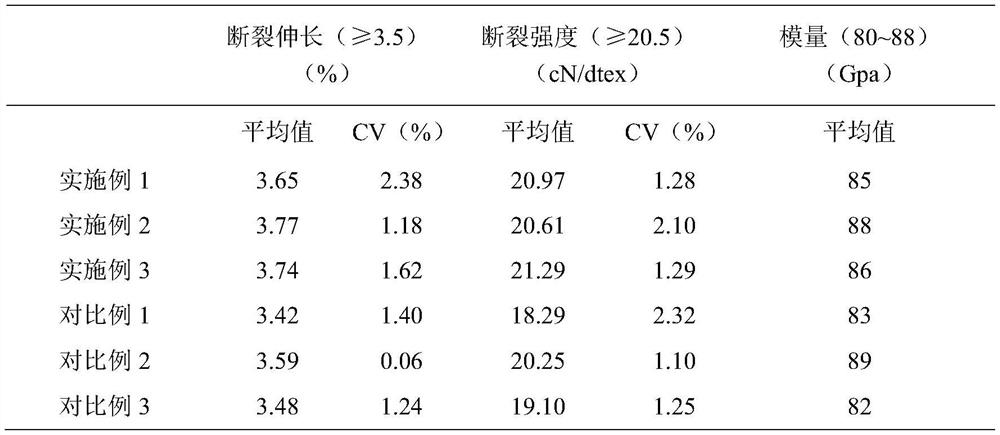

High-elongation low-modulus para-aramid fiber and preparation method thereof

InactiveCN112695390ASolve the problem of unstable elongation controlImprove mechanical propertiesArtificial filament heat treatmentWet spinning methodsPolymer scienceSpinning

The invention discloses a high-elongation low-modulus para-aramid fiber and a preparation method thereof, and belongs to the field of aramid fibers and preparation methods thereof. Low-temperature solution polycondensation and dry-jet wet spinning processes are adopted, so that the problem of non-uniform distribution of polymerization molecular weight is mainly solved, and the distribution of the polymerization molecular weight in a narrower range is realized; a para-aramid spinning process is designed and optimized and a coagulating bath temperature process is set to realize production continuity, and parameters such as fiber orientation degree, nascent fiber mechanical property and the like are controlled to optimize a production process; process setting of temperature in post-treatment processes such as para-aramid washing and drying is carried out, fiber crystallization parameters in a fiber stretching process are controlled, and product performance is improved. The para-aramid fiber obtained based on the preparation method has the elongation at break of greater than or equal to 3.5%, the initial elastic modulus of 80-88 Gpa and the breaking strength of greater than or equal to 20.5 cN / dtex, and meets the application requirements of para-aramid in the fields of automobile rubber tubes, tires and conveyor belts.

Owner:YANTAI TAYHO ADVANCED MATERIALS CO LTD

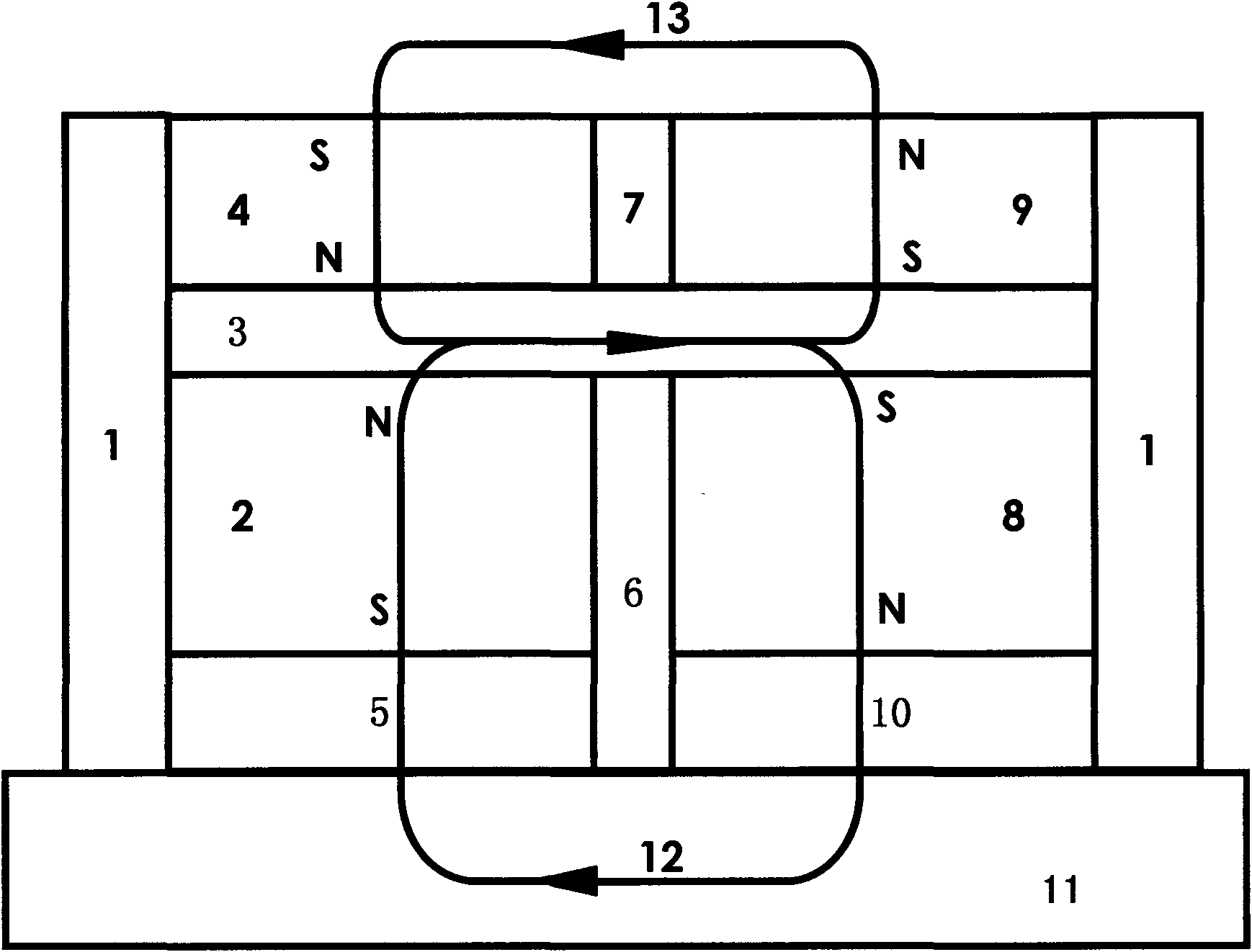

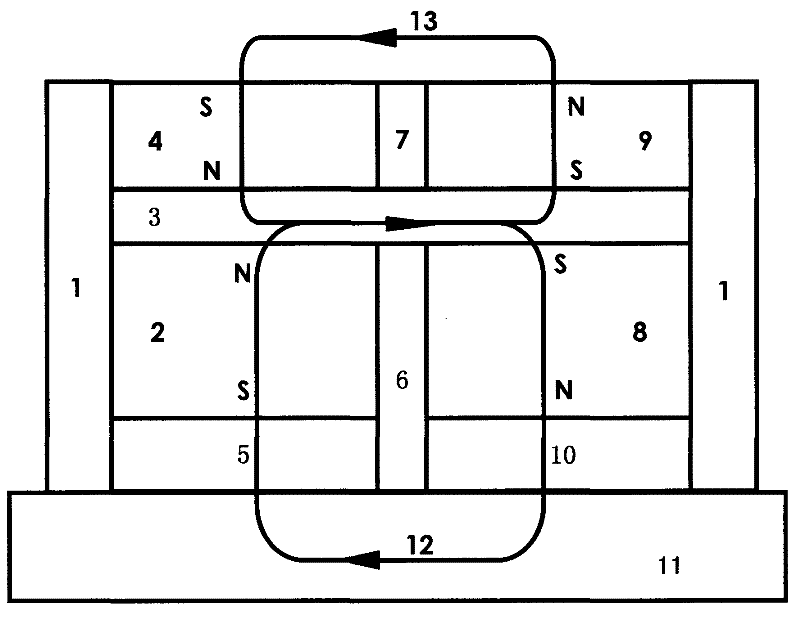

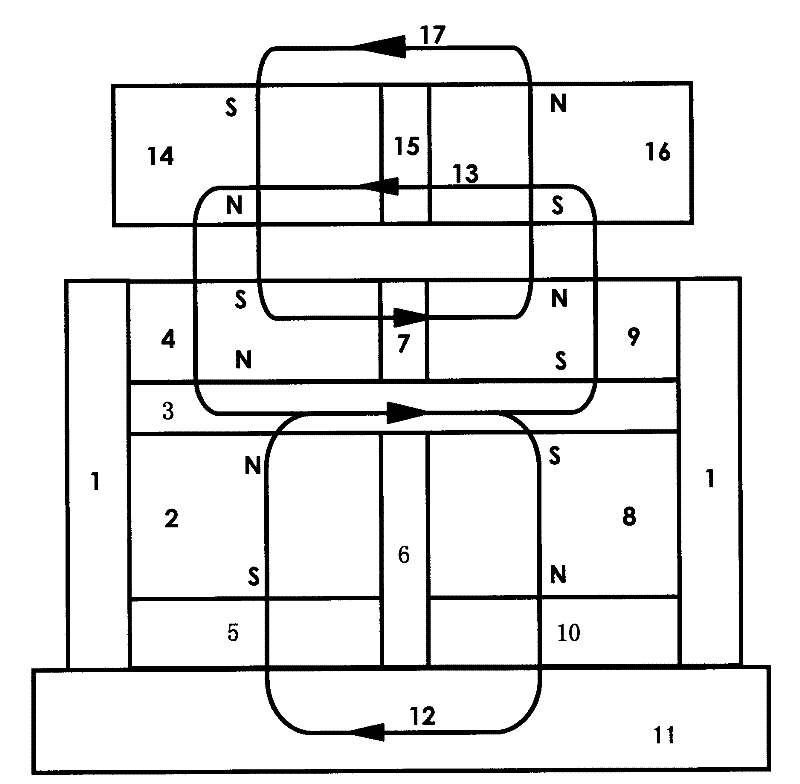

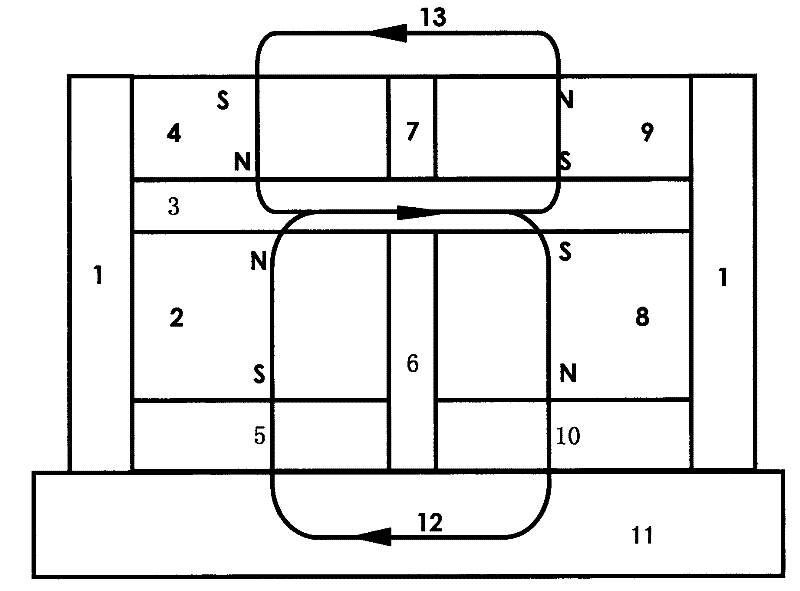

Magnetic absorbing unit for underwater magnetic absorbing wheel-pedrail climbing robot

InactiveCN101638114ASimple structureEasy to implementVehiclesUnderwater equipmentSteel platesClimbing robots

The invention discloses a magnetic absorbing unit for an underwater magnetic absorbing wheel-pedrail climbing robot and relates to a structural design of the magnetic absorbing unit for the magnetic absorbing wheel-pedrail climbing robot. The magnetic absorbing unit comprises a magnetic isolating housing and a yoke, and a first absorbing magnetic block, a second absorbing magnetic block, a first magnetic conductive steel plate, a second magnetic conductive steel plate, a first regulating magnetic block, a second regulating magnetic block, a lower magnetic isolating block and an upper magneticisolating block which are arranged below the yoke respectively form a lower absorbing magnetic circuit and an upper regulating magnetic circuit. The magnetic absorbing unit has simple structure and easy implementation; due to the increase of the regulating magnetic circuit, when the corresponding fixed magnetic absorbing unit is arranged above the pulling-up position of the magnetic absorbing unit, the fixed magnetic absorbing unit and the regulating magnetic circuit attract each other, thereby reducing the pulling-up force and achieving the purposes of reducing the power of a motor and reducing the loads of a flexible crawler. If the fixed absorbing unit is arranged at the tensioning position of the flexible crawler, the fixed absorbing unit can carry out non-contact tensioning on the flexible crawler, thereby solving the contradiction between the tensioning and sealing of the underwater wheel-pedrail magnetic absorbing climbing robot.

Owner:TSINGHUA UNIV

Chain tension automatic adjusting device of scraper conveyer

InactiveCN105059835AHigh adjustment accuracyReduce maintenance frequencyConveyorsLiquid pressureSprocket

A chain tension automatic adjusting device of a scraper conveyer comprises an adjusting hydraulic cylinder, a hydraulic stabilizing mechanism, a liquid inlet pipe connector, a liquid return pipe connector and a shutdown locking button. The adjusting hydraulic cylinder comprises a right cavity, a telescopic rod and a left cavity. The telescopic rod is connected with a chain wheel of the scraper conveyer. The chain wheel of the scraper conveyer is controlled to move leftwards and rightwards through stretching and retracting of the telescopic rod, so that a chain of the scraper conveyer is tensioned or loosened, and the tension of the chain is adjusted. The hydraulic stabilizing mechanism is connected with the right cavity of the adjusting hydraulic cylinder, the liquid inlet pipe connector and the liquid return pipe connector. Liquid is injected into or discharged from the right cavity through the liquid inlet pipe connector or the liquid return pipe connector, so that liquid pressure in the right cavity is kept in a set range, and accordingly the telescopic rod is controlled to stretch and retract. The chain tension automatic adjusting device can guarantee that the chain of the scraper conveyer always runs at optimal tension, the service life of the chain of the scraper conveyer is effectively prolonged, maintenance frequency is reduced, and maintenance strength is reduced. Besides, production efficiency of a fully-mechanized mining face is effectively improved.

