Data-driven multi-drive conveyor torque control method and device

A torque control and data-driven technology, applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve the problems of tape tension reduction, slipping, etc., to improve safety, improve control performance, and solve unloading points Effects of Tape Tension Problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

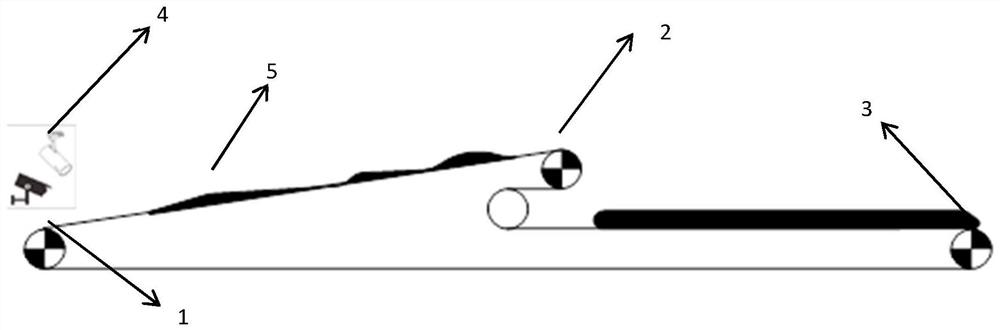

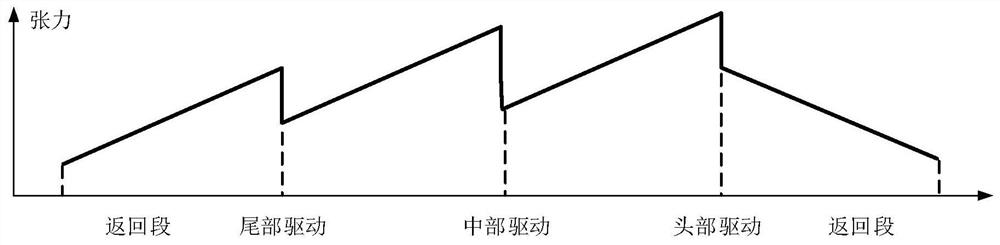

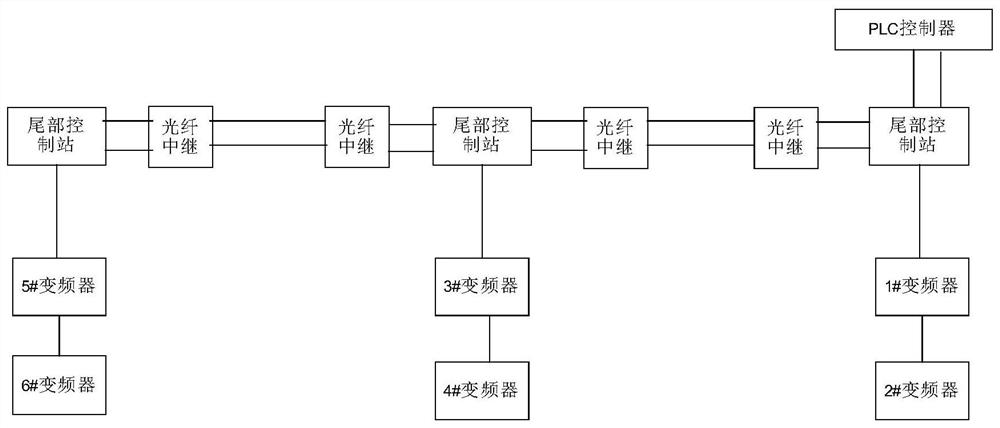

[0066] Such as Figure 1-7 Shown is a data-driven unloading multi-drive conveyor control method and device from the drive unit. The head, middle, and tail of the conveyor are equipped with three drive units, and each drive unit includes two coaxially installed motor. The controller of the motor control system adopts PLC, which is driven by frequency converter. The communication between PLC and frequency converter adopts the field bus protocol to realize the coordinated control between drive units. The bus is made of optical fiber to prevent electromagnetic interference and prevent lightning strikes.

[0067] The two motors in each group of drive units are coaxially installed, which belong to rigid body connection, and are controlled by master and slave. The inverter of the slave motor works in the direct torque control mode and receives the torque set value from the master motor. In the subsequent description, the drive unit composed of two coaxially installed motors will be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com