Patents

Literature

40results about How to "Eliminate environmental concerns" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing SIPE from SIPA by direct esterification method

ActiveCN101265218ALow costEliminate environmental concernsSulfonic acid preparationPolyesterAcid value

The invention discloses a method of preparing m-phthalic acid diglycol ester-5-sulphonate by directly esterifying m-phthalic acid-5-sulphonate. The m-phthalic acid-5-sulphonate (SIPA) and glycol (EG) are used as raw material and are directly esterified to prepare the m-phthalic acid diglycol ester-5-sulphonate (SIPE); the esterification rate is more than 99 percent, the acid value is less than 1(mgKOH / g), and the content of diglycol (DEGA) is less than 2.0 percent. Therefore, the m-phthalic acid diglycol ester-5-sulphonate (SIPE) which is manufactured by adopting the method is almost esterified completely; the disadvantages of high equipment investment, high recovery cost of methanol, and going against environment protection are elminated when the m-phthalic acid diglycol ester-5-sulphonate (SIPE) is prepared by using dimethyl-m-phthalate-5-sulphonate (SIPM) through an interesterification method; the m-phthalic acid diglycol ester-5-sulphonate (SIPE) has the characteristics of low acid value, high purity, less byproducts, etc.; the m-phthalic acid diglycol ester-5-sulphonate (SIPE) is used as a dye modifier or a third monomer and is added in polyester, so that the mass-producing demand is achieved; the method is a preparation method with stable way and excellent quality.