Owner:TIANDI SCI & TECH CO LTD

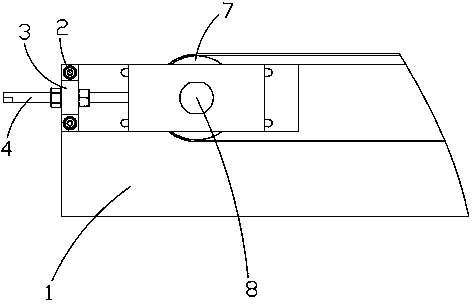

Steel belt tensioning device

The invention provides a steel belt tensioning device which comprises a mounting plate, a belt wheel assembly, a tensioning screw fixing base and tensioning screws. The belt wheel assembly is mounted on the mounting plate. The tensioning screw fixing base is mounted on the mounting plate. Partial tensioning screws are connected to the belt wheel assembly, and partial tensioning screws are connected to the tensioning screw fixing base. The tensioning screws drive the belt wheel assembly to move outwards together when moving outwards relative to the tensioning screw fixing base. The steel belt tensioning device is applied to occasions with narrow space, steel belts can be effectively tensioned through several parts and standard components with simple structures, the parts can be machined conveniently, the performance is reliable and popularization is facilitated.

Owner:SUZHOU VEGA TECH CO LTD

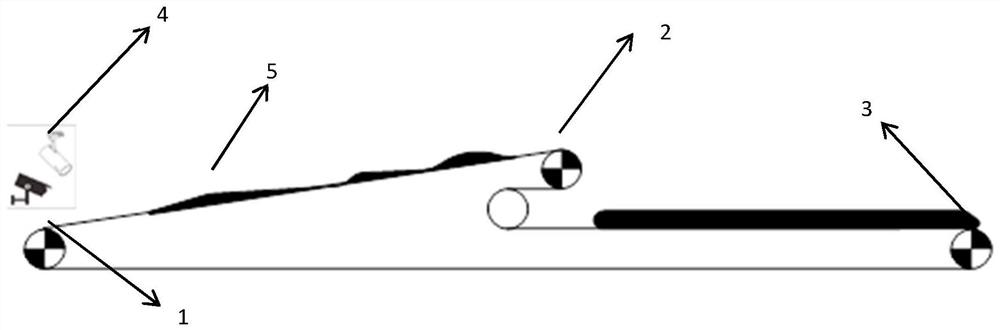

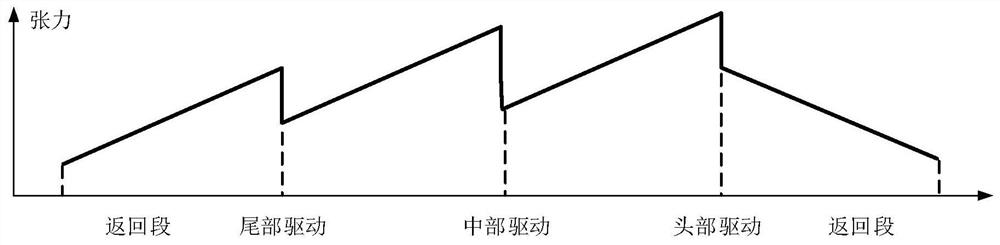

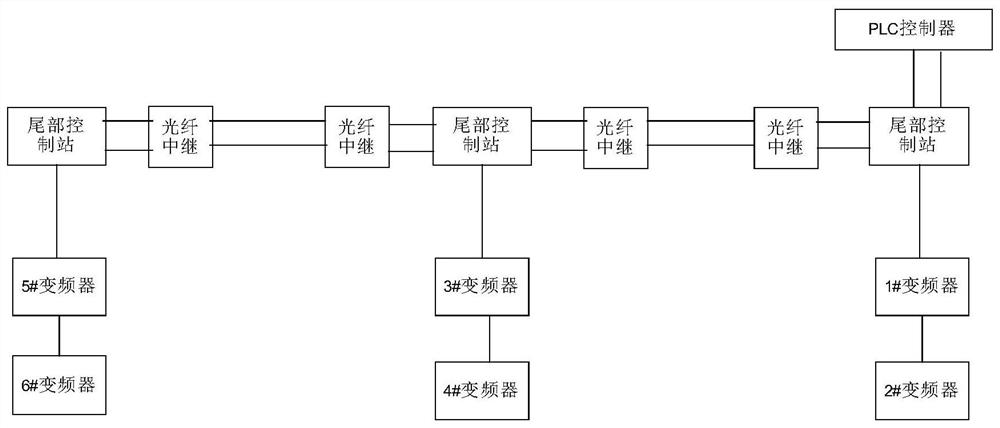

Data-driven multi-drive conveyor torque control method and device

ActiveCN113620024AImprove control performanceImprove securityConveyorsControl devices for conveyorsData-drivenCoordinate control

The invention discloses a data-driven multi-drive conveyor torque control method and device.The control method comprises the following steps: dividing a bearing section of a conveying belt into n equal parts with fixed length, and obtaining the material quantity on each equal part of the conveying belt through an online image loading capacity measurement means; taking the belt speed, the distribution vector, the torque of a main driving unit, the torque of a middle driving unit and the torque of a tail driving unit as input quantities, and establishing a data driving learning model of the torque deviation of the main driving unit and the middle driving unit and the torque deviation of the middle driving unit and the tail driving unit. By means of the online loading capacity measurement means, a torque deviation prediction model is obtained by adopting a data driving method so as to realize coordination control between the master driving unit and the slave driving unit. The control performance of an unloading type multi-point driving conveyor is improved, and the safety of the conveyor is improved. Modeling training is completed through the LSSVM, the requirements for storage space and online computing power are low, the method is suitable for industrial controllers such as a PLC, and the problem of tension of an unloading point rubber belt of an unloading type multi-point driving belt conveyor is solved.

Owner:HUZHOU ELECTRIC POWER SUPPLY CO OF STATE GRID ZHEJIANG ELECTRIC POWER CO LTD +1

Prestressed reinforcement reinforcing system used for dome ring beam and construction method of prestressed reinforcement reinforcing system

PendingCN112227527AReduce stress and deformationReduce the generation of concrete cracksWallsBuilding reinforcementsRebarReinforced concrete

Owner:CNOOC GAS & POWER GRP +1

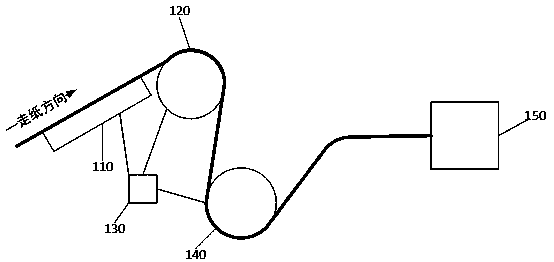

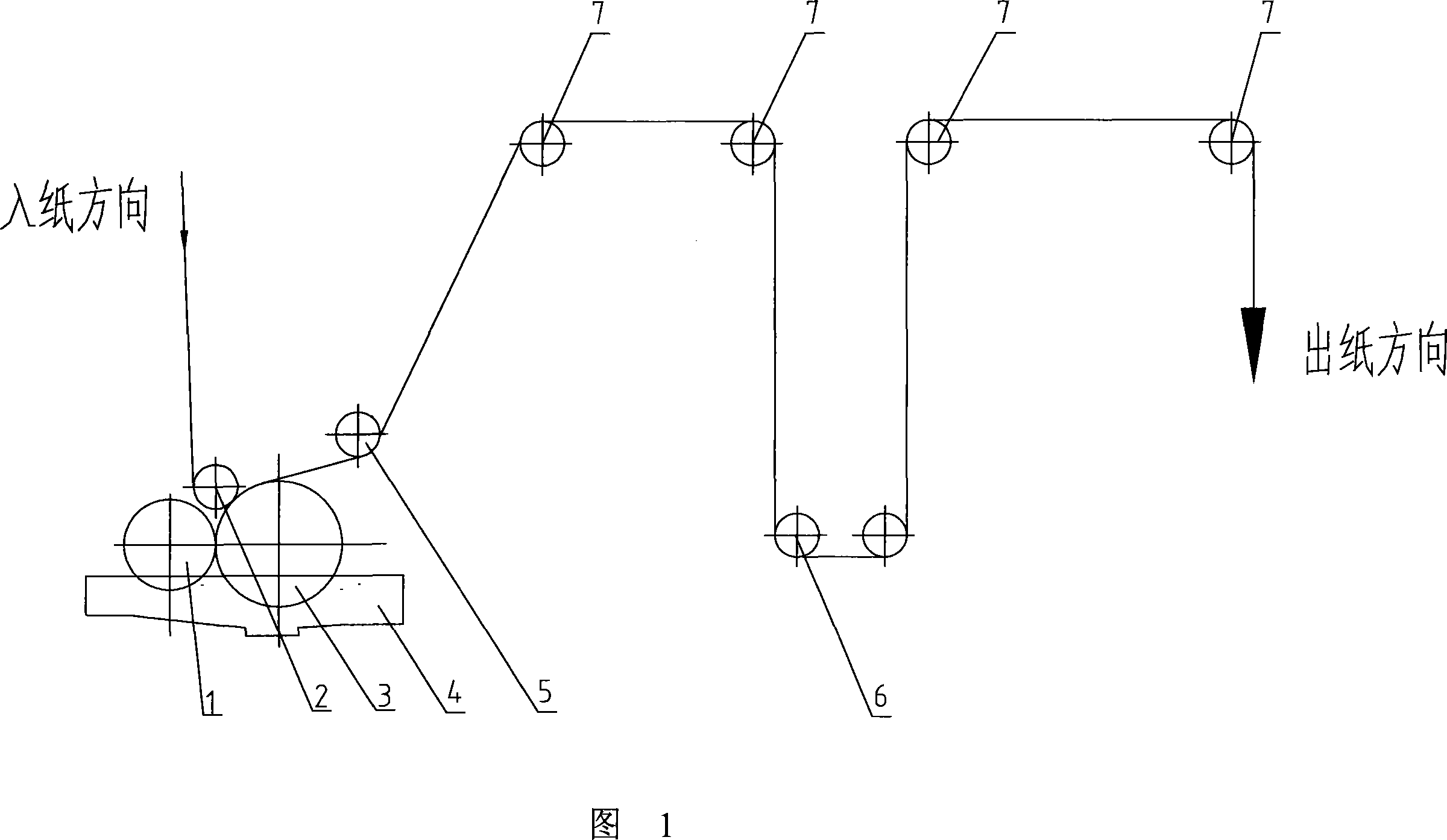

A Tension Control Mechanism for Printing Machine Cloth

ActiveCN103331992BAdjustable tensionSolving Tension ProblemsRotary pressesElectric machineryEngineering

A tension control mechanism of cloth of a printing machine comprises fixing plates, swinging arms, a tension roller component, and angle adjustment components, wherein each swinging arm is pivoted on each fixing plate by a pivot; a sliding groove is formed in each swinging arm, and internally provided with a rolling component capable of moving in a length direction of the sliding groove; first limit switches and second limit switches are arranged on the swinging arms; signal input ends of the first limit switches and the second limit switches are connected with a controller controlling a cloth feeding motor of the printing machine; the tension roller component is positioned at the outer side end parts of the swinging arms; the end parts of the tension roller component are pivoted on the rolling components; and the angle adjustment components are used for driving the inner side ends of the swinging arms to allow the swinging arms to rotate relative to the fixing plates. According to the mechanism, a tension roller slides along the swinging arms to trigger the different limit switches, correspondingly controls the on and off of the cloth feeding motor, and realizes automatic cloth feeding. Since angles of the swinging arms are adjustable, and the swinging arms can be fixed at the adjusted angles, tension force of the tension roller on the cloth is adjustable and can be kept constant; and the cloth tension is realized effectively.

