Explosion-proof time-delay roller of gumming machine

A technology of dipping machine and roller, which is applied to the device and coating of the surface coating liquid, which can solve the problems of easy breaking of the substrate, deformation of the pulling, and failure to ensure the normal operation of the equipment, so as to improve safety, The effect of solving tension problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

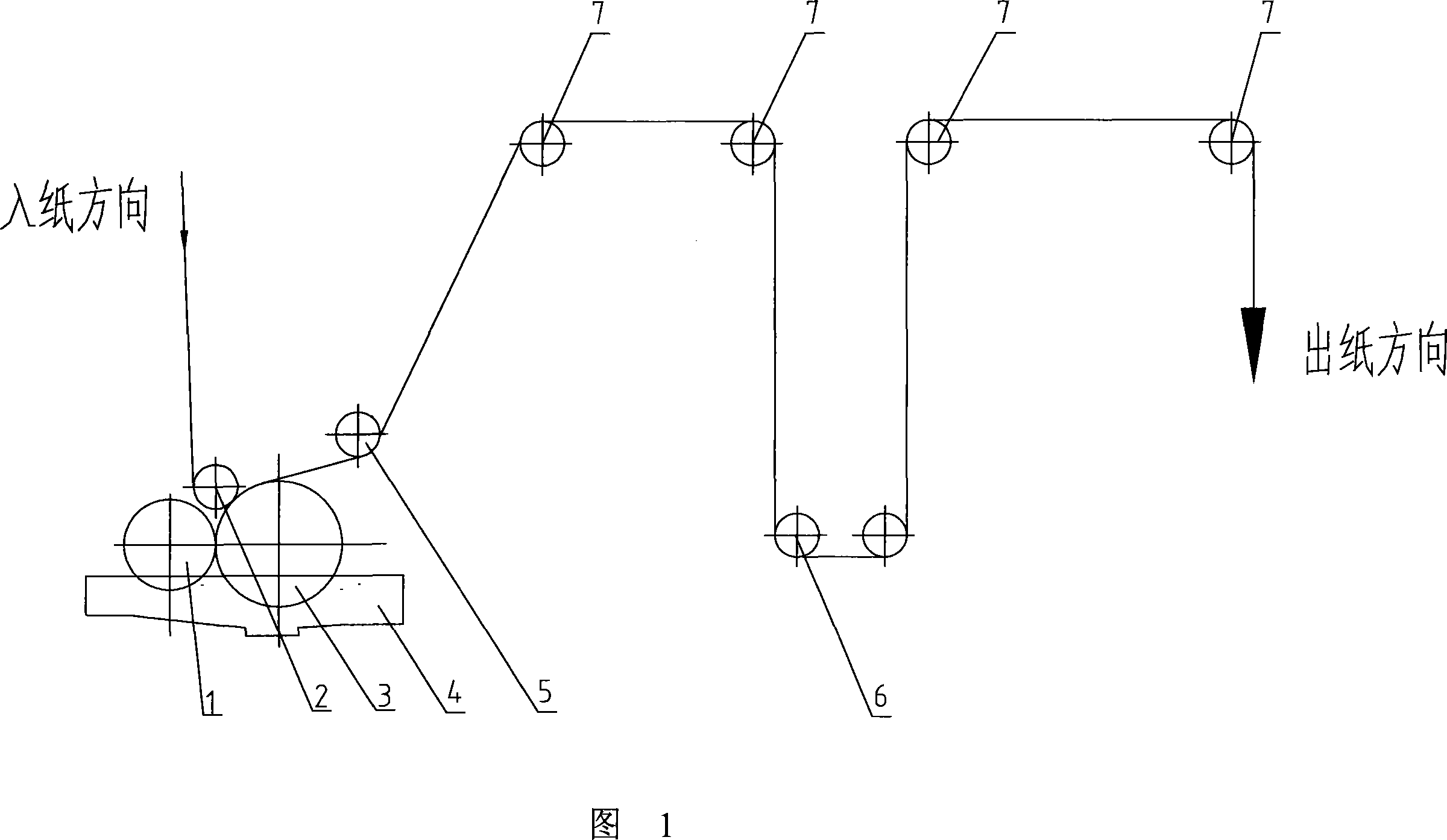

[0014] Example: As shown in Figure 1, an explosion-proof delay roller of a dipping machine includes a roller and a drive motor, and the drive motor is a pneumatic motor.

[0015] The design of the delay roller of the dipping machine of the present invention is to replace the torque motor with a pneumatic motor. It can be seen from the characteristic curve of the air motor: when the air pressure is constant, with the increase of the speed, the torque decreases, and there is a linear relationship between the speed and the torque; from the characteristic curve of the torque motor, it can be seen that when the voltage is set to one Timing, with the increase of the speed, the torque decreases, and the relationship between the speed and the torque is basically linear. It can be seen that the air motor and the torque motor have similar characteristics. Since there is no special explosion-proof torque motor manufacturer in China, it is an ideal choice to replace the explosion-proof t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com