Owner:厦门翔鹭化纤股份有限公司

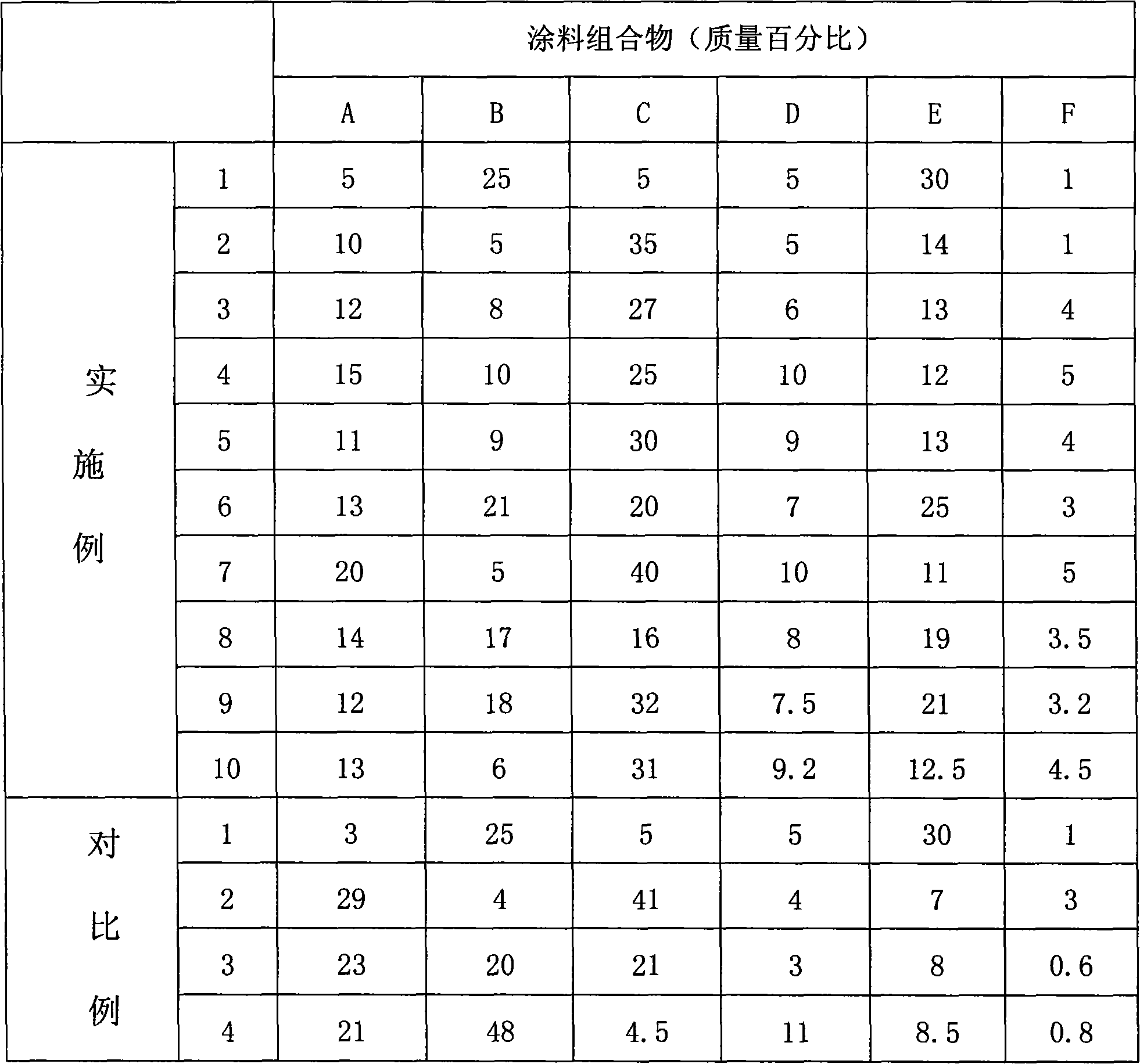

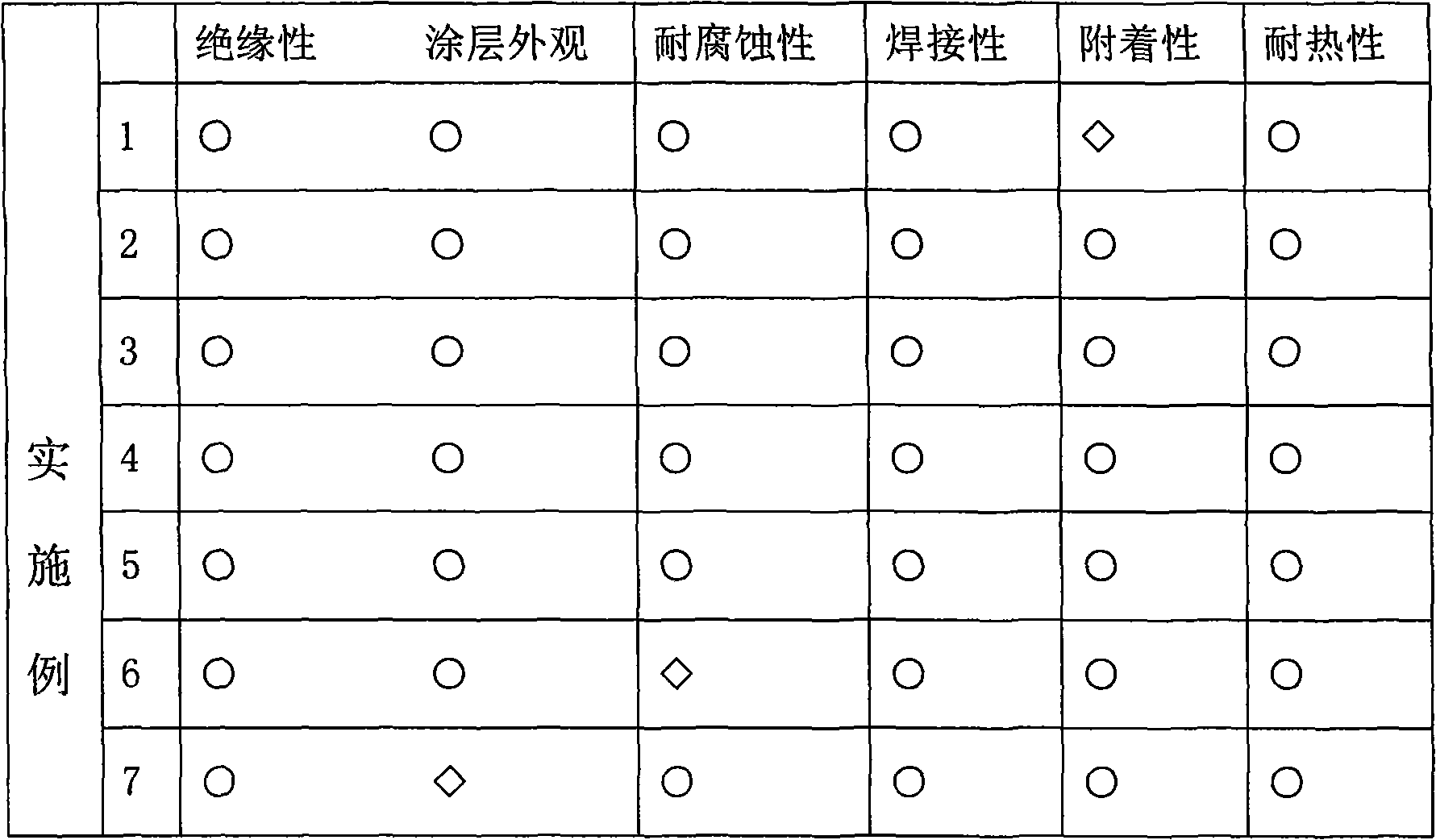

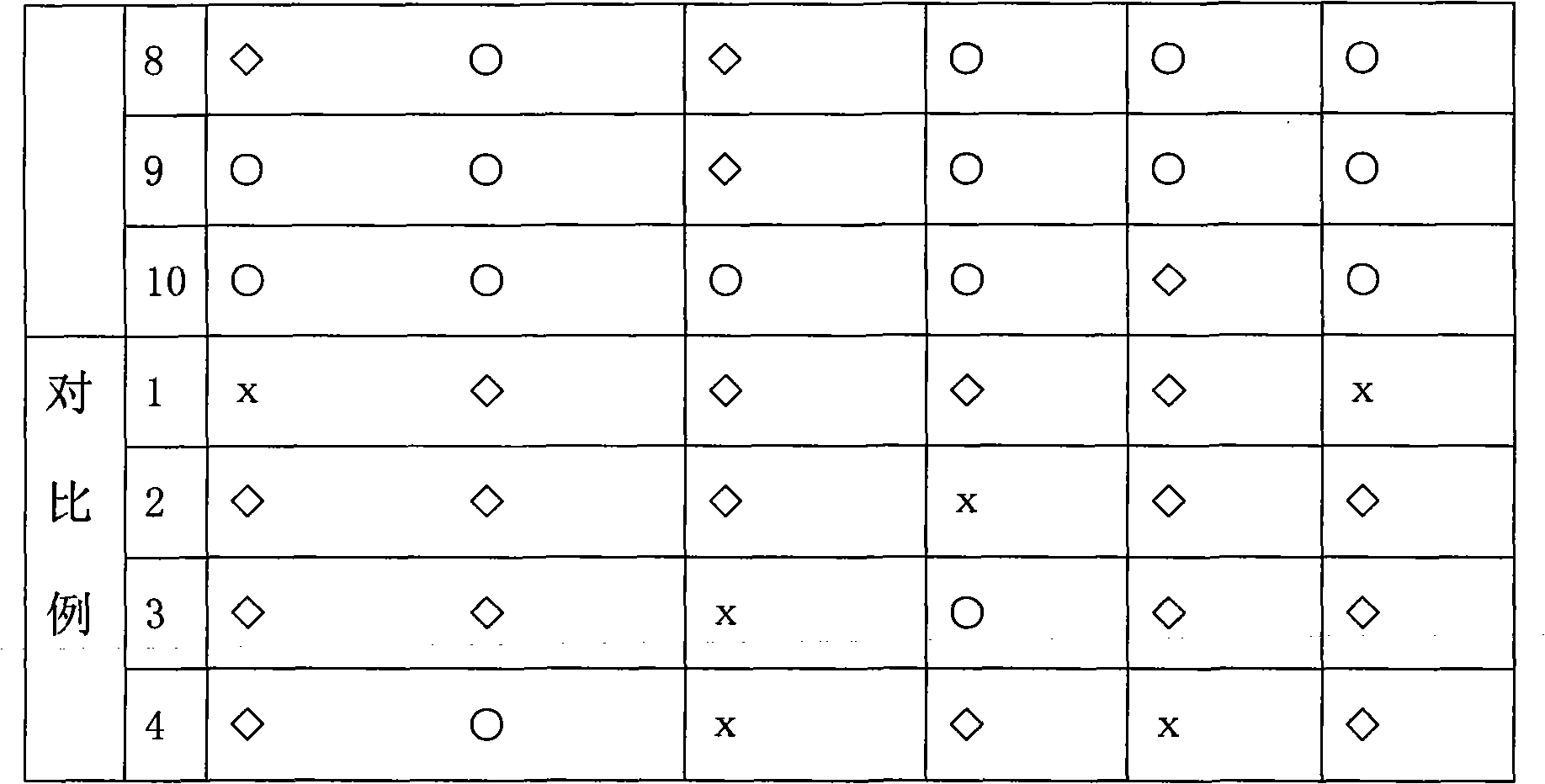

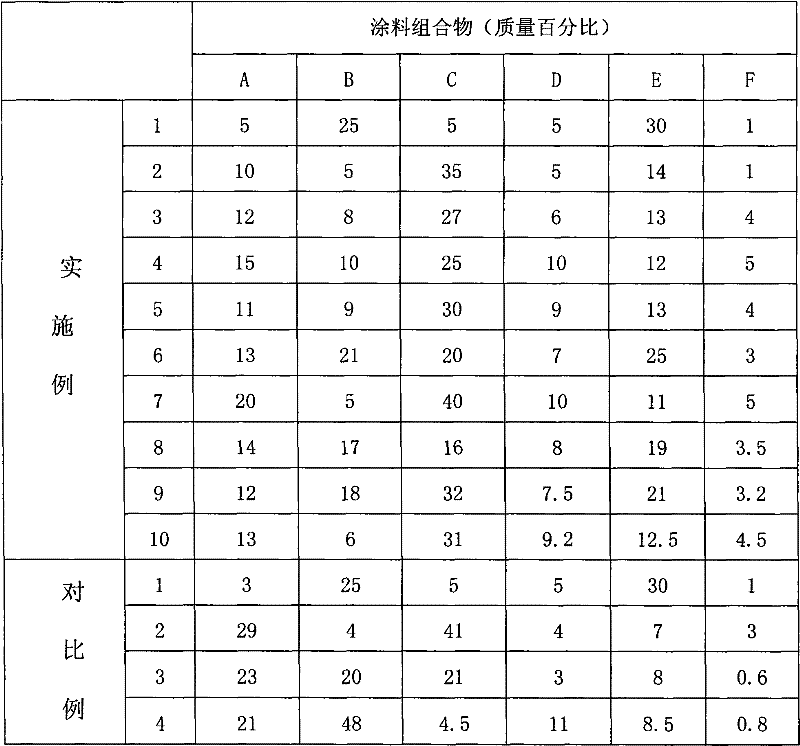

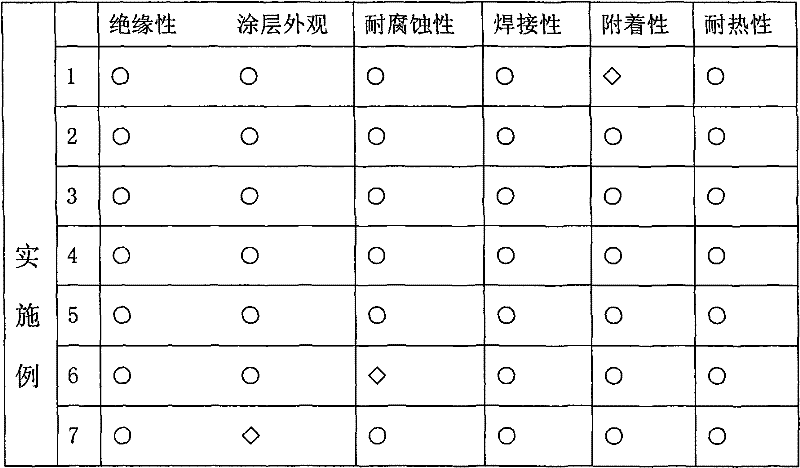

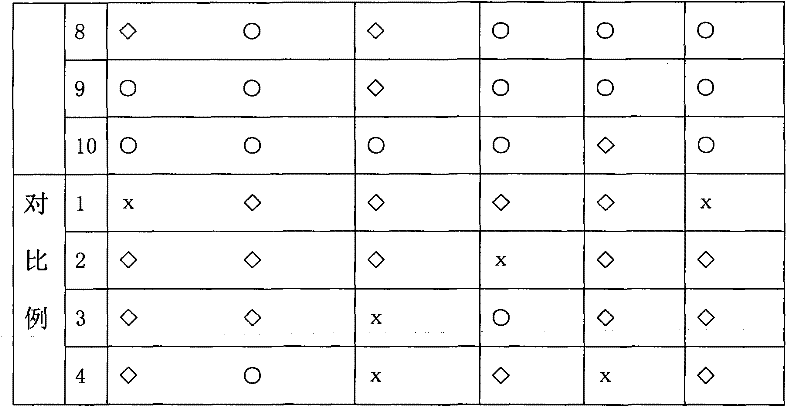

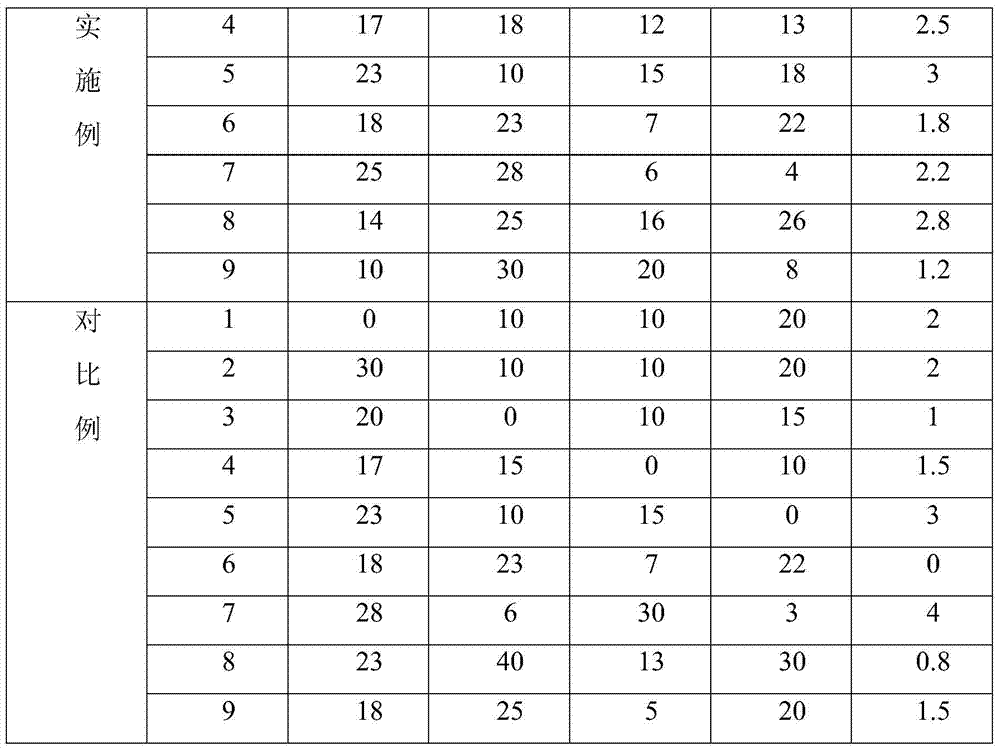

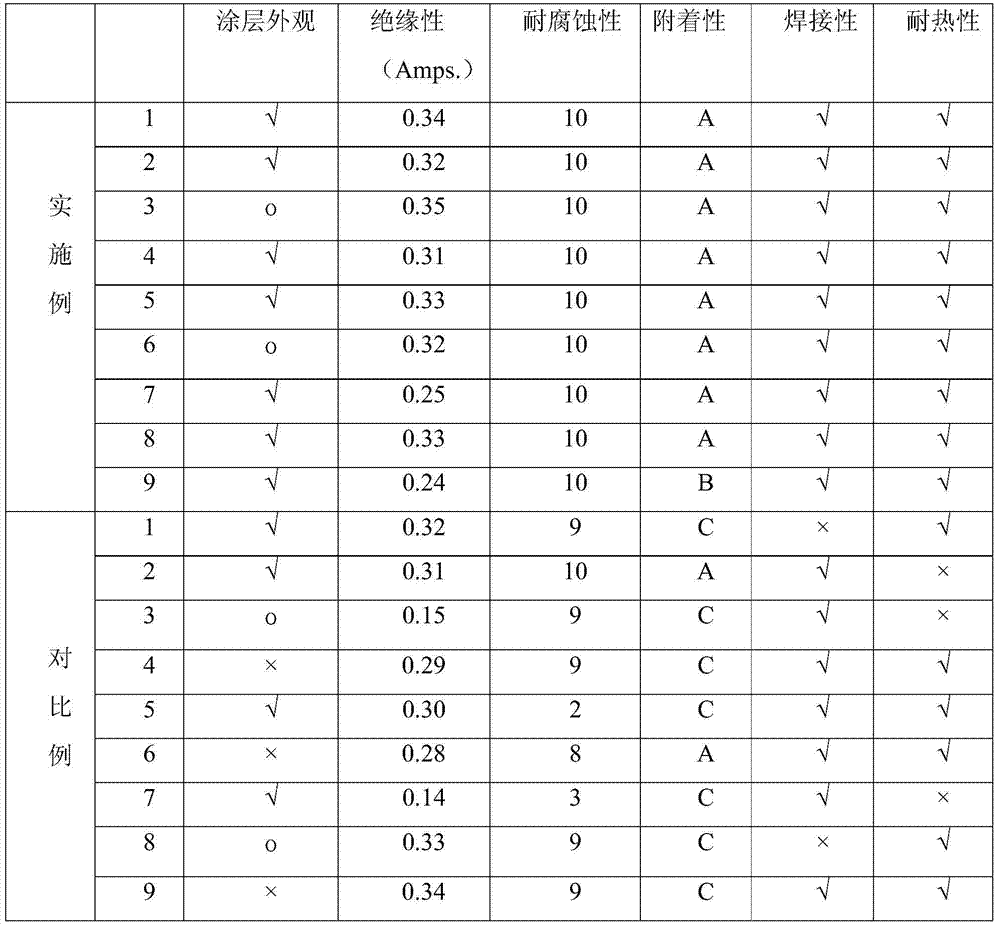

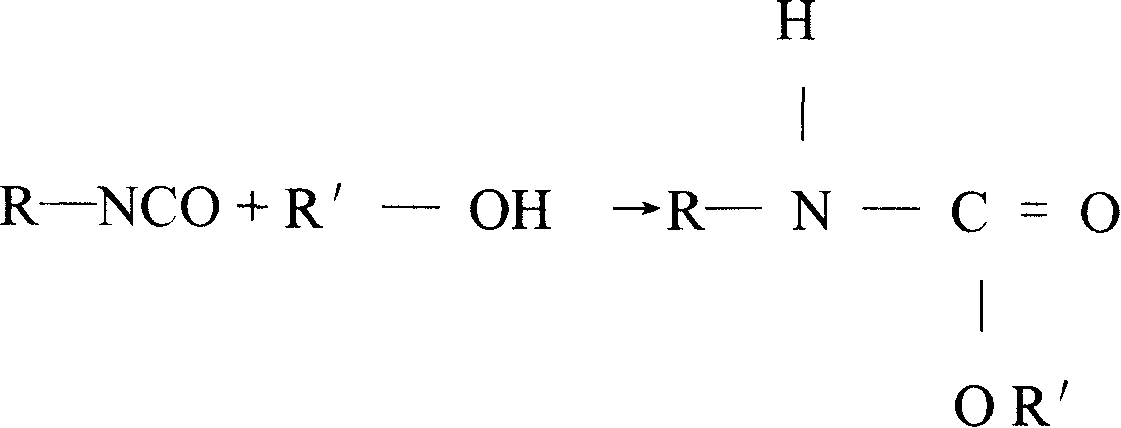

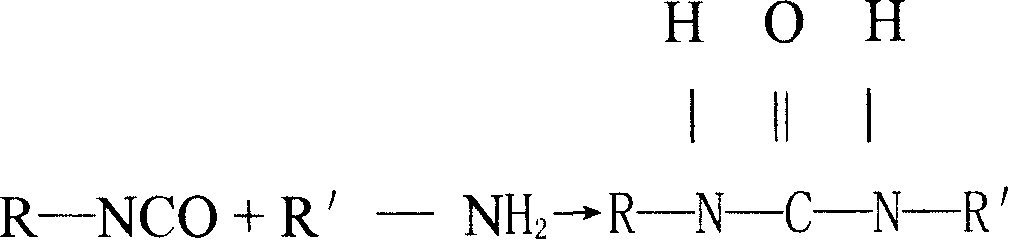

Insulating paint of semi-inorganic environmental non-oriented silicon steel insulating paint and application thereof

ActiveCN101643625AEliminate environmental concernsStrong absorption capacityPolyurea/polyurethane coatingsColloidal silicaPhosphate

The invention relates to an insulating paint of non-oriented silicon steel and discloses an insulating paint of semi-inorganic environmental non-oriented silicon steel insulating paint and an application thereof. The paint of the invention comprises the following components by weight percent: 5-20% of magnesium isopropylate, 5-25% of polyurethane-acrylate-ethylene oxide resin, 5-40% of aluminium dihydrogen phosphate, 5-10% of zinc acetate, 11-30% of colloidal silica, 1-5% of non-ionic surface active agent and the balance deionized water. The insulating paint of semi-inorganic environmental non-oriented silicon steel insulating paint of the invention can not only completely eliminate the environmental problem caused by chromium element, but also ensure that all the performances of the paintsuch as uniformity, corrosion resistance, heat resistance, weldability and the like are good.

Owner:上海迪升防腐新材料科技有限公司

Alkyd resin and preparation

The invention relates to a method for preparing alkyd resin with crude terephthalic acid instead of most of phthalic anhydride. Its characters show as follow: firstly, it uses 45~60wt% of the fatty acid ,14~20wt% of polyol, 9~25wt% of crude terephthalate, and 0.08~0.12wt% of tributyltin catalyst for esterification, after it comes to be transparent, then it adds 1.0~5.0%wt of diphenyl formylic anhydride, 6~14wt% of rosin, 1.0~5.0 wt% of benzoic acid for a further esterification till acid number to be below 14 and grignard viscosity to be 8~11 seconds.

Owner:JIANGSU SANMU GROUP CORPORATION

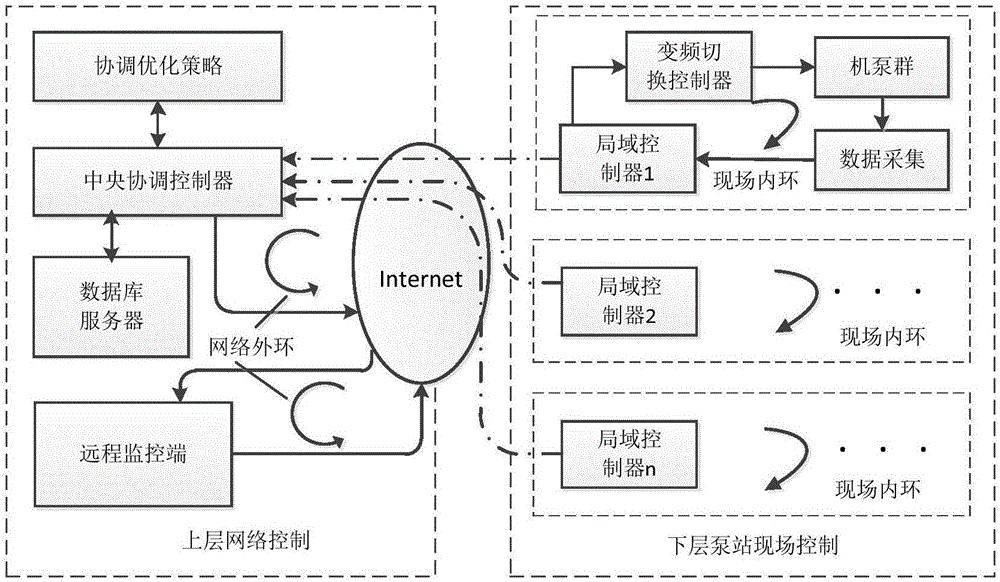

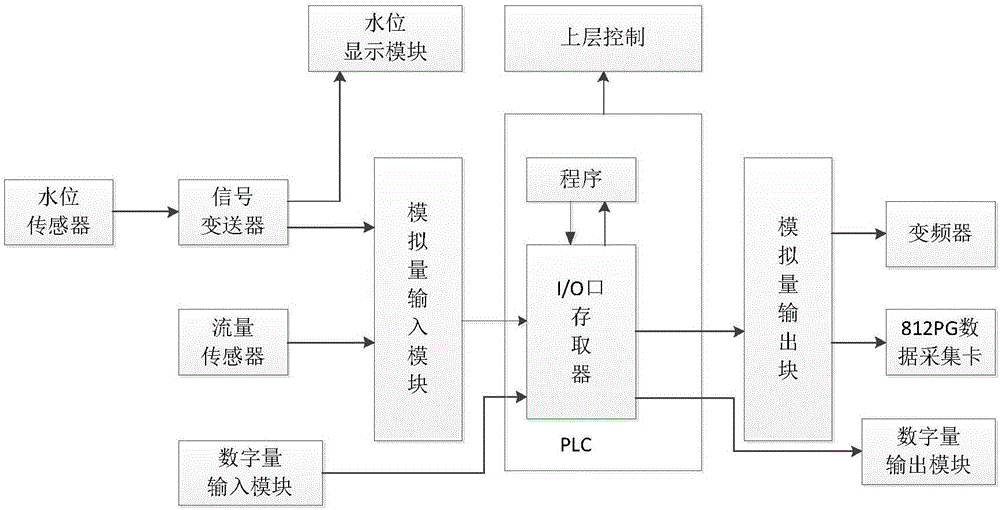

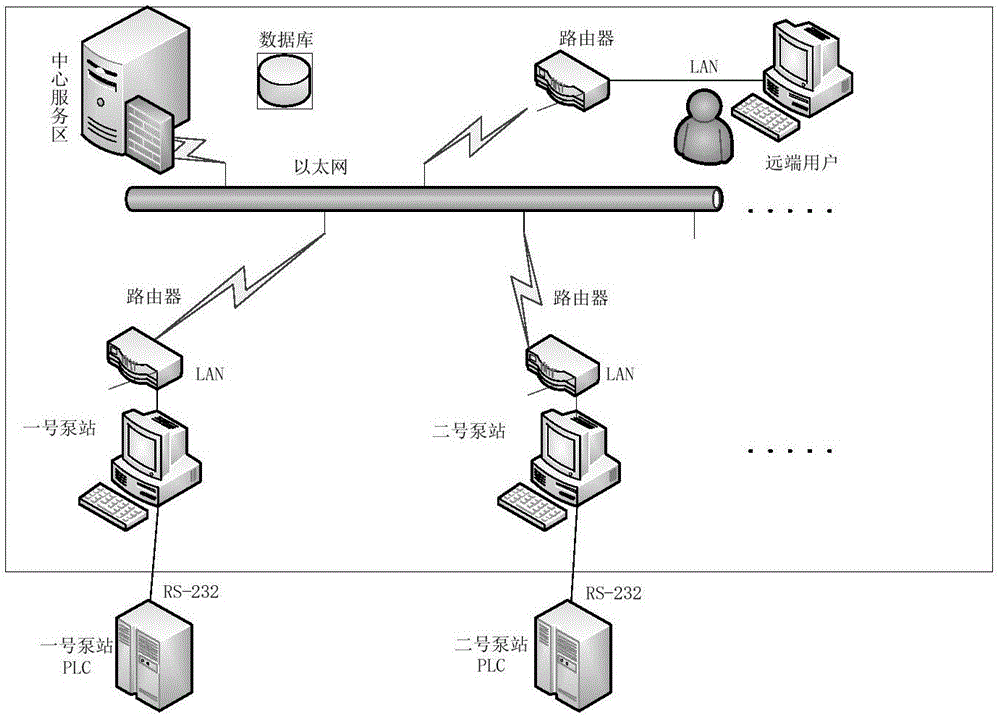

City intelligent drainage control system based on hierarchical control structure

InactiveCN106320497AStrong computing powerEasy networkingSewer pipelinesSystems designRemote control

The invention discloses a city intelligent drainage control system based on a hierarchical control structure, which consists of two relatively independent and interconnected upper network control systems and a pump station site control system with a downstream PLC as the core. The city intelligent drainage control system has the hierarchical control structure with a number of control cores for the large-system design, an industrial personal computer that is high in computing power and convenient in networking is constructed as the upper control core of the pump station, the network-based remote control system is established, global operating condition flow and water level are measured in real time, and according to the extreme value principle and optimization theory, appropriate optimization and coordination control strategies and scheduling methods are devised. At the same time, the reliable-performance PLC is used as the lower control core to construct the local intelligent control system, to ensure long-term non-stop operation of the drainage system to intelligentize the urban distributed pumping station drainage system, and to improve the level of urban waterlogging prevention.

