Injection molding structure and injection molding method of an in-mold insert

An in-mold insert injection molding and in-mold technology, applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve problems such as difficult to obtain metal high-matt decorative effects, achieve good decorative effects, eliminate environmental protection Problems, effects of convenient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

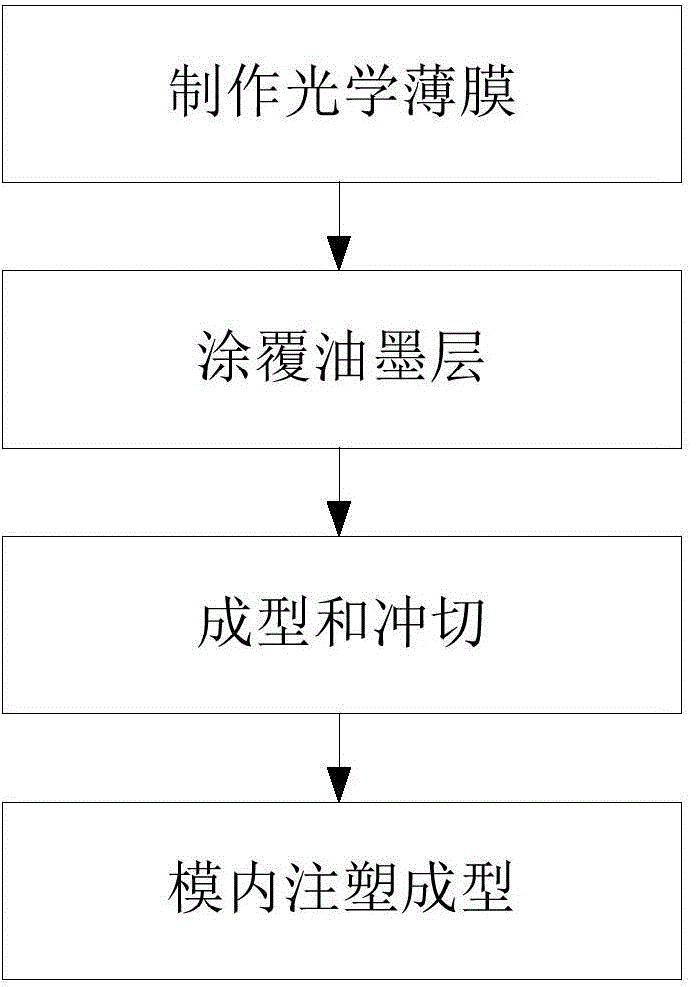

[0028] In some embodiments, an in-mold insert injection molding structure includes an optical film and an ink layer coated on the optical film, the optical film, the ink layer and the injection molding material are integrally injection-molded, the The optical film includes a laminated structure formed by alternately laminating resin films with a higher refractive index and resin films with a lower refractive index. The basic principle of the optical film of the present invention is to use the interference effect of light. When the light is incident on the film with a laminated structure alternately stacked with different refractive indices, a special optical effect will be produced, bringing a metal high mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com