Measuring Mechanism for Tile Expansion Applied in Assembly Line of Automobile Main Reducer

A technology of the main reducer and measuring mechanism, which is applied in the field of tile cover alignment, increase and displacement, can solve the problems of no automatic measurement public reports, etc., and achieve the effect of solving tension and installation difficulties, and simple adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

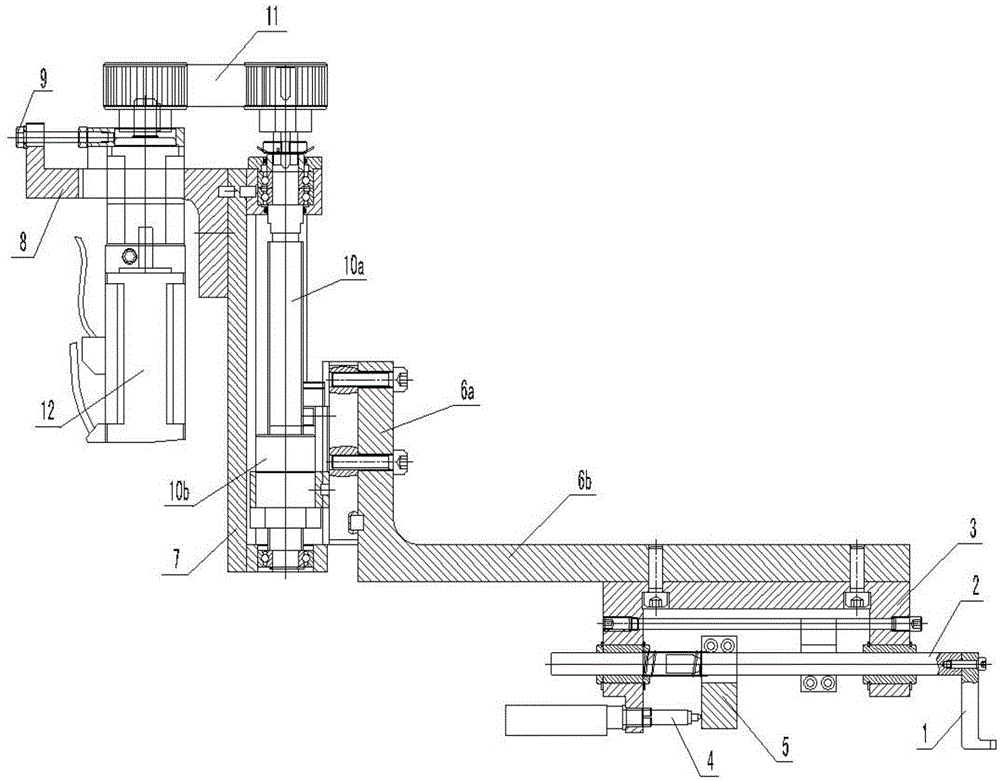

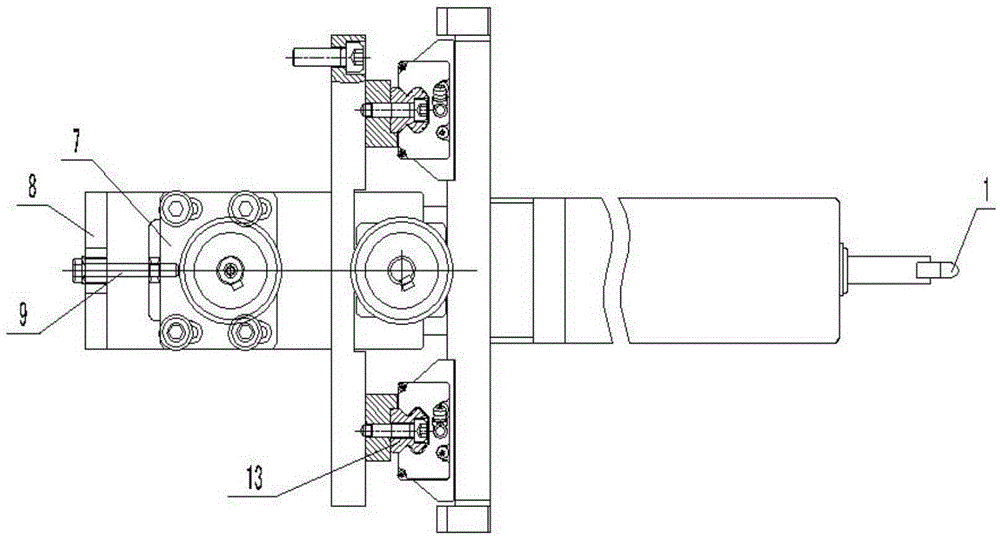

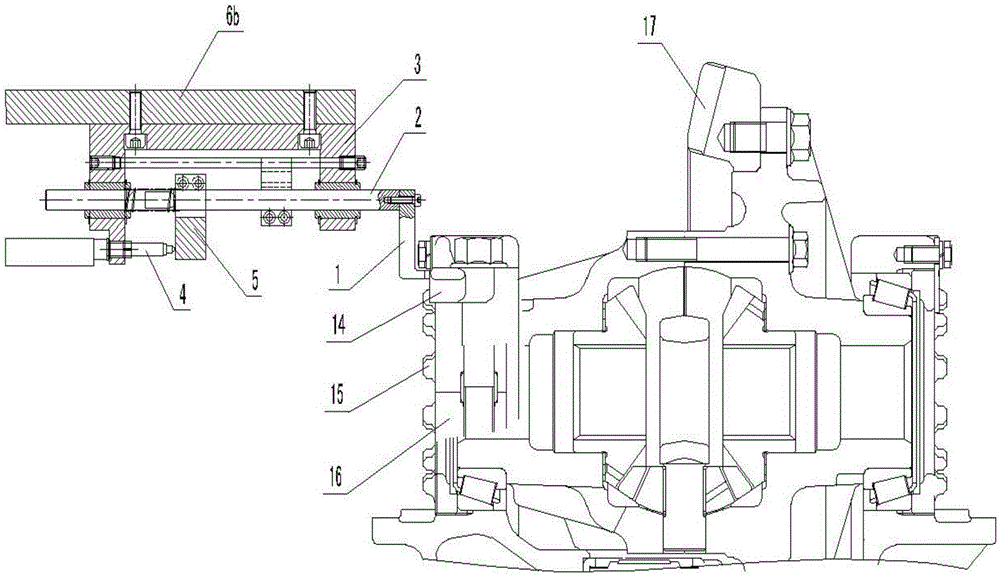

[0017] see figure 1 , figure 2 , image 3 , in this embodiment, the tile cover expansion measurement mechanism applied on the assembly line of the main reducer of the automobile is set as:

[0018] The probe 1 is fixedly connected to the front end of the linear shaft 2, and the linear shaft 2 is supported on the base 3 with clearance fit, and a stopper 5 is fixedly arranged in the middle of the linear shaft 2, between the stopper 5 and the tail plate of the base 3 A return spring is provided, and the stopper 5 protrudes radially along the linear axis.

[0019] On the tail plate of the base 3, a displacement sensor 4 is arranged along a direction parallel to the axis of the linear shaft 2, and the measuring head of the displacement sensor 4 is against the stopper 5 to receive the force from the probe 1 transmitted by the stopper 5. Displacement, the probe 1 touches the tile cover 14, and is used to detect the slight increase of the tile cover 14 caused during the assembly p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com