Owner:SHENZHEN TEXTALK GRAPHIC TECH

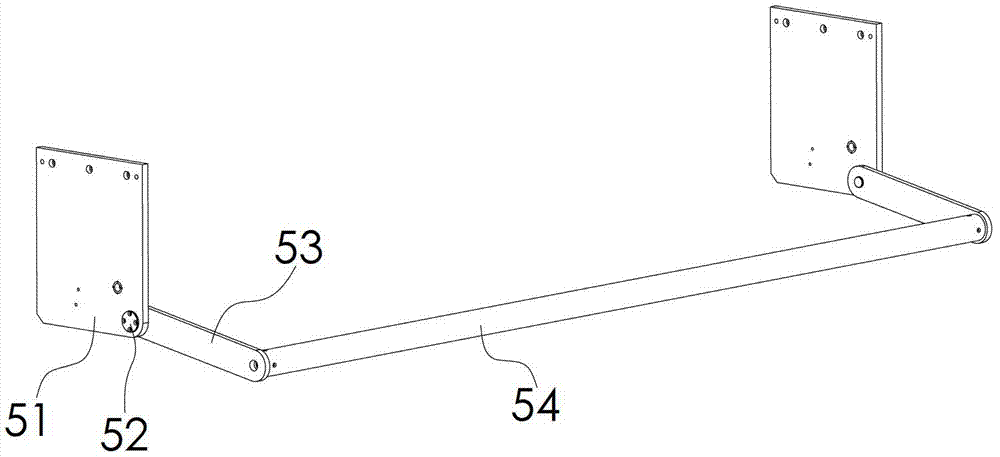

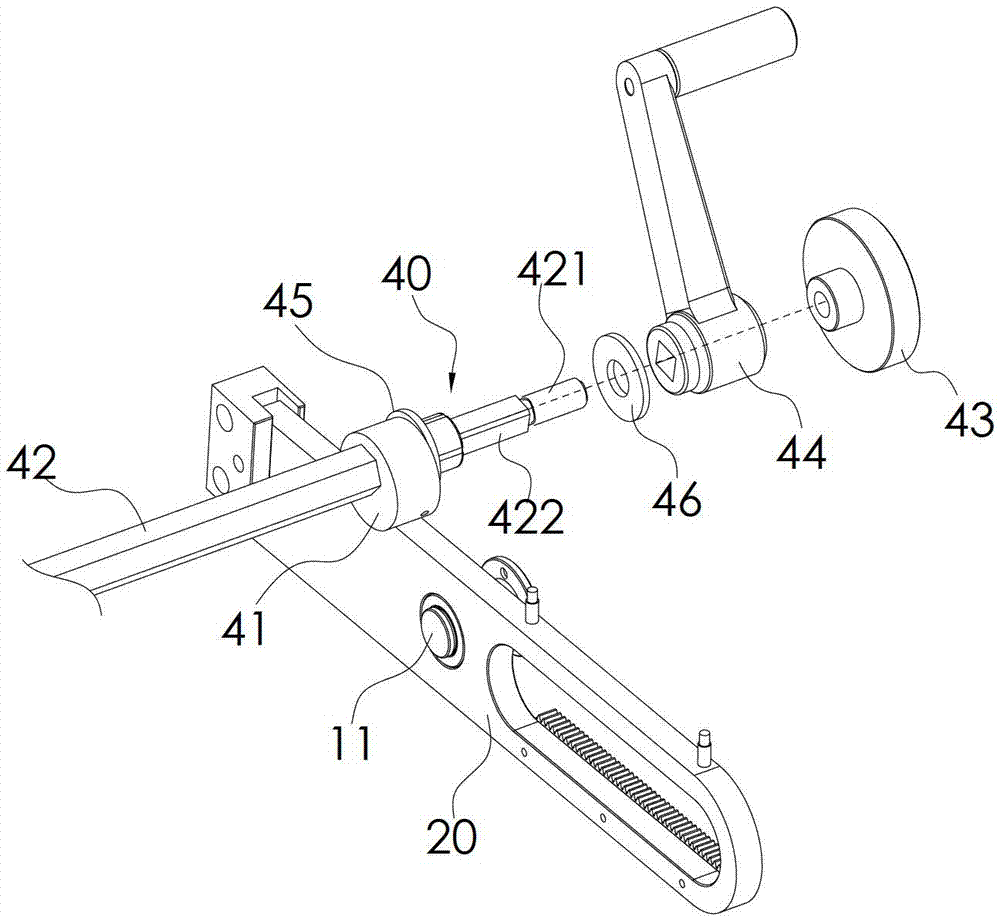

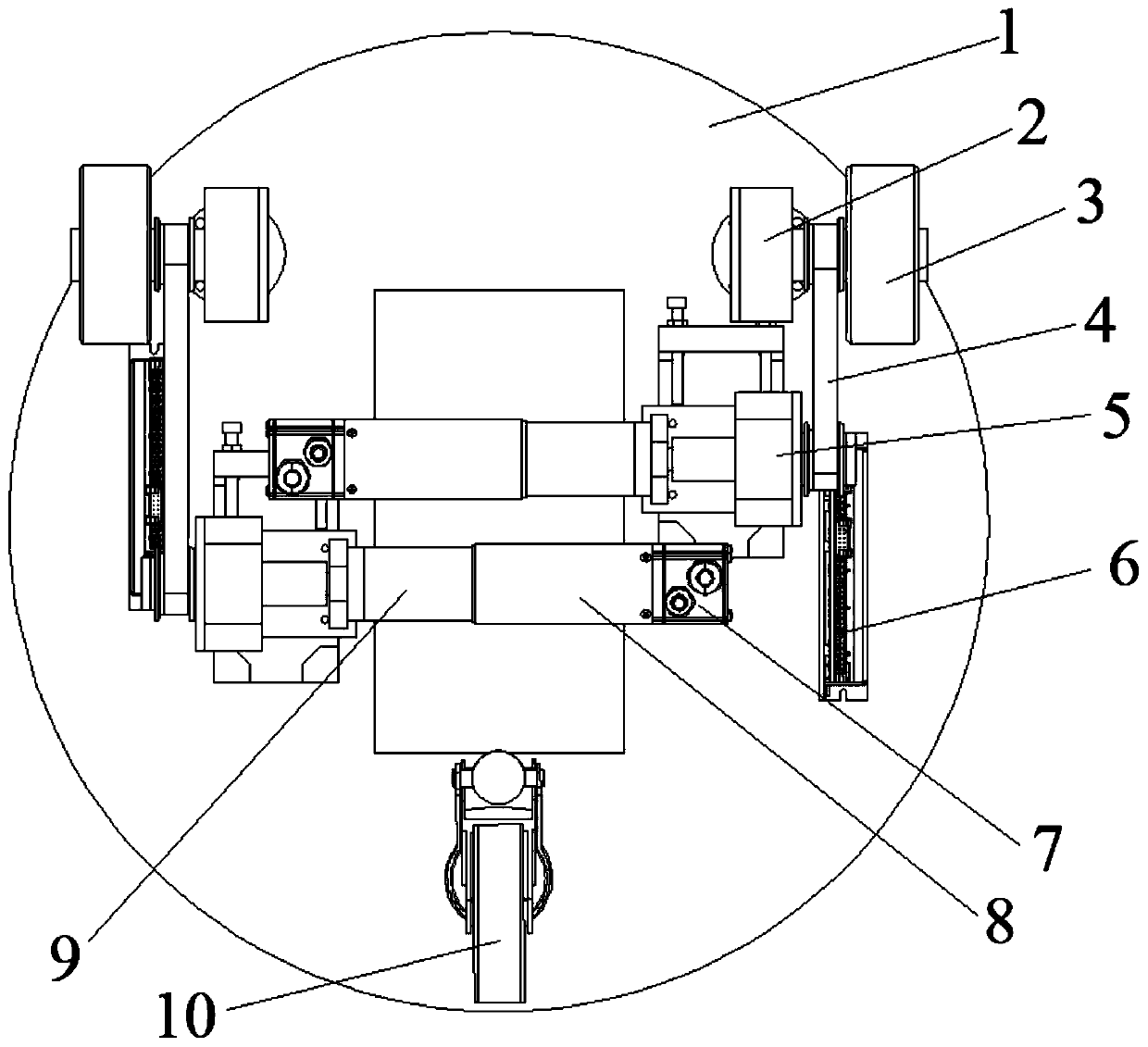

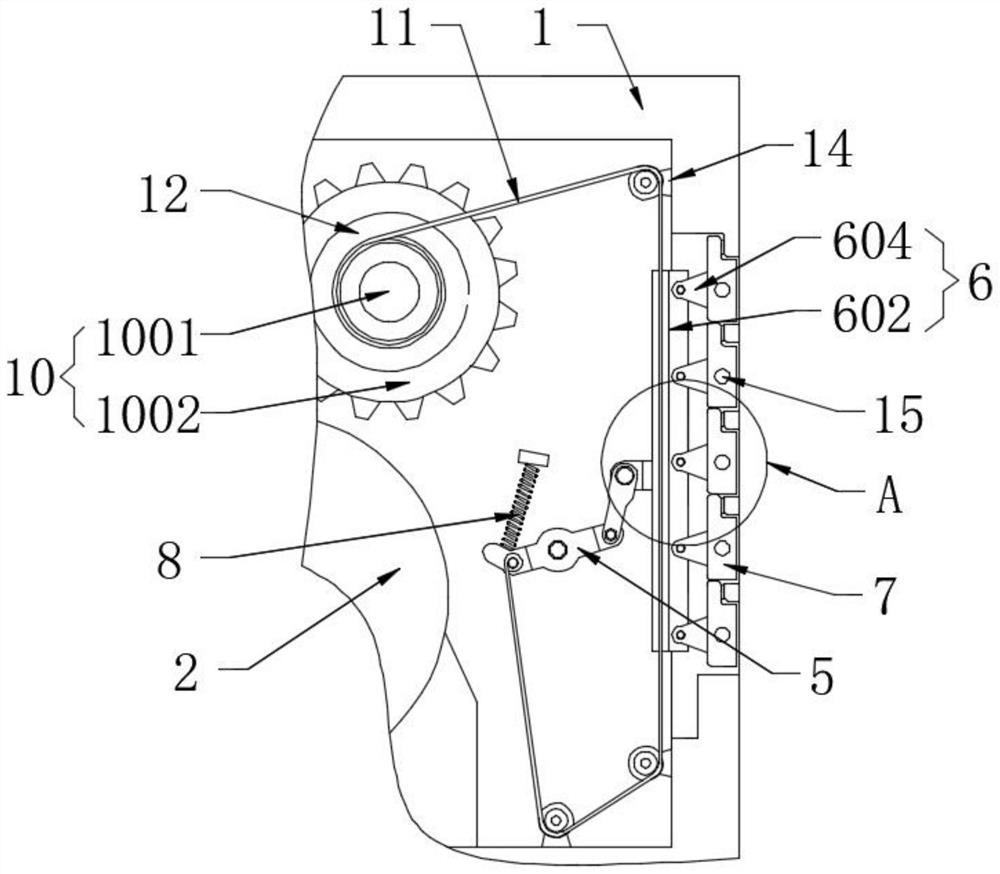

Single-freedom rehabilitation mechanical hand driving device

InactiveCN106272404ASolving Tension ProblemsAvoid harmProgramme-controlled manipulatorEngineeringDrive motor

The invention provides a single-freedom rehabilitation mechanical hand driving device, and relates to a mechanical hand driving device. The single-freedom rehabilitation mechanical hand driving device solves the problems that the existing rehabilitation finger driving device uses rope driving; the rope friction and deformation exist in the rope driving; the rope tension is caused. An output shaft of a driving motor passes through one end of the first section of connecting rod to be fixedly connected with a first joint shaft; a synchronous belt is arranged on a first synchronous belt wheel and a second synchronous belt wheel; a gear is fixedly arranged on the other end of the first section of connecting rod through a first convex sleeve; the upper part of the second section of connecting rod is rotationally connected with the other end of the first section of connecting rod through a second joint shaft; a third joint shaft is arranged at the lower part of the second section of connecting rod; a half gear is fixedly sleeved on the third joint shaft; the gear and the half gear are mutually engaged; the second convex sleeve and the upper end of the third section of connecting rod are sleeved on the third joint shaft; a locking clamp groove is positioned in a position of being rotationally connected with the third section of connecting rod through a pin shaft; one end of the driving rod passes through the fixing block to be arranged in a through hole in a penetrating way. The single-freedom rehabilitation mechanical hand driving device is used for driving a mechanical hand.

Owner:HARBIN INST OF TECH

Steel strand releasing auxiliary tool and prestressed steel strand releasing method

PendingCN112878202ASolve the problem of extensionSolving Tension ProblemsBridge erection/assemblyBuilding material handlingPre stressMaterial consumption

The invention discloses a steel strand releasing auxiliary tool and a prestress steel strand releasing method. The steel strand releasing auxiliary tool comprises: a steel strand connecting component, wherein a first clamping piece taper hole and a second clamping piece taper hole are oppositely formed in the two ends of the steel strand connecting component, and conical clamping pieces are arranged in the first clamping piece taper hole and the second clamping piece taper hole; and a jack jacking table which comprises an upper platform plate and a base, wherein a steel strand hole is formed in the upper platform plate, a bottom hole is formed in the bottom of the base, and the steel strand connecting component can penetrate through the bottom hole and move towards the steel strand hole in the jack jacking table. The auxiliary tool is simple in structure, convenient to mount, low in material consumption and low in use cost; the auxiliary tool can be recycled, and clamping pieces can be removed after releasing, so that repeated utilization can be realized; and the auxiliary tool is novel in structure, and solves the problems of lengthening and releasing of steel strands.

