A kind of pipe belt conveyor tension control method, control device and pipe belt conveyor

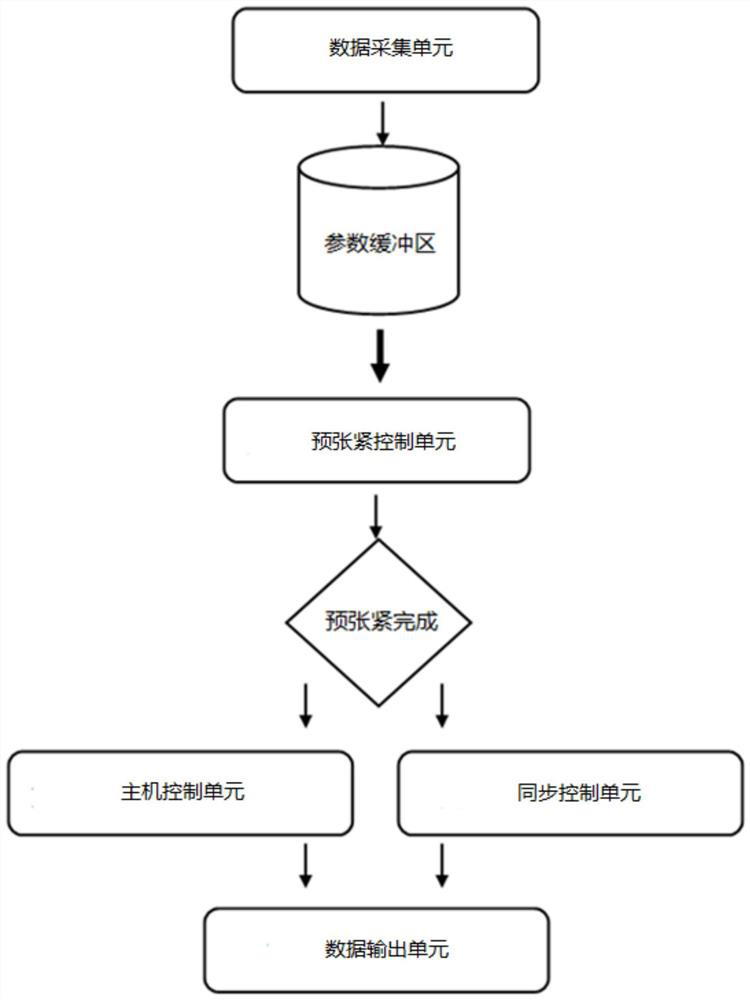

A technology of pipe belt conveying and control method, which is applied in the direction of conveyor control device, conveyor, conveyor objects, etc., which can solve the problem of affecting the normal operation of the pipe belt conveyor, unable to solve the problem of conveyor belt tension in time, and unable to convey the running state of the conveyor belt adjustment and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

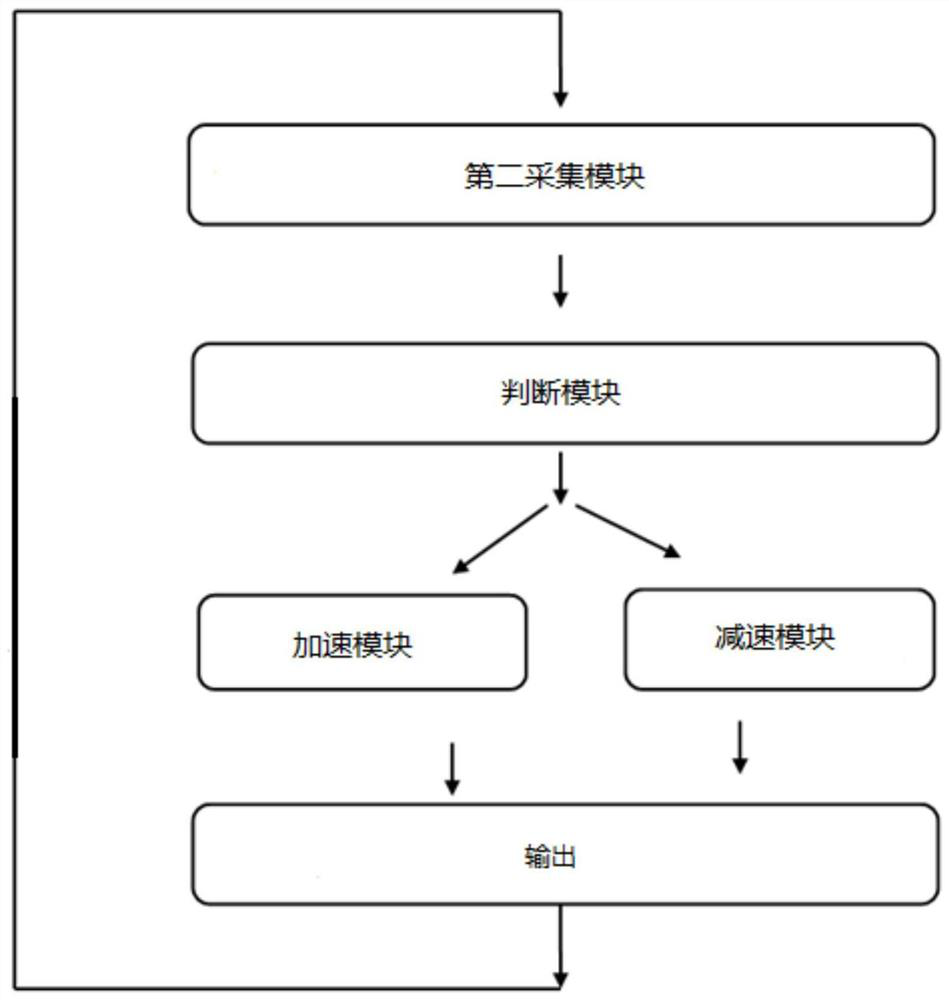

[0047] In order to make those skilled in the art better understand the technical solutions of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

[0048]In this paper, the operating frequency of the master and the operating frequency of the slave are the adjustment values. In the theoretical state, the actual operating frequency of the master after adjustment is equal to the operating frequency of the master, and the actual operating frequency of the slave is equal to the operating frequency of the slave, but in practice, the actual operating frequency of the master is equal to that of the master. There will be a certain error between the frequency and the operating frequency of the master, and there will be a certain error between the actual operating frequency of the slave and the operating frequency of the slave. Therefore, although the operating frequency of the master i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com