Comprehensive cooling control method for new energy vehicle driving motor

A driving motor and cooling control technology, which is applied in the layout of the cooling combination of the power plant, cooling/ventilation devices, electromechanical devices, etc., can solve the problem of not considering the influence of environmental temperature, and achieve reasonable energy distribution, large flow, and optimal control. the effect of logic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical realization of the present invention is further described in detail below in conjunction with accompanying drawing:

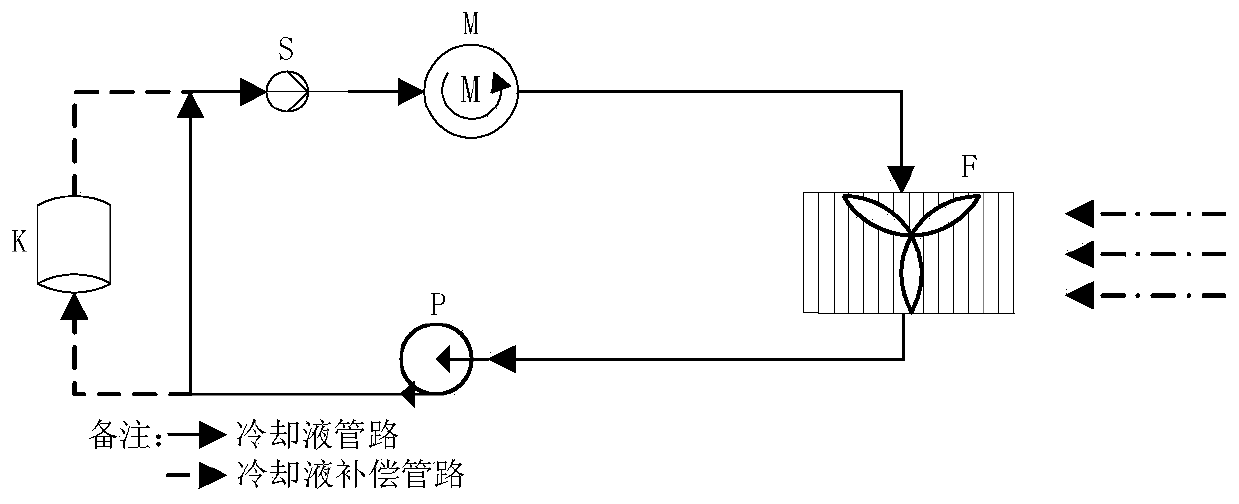

[0037] This embodiment is based on figure 1 The water-cooling system for the driving motor described above, the water-cooling system drives the coolant circulation through the operation of the water pump P, and the heat of the driving motor M is taken out to the front-end radiator through the water jacket of the driving motor; The heat dissipation of the environment achieves the purpose of cooling the driving motor M. Fan F is a PWM fan.

