Insulating coating solution and use thereof in silicon steel

A technology of insulating coating and solution, applied in the direction of coating, etc., to achieve the effect of eliminating environmental protection problems, small power loss between layers, and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

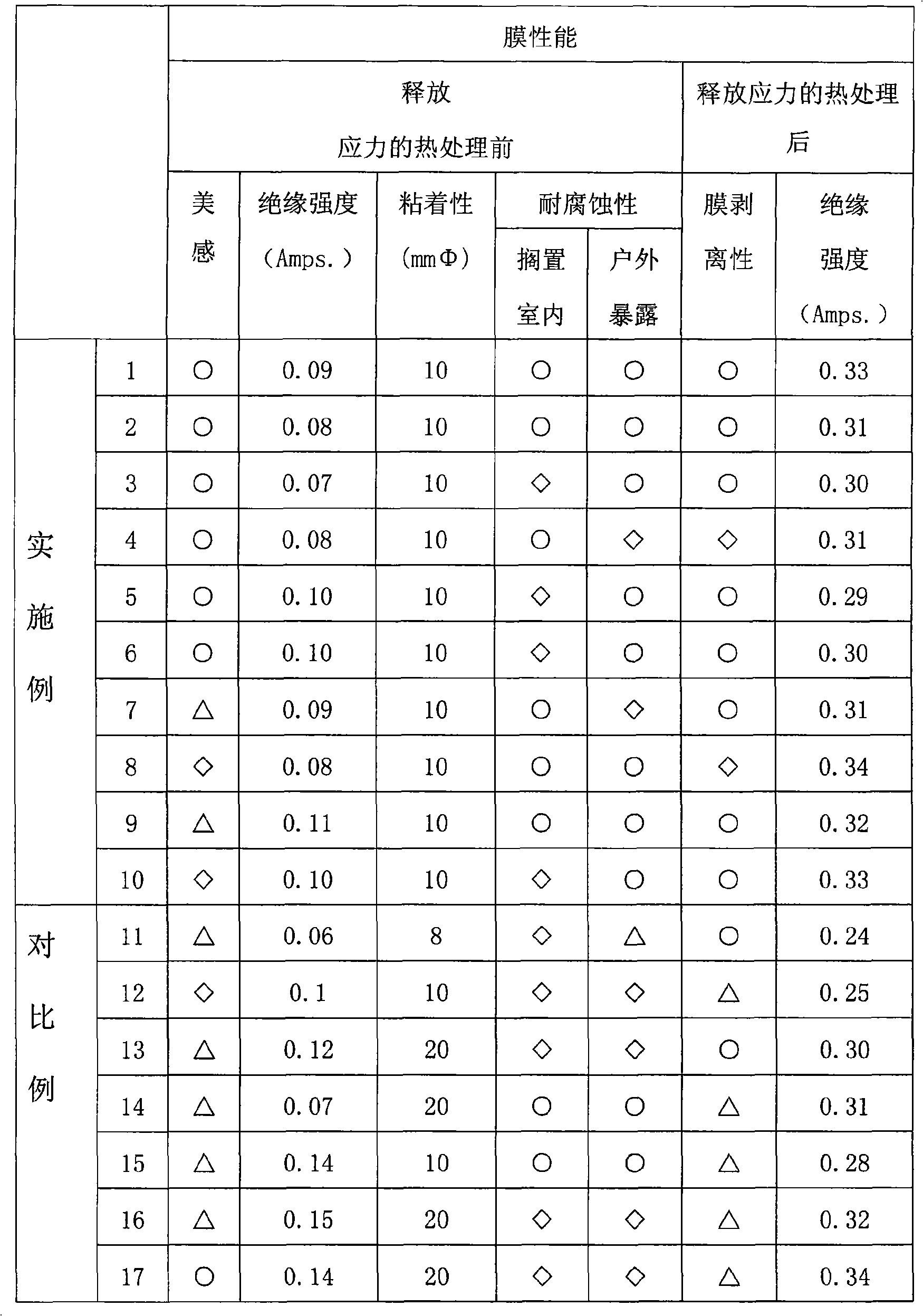

[0024] The insulating coating solution prepared according to the formula shown in Table 1 was coated on the steel plate and heat-treated at 550° C. for 30 seconds to obtain a silicon steel plate with an insulating coating film with a thickness of 1.5 μm.

