Preparation method of degradable TPU based on recycled PET

A technology of reflux distillation and reaction vessel, which is applied in the TPU field, can solve the problems of environmental protection restrictions, limited application range, and low recovery rate, and achieve the effect of eliminating environmental protection problems and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

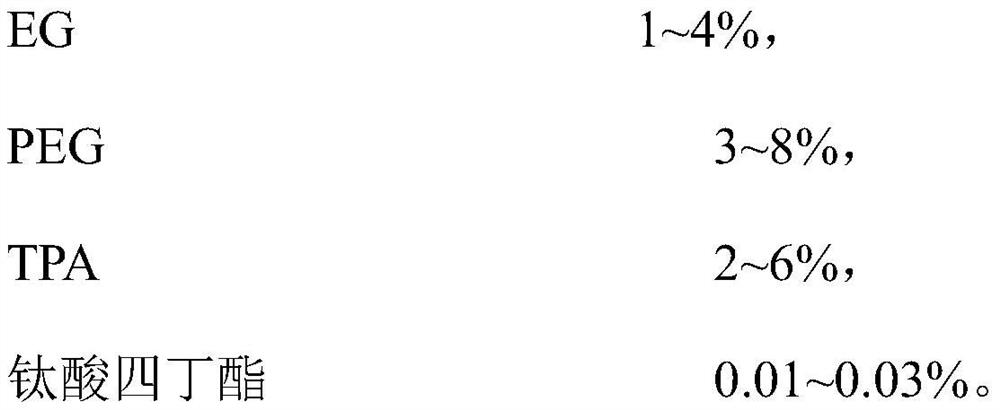

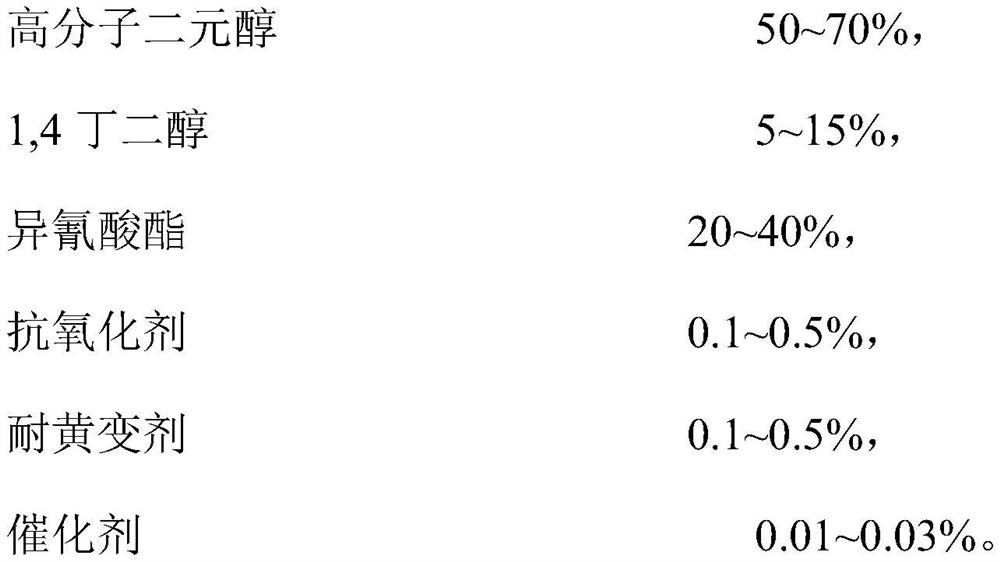

[0045] The present invention provides a kind of degradable TPU preparation method based on reclaimed PET, and this preparation method comprises:

[0046] In the first stage, PET is hydrolyzed:

[0047] Step 1. Put PET, deionized water and zinc acetate into the reaction vessel of the reflux distillation device, raise the temperature to 75-85°C, pressurize to 22800-30400mmhg, and start the reflux distillation device;

[0048] Step 2. Heat up to 265-275°C and stir for more than 1.5h;

[0049] Step 3, cooling down to 75-85°C, filtering the material to obtain a high-viscosity substance;

[0050] Step 4. Heating up to 110°C-150°C, depressurizing to 645-655mmhg for more than 3 hours, and condensing the moisture of the high-viscosity substance in the low-temperature tower of the reflux distillation device;

[0051] Step 5, heat up to 215-225°C, pressurize to 745-755mmhg, obtain REG (Recycle EG, recovered ethylene glycol) and residue, and recover REG;

[0052] Step 6, cooling down t...

Embodiment 1

[0096] Provide a kind of degradable TPU preparation method based on recycled PET, this preparation method comprises:

[0097] In the first stage, PET is hydrolyzed:

[0098] Prepare ingredients according to the following weights:

[0099] PET 10kg,

[0100] 30kg deionized water,

[0101] Zinc acetate 0.01kg,

[0102] Step 1. Put PET, deionized water and zinc acetate into the reaction vessel of the reflux distillation device, raise the temperature to 80°C, pressurize to 22800mmhg, and start the reflux distillation device;

[0103] Step 2. Raise the temperature to 270°C, the heating rate is 30°C / 20min, the heating time is 2h, and stir for 2h;

[0104] Step 3, cooling down to 80°C, filtering the material to obtain a high-viscosity substance;

[0105] Step 4. First raise the temperature to 120°C for 2 hours, then raise the temperature to 140°C for 2 hours, decompress to 650mmhg for 4 hours, and condense the moisture of the high-viscosity substance in the low-temperature tower...

Embodiment 2

[0126] Provide a kind of degradable TPU preparation method based on recycled PET, this preparation method comprises:

[0127] In the first stage, PET is hydrolyzed:

[0128] Prepare ingredients according to the following weights:

[0129] PET 10kg,

[0130] 30kg deionized water,

[0131] Zinc acetate 0.01kg,

[0132] Step 1. Put PET, deionized water and zinc acetate into the reaction vessel of the reflux distillation device, raise the temperature to 80°C, pressurize to 22800mmhg, and start the reflux distillation device;

[0133]Step 2. Raise the temperature to 270°C, the heating rate is 30°C / 20min, the heating time is 2h, and stir for 2h;

[0134] Step 3, cooling down to 80°C, filtering the material to obtain a high-viscosity substance;

[0135] Step 4. First raise the temperature to 120°C for 2 hours, then raise the temperature to 140°C for 2 hours, decompress to 650mmhg for 4 hours, and condense the moisture of the high-viscosity substance in the low-temperature tower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com