Printing die cutting tension automatic control system and control method

A technology of die-cutting tension and tension, applied in printing, printing devices, ink, etc., to achieve automatic control and avoid tension problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

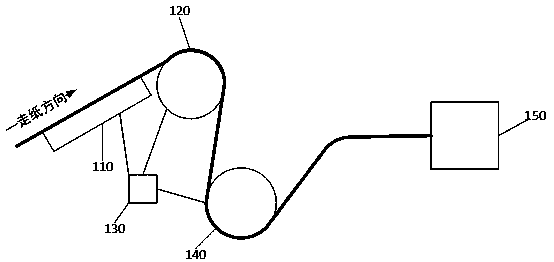

[0028] like figure 1 As shown in the figure, the first embodiment of the present application provides an automatic control system for printing die-cutting tension. According to the conveying direction of the substrate, a printing module 110, a tension detection module 120, a controller 130, a tension adjustment module 140, and a pressure line cross-cutting module are arranged in sequence. 150, the substrates are conveyed by the synchronous belt between the modules.

[0029] The printing module 110 is connected with the controller 130, and the printing operation is completed according to the instructions of the controller 130. Further printing modules can also integrate the substrate conveying chassis, the substrate conveying drive roller, the substrate conveying driven roller and the substrate inclination correction roller. , There are substrate conveying guide plates on both sides of the driving roller and the driven roller, and the two guide plates are arranged opposite each...

Embodiment 2

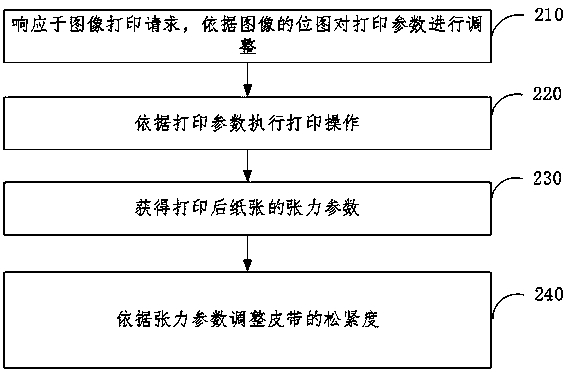

[0040] The second embodiment of the present application provides an automatic control method for printing die-cutting tension, such as figure 2 shown, including:

[0041] Step 210: In response to the image printing request, adjust the printing parameters according to the bitmap of the image; including the following sub-steps:

[0042] Step 2101, splitting a plurality of bitmaps from the image;

[0043] The image is composed of multiple regions, and each region includes information such as region color, transparency, and position. Each region constitutes a bitmap, and the bitmap includes color information, transparency information, and position information.

[0044] Step 2102, storing each bitmap in the print queue according to the print order;

[0045] The print queue is pre-built, and the size of the print queue is allocated according to the number of constructed bitmaps, which are stored according to the positional relationship of the bitmaps, that is, the adjacent storag...

Embodiment 3

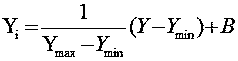

[0083] The scheme of adjusting the belt tightness according to the tension adjustment value is described above, but in the specific adjustment process, if only a single tension adjustment value is adjusted, an adjustment error will occur, for example, the belt is too tight or too loose. Therefore, the following improvement scheme is proposed.

[0084] Step 310, establishing a tension set in advance;

[0085] The tension set F stores N tension arrays f (T i , S i ), where T i is the tension adjustment value, S i is the actual adjustment value, S i To characterize the actual adjustment degree of the belt, the tension set F can be pre-built by the staff and obtained by monitoring the actual working condition of the system.

[0086] Step 320, sorting the tension arrays in the tension set;

[0087] According to the tension adjustment value T i sorted by size.

[0088] Step 330: Cut out the sorted tension array every predetermined length to obtain L subsets M.

[0089] Subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com