Novel environment-friendly multifunctional satellite type washing-free gravure direct printing technology

A multi-functional and environment-friendly technology, applied in the field of fabric printing, can solve the problems of not fundamentally solving environmental problems, lack of affinity, paper resource consumption, etc., to avoid indirect water consumption and water pollution, to facilitate maintenance or replacement, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

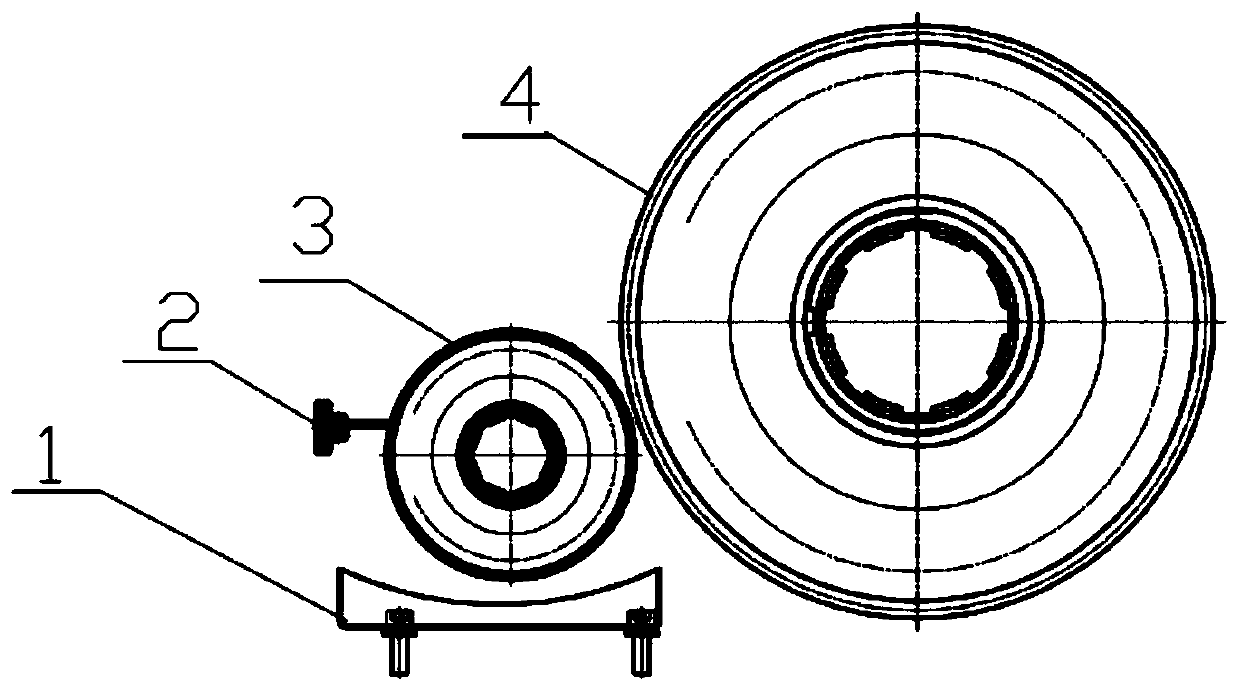

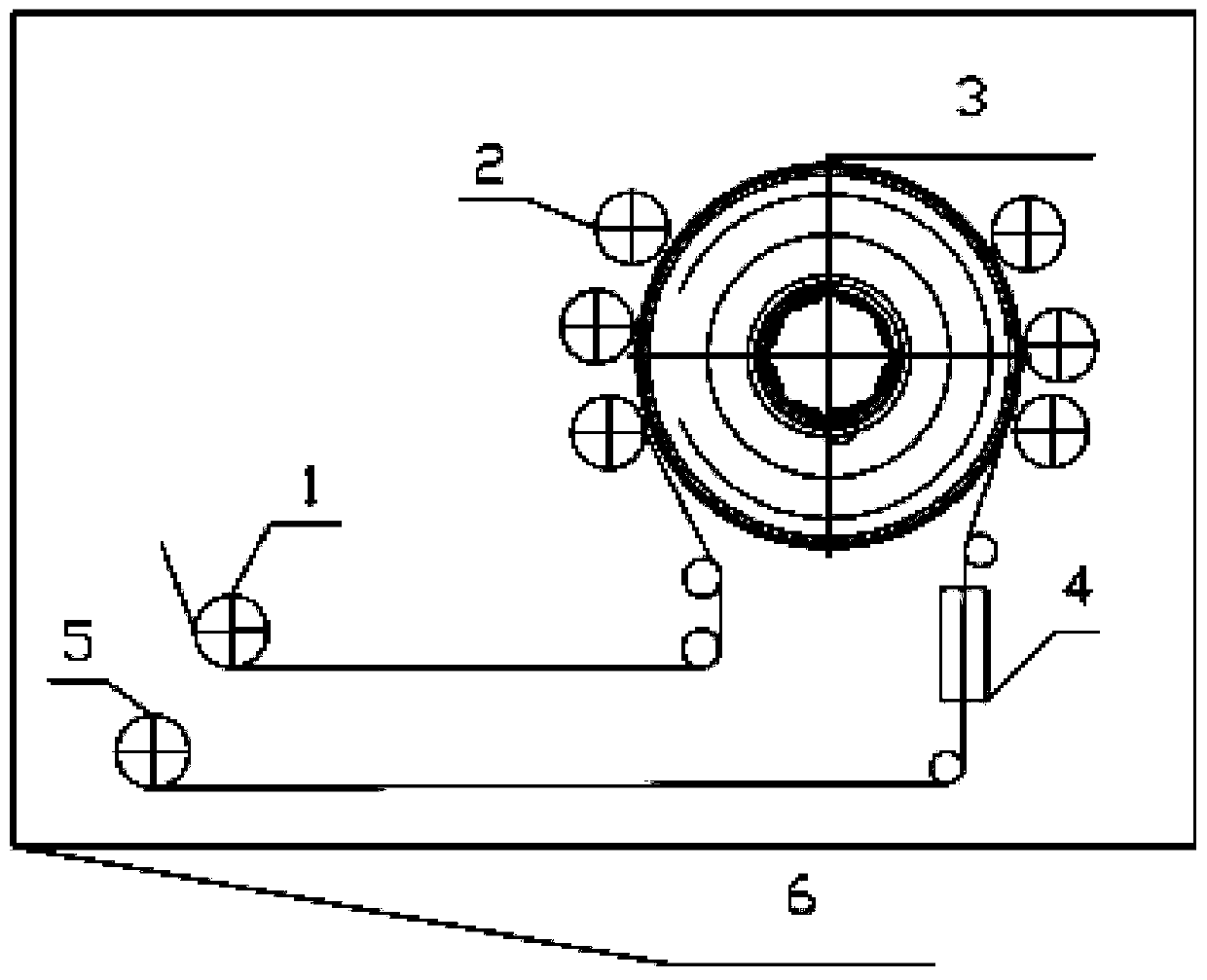

[0026] The realization process of the present invention is:

[0027] The present invention is a new environment-friendly and multifunctional satellite-type wash-free gravure direct printing process, which adopts an environment-friendly wash-free water-based disperse ink instead of solvent-based ink; utilizes the existing satellite-type flexographic printing machine unit to improve and upgrade its components, The material of the central large-diameter roller is changed to a rubber roller, and the central large-diameter roller and the pressure roller are used as a guide belt, and a guide belt gluing device and a cleaning and drying device are installed. Change the flower plate to the intaglio plate of the steel electric engraving process, and directly print the fabric without using paper as a transfer medium.

[0028] The raw materials used in the present invention can be used: environmentally friendly water-based disperse ink without washing, three primary colors plus black, Su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com