Insulating paper automatic winding device

A technology of winding device and insulating paper, applied in coil manufacturing, electrical components, inductor/transformer/magnet manufacturing, etc., can solve the problems of reduced production efficiency, thick insulation wrapping, irregular wrapping, etc., to improve work efficiency and tight wrapping. Real, avoid the effect of non-standard dressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

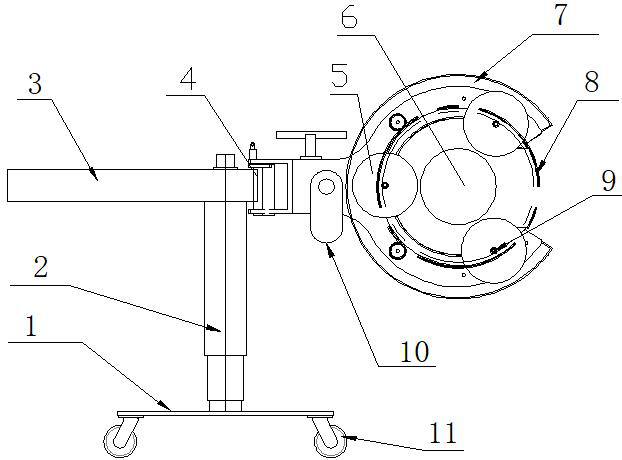

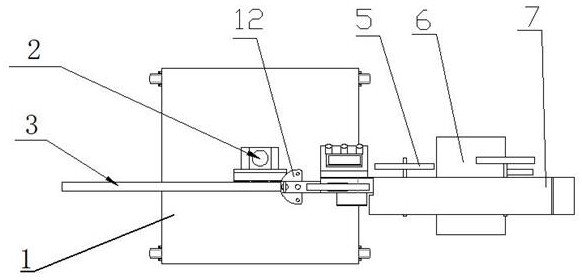

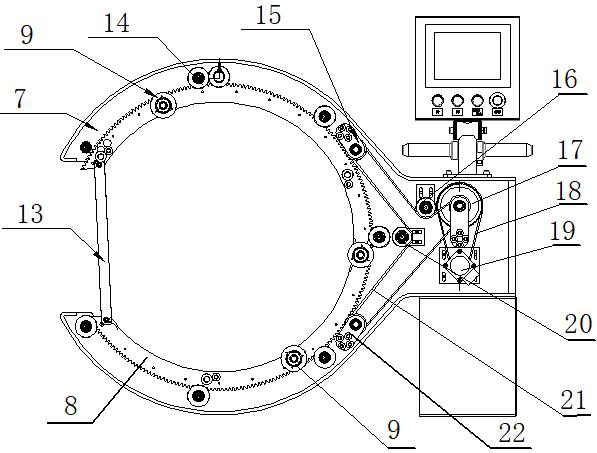

[0023] As shown in the figure, the present embodiment includes a base 1, the bottom of the base 1 is equipped with universal wheels 11, the base 1 is equipped with a column 2, and the column 2 is a lifting structure, and its upper and lower parts are connected by a cylinder or an oil cylinder. The upper end of the column 2 is equipped with a cantilever 3 for support and counterweight. The cantilever 3 is connected to the column 2 near its one end: one side of the cantilever 3 is fixed with a connecting seat, and the upper end of the column 2 is rotatably matched with the hole on the connecting seat. The short end of the cantilever 3 is connected with the C-shaped frame 7 through a vertical shaft. The structure of the C-shaped frame and the cantilever connection part 4 is: the connection part of the C-shaped frame 7 and the cantilever 3 is U-shaped, and its two sides are located at the upper and lower sides of the cantilever 3, and the overlapping part of the C-shaped frame 7 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com