High-precision positioning method applied to rotary cutter

A positioning method and disc shearing technology, which are applied to shearing equipment, shearing devices, metal processing equipment, etc., can solve the problems of inability to guarantee the precision required by the process, inherent errors of disc shearing machinery, mechanical clearance, mechanical wear, etc., and achieve Improve the success rate of edge trimming, overcome the mechanical gap error, and stabilize the control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

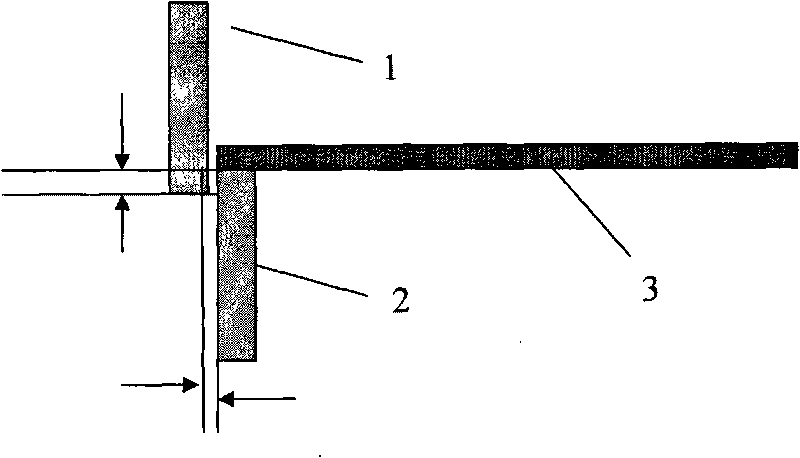

[0022] The schematic diagram of the working principle of the disc shear is as follows image 3 shown. As shown in the figure, the cutter head of the disc scissors is composed of two vertical circular blades that are dislocated up and down, that is, the disc cutter upper blade 1 and the disc cutter blade 2. The running strip 3 passing between the two blades is cut by adjusting a certain gap and overlap between the upper disc cutter 1 and the disc cutter blade 2 . When the running strip 3 passes between the two blades, due to the disc shearing blade 1 and the disc cutting blade 2 applying a certain shearing force to the running strip 3, the contact area between the running strip 3 and the blade is deformed, With the increase of the bite depth, the deformation of the running strip 3 also increases, and when the deformation reaches a cert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com