Device and method for inhibiting corrosion of membrane separation carbon dioxide trapping process

A carbon dioxide and corrosion device technology, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems such as compressor failure, compressor corrosion, and system water imbalance, so as to inhibit process corrosion and eliminate collection of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The method of this embodiment is implemented according to the following steps:

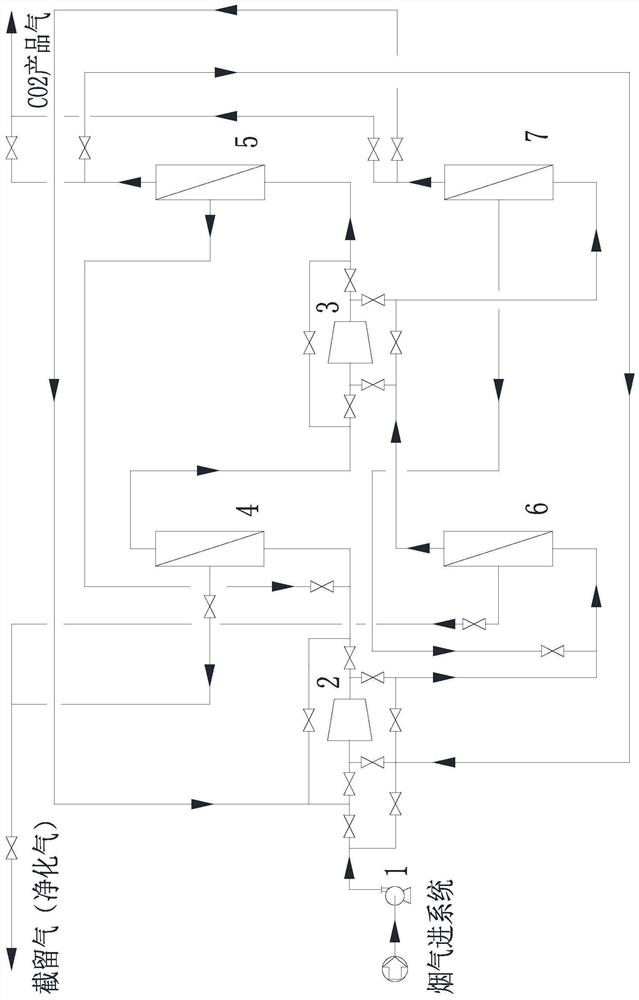

[0036] The carbon dioxide capture performance evaluation test is carried out using the device in the attached figure. After the raw gas is sent into the system by the blower, it is directly compressed by the compressor and then enters the membrane separator for carbon dioxide capture.

[0037] The raw material gas is simulated flue gas, the temperature is 40°C, the pressure is 0.2MPa, the moisture is saturated, and the dry basis content is CO 2 is 12v%, O 2 is 8v%, N 2 is 80v%.

[0038] Test result: CO 2 The capture rate is 58%, and the product gas CO 2 The purity is 70%, and the system drains 22L.

Embodiment 2

[0040] The method of this embodiment is implemented according to the following steps:

[0041] The carbon dioxide capture performance evaluation test was carried out using the device in the attached drawing. After the feed gas was sent into the system by the blower, it first avoided the compressor and directly entered the membrane separator to wet the membrane module, and at the same time the flue gas was dehydrated; then the dehydrated The flue gas is sent to the compressor, and the compressor is pressurized and then enters the membrane separator for carbon dioxide capture.

[0042] The raw material gas is simulated flue gas, the temperature is 40°C, the pressure is 0.2MPa, the moisture is saturated, and the dry basis content is CO 2 is 12v%, O 2 is 8v%, N 2 For 80v%, the wetting time of the flue gas entering the membrane separator is 30 minutes.

[0043] Test result: CO 2 Capture rate 55%, product gas CO 2 The purity is 73%, and the system drains 8L.

Embodiment 3

[0045] The method of this embodiment is implemented according to the following steps:

[0046] The carbon dioxide capture performance evaluation test was carried out using the device in the attached drawing. After the feed gas was sent into the system by the blower, it first avoided the compressor and directly entered the membrane separator to wet the membrane module, and at the same time the flue gas was dehydrated; then the dehydrated The flue gas is sent to the compressor, and the compressor is pressurized and then enters the membrane separator for carbon dioxide capture.

[0047] The raw material gas is simulated flue gas, the temperature is 40°C, the pressure is 0.2MPa, the moisture is saturated, and the dry basis content is CO 2 is 12v%, O 2 is 8v%, N 2 is 80v%, and the wetting time of flue gas entering the membrane separator is 60 minutes.

[0048] Test result: CO 2 The capture rate is 52%, and the product gas CO 2 The purity is 77%, and the system drains 2L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com