Owner:QUZHOU UNIV

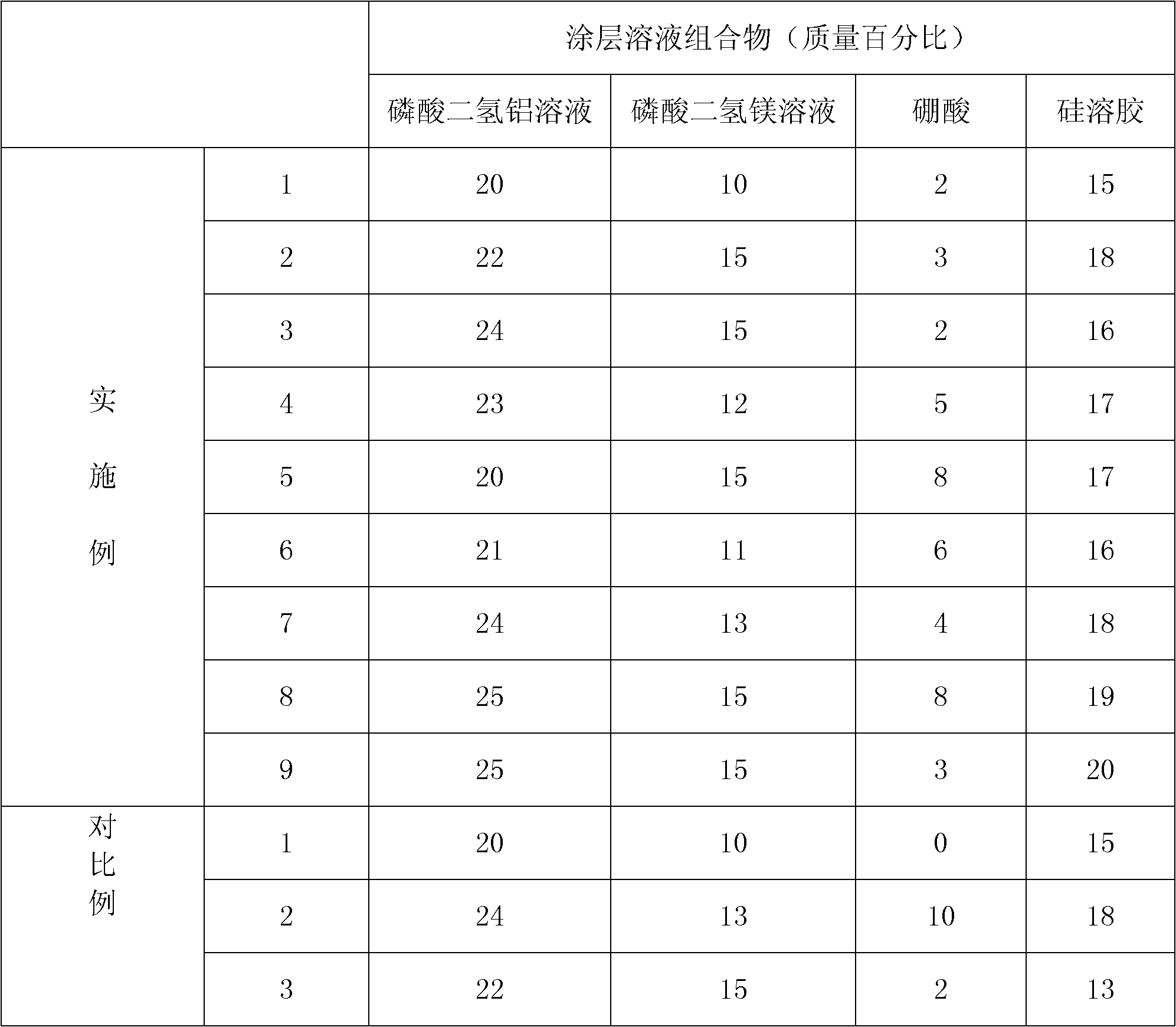

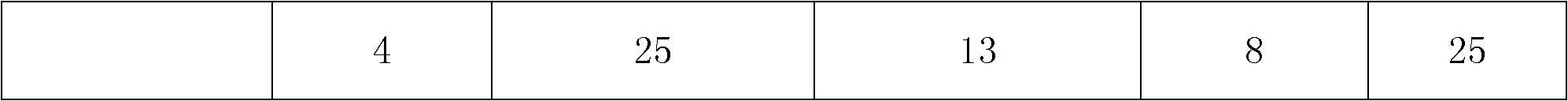

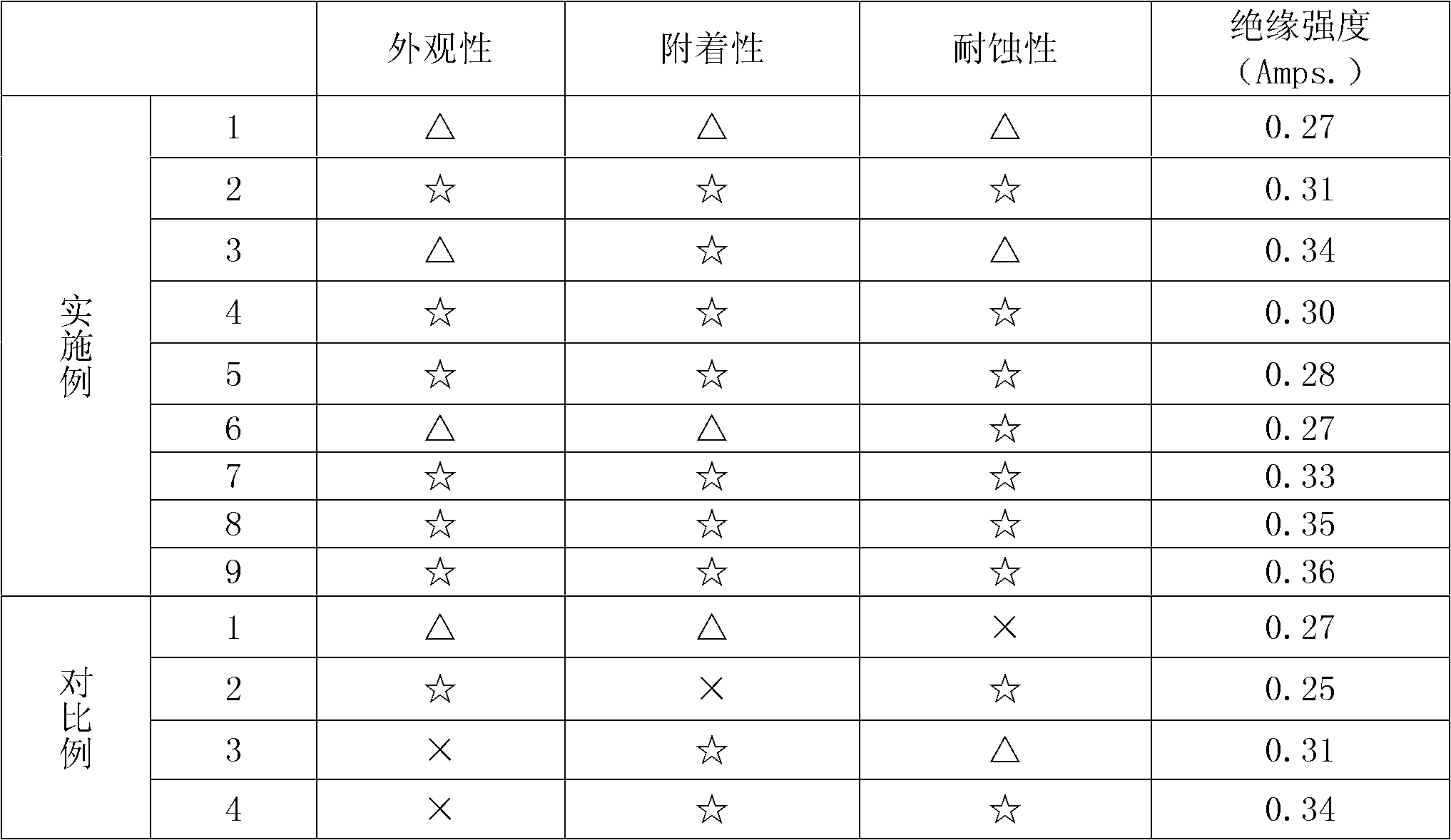

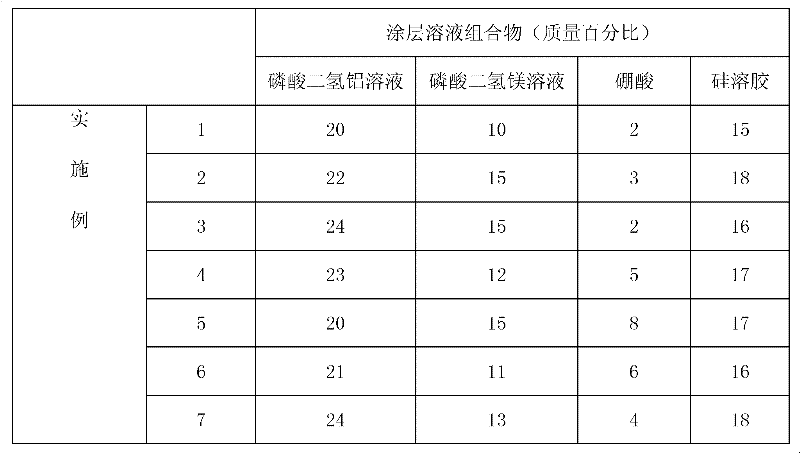

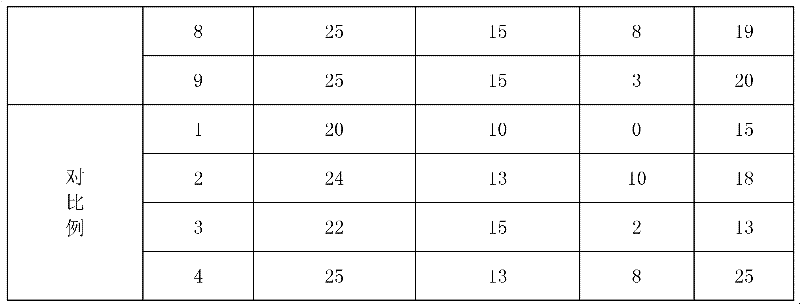

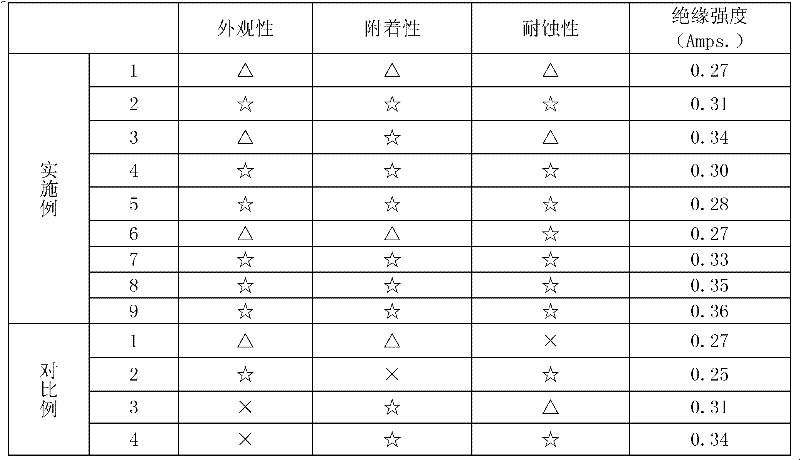

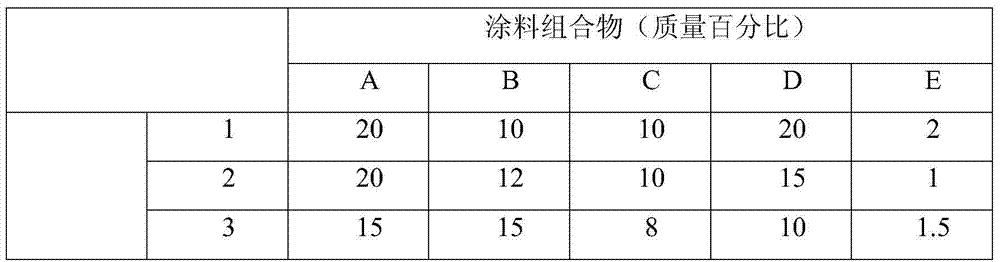

Environment-friendly insulating coating solution used for non-oriented silicon steel and preparation and application thereof

ActiveCN102115881AReduce wearEliminate environmental concernsMetallic material coating processesMonomagnesium phosphatePhosphate

The invention relates to an environment-friendly insulating coating solution used for non-oriented silicon steel and preparation and application thereof, in particular to a phosphate coating solution and preparation and application thereof, belonging to the technical field of preparation of a silicon steel insulating coating. Based on the total mass of the coating solution, the environment-friendly insulating coating solution used for non-oriented silicon steel comprises the components by the mass percentage of: 20 to 25 percent of aluminum dihydric phosphate solution, 10 to 15 percent of magnesium dihydrogen phosphate solution, 15 to 20 percent of ludox, 2 to 8 percent of boric acid and the balance of deionized water. The insulating coating prepared by using the environment-friendly insulating coating solution used for non-oriented silicon steel not only can guarantee that all the performances such as uniformity, insulating performance, adhesiveness, corrosion resistance, heat resistance, weldability and the like are excellent, but also totally solves the problem in environment protection caused by chromium.

Owner:上海迪升防腐新材料科技有限公司

Insulating coating solution and use thereof in silicon steel

The invention relates to insulating coating solution and an application thereof in silicon steel. The invention discloses the insulating coating solution for the silicon steel, the chemical components and the corresponding weight percentages thereof of the coating solution on the basis of the total weight of the coating solution are as follows: 5-25 percent polyurethane-acrylic ester-ethylene oxide resin; 10-40 percent aluminum dihydrogen phosphate; 5-20 percent magnesium nitrate; 10-30 percent colloidal silica; 1-5 percent non-ionic surfactant; and deionized water as the rest. The insulating coating solution can not only totally eliminate the environmental problem caused by chromium element, but can also ensure uniformity, decay resistance, heat resistance and other performances of the coating to be good.