Owner:CRCC HARBOR & CHANNEL ENG BUREAU GRP

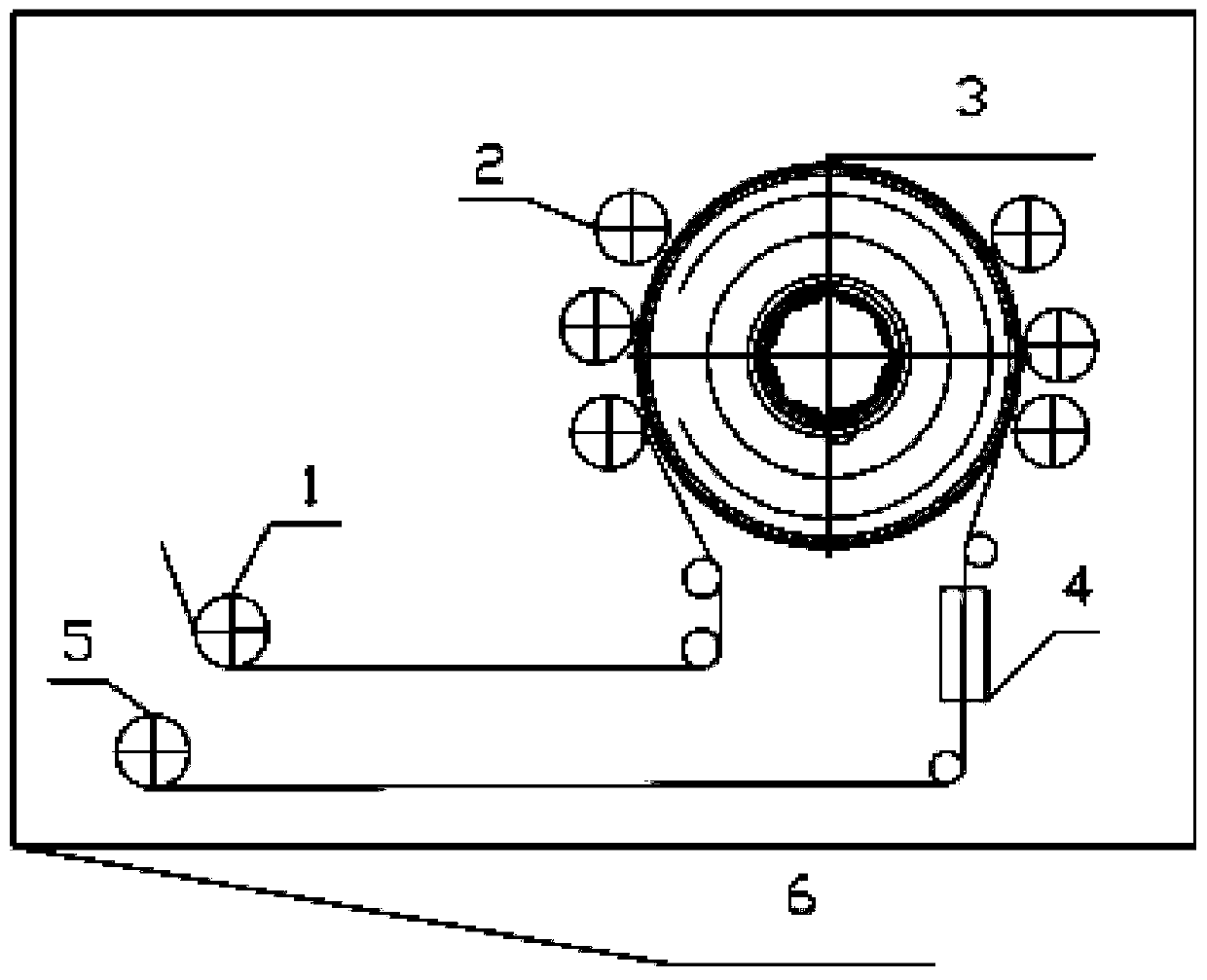

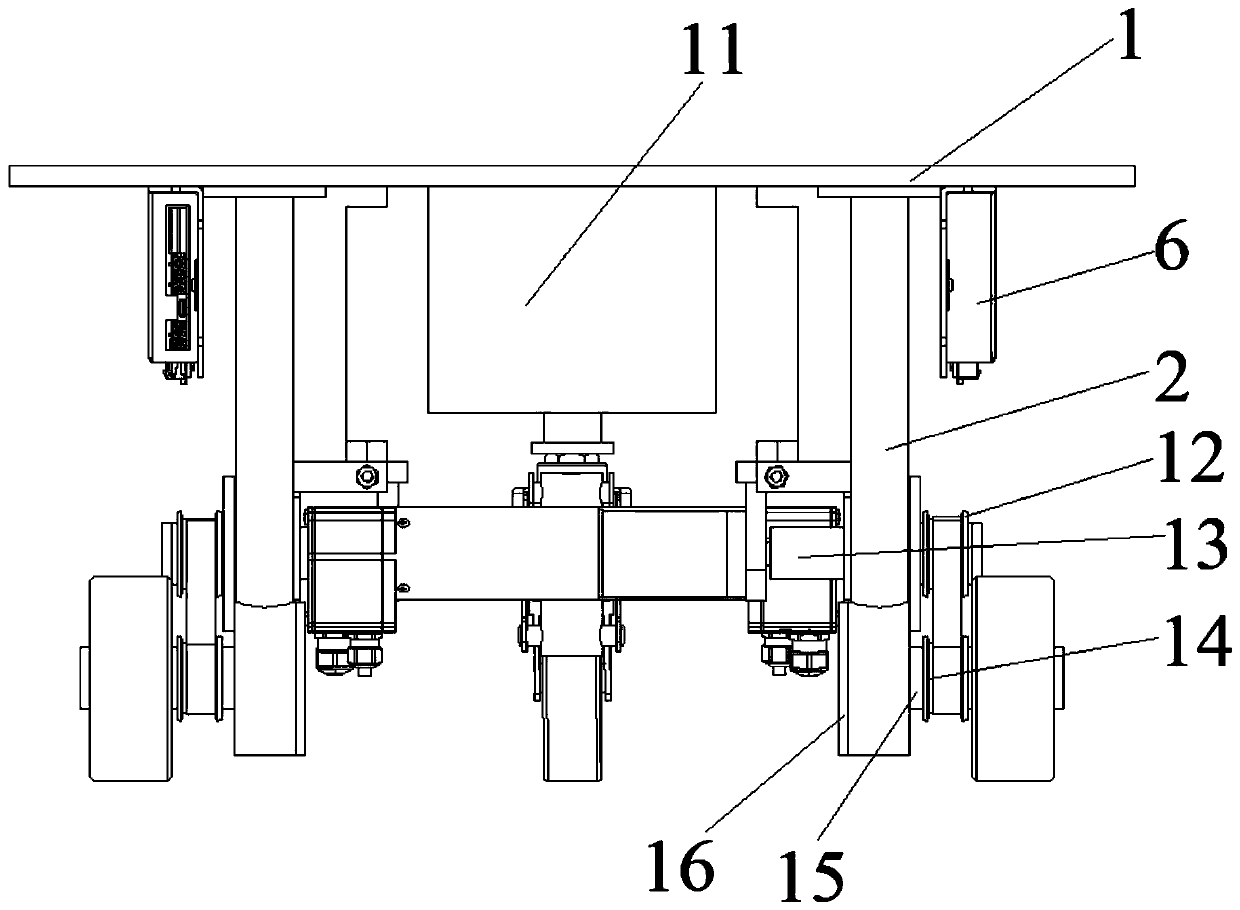

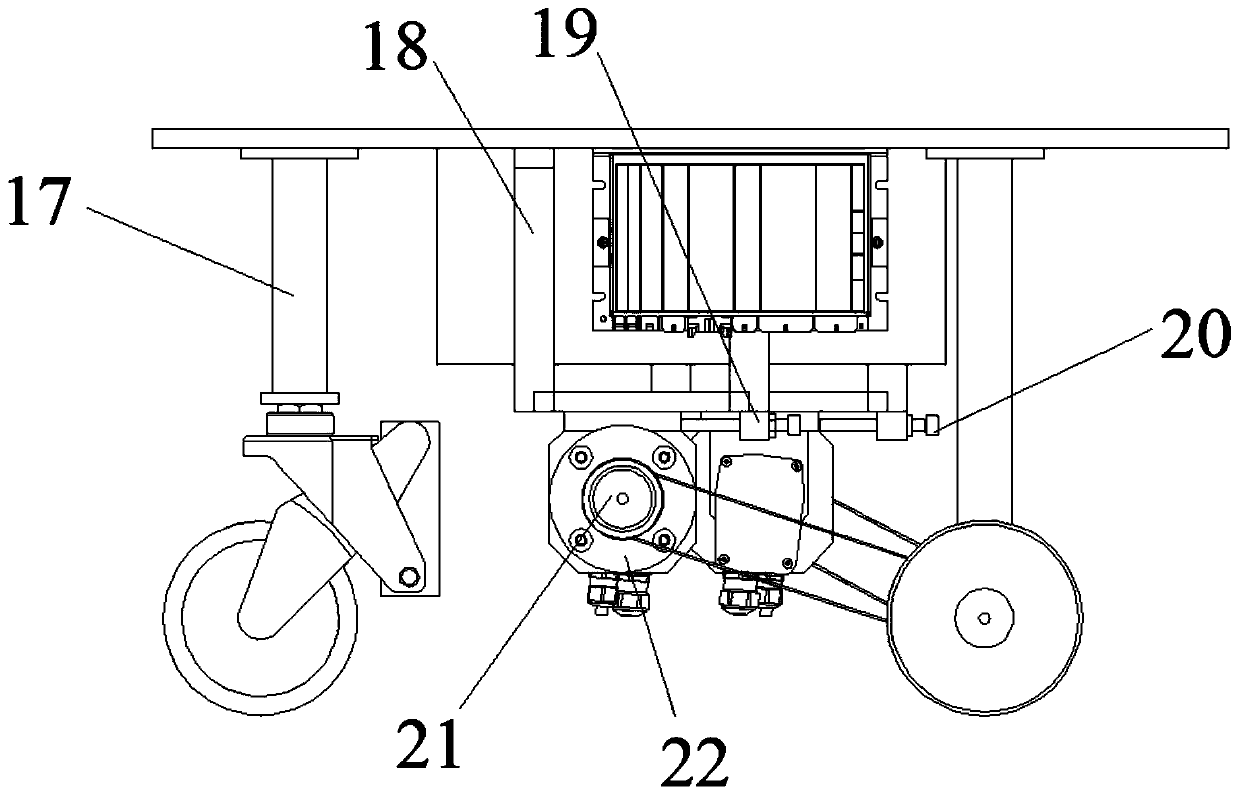

Differential drive mobile robot platform

InactiveCN111452883ASolving Tension ProblemsThe structure is simplified and reasonableElectric propulsion mountingVehiclesDrive wheelControl engineering

The invention belongs to the field of robots, and particularly relates to a differential drive mobile robot platform, which is based on a wheel type moving mechanism, and is characterized by comprising a bottom plate and two driving wheels arranged at the bottom of the bottom plate, and the two driving wheels are each controlled and driven by a driving mechanism and transmission mechanism group. Athree-wheel structure is adopted, differential driving is achieved through the two driving wheels, one universal wheel is used for balancing and steering, the structure is more reasonable and simplerthan that of four wheels, the cost is saved, and advancing, retreating and steering of different radiuses of the moving mechanism are achieved by controlling the rotating speeds of the two motors; meanwhile, the tensioning mechanism is arranged, so that the tensioning problem of a synchronous belt is simply and skillfully solved, the space is saved, and the transmission efficiency is improved.

Owner:CHANGZHOU INST OF DALIAN UNIV OF TECH

A Sun Blanket Even Load, Tension, Displacement Compensation Mechanism

ActiveCN106240847BRealize the displacement compensation functionSolving Tension ProblemsCosmonautic vehiclesCosmonautic power supply systemsIn planePull force

The invention discloses a solar carpet uniform loading, tensioning and displacement compensation mechanism. By applying the solar carpet uniform loading, tensioning and displacement compensating mechanism, when expansion displacement of a solar wing is generated due to spatial high-low temperature alternation, uniform and constant tensioning force can be provided, the effect that the solar wing has stable rigidity property is guaranteed, the displacement compensation dimension is large, and the interference resistance is high. The solar carpet uniform loading, tensioning and displacement compensating mechanism is composed of a constant torque spring taking-up mechanism, tensioning steel wire ropes, a uniform loading beam, uniform loading springs, a flexible transitional carpet and piano wire hinges. By changing the lengths of the tensioning steel wire ropes, the displacement, generated by shrinkage and expansion, of a flexible solar carpet is compensated, and the effect that the tensile force of the tensioning steel wire ropes is constant all the time is guaranteed. Through the uniform loading beam, the uniform loading springs and the flexible transitional carpet, the concentrated tensile force transferred from the tensioning steel wire ropes is dispersed into the in-plane acting force uniformly, and the purpose of uniform loading is achieved.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

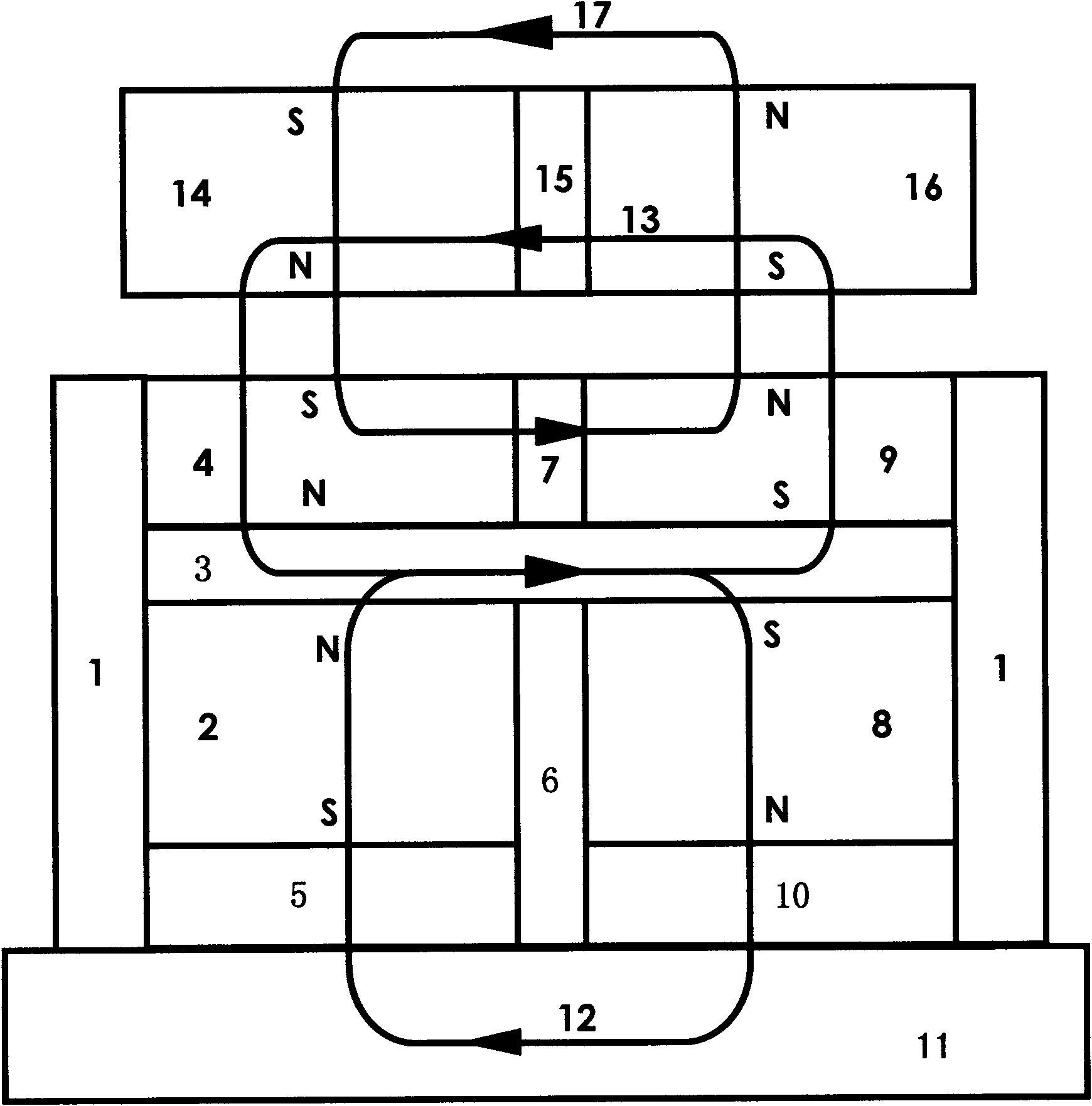

Magnetic absorbing unit for underwater magnetic absorbing wheel-pedrail climbing robot

The invention discloses a magnetic absorbing unit for an underwater magnetic absorbing wheel-pedrail climbing robot and relates to a structural design of the magnetic absorbing unit for the magnetic absorbing wheel-pedrail climbing robot. The magnetic absorbing unit comprises a magnetic isolating housing and a yoke, and a first absorbing magnetic block, a second absorbing magnetic block, a first magnetic conductive steel plate, a second magnetic conductive steel plate, a first regulating magnetic block, a second regulating magnetic block, a lower magnetic isolating block and an upper magnetic isolating block which are arranged below the yoke respectively form a lower absorbing magnetic circuit and an upper regulating magnetic circuit. The magnetic absorbing unit has simple structure and easy implementation; due to the increase of the regulating magnetic circuit, when the corresponding fixed magnetic absorbing unit is arranged above the pulling-up position of the magnetic absorbing unit, the fixed magnetic absorbing unit and the regulating magnetic circuit attract each other, thereby reducing the pulling-up force and achieving the purposes of reducing the power of a motor and reducing the loads of a flexible crawler. If the fixed absorbing unit is arranged at the tensioning position of the flexible crawler, the fixed absorbing unit can carry out non-contact tensioning on the flexible crawler, thereby solving the contradiction between the tensioning and sealing of the underwater wheel-pedrail magnetic absorbing climbing robot.

