High-elongation low-modulus para-aramid fiber and preparation method thereof

A para-aramid fiber, low modulus technology, applied in fiber chemical characteristics, dry spinning, wet spinning, etc., can solve the problems of low production capacity, stable production that has not yet been achieved in batches, high elongation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

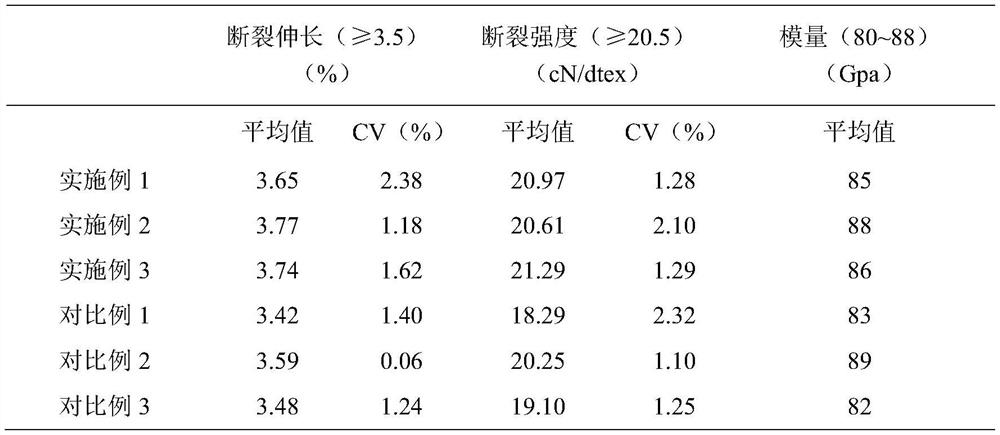

Examples

preparation example Construction

[0034] The invention discloses a preparation method of high-elongation and low-modulus para-aramid fibers, which comprises the following steps:

[0035] (a) Using concentrated sulfuric acid as a solvent, the poly-p-phenylene terephthalamide (PPTA) raw material is formulated into a polymer mixed solution with a mass percentage of 15% to 20%, and the dissolution time is 1 to 4 hours, and then Stand still under vacuum for 2-6 hours for defoaming to obtain spinning solution;

[0036] (b) The spinning solution is extruded and pushed under a pressure above 5MPa. After filtering, it passes through a spinneret with a pore size of 0.080mm. fiber;

[0037] Preferably, the pressure of extrusion is 5-20 MPa.

[0038] Preferably, the high-elongation low-modulus para-aramid fiber preparation step (a) of the PPTA raw material has a viscosity-average molecular weight of 40,000 to 49,000 and an intrinsic viscosity of 6.0 to 7.5 dL / g;

[0039] Wherein, the PPTA raw material is prepared through...

Embodiment 1

[0053] A preparation method of high-elongation low-modulus para-aramid fiber, comprising the steps of:

[0054] (1) Add anhydrous calcium chloride and N-methylpyrrolidone (NMP) into the reactor at a weight ratio of 4:100, then add an appropriate amount of p-phenylenediamine (PPD), and stir at room temperature for 30 minutes;

[0055] (2) The jacket of the reactor is cooled by a refrigerant to lower the temperature of the system to -15° C., add the first batch of terephthaloyl chloride (TPC) which is 20% of the total amount, and continue to stir for 30 minutes;

[0056] (3) Make the temperature of the system drop to -15°C again, add the second batch of TPC which is 80% of the total amount, and stir rapidly. After the reaction system appears gel, climbs rods, and is crushed again, stop the reaction to obtain PPTA , wherein the total molar ratio of adding PPD in step (1) and TPC added in two batches in steps (2) and (3) is 1:1. Finally, the obtained viscosity-average molecular w...

Embodiment 2

[0060] A preparation method of high-elongation low-modulus para-aramid fiber, comprising the steps of:

[0061] (1) Add anhydrous calcium chloride and N-methylpyrrolidone (NMP) into the reactor in a ratio of 20:100 by weight, then add an appropriate amount of p-phenylenediamine (PPD), and stir at room temperature for 30 minutes;

[0062] (2) The jacket of the reactor is cooled by cooling medium, so that the temperature of the system drops to 0° C., and the first batch of terephthaloyl chloride (TPC) which is 40% of the total amount is added, and the stirring is continued for 30 minutes;

[0063] (3) Make the temperature of the system drop to 0°C again, add the second batch of TPC which is 60% of the total amount, and stir rapidly. After the reaction system appears gel, climbs rods, and is crushed again, stop the reaction to obtain PPTA. Wherein the total molar ratio of adding PPD in step (1) and adding TPC in two batches in steps (2) and (3) is 1:1.05. Finally, the obtained v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com