Owner:上海迪升防腐新材料科技有限公司

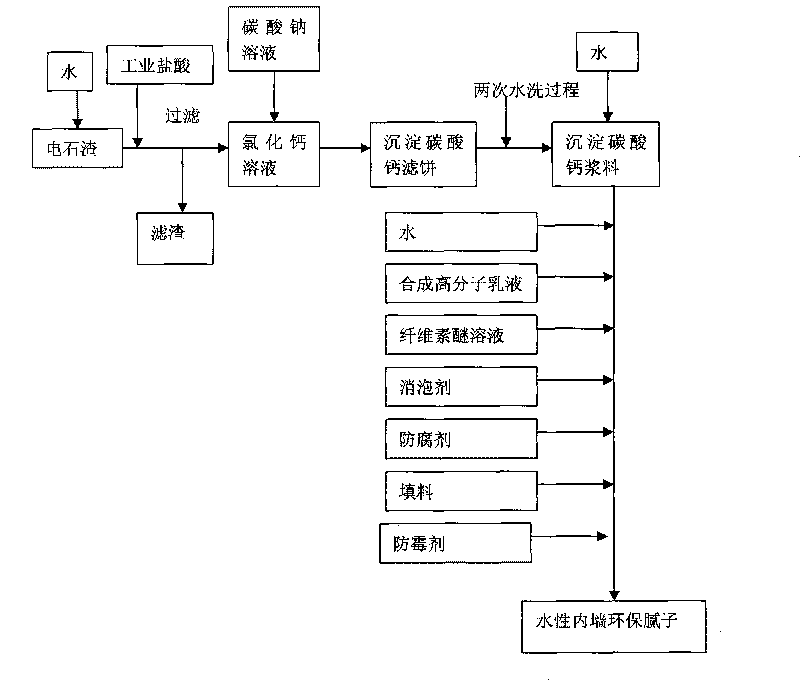

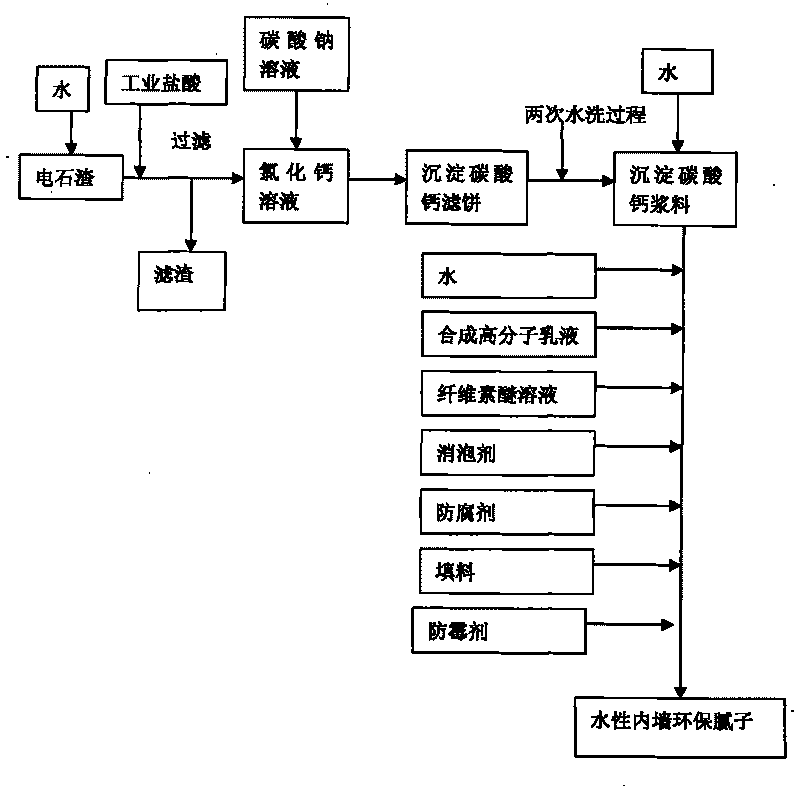

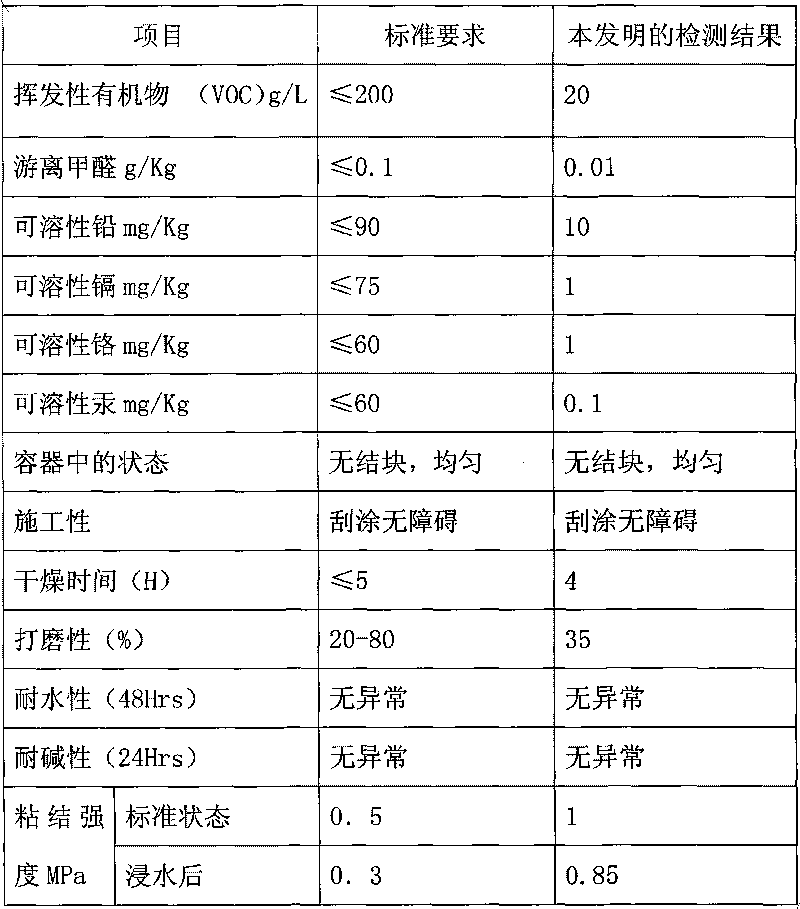

Water-based inner wall environmentally-friendly sealing compound using circulating resources and method for preparing same

The invention relates to a water-based inner wall environmentally-friendly sealing compound using circulating resources, which comprises the following components in percentage by weight: 20 to 30 percent of precipitated calcium carbonate slurry, 20 to 30 percent of filler, 4 to 8 percent of synthetic high molecular emulsion, 20 to 30 percent of cellulose ether solution, 0.1 percent of preservative, 0.1 percent of antiseptic, 0.2 percent of de-foaming agent and the balance of water. The aim of the invention is to provide the efficient, low-cost and environmentally-friendly water-based inner wall environmentally-friendly sealing compound using the circulating resources and a method for preparing the same, which successfully solve the problems of requirements on special equipment, resource waste, non-environmentally-friendly prepared sealing compound containing soluble heavy metals, high VOC content and the like caused by the current preparation of precipitated calcium carbonate from industrial carbide slag.

Owner:佛山市美涂士化工有限公司

Novel environment-friendly multifunctional satellite type washing-free gravure direct printing technology

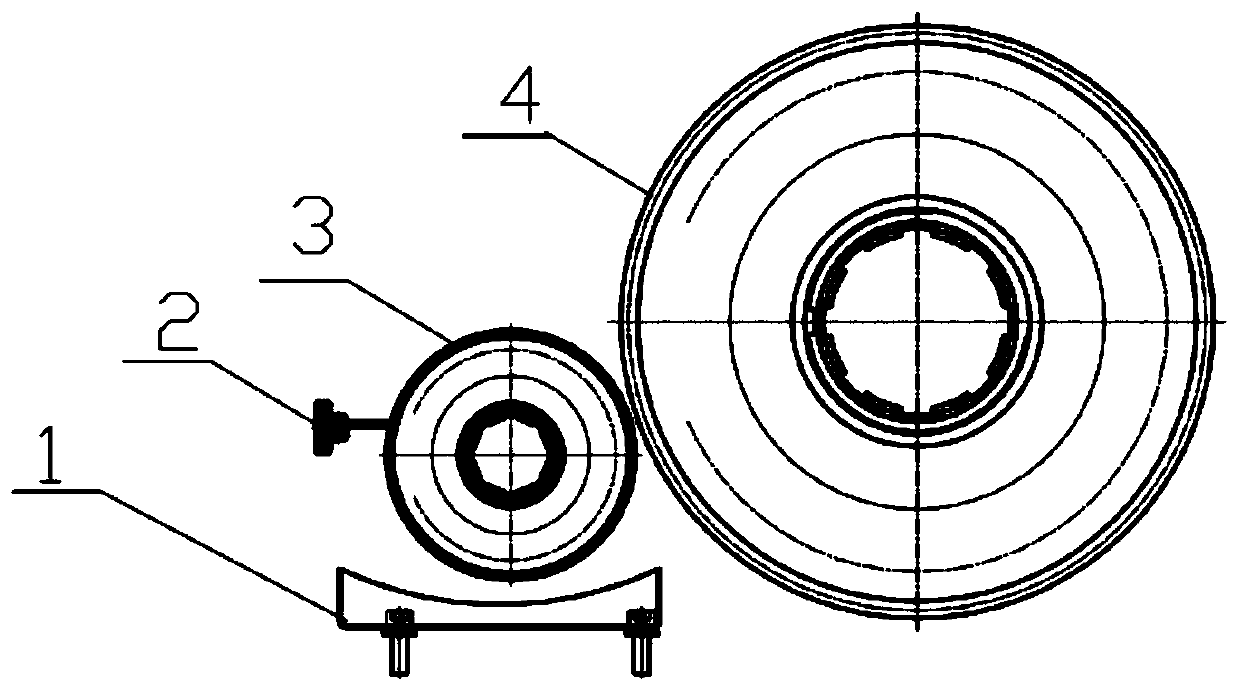

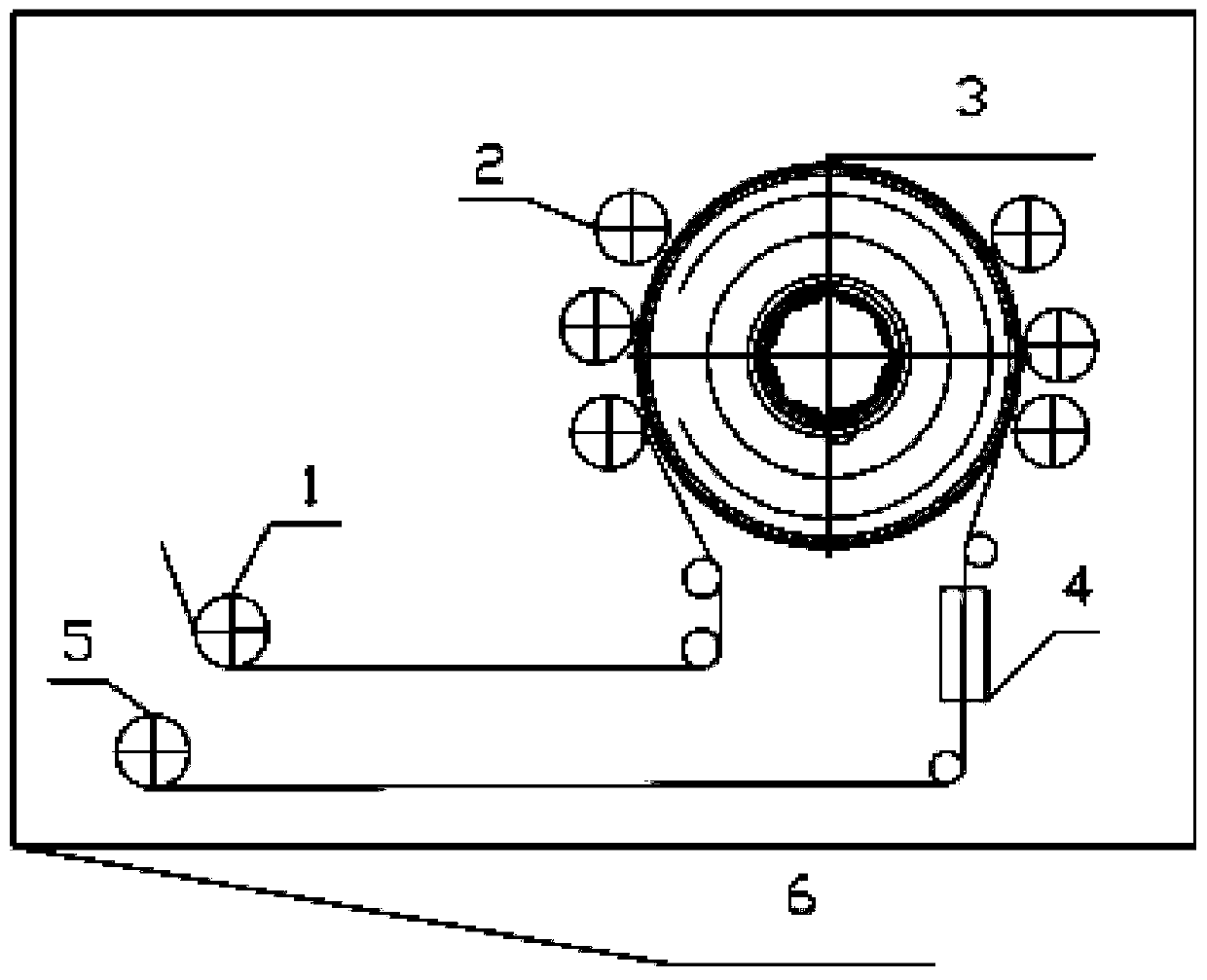

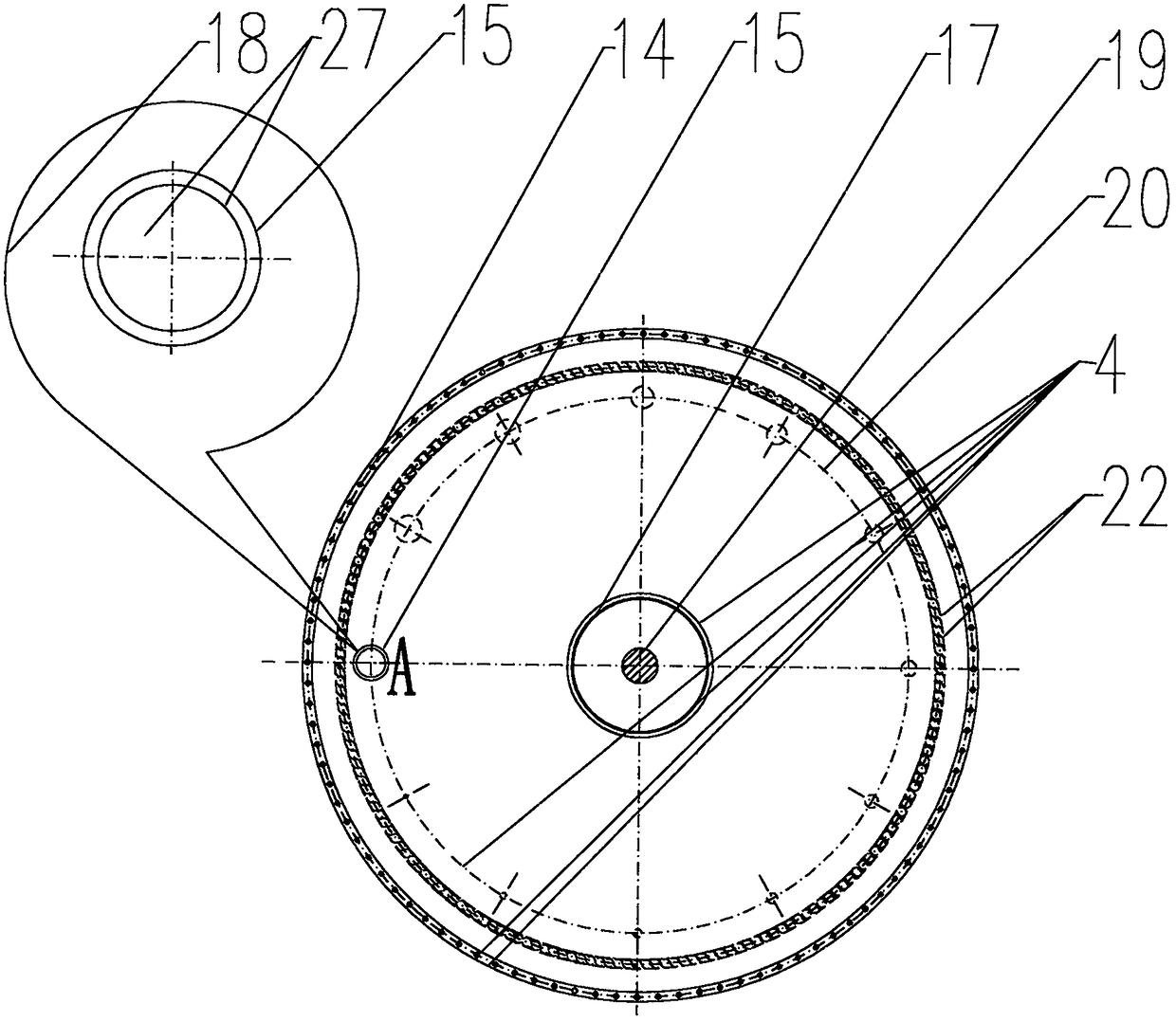

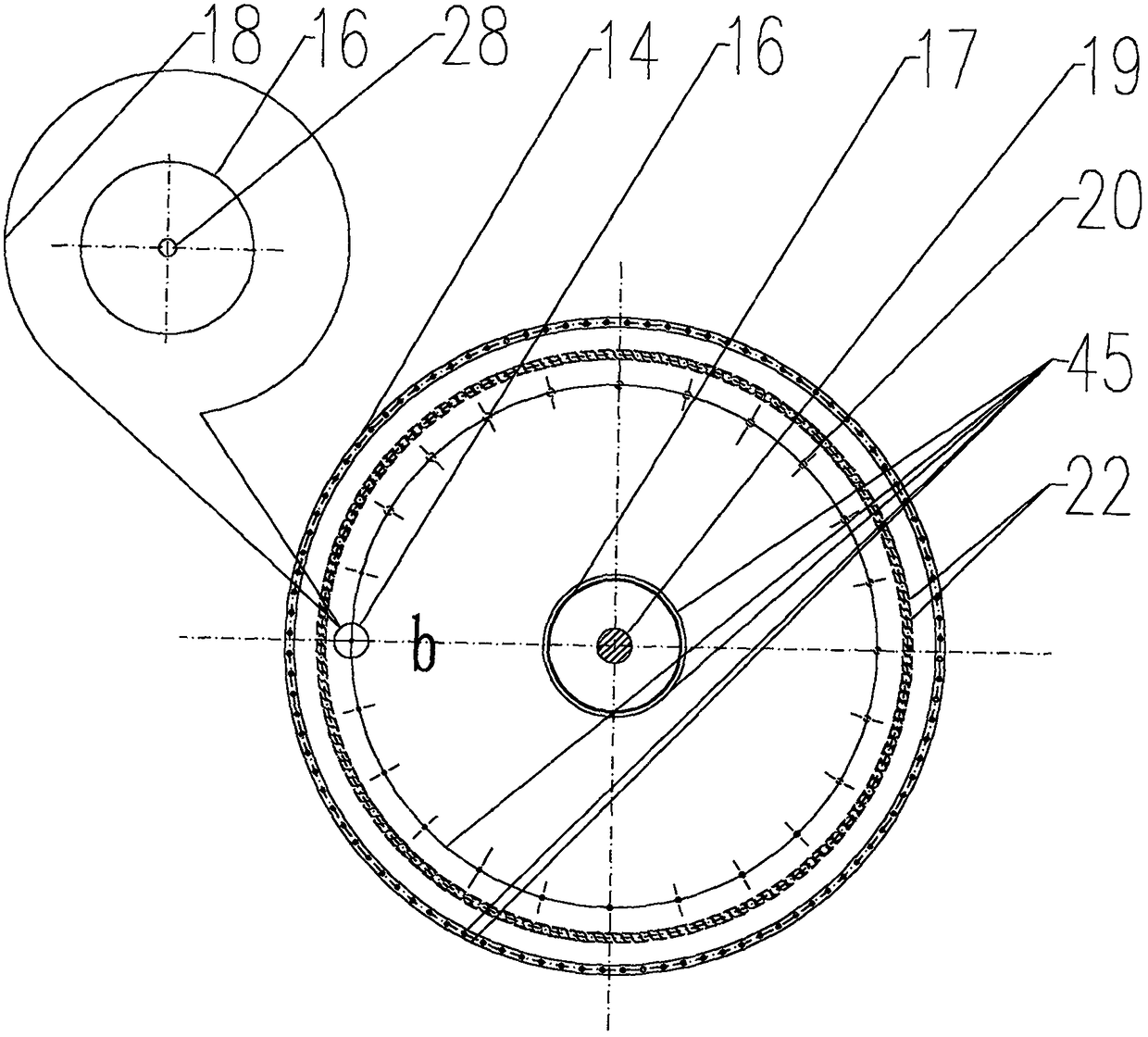

InactiveCN111186224ASolve the emission problemTroubleshooting Tension DifficultiesOther printing apparatusTextile printerPhotogravure

The invention discloses a novel environment-friendly multifunctional satellite type washing-free gravure direct printing technology. An existing satellite type flexo printing machine and environment-friendly washing-free water-based ink are adopted. Different from the existing satellite type flexo printing machine, a large-diameter center roller serves as a base material bearing roller, and the material of the large-diameter center roller is rubber not steel; and a printing plate is gravure, the electric carving technology is adopted, and the material of the printing plate is steel not flexible material. The center large-diameter roller also serves a guide belt for printing fabric, a guide belt glue automatic feeding device and an automatic cleaning device are arranged, the rubber on the surface of the center large-diameter roller is coated with the guide belt glue, the fabric is attached to the rubber large roller for direct printing, the problem that multiple color registers do not have tension is solved, and registration is accurate. The characteristics that occupied space is smaller than the occupied space of an existing photogravure press, few printing materials are wasted, cost is saved, the machine table efficiency is high, and printing of multifunctional materials is wide; and steaming washing is not needed, and the fabric is more bright in color / higher in depth sense compared with fabric printed by the existing satellite type flexo printing machine are achieved.