Owner:TSINGHUA UNIV

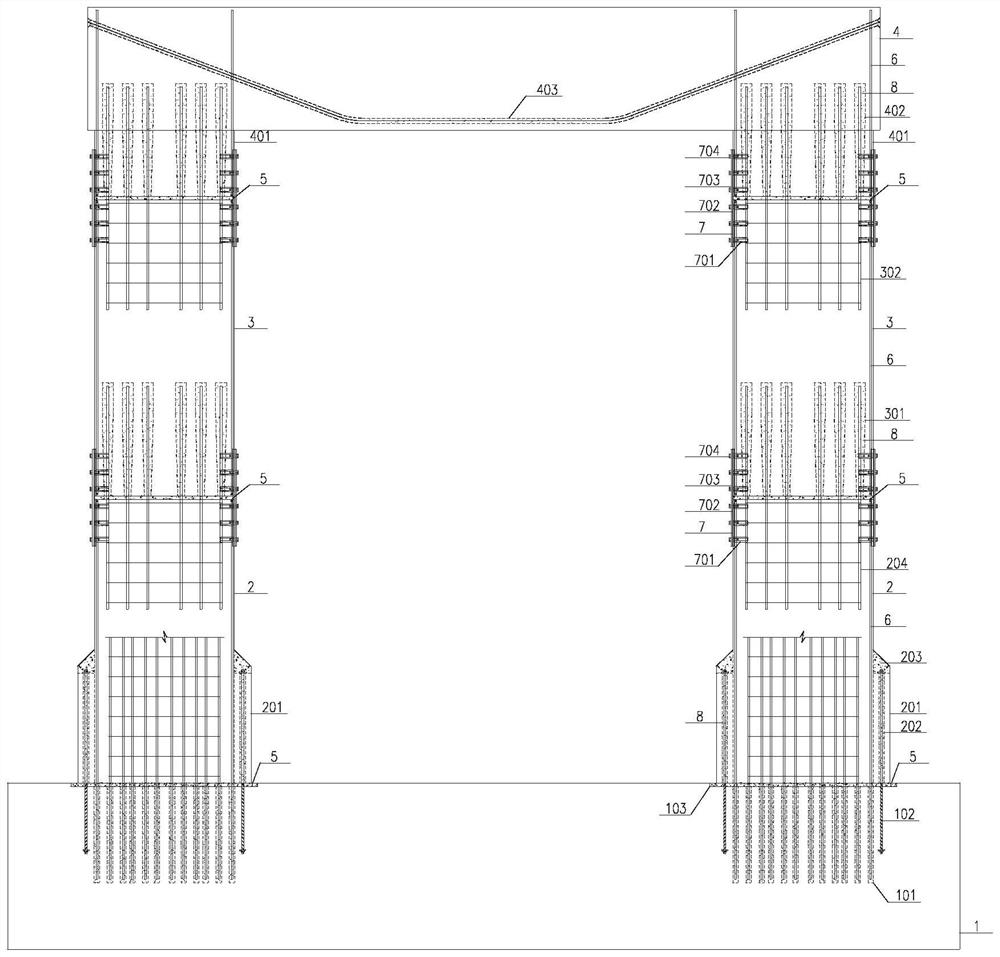

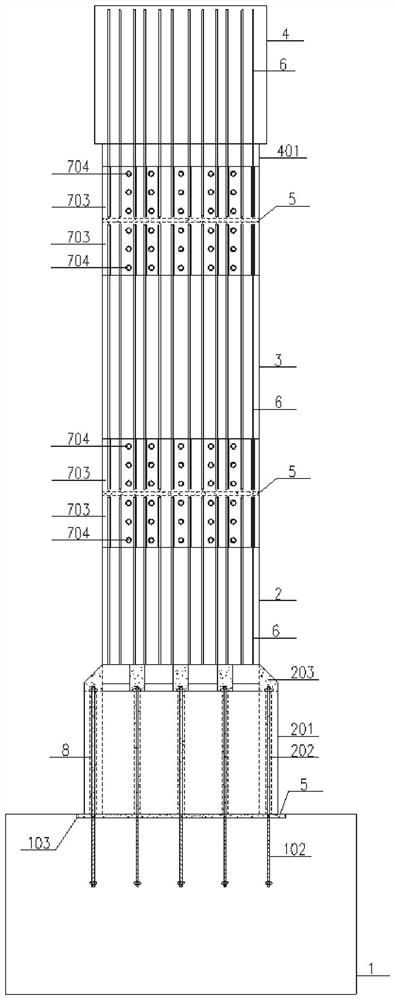

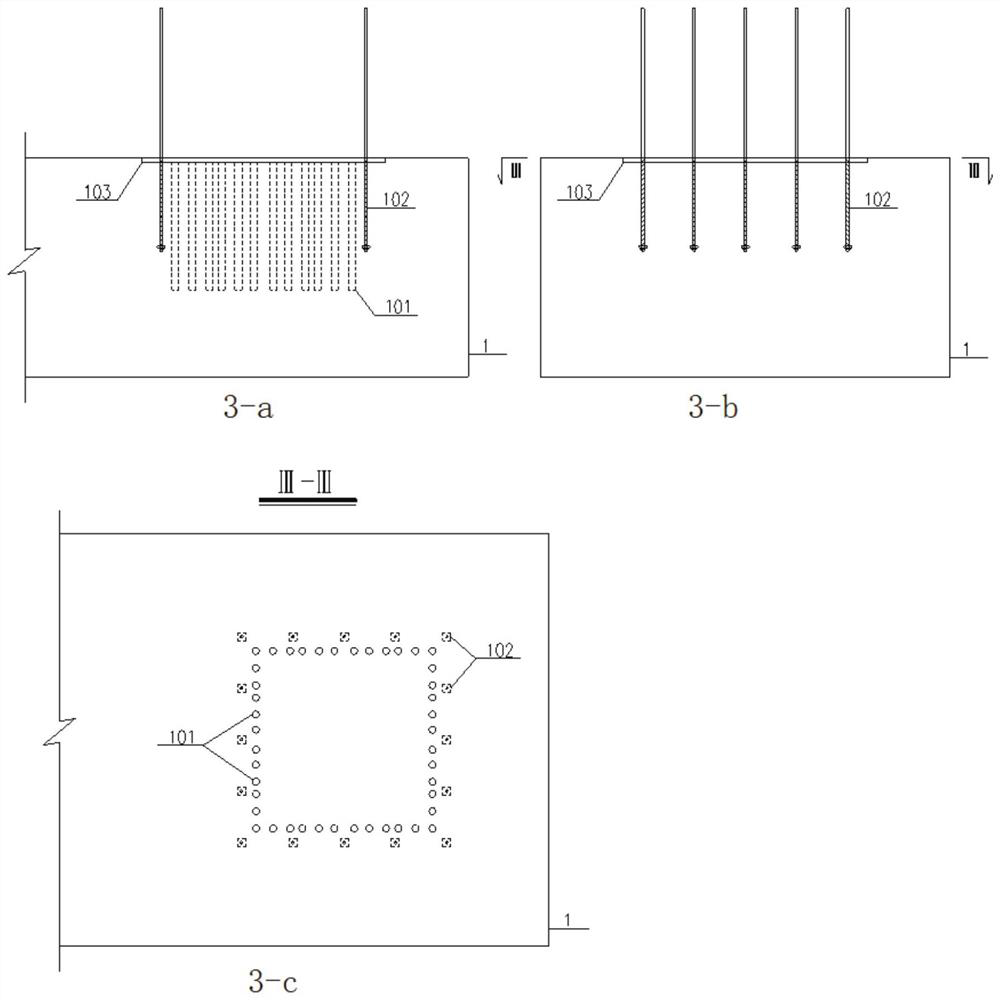

Prefabricated and assembled frame pier with large cross beams and high stand columns and construction method

PendingCN113123214AImprove tensile propertiesImprove shear resistanceBridge structural detailsBridge erection/assemblyArchitectural engineeringRebar

The invention provides a prefabricated and assembled frame pier with large cross beams and high stand columns and a construction method. The frame pier comprises a foundation, a bottom section pier column, a middle section pier column and a cross beam; when the foundation is constructed, steel bar embedded pipes and embedded thick steel bars are arranged, and joint notches are formed; a transition section is arranged below the bottom section pier column during prefabrication, thick steel bar reserved hole channels and sealing anchors are arranged in the transition section, connecting steel bars extend out of the bottom face of the bottom section pier column, and steel plate connecting pieces are embedded in the top face of the bottom section pier column. During prefabrication of the middle-section pier column, steel bar embedded pipes are arranged at the bottom, connecting steel bars are arranged at the top, and steel plate connecting pieces are embedded; when the cross beam is prefabricated, extending columns are arranged at the positions corresponding to pier columns, steel bar embedded pipes are embedded, and steel plate connecting pieces are embedded. The foundation is connected with the bottom-section pier column through thick steel bars and main bars, the bottom-section pier column is connected with the middle-section pier column through connecting steel bars and steel plate connecting pieces, and the middle-section pier column is connected with the cross beam through the connecting steel bars and steel plate connecting pieces. The structure effectively ensures the strength and durability of each joint, and is suitable for the prefabricated assembled frame pier adopting large cross beams and high stand columns.

Owner:CHINA RAILWAYS CORPORATION +1

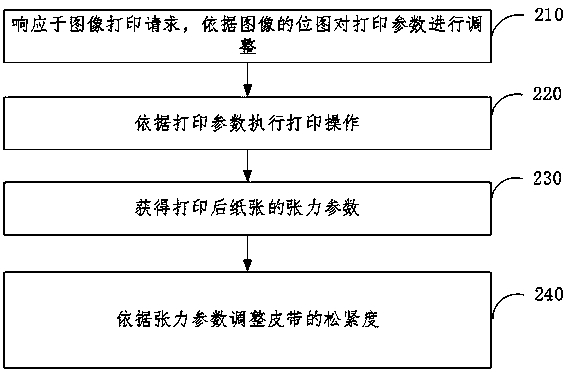

Printing die cutting tension automatic control system and control method

ActiveCN110861419ARealize automatic controlSolving Tension ProblemsInksOther printing apparatusAutomatic controlControl system

The invention discloses a printing die cutting tension automatic control system and control method. The method comprises the following steps of responding to an image printing request, and according to an image bitmap, adjusting printing parameters; according to the printing parameters, executing printing operation; and obtaining tension parameters of paper after printing; and according to the tension parameters, adjusting the elastic degree of the belt. The printing die cutting tension automatic control system and method can achieve automatic control over the printing die cutting, bitmap information in the image is extracted, the position of the printing image is adjusted through a controller, and tension generated during printing can be avoided.

Owner:中体彩印务技术有限公司

Anchoring structure with pre-stressed anchor rods arranged in staggered twisting mode

The invention relates to the technical field of anchoring structures, and discloses an anchoring structure with pre-stressed anchor rods arranged in a staggered twisting mode, the anchoring structure comprises anchor holes, a plurality of anchor bars and anchorage devices, and each anchor bar is provided with an inner section and an outer section; the inner section comprises a bonding section and a free section; the anchor hole is filled with slurry, the slurry wraps the bonding section and the free section, the slurry is bonded and fixed to the stratum and the bonding section, the free section is sleeved with an isolation layer, and the isolation layer is bonded and fixed to the slurry; the isolating layers on the anchor bars are different in length and are arranged in a staggered twisting mode. The free sections of the anchor bars are sleeved with the isolation layers, the lengths of the isolation layers on the anchor bars are arranged in the staggered rubbing shape, the lengths of the free sections of the anchor bars are different, and therefore when tensioning and anchoring are conducted, only one jack is needed to conduct anchoring on the anchor bars at the same time, and obvious tension difference or deformation difference cannot be generated; the anchor rod which is tensioned and anchored can obtain the same high bearing capacity as that of a tension dispersing type anchor rod.

