A fully automatic bandaging device and method suitable for ductile insulating materials

A fully automatic bandaging and insulating material technology, which is applied in coil manufacturing and other directions, can solve the problems that the tension and wrapping rate cannot be effectively controlled, and achieve the effect of meeting the requirements of constant tension and wrapping rate, ensuring product quality and reliable wrapping quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

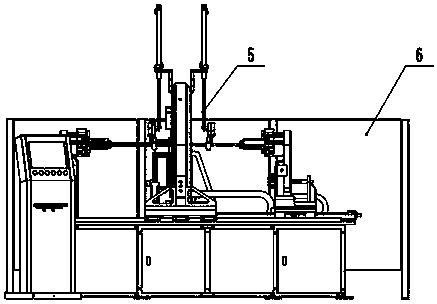

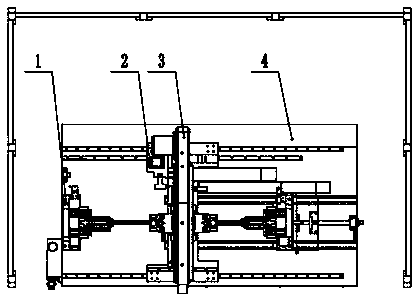

[0025] Please refer to figure 1 and figure 2 , a fully automatic bandaging device suitable for ductile insulating materials, including a clamp assembly 1, a moving assembly 2, a wrapping head 3, a frame assembly 4, a follow-up clamping assembly 5 and an enclosure assembly 6 and other main components. The clamp assembly is used to clamp the end of the lead wire and straighten and tighten the lead wire; the wrapping machine head can realize lead wire insulation reciprocating half-fold wrapping; the follower clamping assembly can clamp the lead wire during the wrapping process to prevent the lead wire from swinging. The device is equipped with a constant tension system, a wrapping rate setting control system, and a wrapping thickness (number of layers) measurement and control system, which can reliably achieve constant tension and half-fold wrapping to ensure the wrapping quality.

[0026]The fixture assembly clamps the workpiece, and the wrapping machine head reciprocates arou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com