Owner:苏州维宁斯化工有限公司

Grouting electric heating tank system for magnesium catalytic furnace chamber CO2 combustion and carbon fixation

InactiveCN109140432AEliminate disadvantagesEliminate environmental concernsCombustion using catalytic materialCombustion apparatusCoal waterSlag

Provided is a grouting electric heating tank system technology for magnesium catalytic furnace chamber CO2 combustion and carbon fixation. The technology is a fuel gas-fired boiler of a ZL201210566497.4 patented product and used as a matching object, a coal water slurry electrothermal over-pressure slag gas separation tank is provided with a gas outlet rotary disc valve assembly and a slag discharge outlet rotary disc valve assembly to ensure safe and normal gas production and slagging of the grouting electric heating tank system, gas and slag separation is achieved and combined with dolomitepowder roasting or fluidized bed rich powder to produce magnesium vapors for supply air-free combustion matched with boilers, which is used for the purposes that the big and small boilers in active duty are remade and manufactured, the energy is saved by 50-60%, the carbon emission is reduced by more than 50% and nitrogen oxides are reduced by more than 95%, and the system must produce huge impetus for energy reform of magnesium catalysis of China.

Owner:管理

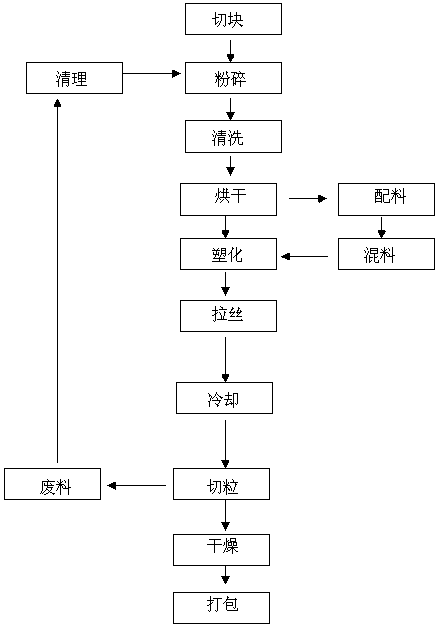

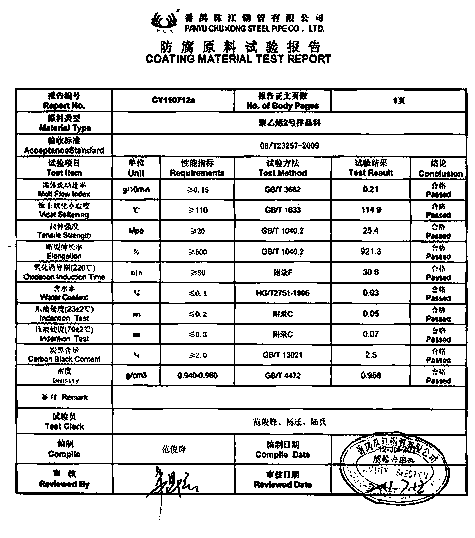

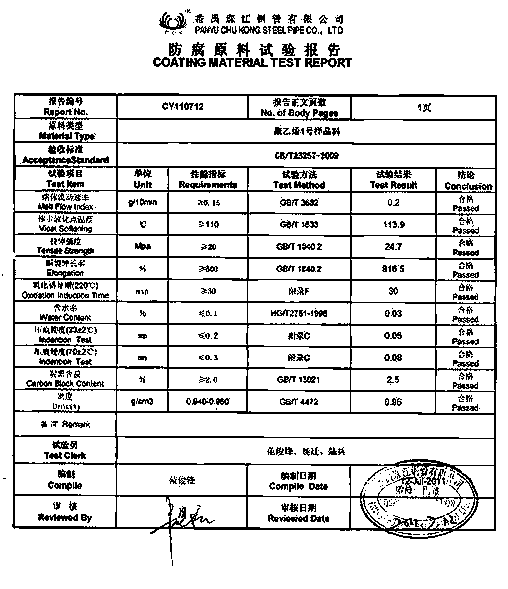

Method for recycling waste plastic for pipeline anticorrosion

ActiveCN103448159AImprove the mixing effectImprove plasticizing qualityPlastic recyclingSteel tubeEnvironmental resistance

The invention discloses a method for recycling waste plastic for pipeline anticorrosion, belonging to the technical field of high molecular materials applied to steel tube anticorrosion. The method is characterized by comprising the following steps: crushing; cleaning; re-proportioning anticorrosive 3PE (Poly Ethylene) waste plastic of a pipeline 3, namely the ratio of regenerating prilling materials: resin: an antioxygen: a processing agent=( is (80-70):(18-15):0.2:1.0. After prilling, the quality of the waste plastic satisfies the demand of technical standard (SY / T0413-2002) on the polyethylene anticorrosive layer of the buried steel pipeline, and the waste plastic can be reused to 3PE anticorrosion. The environmental pollution is eliminated and the environment problem is solved. The cost of raw materials for pipeline anticorrosion is saved, the utilization ratio of resources is improved, and the domestic blank is filled. The method belongs to circular economy, obtains good economic and social benefits, and has better popularization and application valves.

Owner:PANYU ZHUJIANG STEEL PIPE LIANYUNGANG

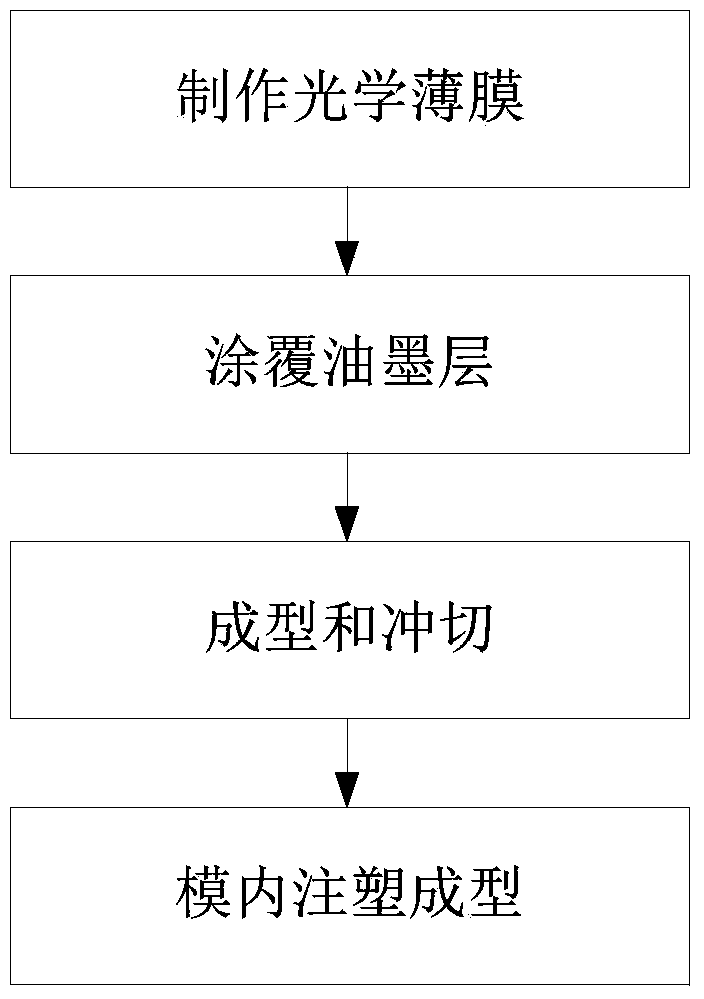

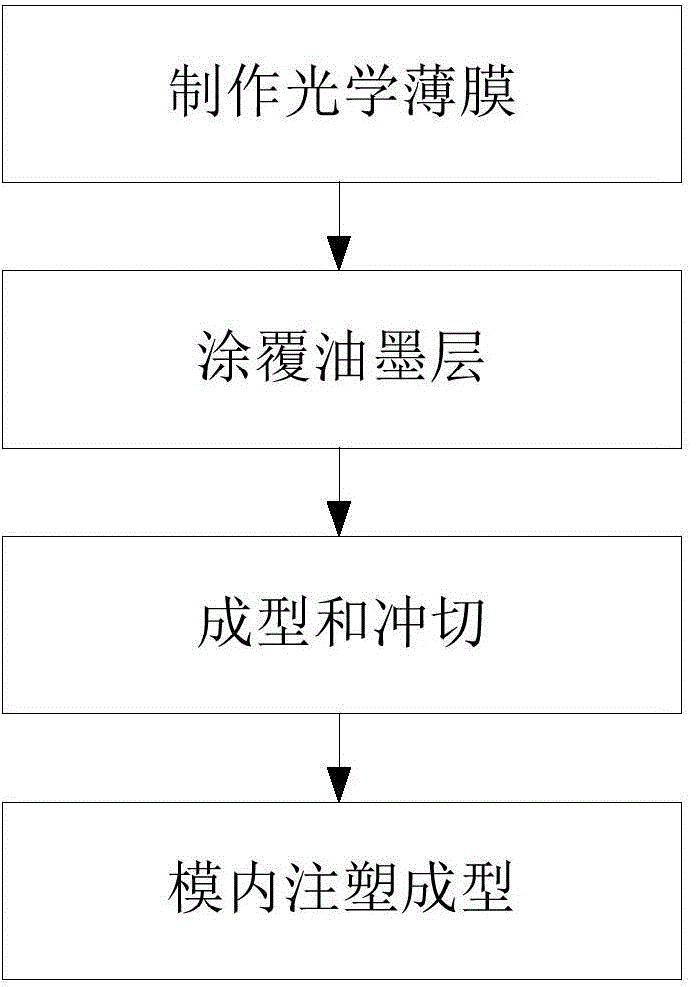

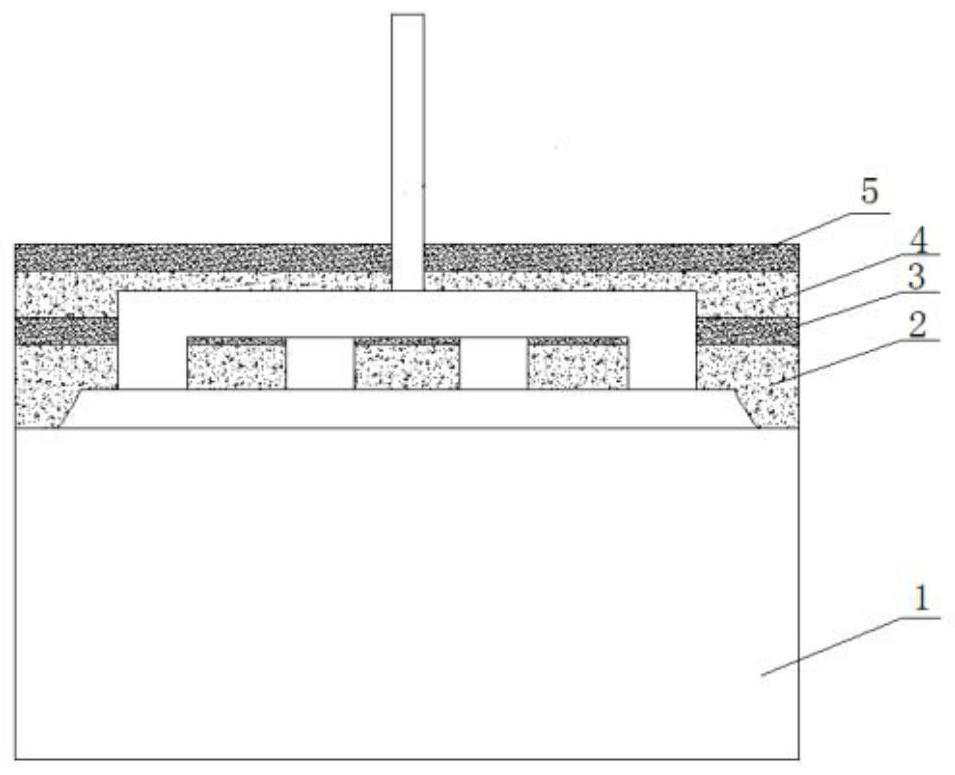

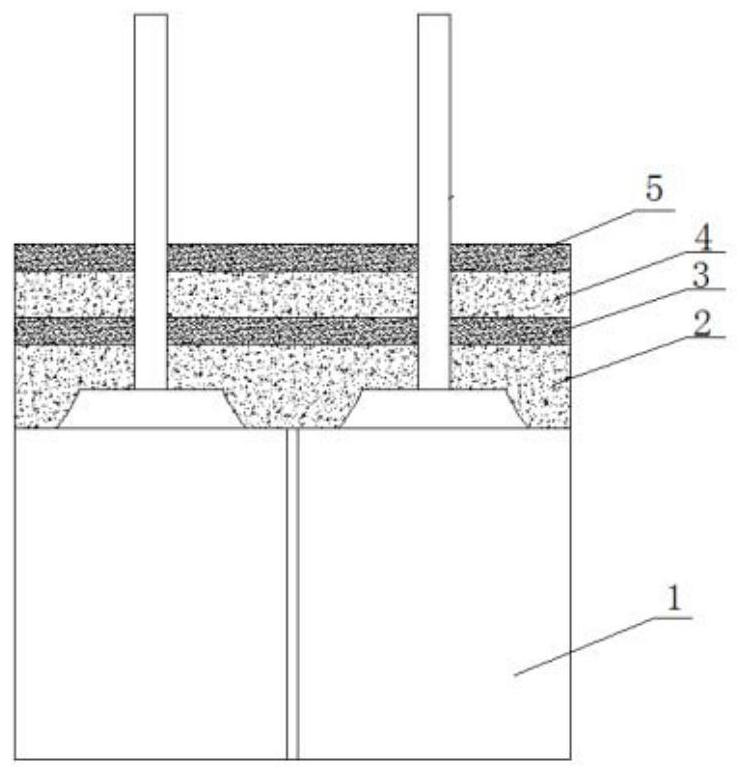

IML (in molding label) structure and injection molding method

ActiveCN103660133AAchieve high matte decorative effectEasy to recycleSynthetic resin layered productsRefractive indexOptical thin film

The invention discloses an IML (in molding label) structure which comprises an optical thin film and an ink layer, wherein the optical thin film is coated with the ink layer; the optical thin film, the ink layer and an injection molding material are formed into a whole through injection molding; and the optical thin film adopts a stacked structure formed by alternatively laminating a resin film with a higher refractive index and a resin film with a lower refractive index. The invention further discloses an injection molding method of the IML structure. The metallic high-matte decoration of a product can be realized through one-time injection molding, and a non-conductive and environment-friendly metallic surface treatment effect of a structural member of a casing of an electronic product is realized.