Owner:SHENZHEN GONGKAN GEOTECHN GRP

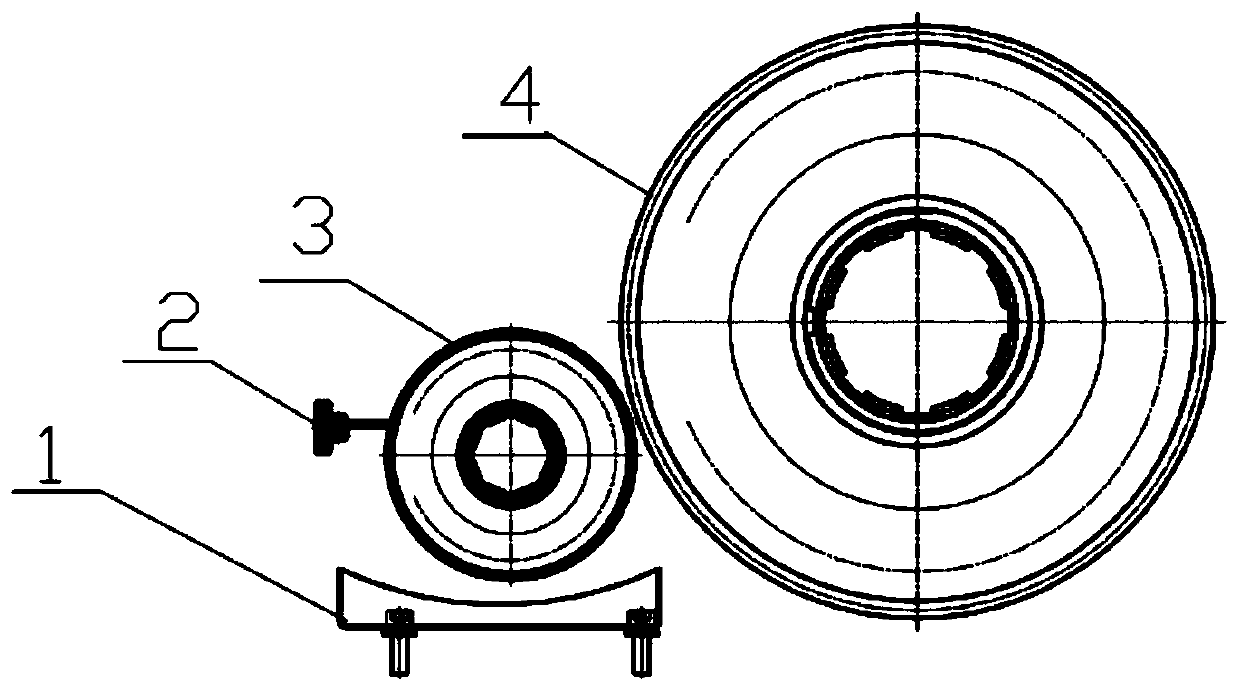

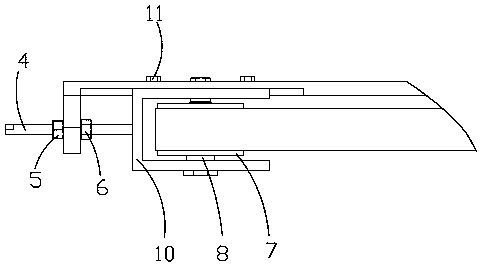

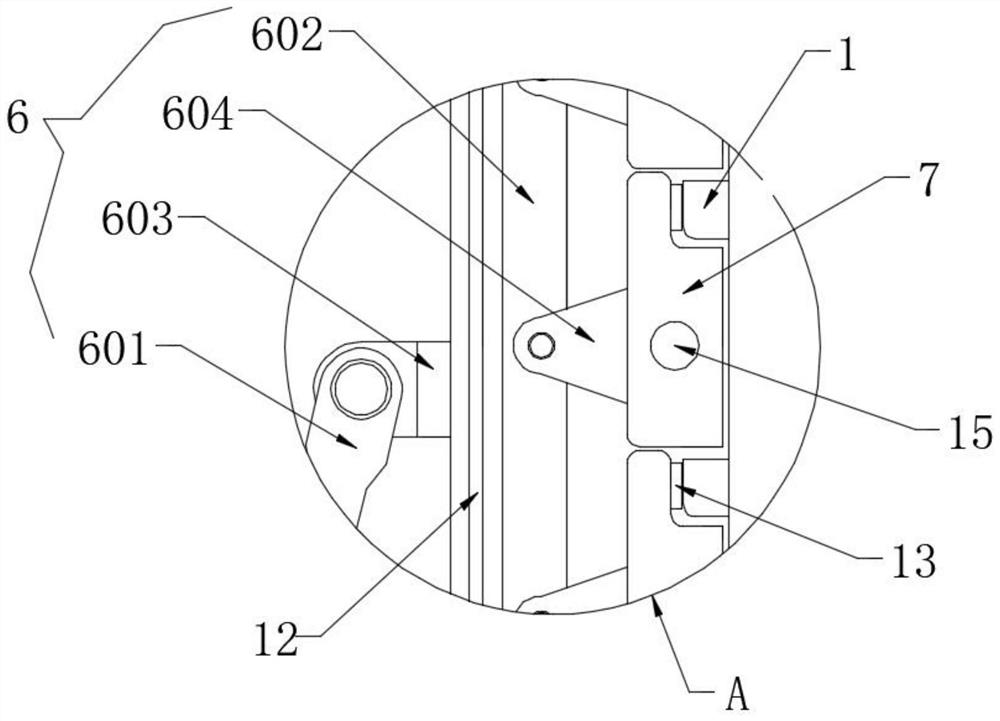

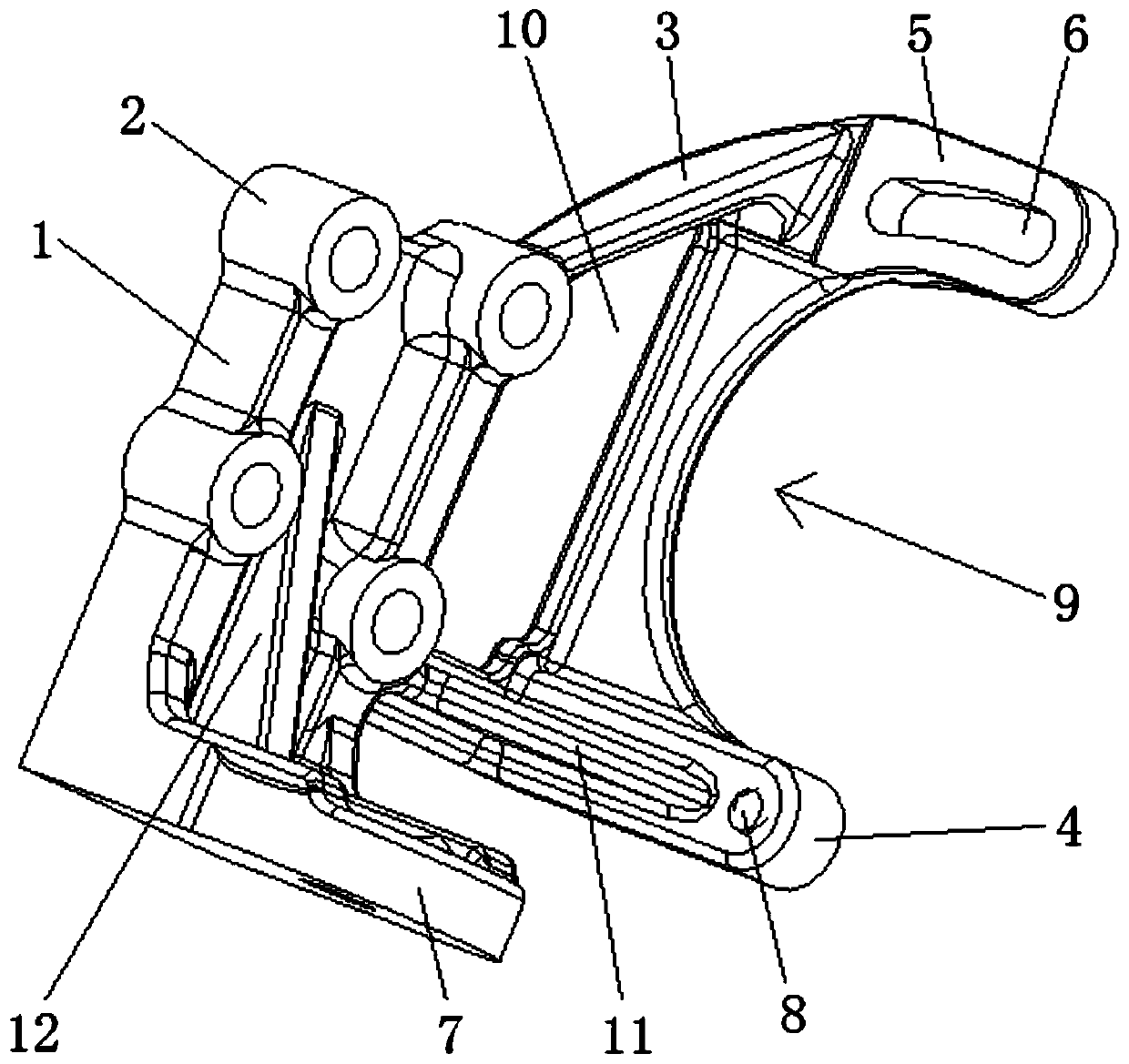

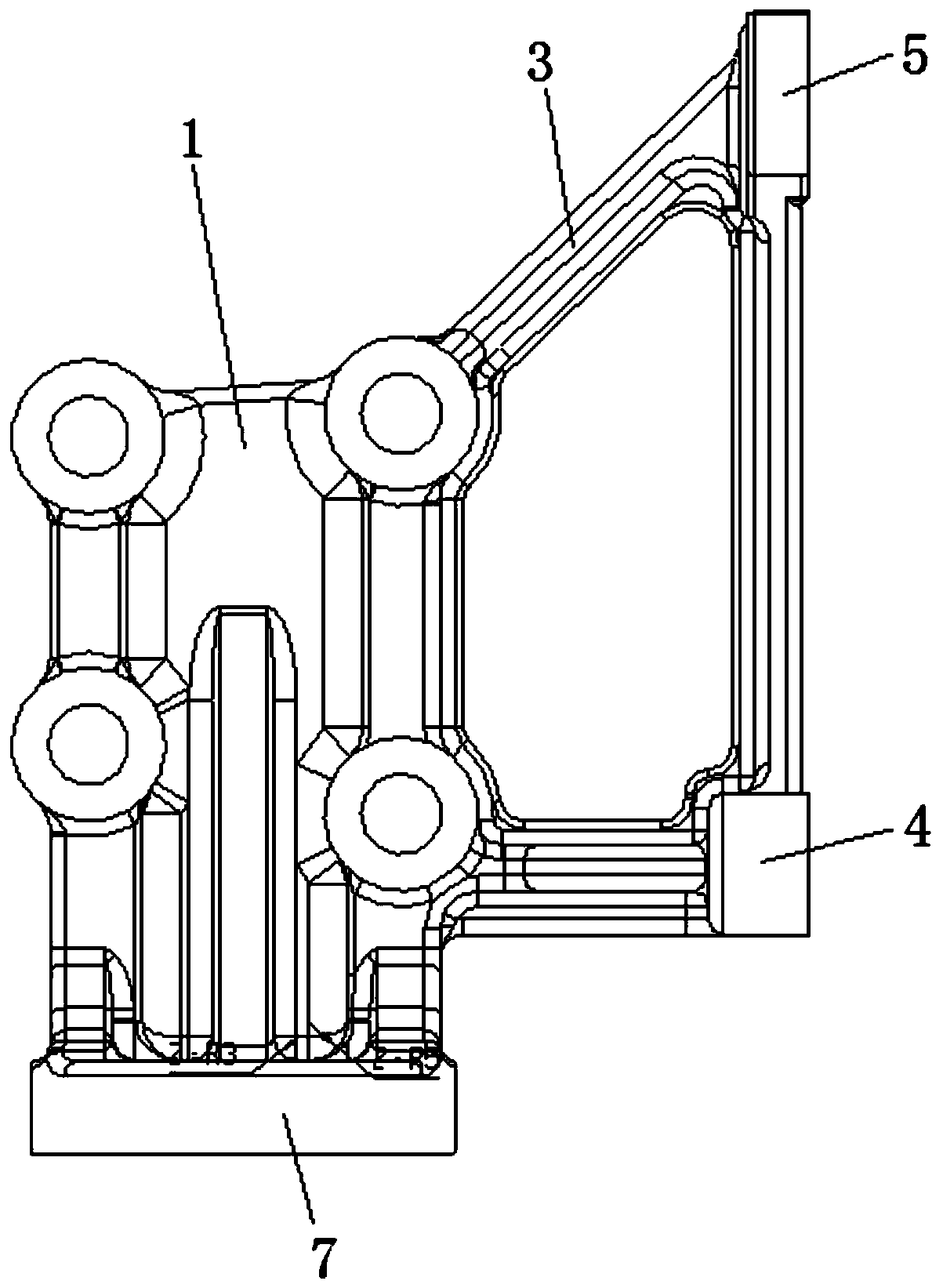

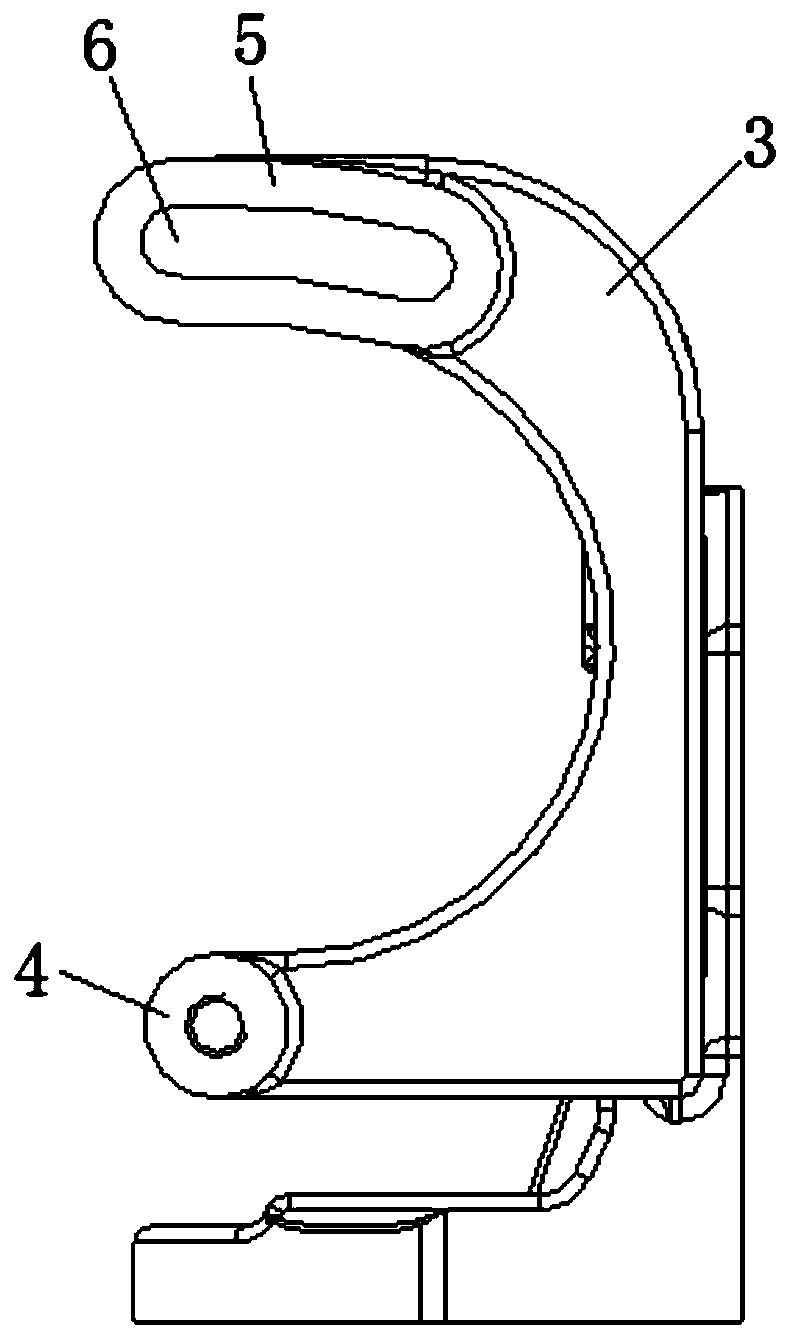

Gripper for detecting the side runout of the pulley groove of the shock absorber

ActiveCN105058269BSolving Tension ProblemsReduce mistakesAngles/taper measurementsWork holdersEngineeringShock absorber

The invention discloses a clamping piece for detecting the radial run-out of the side face of a pulley groove of a shock absorber. The clamping piece comprises a mandrel and a locking swivel nut. The mandrel comprises a mandrel body. Three elastic jaws are circumferentially arranged in the middle position of the mandrel body at intervals. The outer walls of the elastic jaws are conic. The middle positions of the inner sides of the elastic jaws are connected with the side wall of the mandrel body through a supporting body. Gaps are formed between the inner sides of the elastic jaws located on the two sides of the supporting body and the side wall of the mandrel body. The elastic jaws can swing around the supporting body, so that the radial distances between the outer walls of the three elastic jaws and the center of the mandrel body are changed. The locking swivel nut is in threaded connection with the front end of the mandrel body. When the mandrel body is sleeved with a pulley of the shock absorber, the pulley of the shock absorber can be driven by the locking swivel nut to be tensioned on the outer walls of the three elastic jaws. The clamping piece can be used for clamping the shock absorber with an inner hole large in taper and with a stepped hole, detection is convenient, and accuracy is high.

Owner:GUANGXI YUCHAI MASCH CO LTD

Explosion-proof time-delay roller of gumming machine

InactiveCN101157075ASolving Tension ProblemsImprove securityLiquid surface applicatorsCoatingsTime delaysElectric machinery

The invention discloses an explosion-proof time-delay roller of a dipping machine. The time-delay roller comprises a roll and a driving motor, wherein, the driving motor is a pneumatic motor; because any special explosion-proof type moment motor manufacturer does not also exist in China at present, an explosion-proof moment motor is replaced with the pneumatic motor to be used as the power of the time-delay roller in the explosion-proof area (in particular to the first-class explosion-proof area), thereby being a more ideal selection, and the invention not only solves the problem of paper tension in the running process, but also improves the security of the equipment.