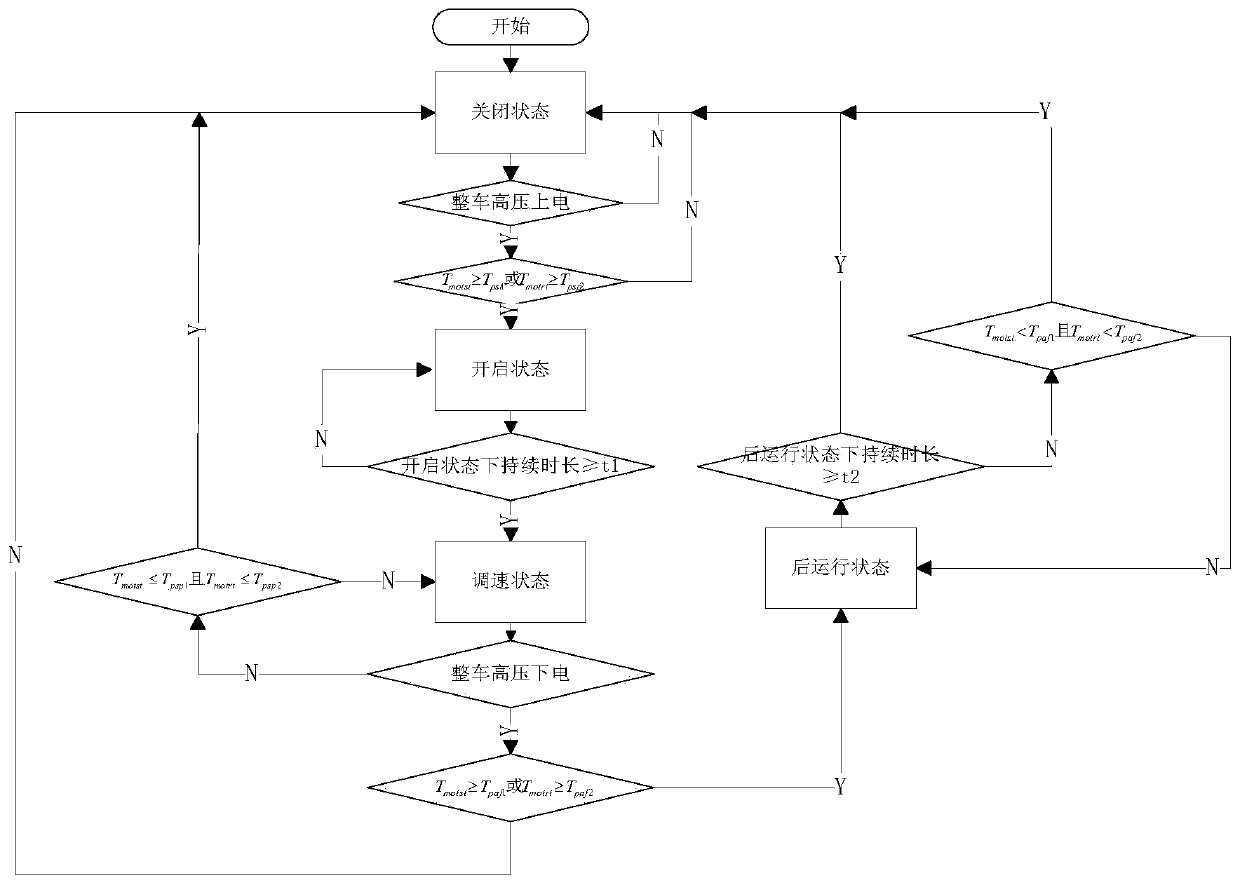

[0038] Based on the above new energy vehicle drive motor water cooling system, see Figure 5 , the cooling control process is as follows:

[0039] Step 1. Obtain the input signal required for control

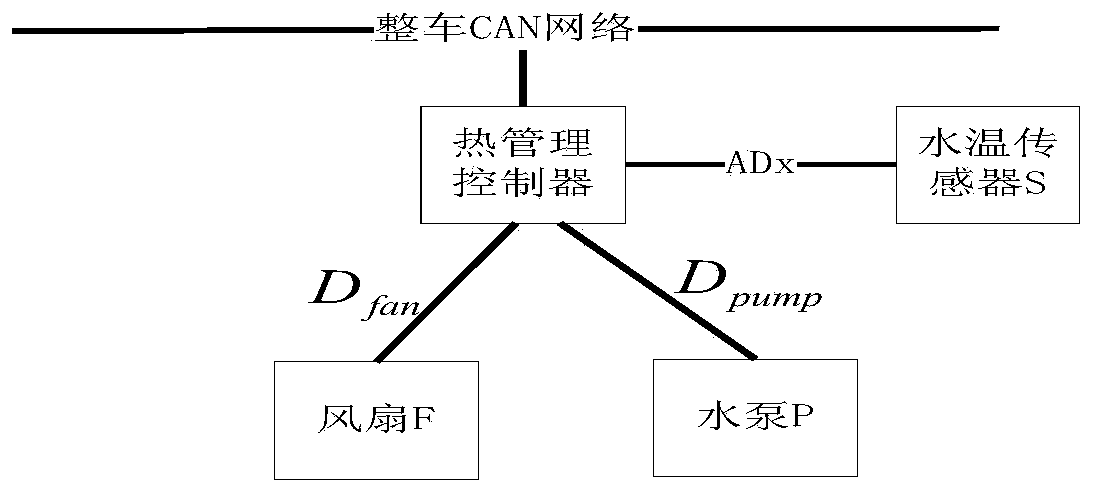

[0040] Obtain the stator temperature T of the drive motor through the vehicle CAN network motst , rotor temperature T motrt , real-time input power P in and real-time efficiency Ambient temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com