Owner:GUANGDONG JANUS SMART GRP CO LTD

Safe slag discharging device for boiling furnace

InactiveCN107676801AAvoid cloggingAvoid getting stuckLighting and heating apparatusSlagFluidized bed

The invention relates to the technical field of chemical production, and discloses a safety slag discharge device for fluidized fluidized furnace. The device includes a slag discharge pipe, a gas purging ring, a slag discharge cut-off valve, a gas cut-off valve, a slag discharge tank and a slag receiving hopper. The invention has simple equipment, uses nitrogen to purge the material in the slag discharge shut-off valve and the slag discharge pipeline through the gas purging ring, avoids the blockage or jamming of the slag discharge shut-off valve by granular materials, and realizes the safety, continuity and reliability of the fluidized fluidized furnace. Controlled slag discharge eliminates the safety accidents and environmental protection accidents caused by it.

Owner:张园园

Dump leaching processing method for waste furnace-constructing refractory materials of aluminum electrolytic bath

InactiveCN107313075AEliminate environmental concernsRealize closed-loop resource applicationAlkali metal fluoridesCarbonate preparationElectrolysisRefractory

Disclosed is a d ump leaching processing method for waste furnace-constructing refractory materials of an aluminum electrolytic bath. The method comprises the following steps that the waste furnace-constructing refractory materials which are sorted from bath residues generated in overhaul the aluminum electrolytic bath are crushed and screened, and then pre-leaching, dump leaching and washing are circularly conducted on the waste furnace-constructing refractory materials; generated pre-leached liquid and dump leached liquid are subjected to oxidative decyanide treatment and then are filter-pressed; and CO2 gas is led in filter-pressed filtered liquid, then the filter-pressed filtered liquid is subjected to carbon-neutralization treatment, through concentration and crystallization, sodium salt is recovered, and mixture of fluorinated NaHCO3, fluorinated Na2CO3 and NaF is obtained. By means of the dump leaching processing method, innocent treatment and comprehensive using of the waste furnace-constructing refractory materials of the aluminum electrolytic bath can be achieved.

Owner:YUNNAN RUNXIN ALUMINUM

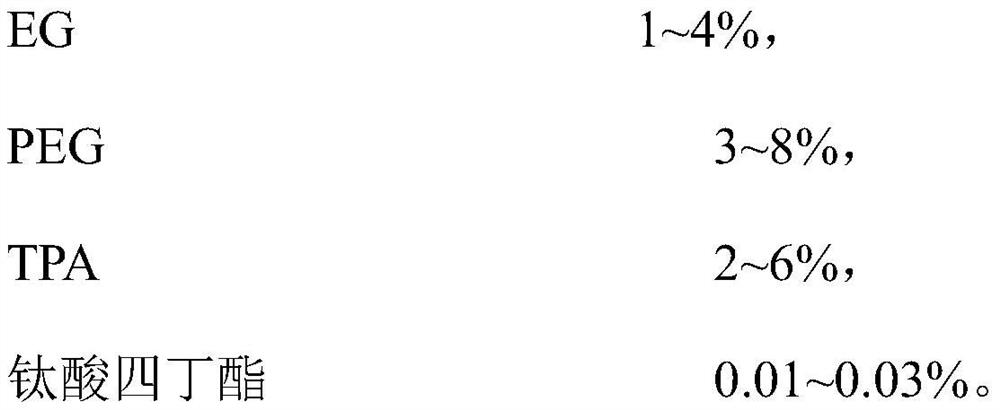

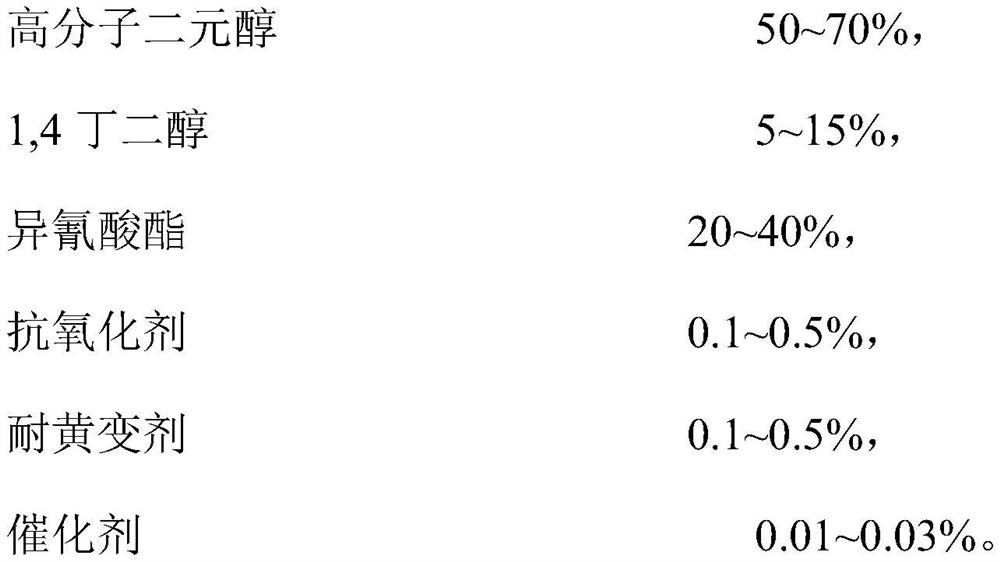

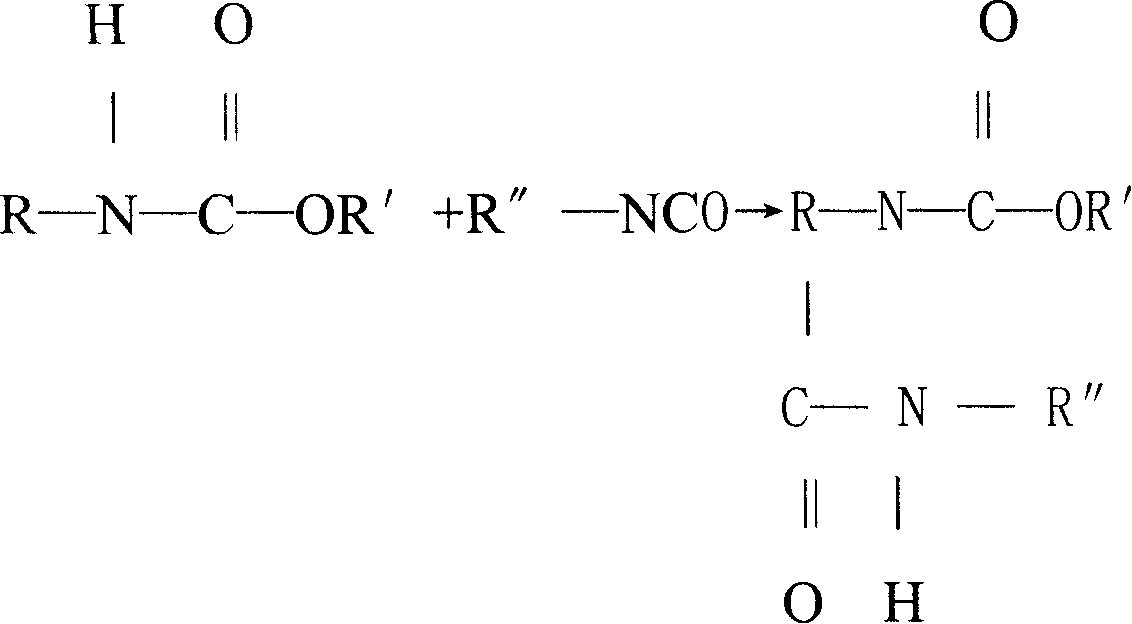

Preparation method of degradable TPU based on recycled PET

A degradable TPU preparation method based on recycled PET comprises the following steps: a first stage: hydrolyzing PET; a second stage of preparing high-molecular dihydric alcohol; a third stage of preparing the degradable TPU. The degradable TPU formed by the preparation method disclosed by the invention has good degradation performance. The product is beneficial to environmental protection, also has good basic physical properties, can be suitable for high-end products, and is wide in application range. Meanwhile, when the PET is recycled, the modes of acidolysis, alkaline hydrolysis, alcoholysis and the like are not used, but a high-temperature deionized hydrolysis mode is used, so that the environmental protection problem in the manufacturing process is avoided, and waste caused by use of petrochemical raw materials is avoided.

Owner:东莞市米儿塑胶原料有限公司

Resin solution for producing copper-clad plate

The invention relates to resin solution for producing a copper-clad plate. The resin solution consists of the following components in part by weight: 100 parts of phosphoric epoxy resin, 6 to 8 parts of phenolic resin curing agent, 20 to 40 parts of solvent, 5 to 15 parts of silicon dioxide, 2.0 to 5.0 parts of aluminum hydroxide, 2.0 to 5.0 parts of magnesium hydroxide and 1.0 to 1.5 parts of modified barium carbonate. Due to the adoption of the phosphoric epoxy resin, the manufactured copper-clad plate is suitable for lead-free solders, and the phosphoric epoxy resin can replace the bromine-containing epoxy resin in the prior art so as to meet the requirement of flame retardancy and eliminate the problem of environmental protection; and due to the adoption of a multi-component compound filler, the copper-clad plate produced by using the resin solution has good hardness, good electric insulation property, deformation resistance at a high temperature and excellent integral performance.

Owner:方建军

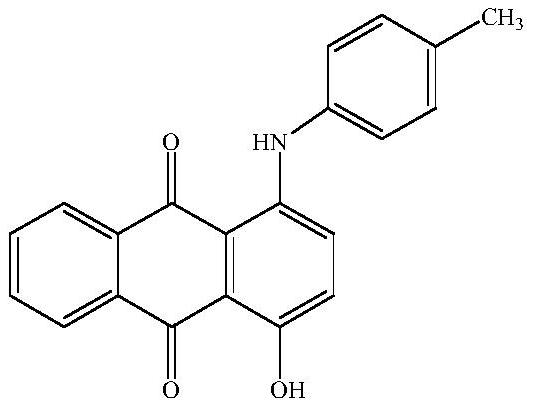

Method for preparing solvent violet 13

ActiveCN111675917AThe total yield of the reaction is highThe amount of solid waste is reducedOrganic chemistryOrganic compound preparationSolvent Violet 13Hydroxyanthraquinone

The invention relates to a synthetic method of a dye, specifically to a method for preparing solvent violet 13. The method comprises the following steps: with 1,4-dihydroxy anthraquinone, a 1,4-dihydroxy anthraquinone leuco body and p-toluidine as raw materials, performing a condensation reaction by taking water as a reaction medium in the presence of alkali, boric acid and a phase transfer catalyst, and after the reaction is finished, filtering, washing and drying a reacted material to obtain a solvent violet 13 product.

Owner:JIANGSU DAOBO CHEM

Method for mixing electrolytic aluminum waste cathode particles and coke particles for electrolytic cell roasting

InactiveCN110747491AReduce pressure on environmental protectionReduce use costMetallurgyWaste treatment

The invention discloses a method for mixing electrolytic aluminum waste cathode particles and coke particles for electrolytic cell roasting. Through mixing the electrolytic aluminum waste cathode particles and the coke particles, a novel electrolytic cell roasting heating medium is formed. According to the method, harmless treatment and comprehensive utilization of the electrolytic cell waste cathode can be realized, the pollution of waste cathode carbon blocks of an electrolytic cell to the environment is eliminated, the production and treatment cost is reduced, and the environmental protection pressure of the enterprise for solid waste treatment is reduced.

Owner:YUNNAN RUNXIN ALUMINUM

Environment-friendly insulating coating solution used for non-oriented silicon steel and preparation and application thereof

ActiveCN102115881BReduce wearEliminate environmental concernsMetallic material coating processesMonomagnesium phosphatePhosphate

The invention relates to an environment-friendly insulating coating solution used for non-oriented silicon steel and preparation and application thereof, in particular to a phosphate coating solution and preparation and application thereof, belonging to the technical field of preparation of a silicon steel insulating coating. Based on the total mass of the coating solution, the environment-friendly insulating coating solution used for non-oriented silicon steel comprises the components by the mass percentage of: 20 to 25 percent of aluminum dihydric phosphate solution, 10 to 15 percent of magnesium dihydrogen phosphate solution, 15 to 20 percent of ludox, 2 to 8 percent of boric acid and the balance of deionized water. The insulating coating prepared by using the environment-friendly insulating coating solution used for non-oriented silicon steel not only can guarantee that all the performances such as uniformity, insulating performance, adhesiveness, corrosion resistance, heat resistance, weldability and the like are excellent, but also totally solves the problem in environment protection caused by chromium.

Owner:上海迪升防腐新材料科技有限公司

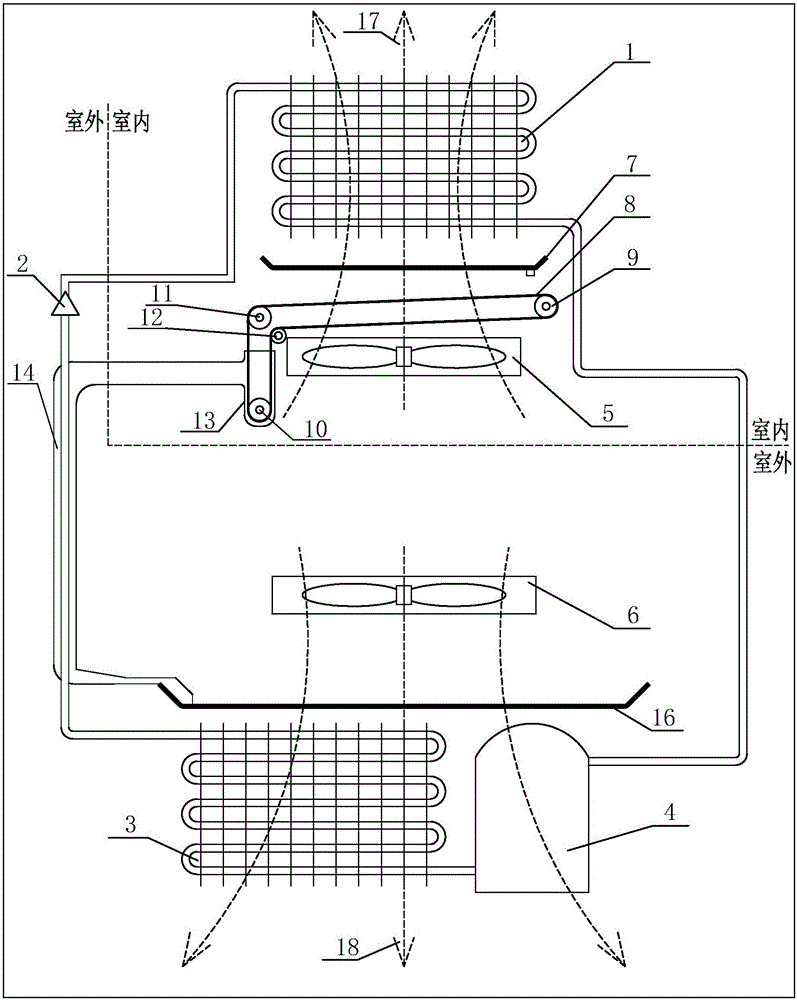

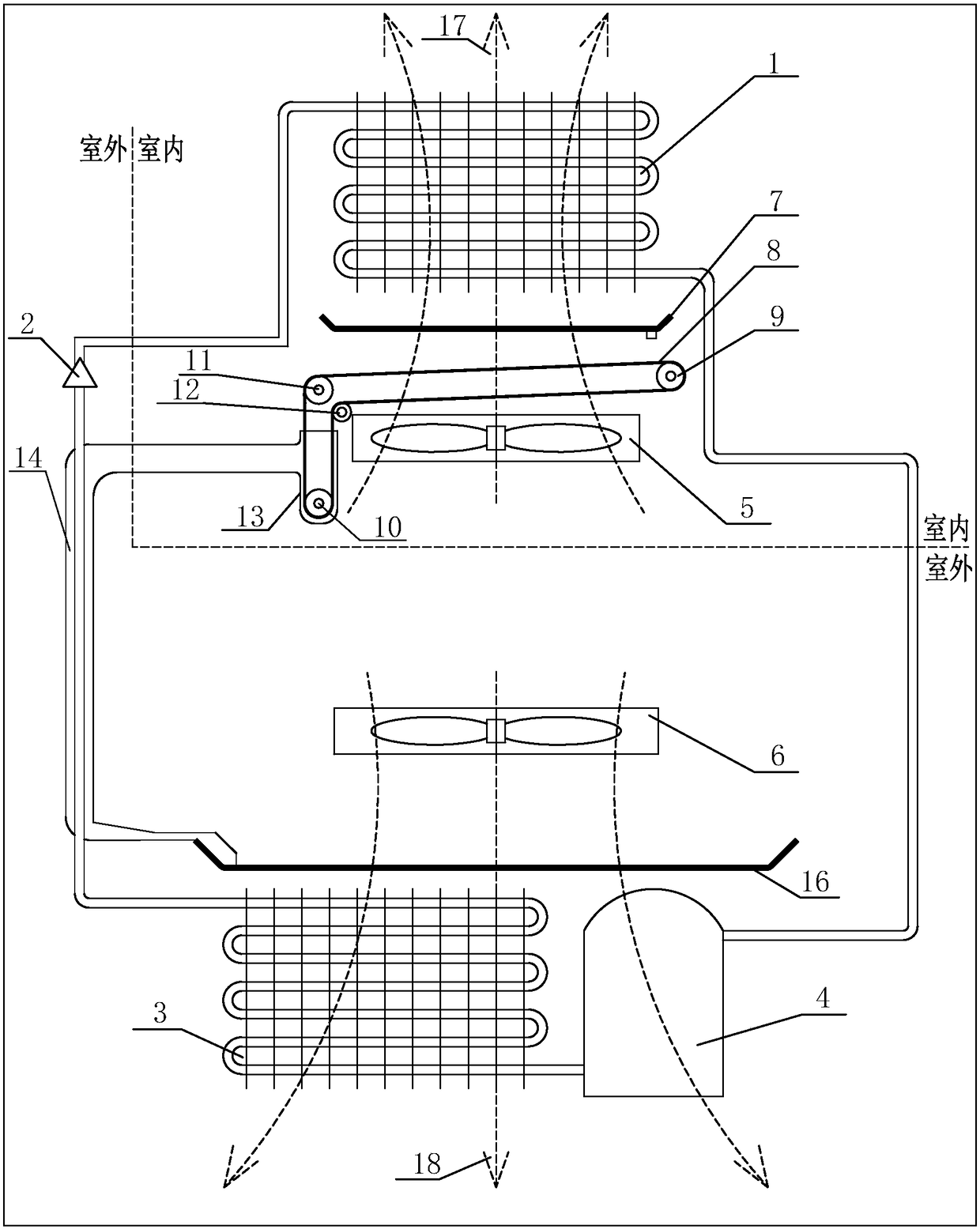

Condensate water treatment device for air conditioner and air conditioner with condensate water treatment device