Owner:苏州市益维高科技发展有限公司

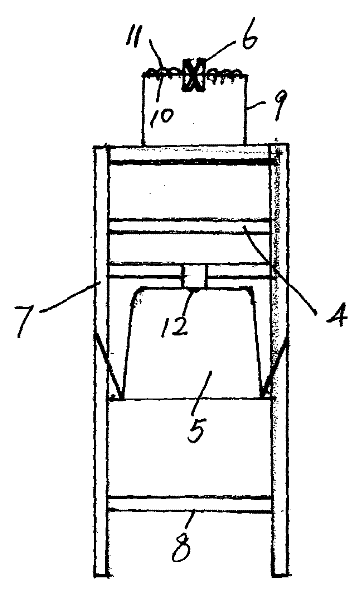

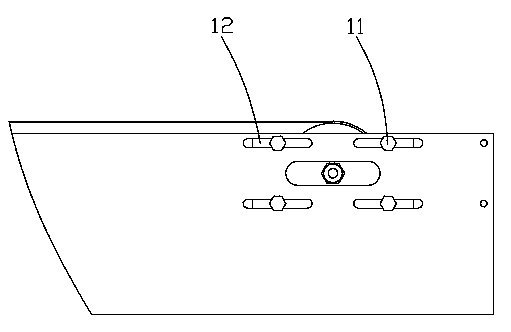

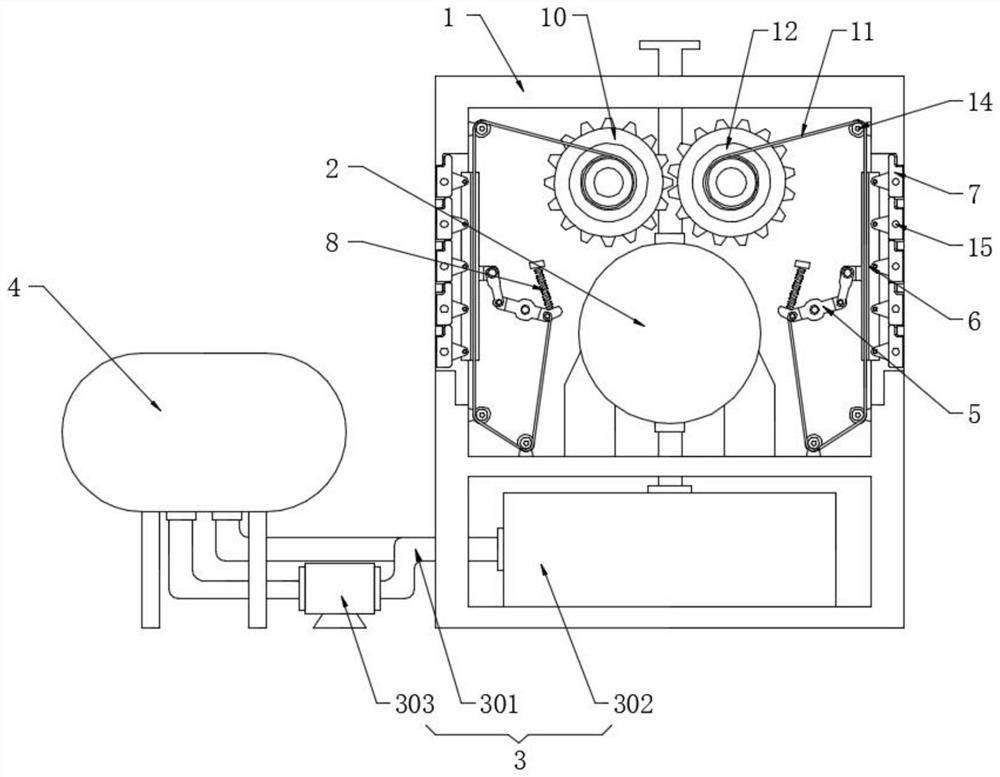

A fully automatic bandaging device and method suitable for ductile insulating materials

ActiveCN106252062BRealize fully automatic dressingSolving Tension ProblemsCoils manufactureEngineeringFully automatic

The invention discloses a full-automatic binding device and method suitable for a ductile insulating material. The full-automatic binding device suitable for the ductile insulating material comprises a machine frame assembly, a binding machine head, a movable assembly, a clamp assembly and a servo clamping assembly. The clamp assembly comprises a movable end clamp and a fixed end clamp, the movable end clamp and the binding machine head are installed on the machine frame assembly through the movable assembly, and the servo clamping assembly is installed on the binding machine head. The end of a lead is clamped by the clamp assembly, then the lead is straightened and tensioned, a lead body is fixed, and insulating full-automatic binding of the lead is achieved by means of constant-speed constant-tension rotation of the binding machine head. The device is easy and quick to use, binding quality is reliable, and binding efficiency is high. By means of the device and method, the problem that tension and the folding rate cannot be effectively controlled during binding of the ductile insulating material can be effectively solved, product quality is ensured, and work efficiency is improved.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