[0025] The specific preparation steps are as follows: according to the formula ratio in Table 1, add the corresponding amount of polyurethane-acrylate-ethylene oxide resin into a 500ml three-necked flask, and then add the corresponding amount of aluminum dihydrogen phosphate, magnesium nitrate, colloid Silicon dioxide, nonionic surfactant and deionized water are stirred evenly to prepare a coating solution.

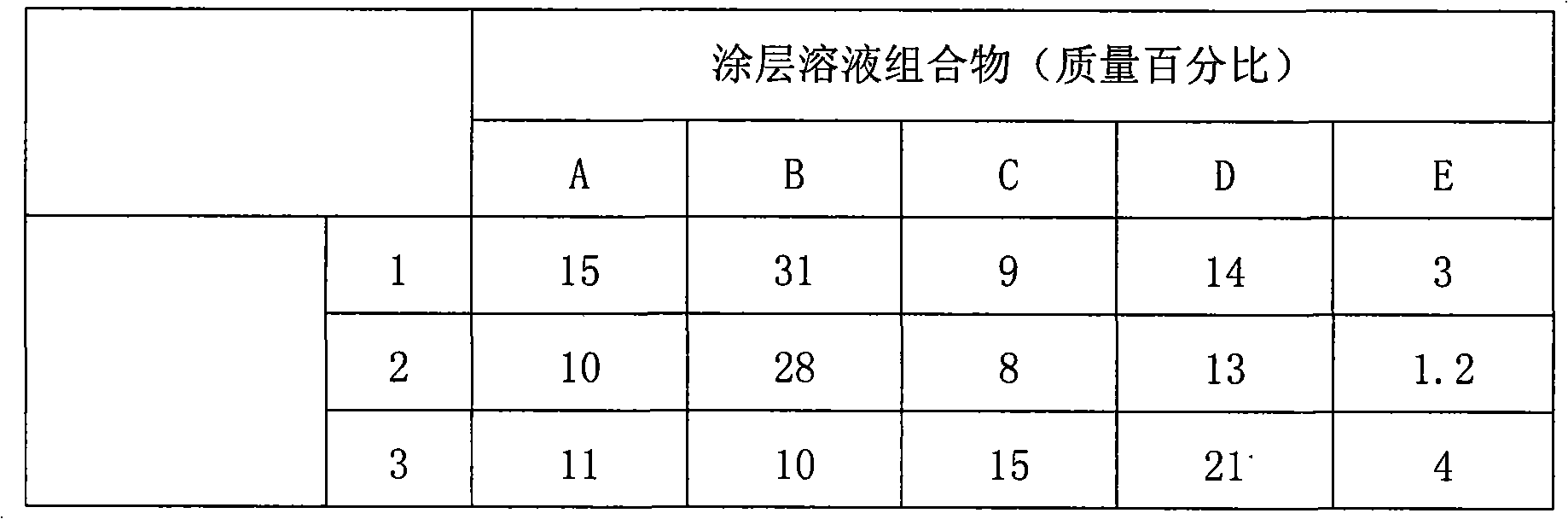

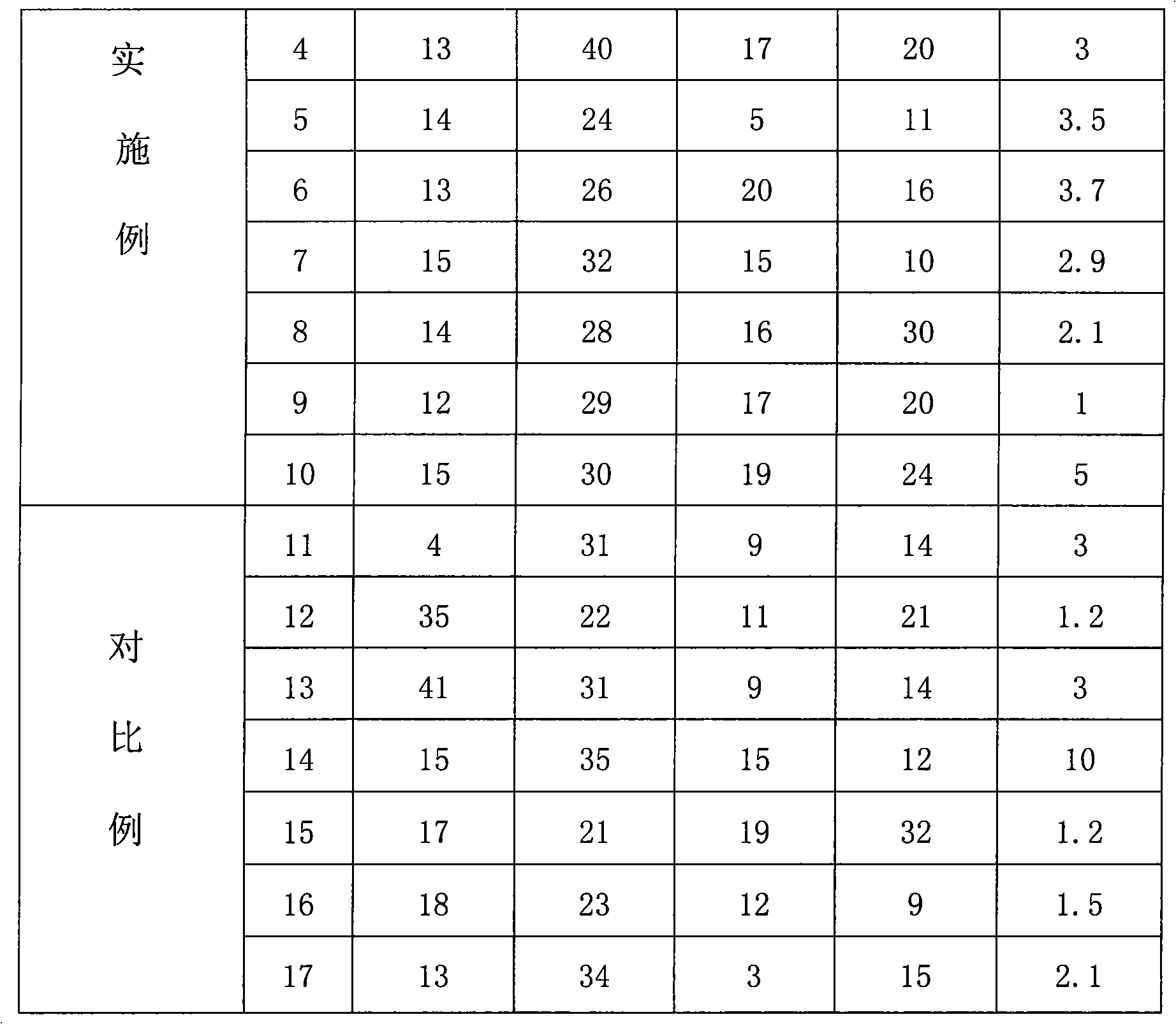

[0026] The formula of each composition is as shown in table 1:

[0027] Table 1 Composition of Coating Solution Components

[0028]

[0029]

[0030] (Note: A polyurethane-acrylate-ethylene oxide resin, B is aluminum dihydrogen phosphate, C is magnesium nitrate, D is colloidal silicon dioxide, E is non-ionic surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com