ActiveCN105698358AGuaranteed pre-cooling effectTake advantage ofCondensate preventionLighting and heating apparatusFiberRefrigerant

The invention discloses a condensate water treatment device for an air conditioner and the air conditioner with the condensate water treatment device. Air in a room is pre-cooled through porous hydrophilic breathable fabric stored with condensate water, and after the porous hydrophilic breathable fabric which exchanges heat with the air is rotated into a condensate water tank, the fabric exchanges heat with the condensate water in the condensate water tank for replacement, so that the porous hydrophilic breathable fabric located on an air flow path is kept at the lower temperature; the condensate water is guided through a heat exchange pipe to cool a refrigerant flowing out from a condenser; the condensate water is also used for water-cooling the condenser; and accordingly, the low-temperature energy contained in the condensate water is fully used, the energy waste is reduced, and the energy utilization rate of the air conditioner is increased.

Owner:山东单兵环保科技有限公司

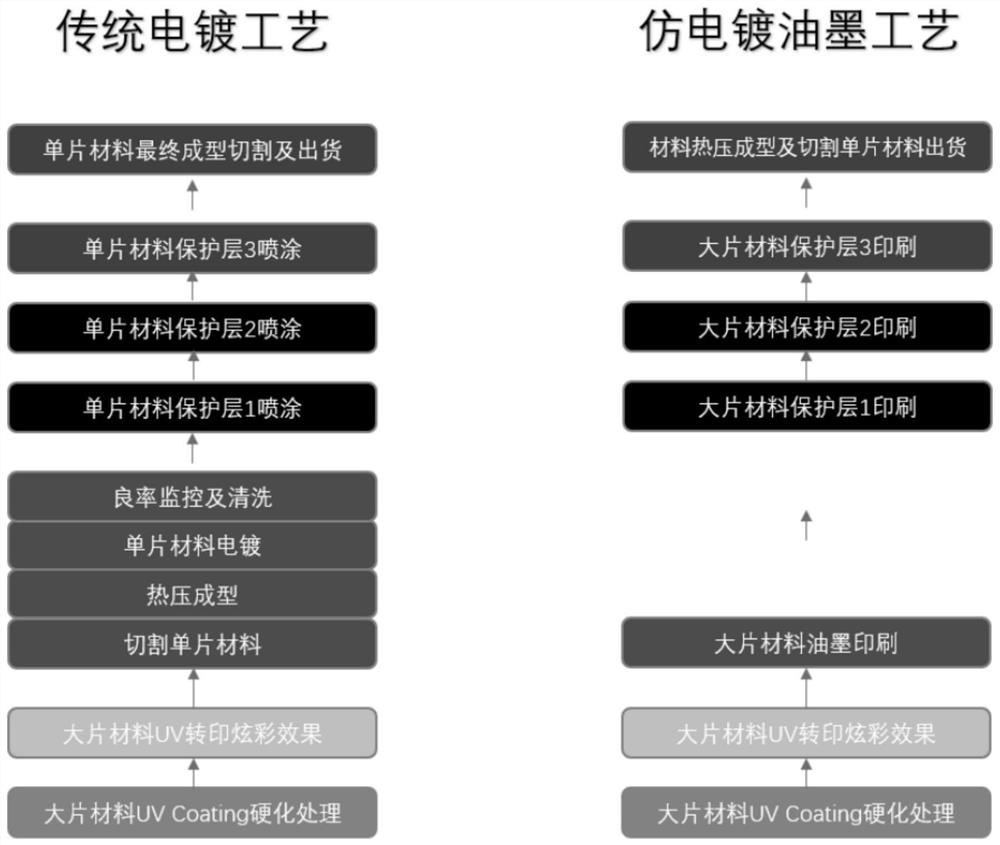

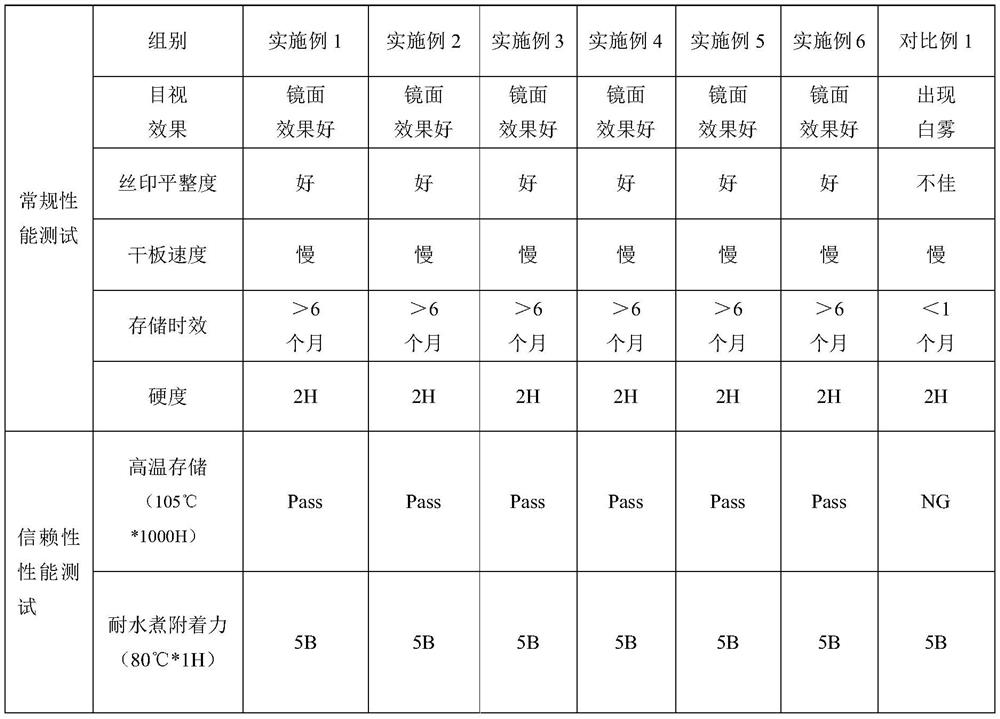

Single-component low-temperature curing imitation electroplating ink and preparation method thereof

PendingCN113354984AWith high temperature resistanceHigh calendered tensile propertiesInksAcrylic resinLow temperature curing

The invention relates to the technical field of electroplating ink, and discloses single-component low-temperature curing imitation electroplating ink, wherein a formula of the ink is prepared from the following components: 5-15 parts by weight of acrylic resin, 0.5-1.5 parts by weight of phenoxy resin, 10-40 parts by weight of silver powder of which the particle size D100 is less than or equal to 200 nm, 50-80 parts by volume of a solvent, 0.1-0.3 part by volume of a leveling agent, 1-3 parts by volume of a defoaming agent, 0.25-1.5 parts by volume of a coupling agent, 0.1-0.5 part by volume of a wetting agent, 0.05-0.2 part by volume of an anti-settling agent, 1-5 parts by volume of a dispersant, and 1-5 parts by volume of a curing agent. The slurry ink disclosed by the invention has high temperature resistance and high calendering tensile property, and can be subjected to high-temperature hot-pressing secondary forming after printing curing, and the surface of the slurry ink does not crack and fall off after high-temperature hot-pressing secondary forming. Meanwhile, the prepared ink is good in stability in a normal-temperature state and long in storage period.

Owner:江苏德恒新材料科技有限公司

Condensed water treatment device for air conditioner and air conditioner thereof

ActiveCN105698358BGuaranteed pre-cooling effectTake advantage ofCondensate preventionLighting and heating apparatusFiberRefrigerant

Owner:山东单兵环保科技有限公司

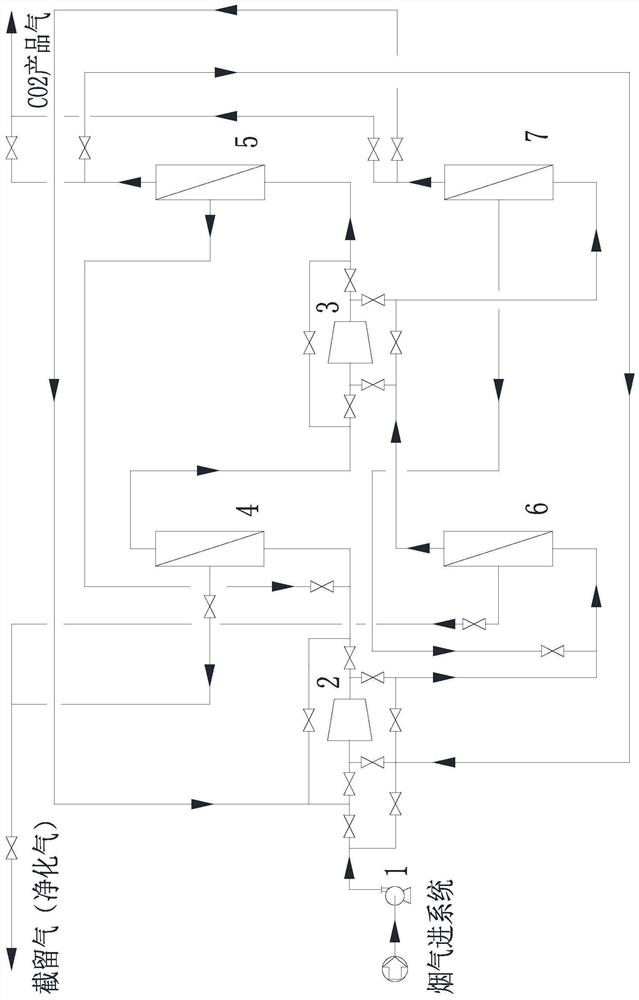

Device and method for inhibiting corrosion of membrane separation carbon dioxide trapping process

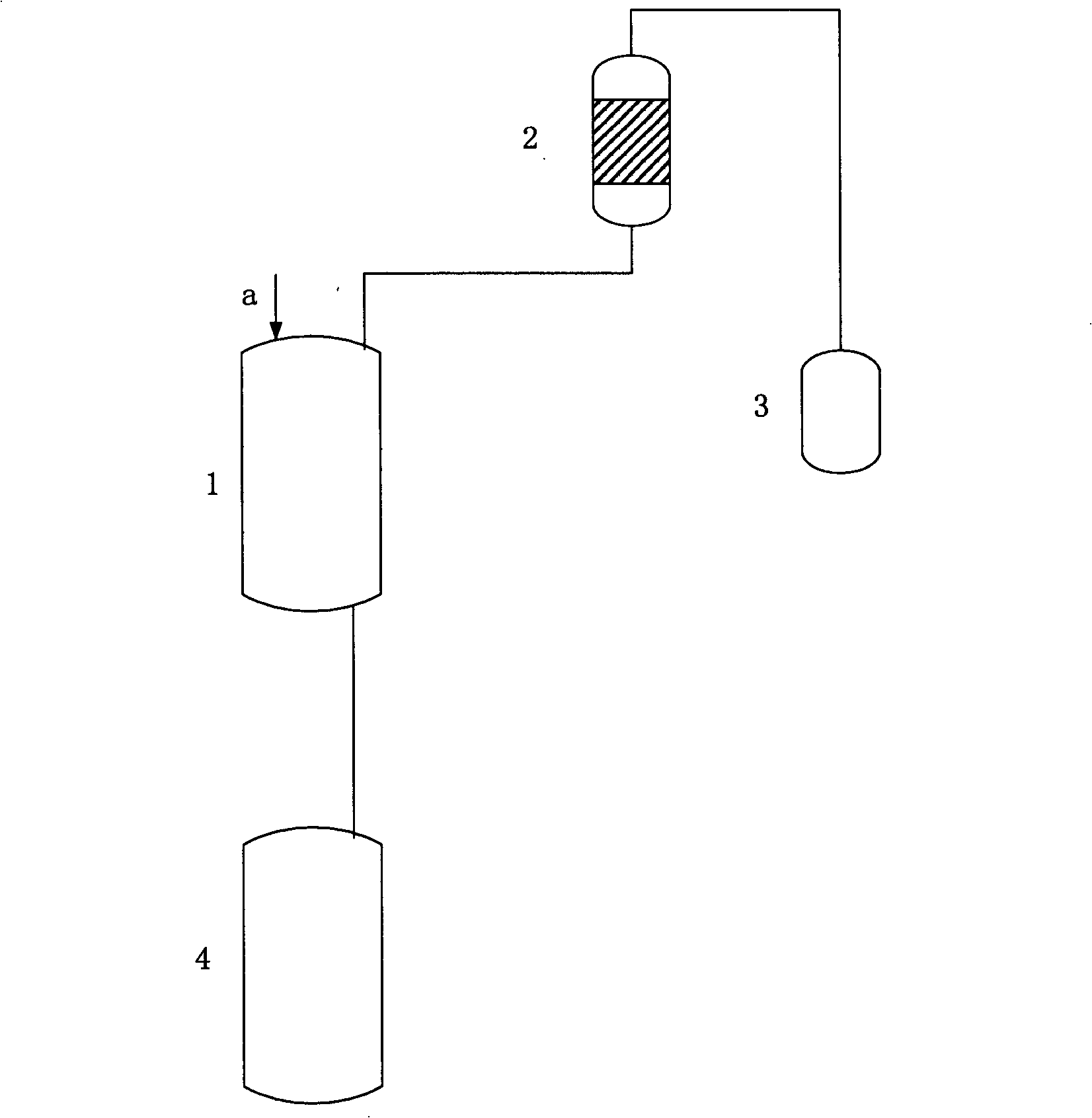

ActiveCN112588088AOvercoming severe corrosion problemsExempt from collectionGas treatmentDispersed particle separationFlue gasWastewater

The invention belongs to the technical field of gas separation, and relates to a device and method for inhibiting corrosion of a membrane separation carbon dioxide trapping process. The method utilizes the water absorption of a membrane component, and enables flue gas to avoid a compressor and directly enter a membrane separator to wet the membrane component by additionally arranging a pipeline and a valve, thereby achieving the purpose of flue gas dehydration; and dehydrated flue gas is recycled to enter the compressor to be compressed and then enters the membrane separator again, and finally, the carbon dioxide in the flue gas is captured by a membrane separation method. According to the method provided by the invention, the problem of corrosion of the flue gas to the compressor in the traditional membrane separation process can be remarkably reduced, and meanwhile, the saturated water in the flue gas is used for wetting the membrane module, so that the step of supplementing processwater into the system is reduced, the discharge of process wastewater is further reduced, and the environmental protection problems of wastewater collection, treatment and the like are avoided. The method has a good application prospect in the technical field of flue gas carbon dioxide capture.

Owner:SINOPEC NANJING RES INST OF CHEM IND CO LTD +1

Method of treating husk from rice-husking mill

InactiveCN1931544AHigh densityEliminate environmental concernsDomestic articlesHollow articlesHuskPulp and paper industry

The method of treating husk from rice-husking mill consists of the following steps: moderating husk; regulating water content; pressing into block; and cooling to obtain husk block product. The husk block product is used directly for burning in boiler, etc. The present invention makes the waste husk into useful material while reducing pollution and hidden danger.