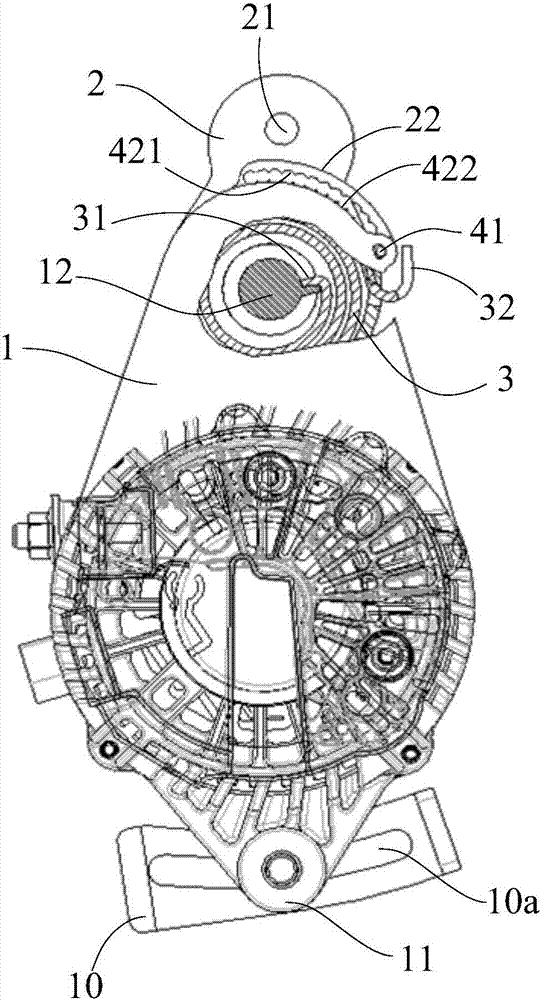

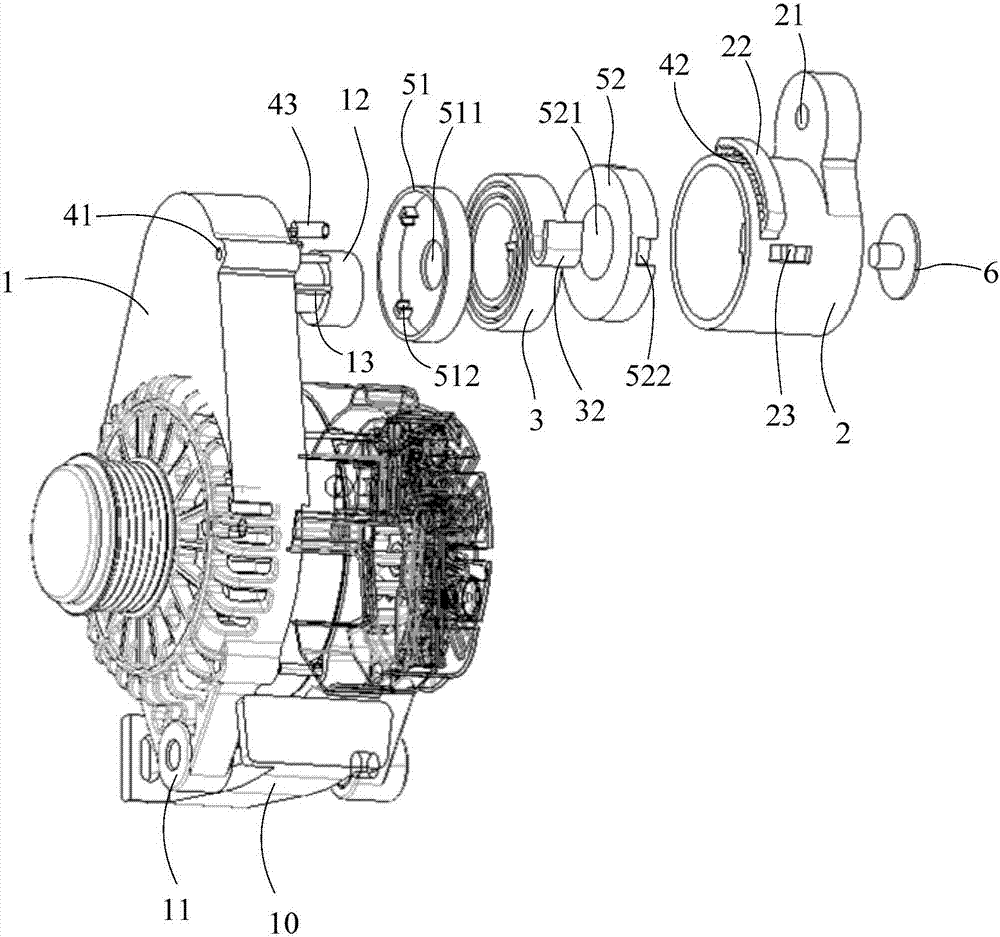

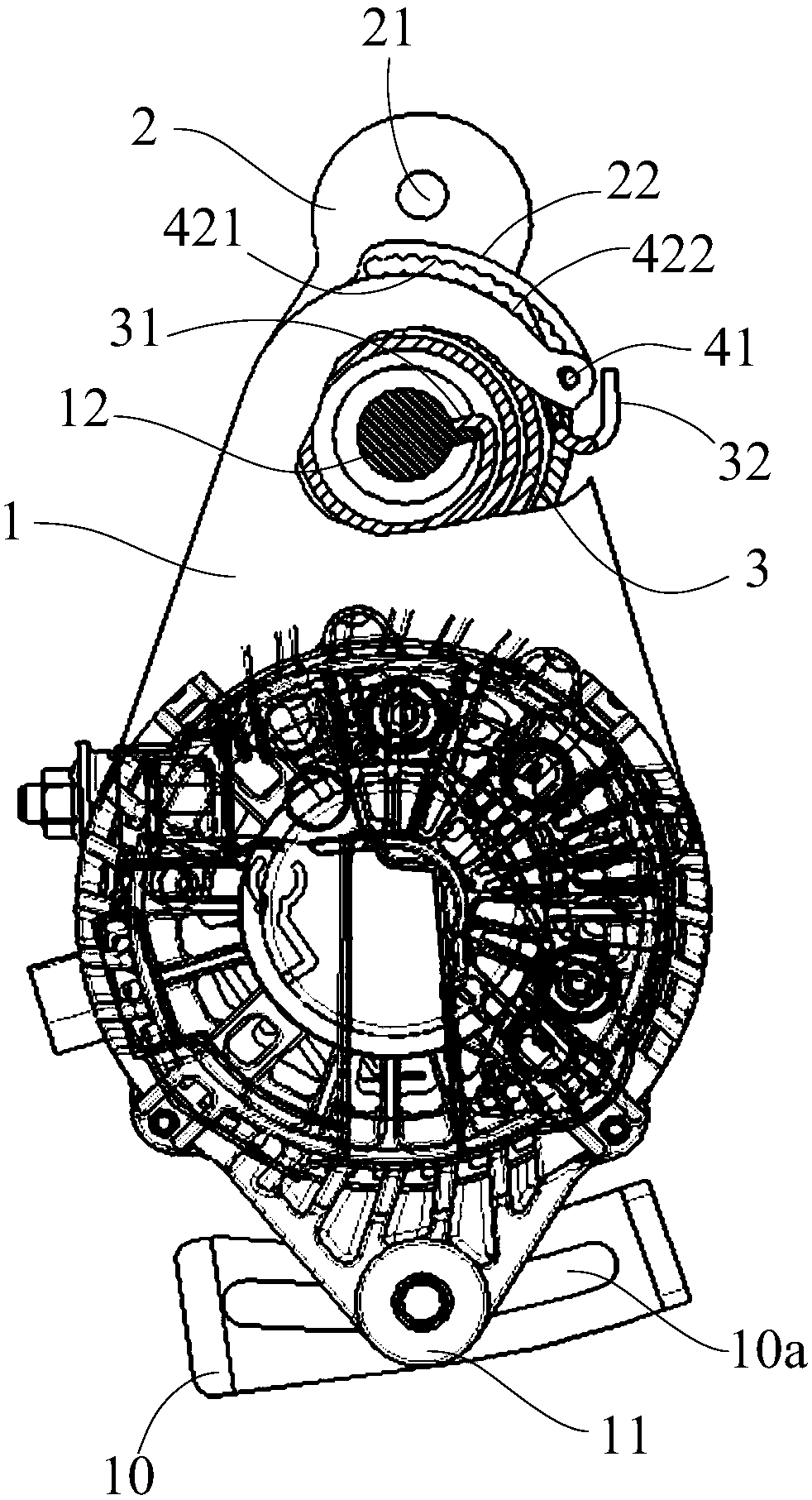

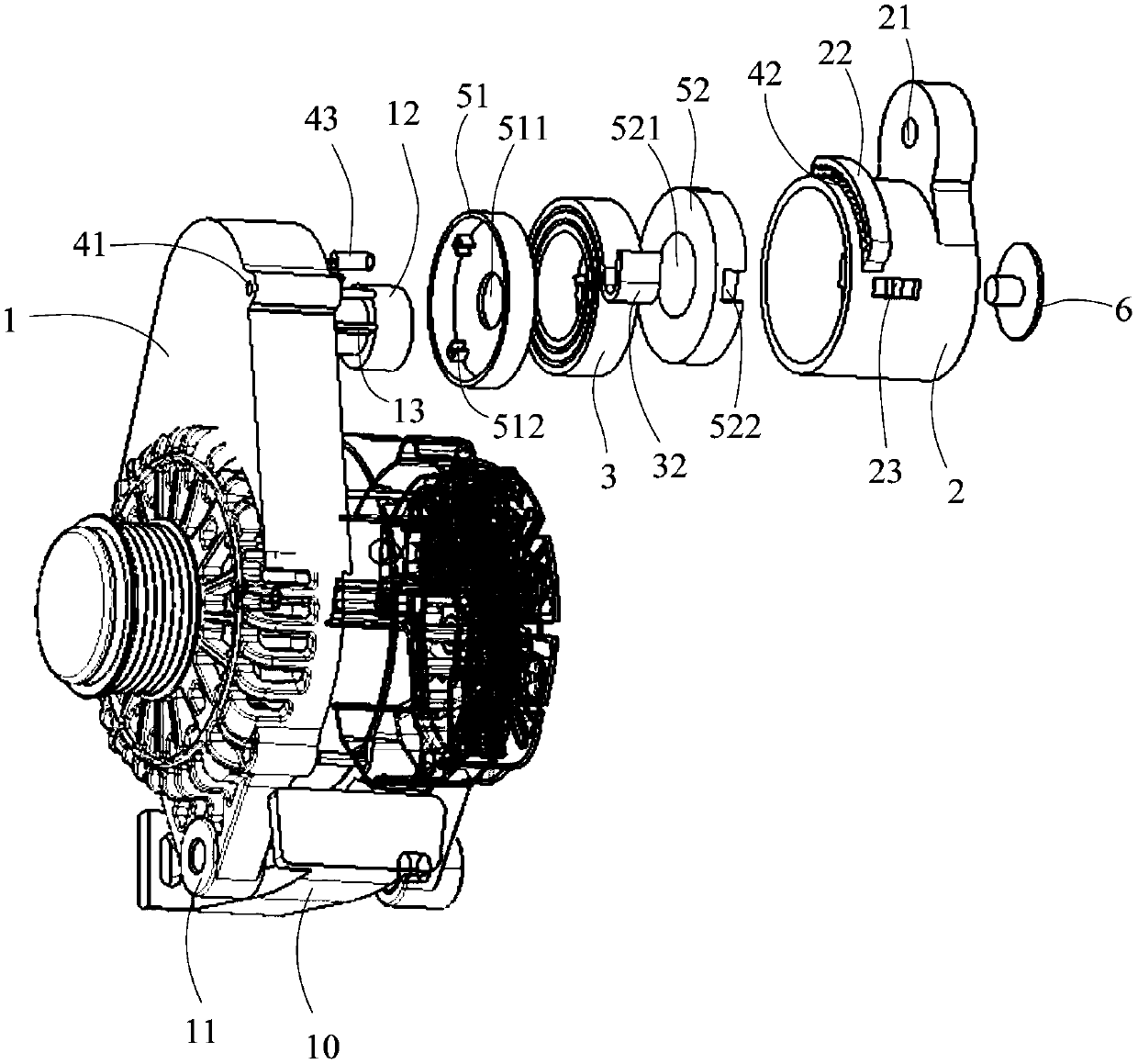

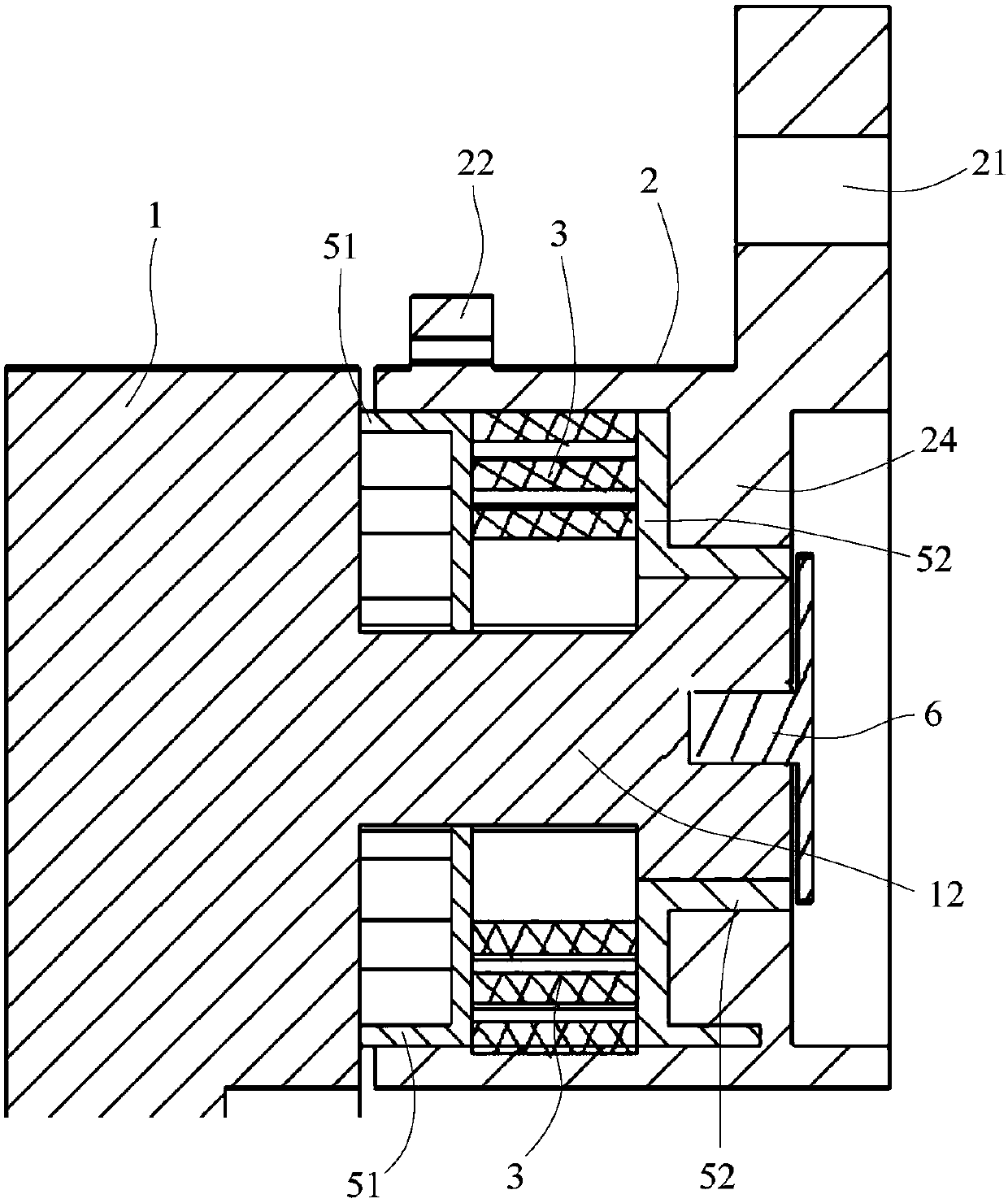

Automatic tensioning type generator and automobile

InactiveCN107104543ASolving Tension ProblemsEasy to useMechanical energy handlingCentre of rotationEngineering

The present invention provides an automatic tensioning type generator and an automobile. The automatic tensioning type generator comprises an end cover, a base, an elastic piece and a positioning assembly. The bottom of the end cover is provided with a lower hanging corner capable of sliding inside a lower corner sliding groove. The top of the base is provided with an upper fulcrum. The end cover and the base are positioned oppositely. The elastic piece is located within the base. The end cover is provided with a rotation center axis extending into the base. The rotation center axis successively passes through the elastic piece and the base. The inner end of the elastic piece is connected with the rotation center axis. The outer end of the elastic piece is connected with the base. The end cover rotates relative to the base under the torsion effect of the elastic member, so that the lower hanging corner is capable of sliding inside the lower corner sliding groove. Therefore, the generator is automatically rotated to be tensioned under the torsion effect of the elastic member. When a belt is tensioned, the end cover and the base are fixed relative to each other through the positioning assembly. Therefore, the belt tensioning problem of the generator can be solved without much effort. The time and the external force are saved.

Owner:INNER MONGOLIA OED ENGINE

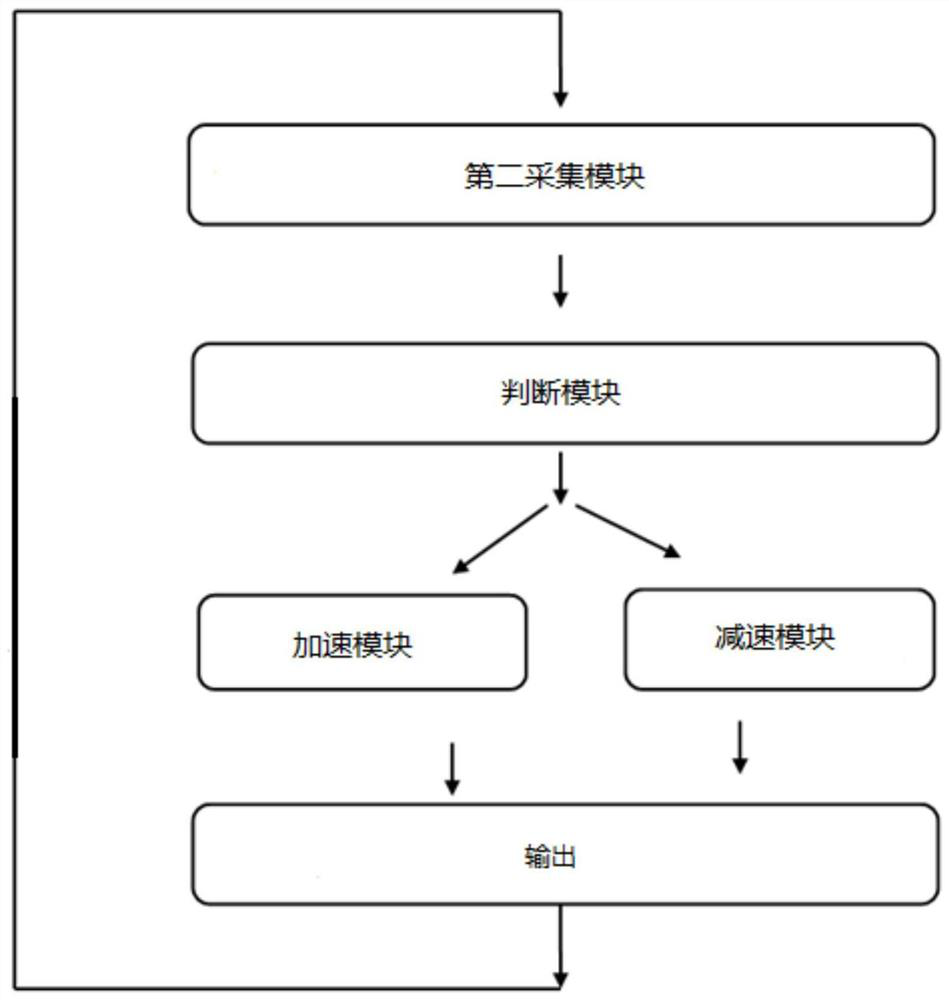

A kind of pipe belt conveyor tension control method, control device and pipe belt conveyor

ActiveCN112520325BGuaranteed uptimeSolving Tension ProblemsConveyorsControl devices for conveyorsMachineControl theory

The present invention provides a tension control method for a pipe belt conveyor. The pipe belt conveyor includes a main machine and a slave machine. The main machine and the slave machine are used to drive the movement of the conveyor belt. In the operation stage, it includes step A: obtaining The actual operating frequency of the slave machine, if the deviation between the actual operating frequency of the slave machine and the preset operating frequency of the master machine is greater than the set condition, the actual adjustment amount of the actual operating frequency of the slave machine is determined, and according to the actual adjustment amount The slave is adjusted so that the adjusted operating frequency of the slave is consistent with the preset operating frequency of the master. The invention also provides a tension control device for a pipe belt conveyor and a pipe belt conveyor. The invention can adjust the actual operating frequency of the slave machine in real time according to the tension state of the conveyor belt in the running stage, so that the master machine and the slave machine can run synchronously as much as possible, ensure that the conveyor belt is in a stable tension state throughout the whole process, and improve the stability of the conveyor operation. sex.

Owner:FUJIAN LONGKING

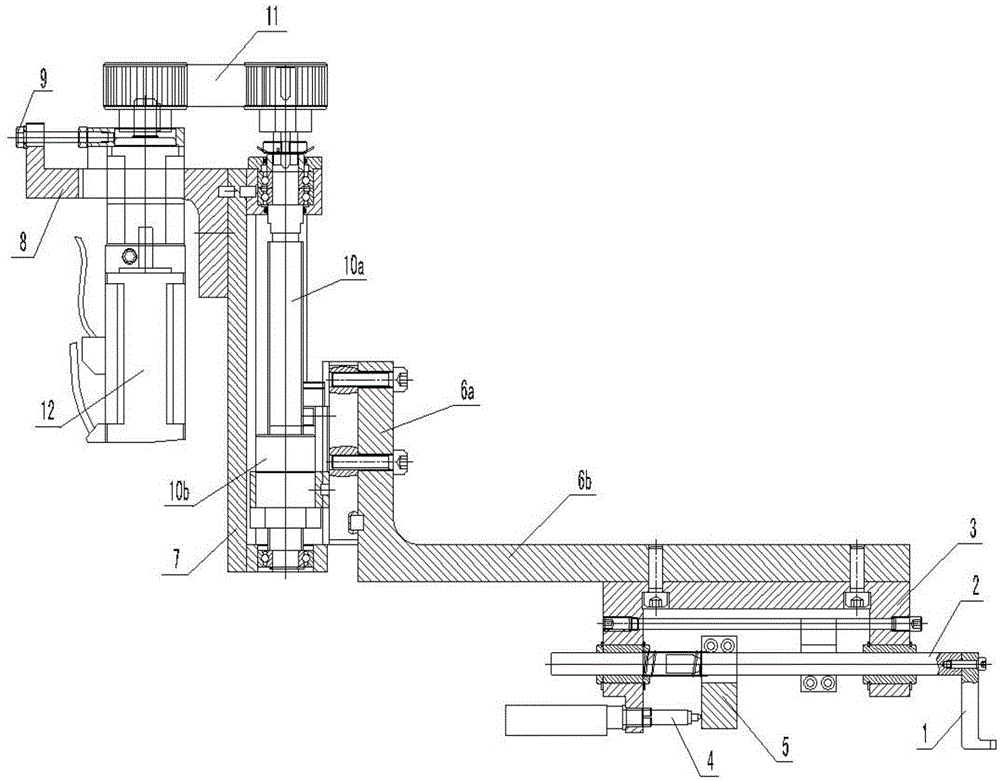

Measuring Mechanism for Tile Expansion Applied in Assembly Line of Automobile Main Reducer

The invention discloses a cover expansion quantity measuring mechanism applied to an automobile main reducing gear combined assembly line. The cover expansion quantity measuring mechanism is characterized in that a probe is fixedly connected to the front end of a linear axle, the linear axle is supported on a base in a clearance fit mode, a check block is fixed to the middle of the linear axle, a reset spring is arranged between the check block and a tail-board of the base, and the check block protrudes and extends upward in the radial direction of the linear axle; a displacement sensor is arranged on the tail-board of the base in the direction parallel to the axis of the linear axle, wherein a measuring head of the displacement sensor abuts against the check block so as to receive the displacement, transmitted by the check block, of the probe; the probe abuts against a cover and is used for detecting and sensing the expansion quantity of the cover in the assembly process of a main reducing gear. According to the cover expansion quantity measuring mechanism applied to the automobile main reducing gear combined assembly line, high-precision measurement of a small expansion quantity of the cover when adjustment knurled nuts at the two ends of the main reducing gear are screwed up can be realized.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

Protective device for heat-conducting oil heater

PendingCN114061145APrevent leakageSolve casualtiesDomestic cooling apparatusStorage heatersThermodynamicsElectric machinery

The invention discloses a protection device for a heat-conducting oil heater, and relates to the technical field of heating equipment. The protection device for the heat-conducting oil heater comprises a placing frame; a heater body is arranged in the placing frame, an expansion groove is formed in the placing frame through a cooling device, the cooling device is used for cooling a heating medium, a detection device is arranged in the placing frame, and an adjusting piece is arranged in the placing frame; and the adjusting piece is provided with a closing plate through an adjusting mechanism, the closing plate is connected to the surface of the placing frame, the adjusting mechanism is used for driving the closing plate to rotate, a reset spring is arranged on the surface of the adjusting piece, and a driving motor is connected to the surface of the placing frame. By arranging the adjusting piece, an adjusting rod, a steel wire rope and the sealing plate, the problems that fire accidents is possible to be caused and even explosion is possible to occur if leakage occurs due to the fact that heat conduction liquid in a furnace is high in temperature and mostly made of flammable and explosive materials, and casualties and property losses are caused are solved.

Owner:盐城市中然机械有限公司

Multifunctional suspension bracket

InactiveCN109779756ASolve the problem of belt tensionSolving Tension ProblemsNon-rotating vibration suppressionMachines/enginesSoftware engineeringElectric generator

Owner:GUANGXI YUCHAI MASCH CO LTD

Automatic Tensioner and Automobile

InactiveCN107104543BSolving Tension ProblemsEasy to useMechanical energy handlingCentre of rotationEngineering

The present invention provides an automatic tensioning type generator and an automobile. The automatic tensioning type generator comprises an end cover, a base, an elastic piece and a positioning assembly. The bottom of the end cover is provided with a lower hanging corner capable of sliding inside a lower corner sliding groove. The top of the base is provided with an upper fulcrum. The end cover and the base are positioned oppositely. The elastic piece is located within the base. The end cover is provided with a rotation center axis extending into the base. The rotation center axis successively passes through the elastic piece and the base. The inner end of the elastic piece is connected with the rotation center axis. The outer end of the elastic piece is connected with the base. The end cover rotates relative to the base under the torsion effect of the elastic member, so that the lower hanging corner is capable of sliding inside the lower corner sliding groove. Therefore, the generator is automatically rotated to be tensioned under the torsion effect of the elastic member. When a belt is tensioned, the end cover and the base are fixed relative to each other through the positioning assembly. Therefore, the belt tensioning problem of the generator can be solved without much effort. The time and the external force are saved.

Owner:INNER MONGOLIA OED ENGINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com