Owner:丁平

Insulating paint of semi-inorganic environmental non-oriented silicon steel insulating paint and application thereof

ActiveCN101643625BEliminate environmental concernsStrong absorption capacityPolyurea/polyurethane coatingsColloidal silicaActive agent

The invention relates to an insulating paint of non-oriented silicon steel and discloses an insulating paint of semi-inorganic environmental non-oriented silicon steel insulating paint and an application thereof. The paint of the invention comprises the following components by weight percent: 5-20% of magnesium isopropylate, 5-25% of polyurethane-acrylate-ethylene oxide resin, 5-40% of aluminium dihydrogen phosphate, 5-10% of zinc acetate, 11-30% of colloidal silica, 1-5% of non-ionic surface active agent and the balance deionized water. The insulating paint of semi-inorganic environmental non-oriented silicon steel insulating paint of the invention can not only completely eliminate the environmental problem caused by chromium element, but also ensure that all the performances of the paint such as uniformity, corrosion resistance, heat resistance, weldability and the like are good.

Owner:上海迪升防腐新材料科技有限公司

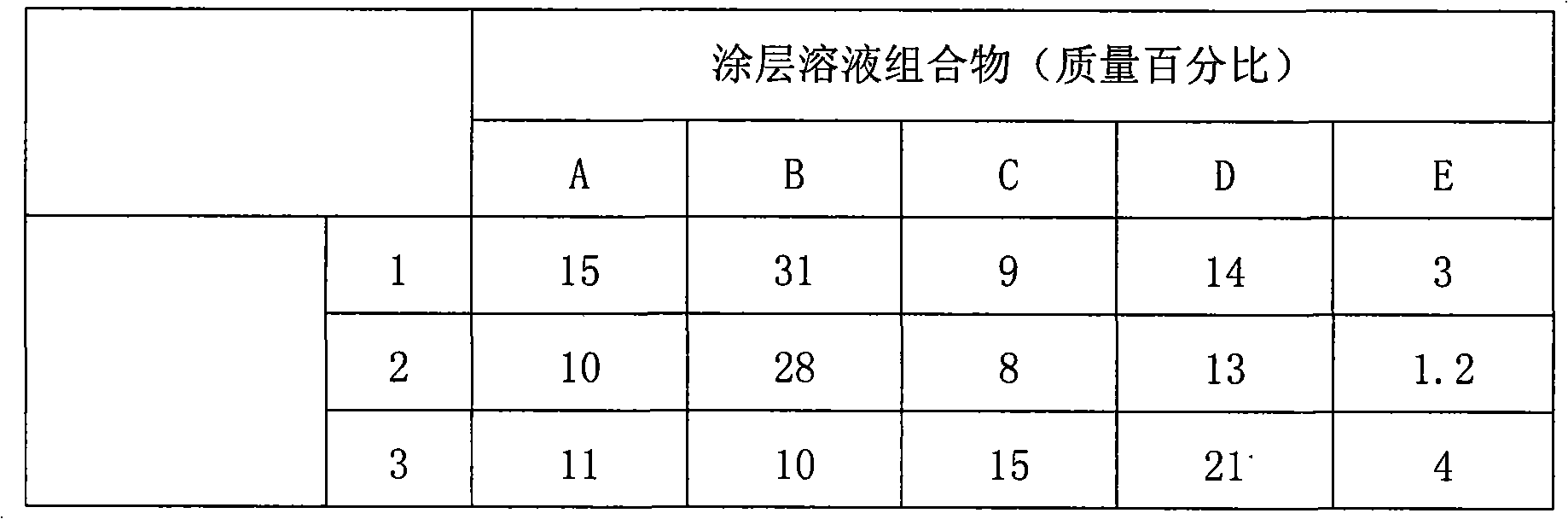

A kind of non-oriented silicon steel coating and its application

ActiveCN105153930BEliminate environmental concernsHigh interlayer resistivityAnti-corrosive paintsPhosphatePhosphoric acid

Owner:上海迪升防腐新材料科技有限公司

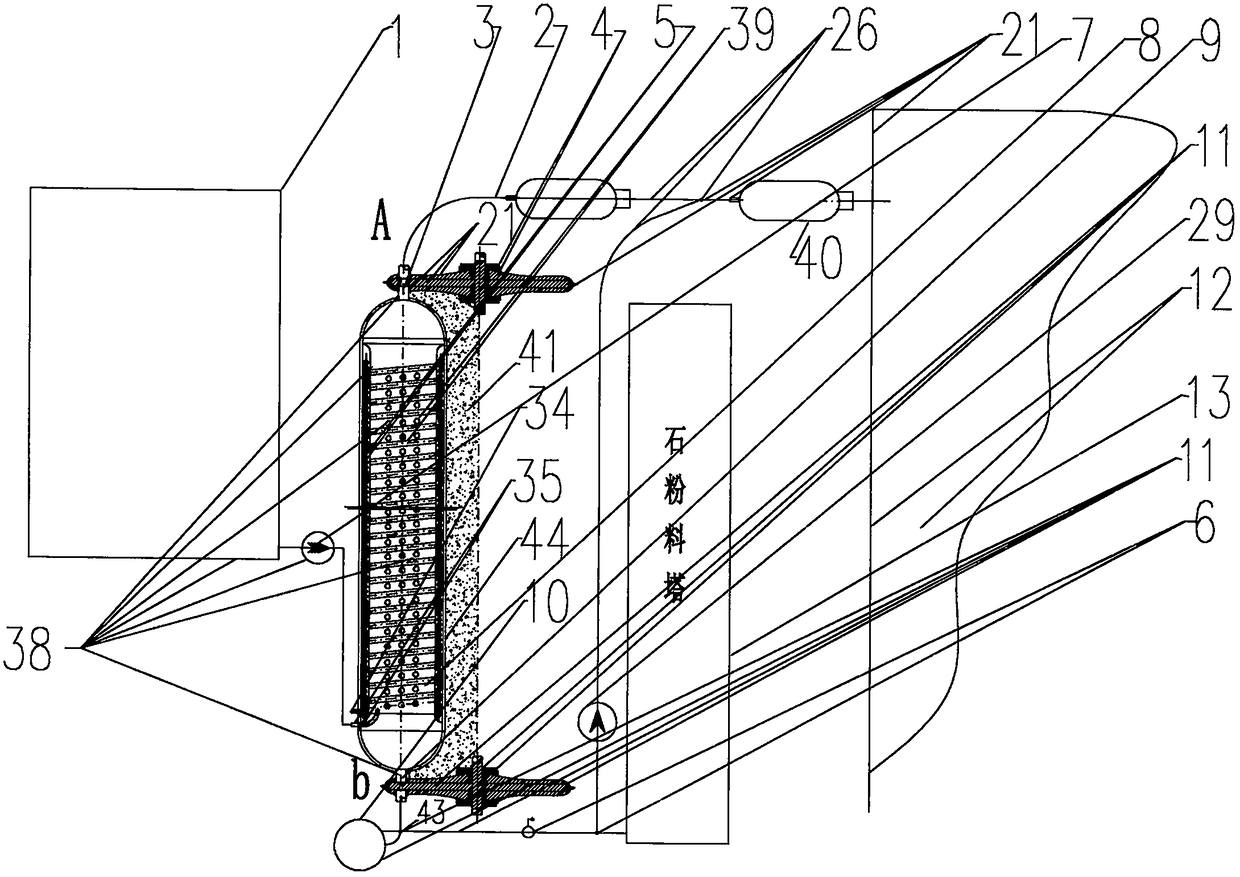

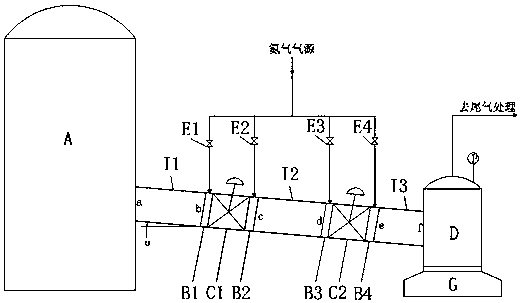

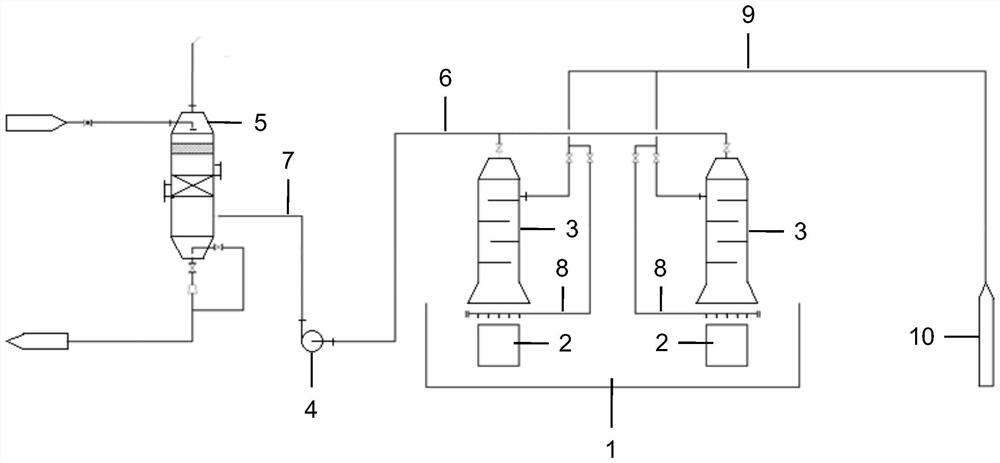

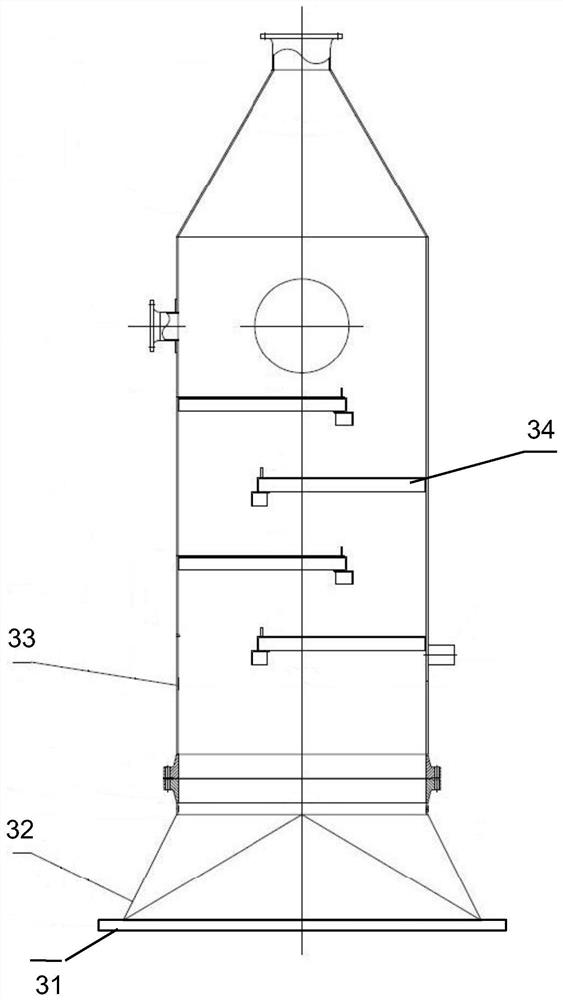

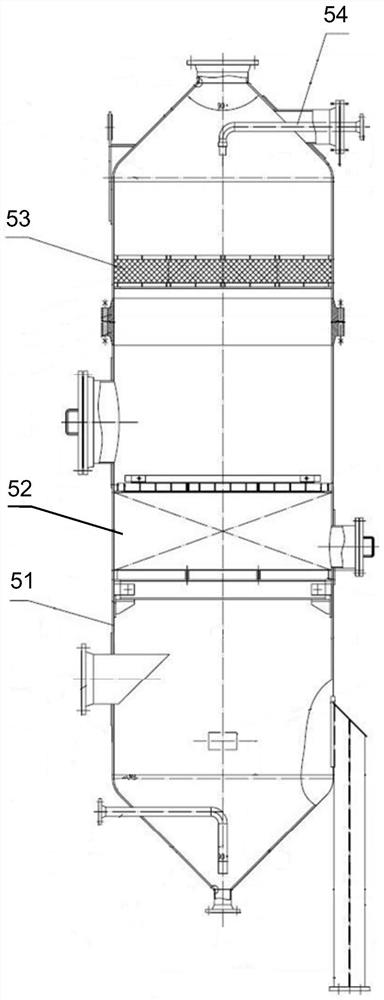

Coke pit exhaust gas collecting and purifying system

The invention discloses a coke pit exhaust gas collecting and purifying system which is arranged in a position of a coke outlet of a coke pit. The system comprises gas collecting hoods, a gas collecting fan and a coke adsorption tower. The gas collecting hoods are arranged at the coke outlet of the coke pit and are connected to the gas collecting fan through a connecting pipeline, and the gas collecting fan is connected to the coke adsorption tower through the connecting pipeline. A spray pipe is arranged at the bottom of the gas collecting hood, a plurality of spray ports for spraying condensate water are arranged on the spray pipe, and multiple layers of baffle plates are arranged in the gas collecting hood; the coke adsorption tower comprises a tower body, and packing, a mist capturingsystem and a spraying system arranged in the tower body, wherein the packing is located in a middle section of the tower body, the mist capturing layer is located above the packing, and the spraying system is located above the mist capturing layer. By additionally arranging two gas collecting hoods at the coke outlet of the coke pit, more than 90% of coke powder and water vapor are extracted to the coke adsorption tower through the gas collecting fan to be treated and discharged by reaching the standard.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD +1

Method for synchronous production of concentrated soybean phospholipids by enzymatic degumming and physical refining of soybean crude oil

ActiveCN103773603BReduce moistureAchieve recyclingFatty-oils/fats refiningPhosphatide foodstuff compositionsOrganic solventPhospholipase

The invention discloses a method for physically refining soybean crude oil and synchronously preparing soybean concentrated phospholipids employing enzymatic degumming. The method comprises the following steps: (1) taking soybean crude oil, and adding a citric acid to homogenize; (2) adding phospholipase and / or degummase to the homogenized soybean crude oil to homogenize; (3) stewing the crude oil homogenized in the step (2) for 1.5-3 hours, and then centrifugally separating, so as to obtain degummed oil and residues; (4) carrying out decolorizing, deodorizing and deacidifying on the degummed oil which is centrifugally separated in the step (3), so as to obtain product oil; (5) adding an organic solvent to remove neutral oil in the residues which are centrifugally separated in the step (3). By adopting enzymatic degumming, not only is a water resource saved, but also the produced product oil and residues are low in moisture, the quality of the phospholipids is easily controlled, and the product is stable in quality. Thus, the economic benefits are greatly improved.

Owner:SHANDONG GAOTANG LANSHAN GRP CORP

Injection molding structure and injection molding method of an in-mold insert

ActiveCN103660133BAchieve high matte decorative effectEasy to recycleSynthetic resin layered productsRefractive indexTherapeutic effect

The invention discloses an IML (in molding label) structure which comprises an optical thin film and an ink layer, wherein the optical thin film is coated with the ink layer; the optical thin film, the ink layer and an injection molding material are formed into a whole through injection molding; and the optical thin film adopts a stacked structure formed by alternatively laminating a resin film with a higher refractive index and a resin film with a lower refractive index. The invention further discloses an injection molding method of the IML structure. The metallic high-matte decoration of a product can be realized through one-time injection molding, and a non-conductive and environment-friendly metallic surface treatment effect of a structural member of a casing of an electronic product is realized.

Owner:GUANGDONG JANUS SMART GRP CO LTD

Method for recycling waste cell lining electrolyte material of aluminum electrolysis cell

PendingCN112342574AEffectively fills the voidReduce the cost of electrolytic productionThermal insulationAluminum electrolysis

The invention relates to a method for recycling a waste cell lining electrolyte material in an aluminum electrolysis cell. The method comprises the following steps that an electrolyte recovery material in a waste cell lining generated in an aluminum electrolysis production process is screened out, a replaced anode scrap is separated from a thermal insulation material, the separated thermal insulation material is crushed into crushed material blocks, and the crushed material blocks are taken as a first priming coat to be made into an aggregate thermal insulation material to be added into the surface of an aluminum electrolysis anode, the electrolyte recovery material is taken as a second-layer thermal insulation material to be paved on the first-layer priming coat, the crushed material blocks are paved on the surface of the second-layer thermal insulation material as a third-layer thermal insulation material, and the electrolyte recovery material is paved on the third-layer thermal insulation material to be taken as a fourth-layer thermal insulation material to prepare an aluminum electrolysis cell thermal insulation material meeting the requirements of aluminum electrolysis production. According to the method, comprehensive utilization of the aluminum electrolysis waste cell lining electrolyte material can be realized, and the environmental protection problem caused by the aluminum electrolysis waste cell lining electrolyte material is solved.

Owner:YUNNAN RUNXIN ALUMINUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com